Patents

Literature

97results about How to "Feel thick" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Poly siloxane leather coating material and its preparation method

InactiveCN1693578ANo migrationDoes not volatilizeCoatingsTextiles and paperPolymer scienceSolid content

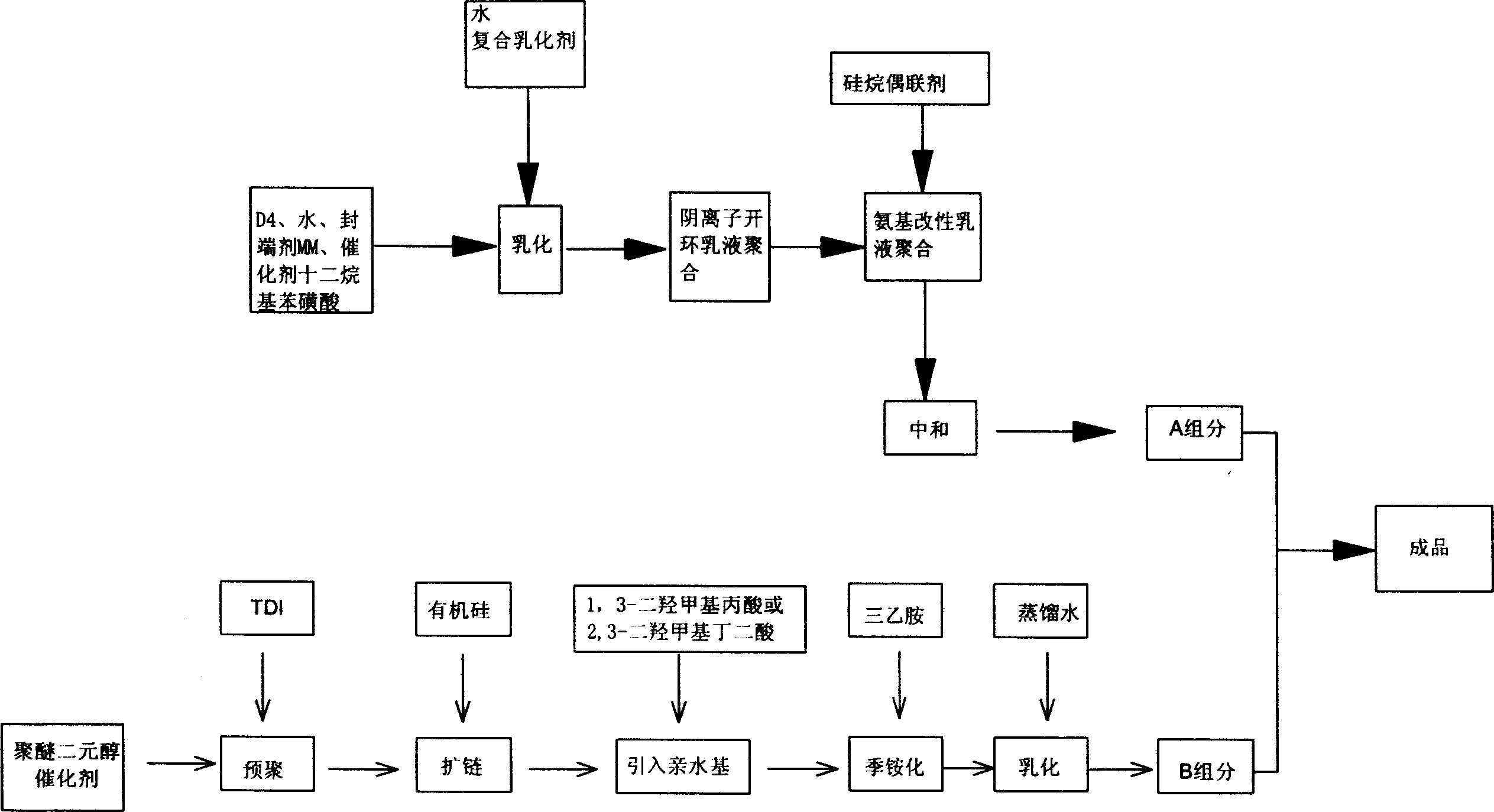

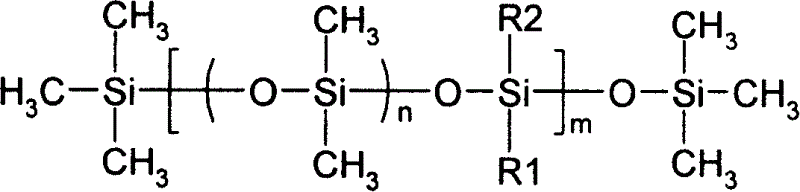

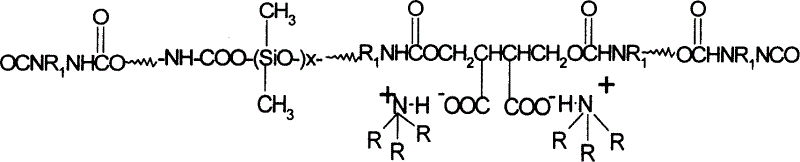

The invention discloses a polysiloxane leather coating material, prepared of the below components: component A polysiloxane latex, wherein amine value of polysiloxane is 0.21-0.53, viscosity average molecular weight is 25,000-73,000, and solid content is 18-35%; component B polysiloxane-polyurethane copolymerized latex, wherein solid content is 18-35%; the weight ratio of components A to B is 2:1 to 5:1. The invention discloses a process method for preparing this painting material. After used, this painting material of the invention gives a leather warm high smoothness, thickness, silk-like soft handling and has good permanence; the process method of the invention has simple process flow, uses small amount of emulsifier and produces less pollutants.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

PVC artificial leather and its preparation method

InactiveCN104389194AImprove folding resistanceImprove scratch resistanceSynthetic resin layered productsCoatingsPolyurethane adhesiveSurface layer

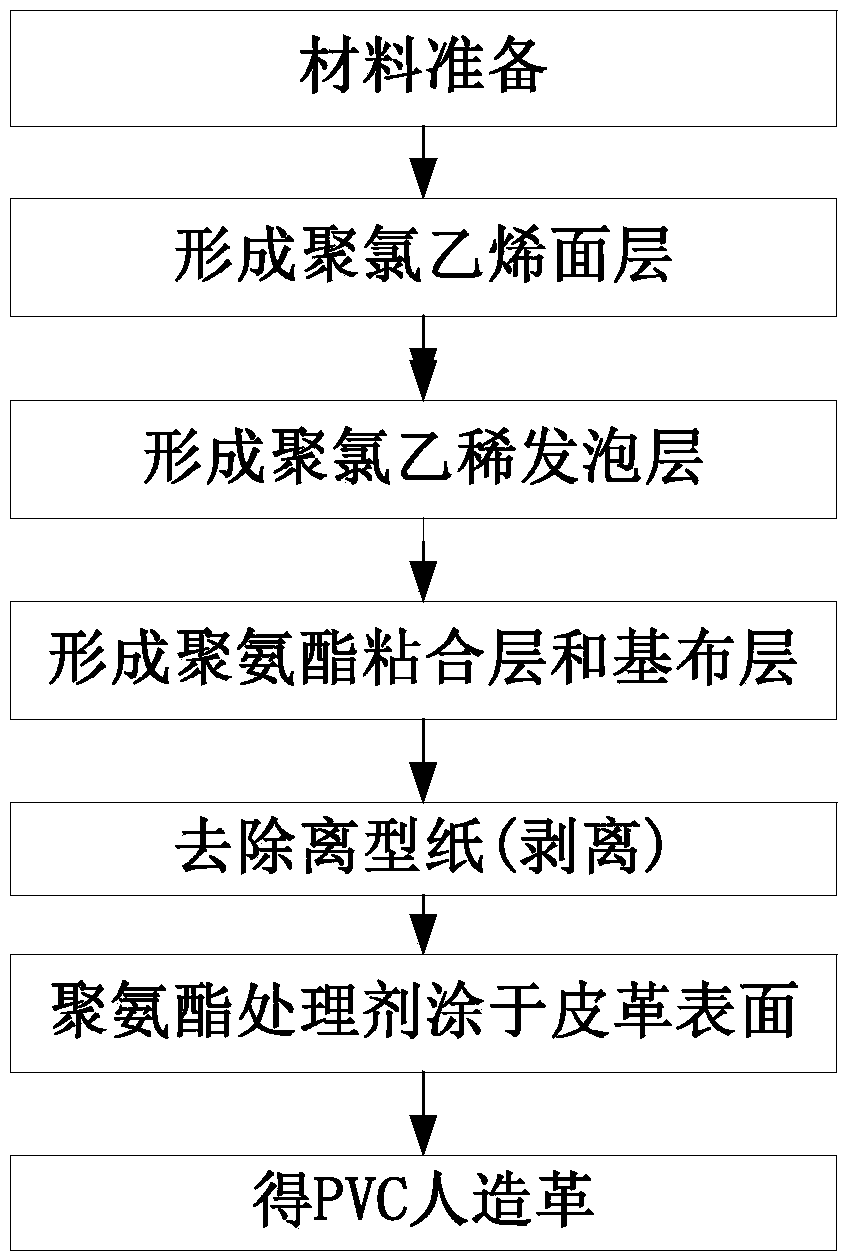

The invention relates to the field of synthetic leather production, and especially relates to a PVC artificial leather and its preparation method. The preparation method of the PVC artificial leather comprises the following steps: 1, preparing materials; 2, coating release paper with a prepared PVC surface slurry to form a PVC surface layer; 3, coating the PVC surface layer with a prepared PVC foaming slurry to form a PVC foam layer; 4, coating the PVC foam layer with a prepared polyurethane adhesive to form a polyurethane adhesion layer and a base cloth layer; 5, removing the release paper; 6, carrying out roller coating on the surface of leather by using a prepared polyurethane treatment agent; and 7, drying, and carrying out cooling molding to form the PVC artificial leather. Compared with present products, the PVC artificial leather prepared through the method, having the PVC surface layer, has the advantages of increased bending strength and scraping resistance, firm handfeel and good physical properties, and can resist bending 100000 times.

Owner:FUJIAN POLYTECH TECH CO LTD

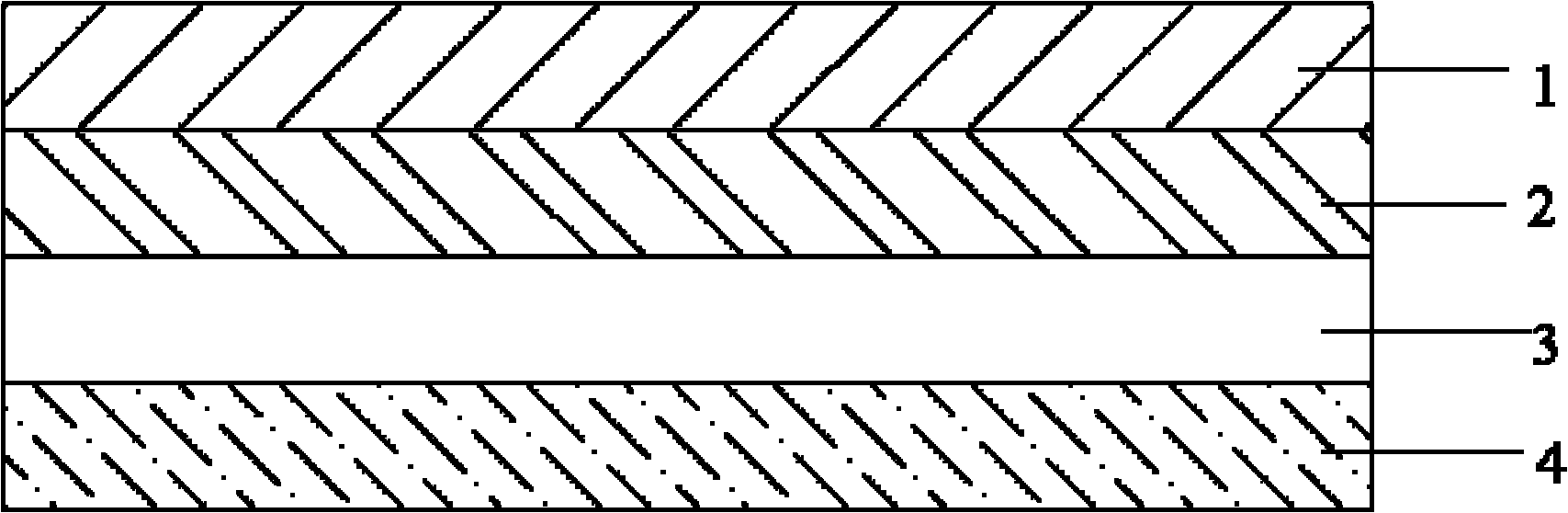

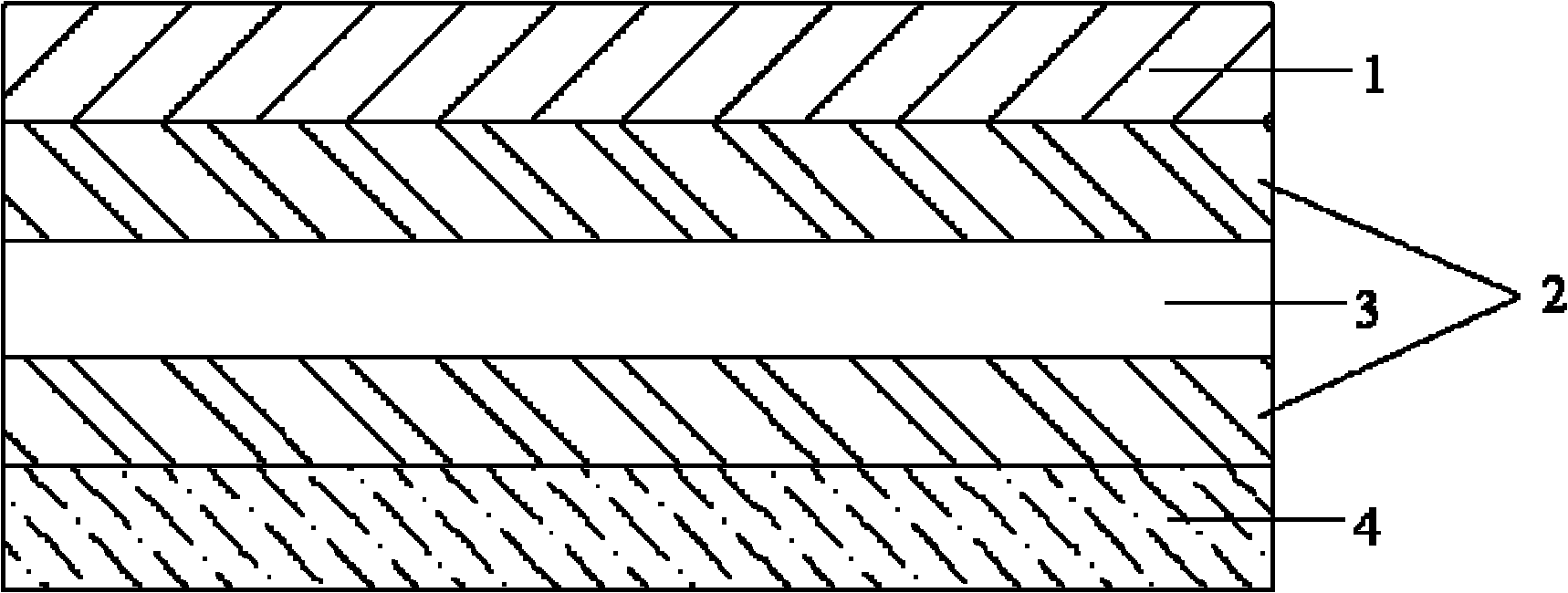

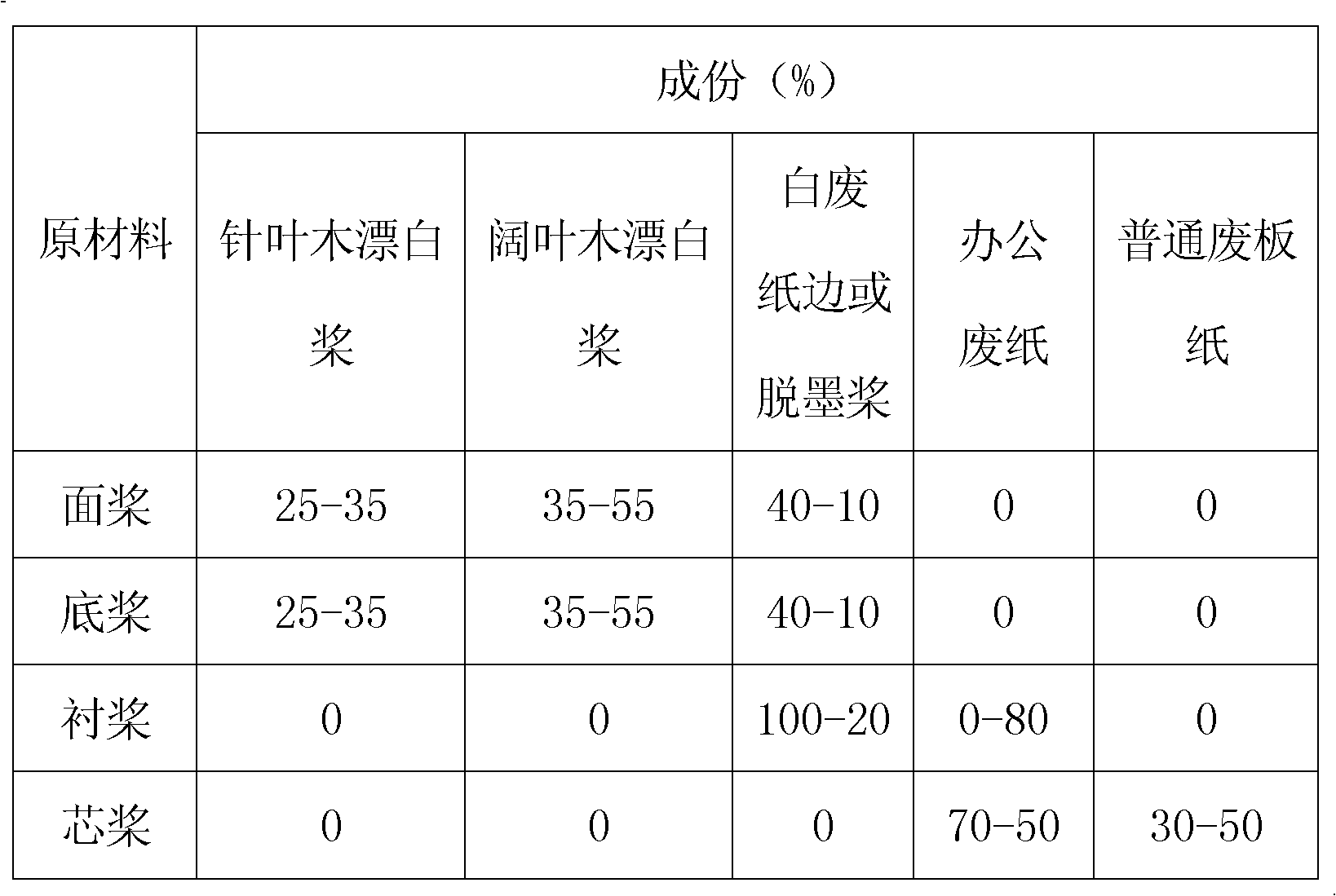

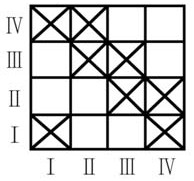

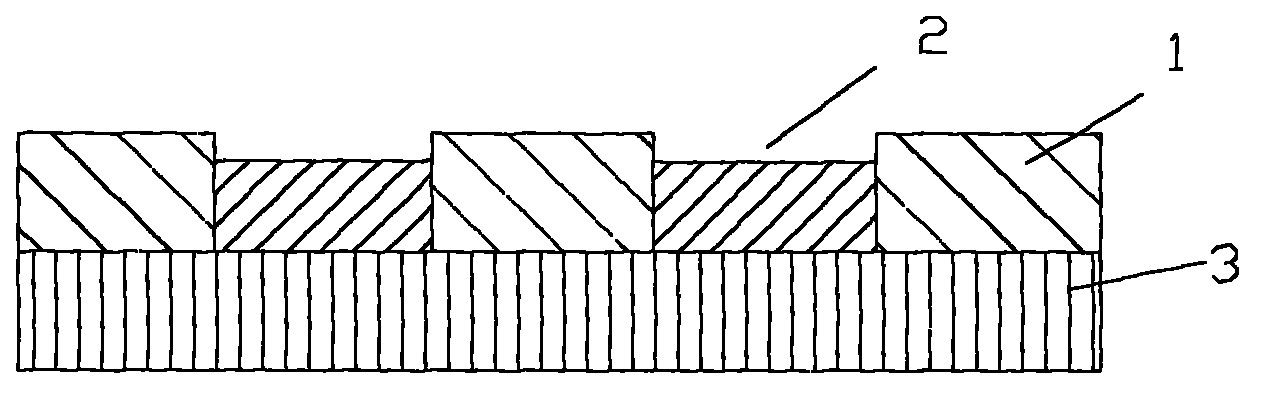

Double-sided composite card paper and preparation method thereof

InactiveCN101818466AFeel thickCrisp paperSpecial paperWaste product additionEconomic benefitsEngineering

The invention provides double-sided composite card paper and a preparation method thereof. A lining pulp layer is covered on one side of a core pulp layer, a bottom pulp layer is covered on the other side of the core pulp layer and a surface pulp layer is covered on the lining pulp layer; or lining pulp layers are covered on two sides of a core pulp layer, a surface pulp layer is covered on the lining pulp layer on one side, and a bottom pulp layer is covered on the lining pulp layer on the other side. Common waste paper pulp (office waste paper, common waste paper boards and the like) is used for replacing wood pulp to serve as core pulp, and waste paper de-inking pulp and waste white paper edge pulp are used for replacing wood pulp to serve as lining pulp so as to save the cost; each layer is specifically quantified; and the obtained double-sided composite card paper has heavy handfeel and crisp paper surface, press molding and embossing processes required for processing and molding have better implementing effects, the expressed levels are richer, the dependency of the product on operating workers is furthest reduced, and effective expansion of the capacity and increment of the economic benefit are furthest realized.

Owner:CHANGSHA TIANTIAN PAPER

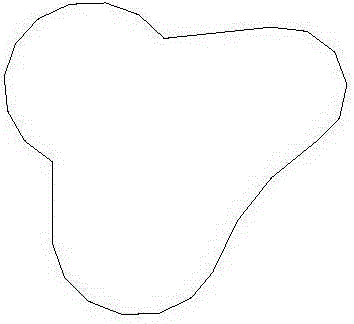

Porous super-bright polyester fiber and preparation method thereof

ActiveCN104532392AGood flexibilityGood compatibilityMonocomponent polyesters artificial filamentArtifical filament manufactureYarnPolyester

Owner:JIANGSU HENGLI CHEM FIBER

Stiffening agent and production method thereof

InactiveCN102454106AExcellent yarn cohesionDoes not affect shadeFibre treatmentPolymer sciencePolyvinyl acetate

The invention discloses a stiffening agent and a production method thereof. The stiffening agent is composed of 40% polyvinyl acetate emulsion, soluble starch, gelatin, and deionized water. With the stiffening agent, fabric is provided with a stiff and thick texture, and can be prevented from coiling. Finished fabric is prevented from moisture regaining and mellowing, and is provided with certain washing fastness. With the stiffening agent, the strength of the fabric can be maintained to a maximal extent, and a fabric gliding phenomenon can be prevented. The stiffening agent can be used in a same bath with most of finishing agents.

Owner:南通斯恩特纺织科技有限公司

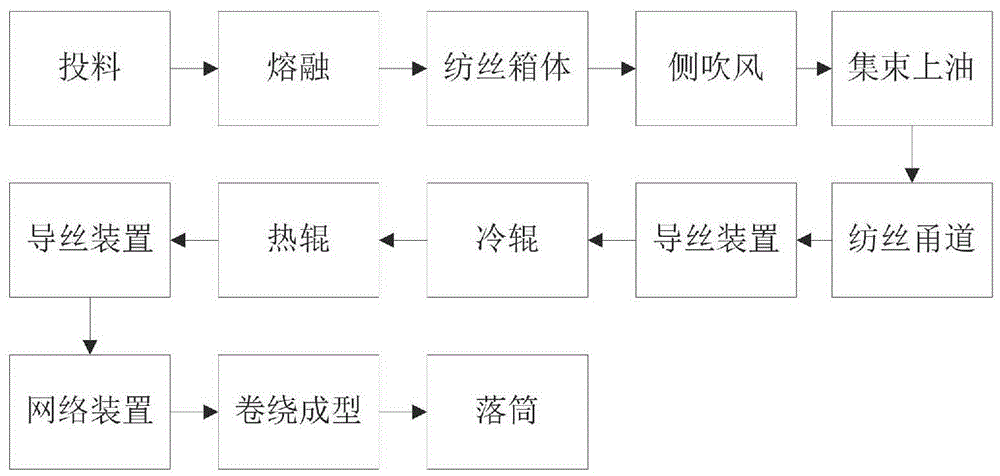

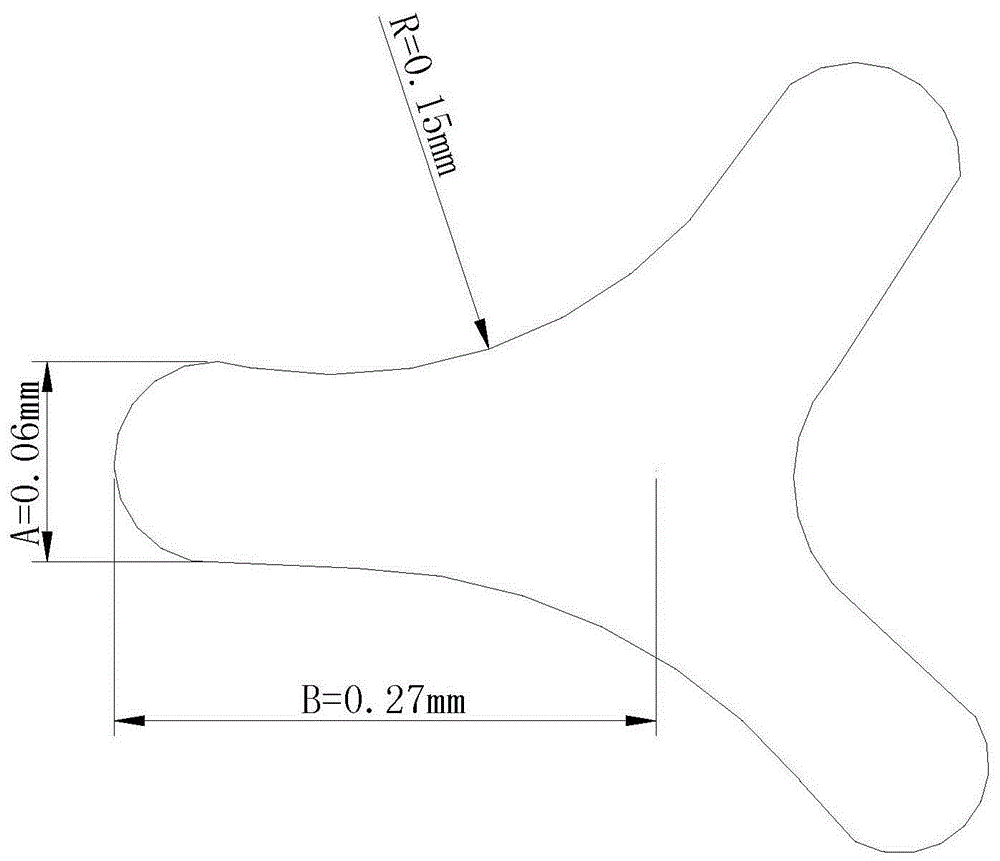

Production method of fine-denier porous super-bright trilobal nylon 6 filament

InactiveCN106835309AFeel thickFluffy goodNew-spun product collectionFilament/thread formingPolymer scienceNylon 6

The invention provides a production method of fine-denier porous super-bright trilobal nylon 6 filament; spinning-level nylon 6 having relative viscosity of 2.48+ / -0.02 and water content of < / =500 ppm is sliced, slices are charged into a stock bin, a screw extruder serves for heating and melting, and melt is fed into a spinning box through a melt distribution pipe; the melt enters a spinning component from the spinning box and is sprayed via trilobal-section spinneret orifices which hare arranged in 'circular shape'; trilobal-section as-spun fibers are cooled by side blowing, the cooled fibers are oiled via an oil nozzle, and the oiled fibers are fed into a spinning passage; tows are passed through a cold roller, a hot roller, a laying unit and a tension roller for the purpose of one-step winding. The fine-denier porous super-bright trilobal nylon 6 filament has profile degree of 20-30% and denier per filament of 0.8-1.2 D, and is fully, highly breathable and super-bright.

Owner:CHANGLE LIHENG POLYAMIDE TECH

Novel environmentally-friendly aqueous PU leather

ActiveCN101979759AReduce the ratioQuick drying moldingSynthetic resin layered productsTextiles and paperEnvironmental resistanceSurface layer

The invention relates to novel environmentally-friendly aqueous PU leather, which comprises a surface layer, an adhesive layer and a backer. The surface layer host is aqueous polyurethane resin, the adhesive layer host is an aqueous polyurethane acrylic resin; a middle layer is further arranged between the surface layer and the adhesive layer, the middle layer host is aqueous polyurethane resin; 2 to 10 mass percent of aqueous pigment is between the surface layer and the middle layer. The invention solves the problems that the production efficiency of the environmentally-friendly aqueous PU leather is low and the full environment protection is difficult to realize in the prior art, thereby providing novel environmentally-friendly aqueous PU leather with highly efficient production.

Owner:浙江昶丰新材料有限公司

Production method of high-strength easily-dispersed toilet wiping paper

PendingCN112553962AGood flexibilityHigh folding resistanceNon-fibrous pulp additionNatural cellulose pulp/paperPulp (paper)Paper sheet

The invention relates to a production method of high-strength easily-dispersed toilet wiping paper, wherein the production method comprises the following steps: (1) respectively putting softwood pulpand hardwood pulp into a long-fiber pulper and a short-fiber pulper, adding CMC on a pulp board, respectively pulping after adding water, and respectively pumping into a long-fiber pre-beating pulp pool and a short-fiber pre-beating pulp pool; (2) adding water into the softwood pulp from the long-fiber pre-beating pulp pool, grinding the softwood pulp by a grinding machine, cutting off fibers, separating and brooming, and then feeding the softwood pulp into a long-fiber post-beating pulp pool; (3) adding water into the hardwood pulp from the short-fiber pre-beating pulp pool, defibering the hardwood pulp by a defibering machine, and enabling the defibered hardwood pulp to enter a short fiber post-beating pulp pool; (4) pumping the softwood pulp and the hardwood pulp into a mixed pulp pool,adding water into the mixed pulp pool, then enabling the mixed pulp to enter a pulping machine, further separating and brooming fibers, and enabling the separated and broomed fibers to enter a pulping pool; and (5) feeding the pulp discharged from the pulping pool into a paper machine for forming, squeezing and drying. Compared with the prior art, the method is simple in process and convenient tooperate, and the produced paper has the advantages of being good in strength, easy to disperse and the like.

Owner:上海东冠纸业有限公司

Production technology of low-twist yarn

The invention discloses a production technology of low-twist yarn. The production technology comprises the steps of cotton selection, fore-spinning and post-spinning, wherein the fore-spinning processcomprises the steps of blowing, carding, drawing and roving, and the post-spinning process comprises the steps of spinning and winding. According to the production technology of the low-twist yarn, through selection control on raw materials, optimized configuration on the fore-spinning process, false twist treatment on the spinning step and vacuum low-temperature steam yarn shaping treatment on yarn fruits, the problems of more broken ends in weaving, deterioration of quality indicators, difficulty in spinning and the like caused by reduction of yarn twist in the prior art can be effectivelysolved.

Owner:ZHONGHUA GRP

Short-process production method capable of improving crease resistance and dye uptake of fibers, yarns or fabrics

The invention relates to a short-process production method capable of improving the crease resistance and dye uptake of fibers, yarns or fabrics. In the short-process production method, an alkali contraction step and an oxygen bleaching or cold batch padding pretreatment step for fibers, yarns or fabrics are combined under the condition of a low temperature; and working solution is composed of 80-210g / L of caustic soda, 3-30 g / L of hydrogen peroxide, 3-35 g / L of fiber bleaching nano-material composition, and the balance of water. The short-process production method has the beneficial effects of greatly shortening the production process and saving the costs of steam, water and electricity. A fiber fabric after being treated is softer and crease-resistant, and especially better in wet crease resistance and obviously improved in washing and wearing property; the crease resistant effect of the fabric treated by the method is close to advanced crease resistant effect obtained through treatment by using liquid nitrogen; the dimensional stability of the fabric is improved; the fabric feels thick, fluffy and soft; and the dosage of about 50% of softening agent can be reduced. Moreover, the dye uptake is improved by more than 30% in contrast with the traditional process; the dosage of a dye is greatly reduced; and the indexes such as COD (Chemical Oxygen Demand), chroma and the like of waste water are reduced.

Owner:苏州麻朵纺织科技有限公司

Production method of weft-knitted double knitted polar fleece

InactiveCN110565246AIncrease elasticityLight in massWeft knittingHeating/cooling textile fabricsRoll formingEngineering

The invention discloses a production method of weft-knitted double knitted polar fleece, and relates to a fabric production method. The problem that double napping is poor in effect is solved. The production method of the weft-knitted double knitted polar fleece comprises the following specific steps of S1 gray fabric preparation, S2 dyeing process implementation, S3 finishing for shaping and S4 cutting and packaging for roll forming. The production method of the weft-knitted double knitted polar fleece adopts traditional common raw materials, in combination with a double-sided mini-jacquard weaving technology, and under the assistance of a conventional dyeing and finishing process, a knitted fabric with one side being cotton and the polar fleece side being terylene is produced, and the knitted fabric has the prominent advantages of being fluffy and soft in cloth body, good in elasticity, light in weight, thick in hand feeling, high in skin-friendly feeling, good in heat retention property, good in structural stability, small in shrinkage and the like, can be widely used for bottoming underwear or T-shirts, small casual coats with hoods, baby shoes and the like of spring, autumn and winter clothing, and has broad market application prospects.

Owner:FOSHAN HENGTE TEXTILE CO LTD

Permanent press finishing process of wool fabric

The invention provides a permanent press finishing process of a wool fabric. The process comprises the following steps: firstly, performing pad-roll treatment on a finishing solution consisting of 80g / L-100g / L of a 2D resin finishing agent, 1g / L-3g / L of a penetrating agent, 20g / L-50g / L of a softening agent and 10g / L-15g / L of a catalyst at room temperature for two times, wherein the padding rate is 70%-80%; secondly, folding and pressurizing by using a heavy hammer; thirdly, pre-drying at 80-90 DEG C for 3-5 minutes; fourthly, baking at 120-160 DEG C for 60-90 seconds; fifthly, steaming at 90-100 DEG C for 8-10 minutes; lastly, drying and doffing. The wool fabric treated with the finishing process provided by the invention has an excellent wash and wear effect, and is outstanding in rebound resilience and durable press performance, full in hand feel, smooth, thick and free from color change and color fading.

Owner:朱文潮

Method for preparing roller brush fabric from thermoplastic fiber

InactiveCN109868542AHas the effect of hot melt adhesionNot fusion strongBristlePile-fabric loomsFiberEnvironmental resistance

The invention provides a method for preparing a roller brush fabric from thermoplastic fiber. A certain proportion of thermoplastic fiber serves as main fiber materials of upper-layer base cloth and lower-layer base layer, conventional fiber is used for connection of the upper-layer base cloth and the lower-layer base cloth, blank cloth is prepared through a machine knitting method, the upper-layer base cloth and the lower-layer base cloth have hot melting adhesion effects through pile cutting, heating and solidification, and the solidification and non-nap-off effects are achieved without gluing. The fabric can be used for a roller brush and a scrubbing brush, the environmental protection purpose is achieved by omitting the coating process, compared with the similar products, the fabric has fuller suede, a thick and solid hand feeling and non-silk-off and non-nap-off effects, and the solidification effect and the bottom stiffness are good.

Owner:沂水恒泰纺园有限公司

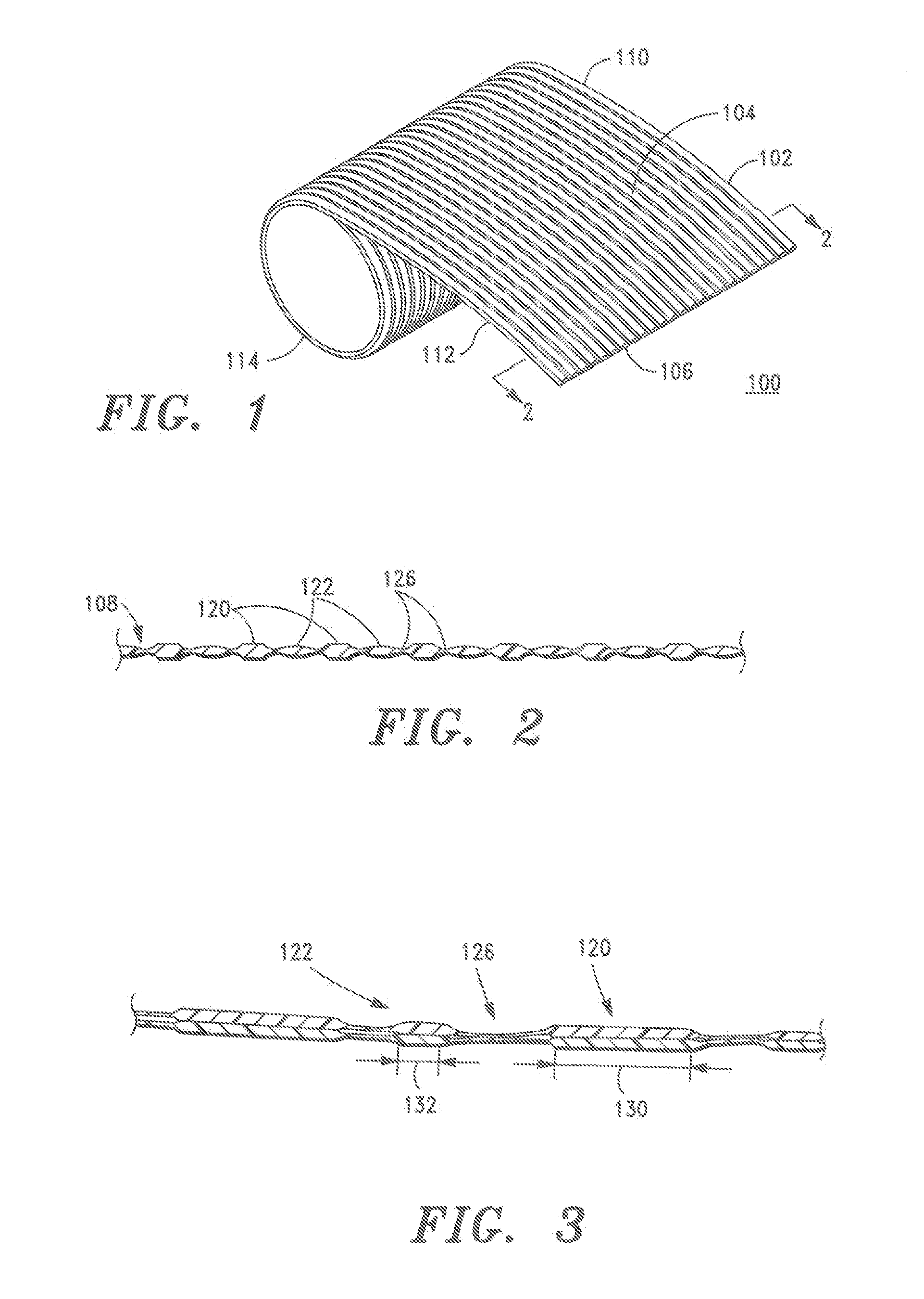

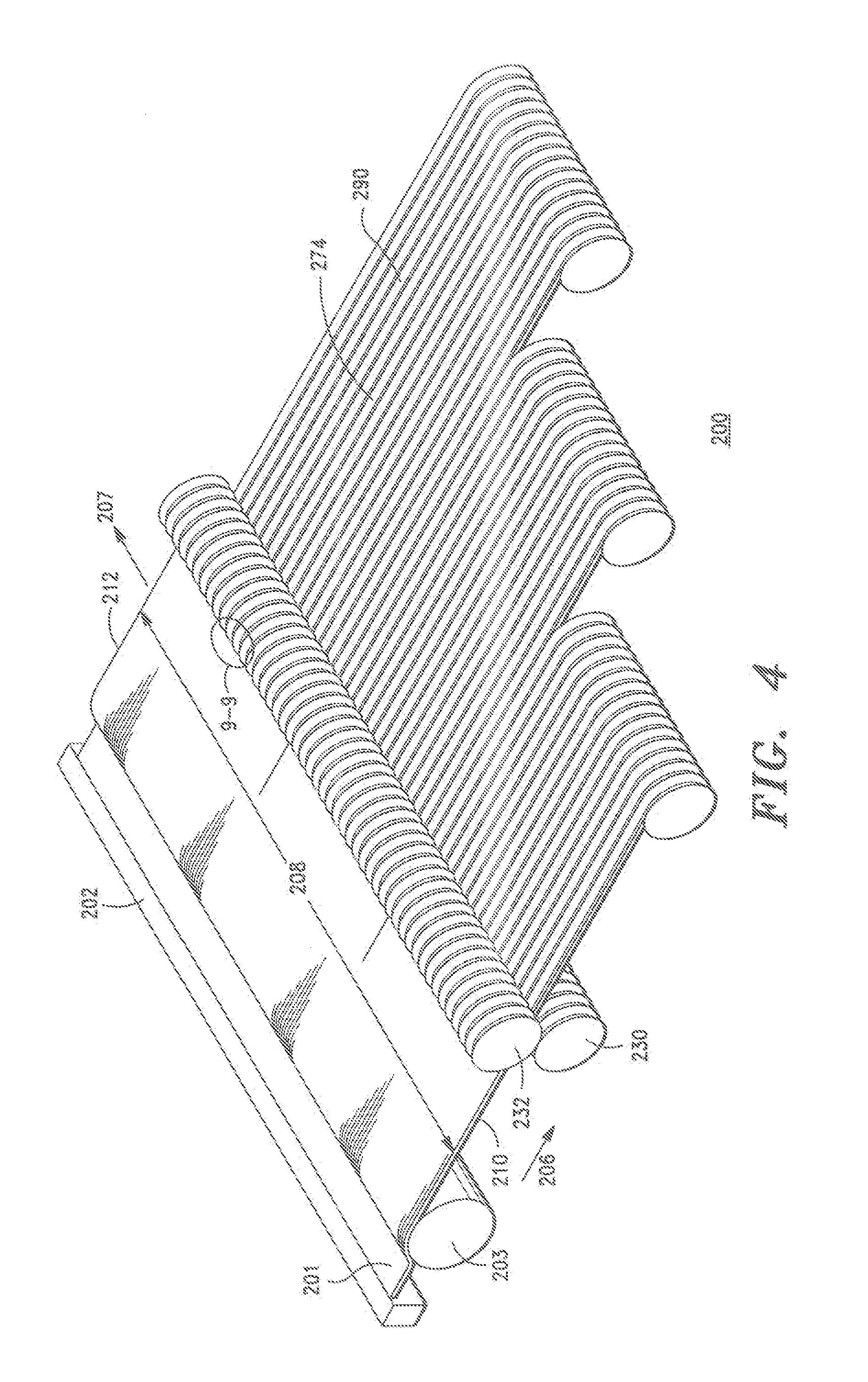

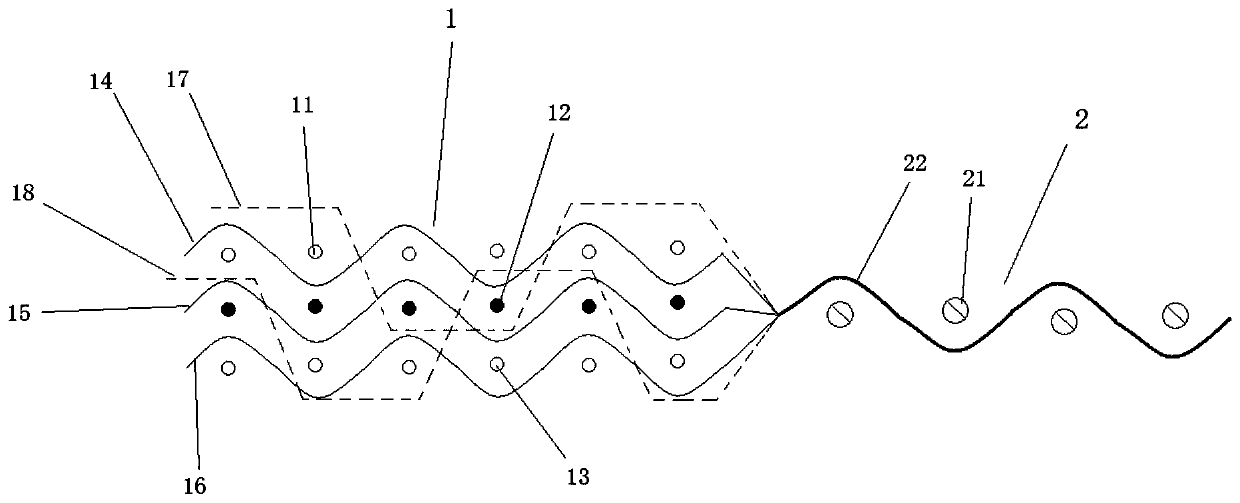

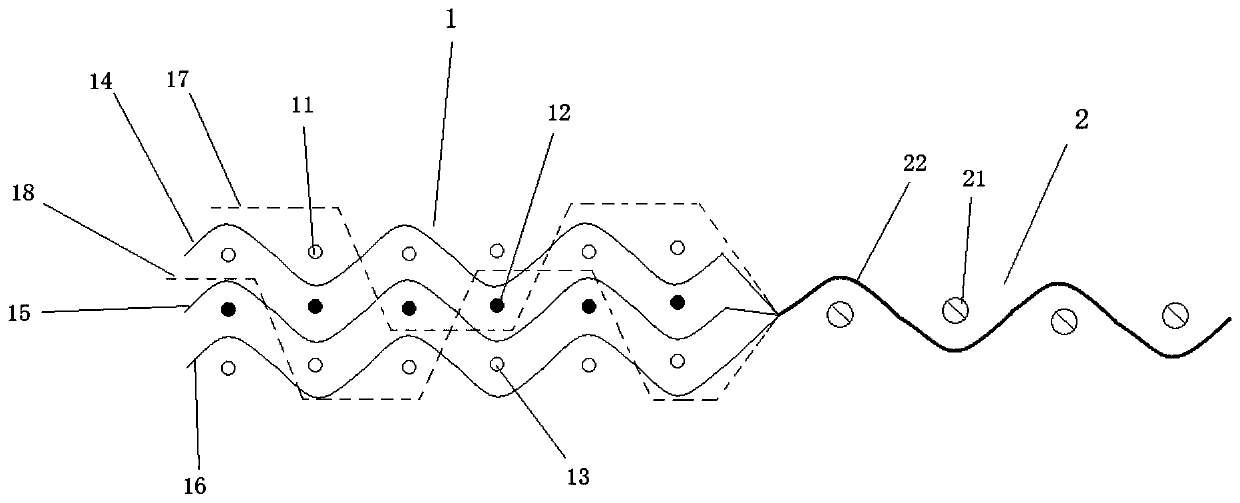

Cling wrap

ActiveUS20130140207A1Easy to processGreat loftContainers for annular articlesDispensing apparatusPlastic wrapEngineering

A thermoplastic food wrap film including a plurality of parallel ribs formed therein. To produce the film, a thermoplastic web may be directed between opposing first and second rollers having ridges. The formation of the ribs may increase the width of the web. The film may be formed into a roll and inserted into a box having a cutting strip.

Owner:THE GLAD PROD CO

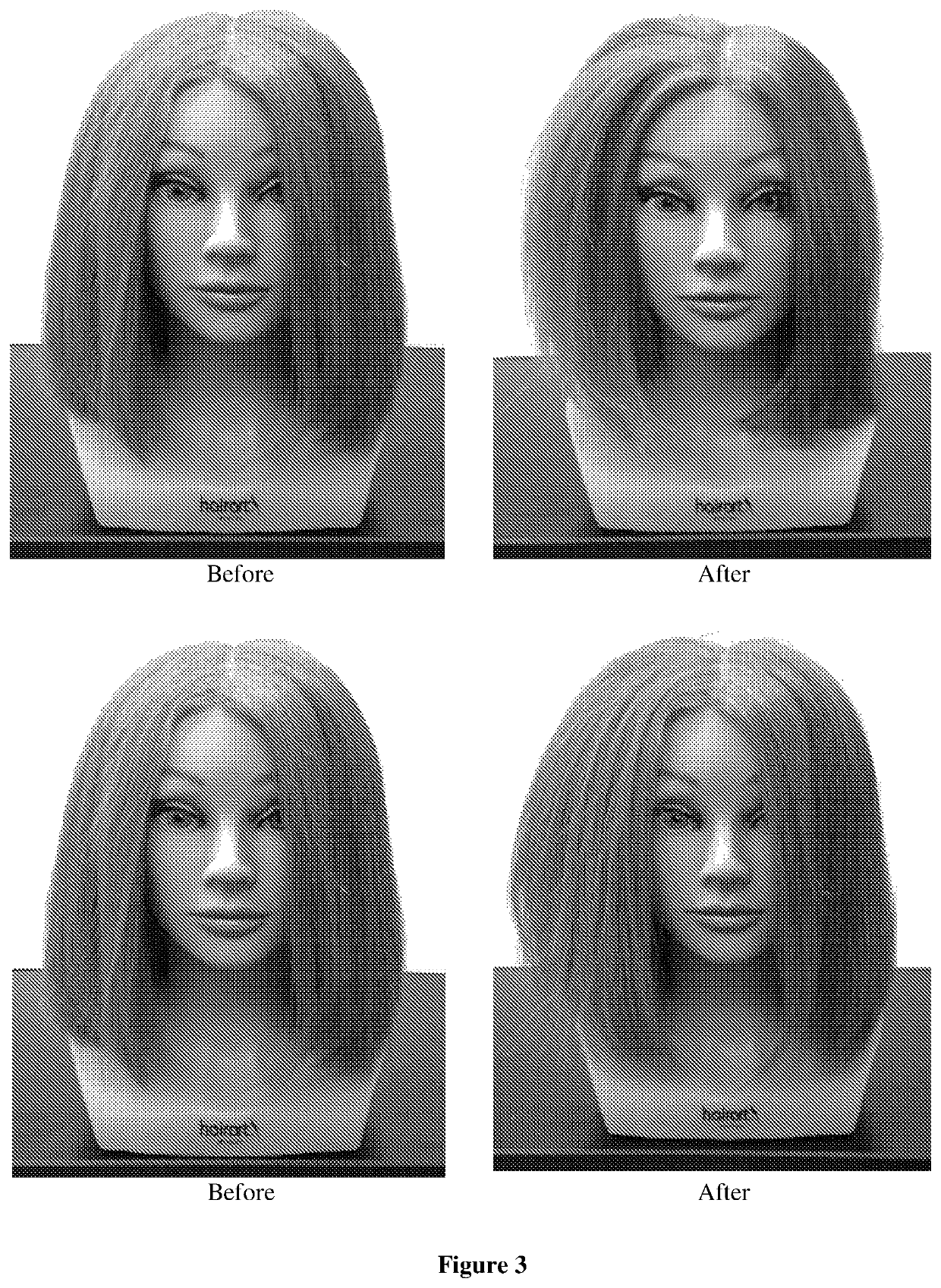

Hair compositions and methods of use thereof

ActiveUS10987286B2Increase hair volumeLow densityCosmetic preparationsHair cosmeticsPolymer scienceMicrosphere

Owner:LIVING PROOF INC

Wool fabric treatment process for improving bulkiness

InactiveCN107503111AImprove bulkFeel thickShrinking resistant fibresAnimal fibresOxidizing agentReducing agent

The invention relates to a wool fabric treatment process for improving bulkiness, which comprises first soaking the wool fabric in water added with sodium chloride at 35-50 DEG C for 60-80 min, wherein the mass ratio of sodium chloride to wool fabric is 1: 180; then add oxidizing agent, the mass ratio of oxidizing agent and wool fabric is 1:90, the temperature of the oxidation process is kept at 45 ° C for 30 minutes; then the softener is added, the mass ratio of softener and wool fabric is 1:120, and the temperature of the softening process is 1:120. Keep at 30°C for 20min; then add reducing agent, the mass ratio of reducing agent and wool fabric is 1:100, and the temperature of the reduction process is kept at 40°C for 30min. It is characterized in that: before adding softener, add Fluffing agent. The present invention has the advantages that: before adding softening agent, adding fluffing agent, through the action of fluffing agent, the finished wool fabric can have high bulkiness and thick hand feeling, and the surface of the fabric has no hardening phenomenon, which improves the warmth retention of wool fabric. sex and comfort.

Owner:JIANGSU SUNSHINE

Wear-resisting oxford fabric

The invention relates to a wear-resisting oxford fabric comprising a shell fabric layer and at least one layer of sizing agent coating, wherein the shell fabric layer is interweaved by 150-350D polyester filament yarn; and the sizing agent coating is composed of the following components in parts by weight: 60-80 parts of organic silicon resin, 5-10 parts of silane coupling reagent, 3-6 parts of cross-linking agent, 4-8 parts of alumina silicate fiber, 6-10 parts of copper oxide powder and 10-15 parts of solvent. The wear-resisting oxford fabric provided by the technical scheme is high in strength, firm, wear-resisting and firm in handfeel, has good coating stability and can be used as a material of products of cases, traveling bags, tent bottoms, and the like.

Owner:NANTONG QUANJI TEXTILE COATING

Short-process production method capable of improving crease resistance and dye uptake of fibers, yarns or fabrics

The invention relates to a short-process production method capable of improving the crease resistance and dye uptake of fibers, yarns or fabrics. In the short-process production method, an alkali contraction step and an oxygen bleaching or cold batch padding pretreatment step for fibers, yarns or fabrics are combined under the condition of a low temperature; and working solution is composed of 80-210g / L of caustic soda, 3-30 g / L of hydrogen peroxide, 3-35 g / L of fiber bleaching nano-material composition, and the balance of water. The short-process production method has the beneficial effects of greatly shortening the production process and saving the costs of steam, water and electricity. A fiber fabric after being treated is softer and crease-resistant, and especially better in wet crease resistance and obviously improved in washing and wearing property; the crease resistant effect of the fabric treated by the method is close to advanced crease resistant effect obtained through treatment by using liquid nitrogen; the dimensional stability of the fabric is improved; the fabric feels thick, fluffy and soft; and the dosage of about 50% of softening agent can be reduced. Moreover, the dye uptake is improved by more than 30% in contrast with the traditional process; the dosage of a dye is greatly reduced; and the indexes such as COD (Chemical Oxygen Demand), chroma and the like of waste water are reduced.

Owner:苏州麻朵纺织科技有限公司

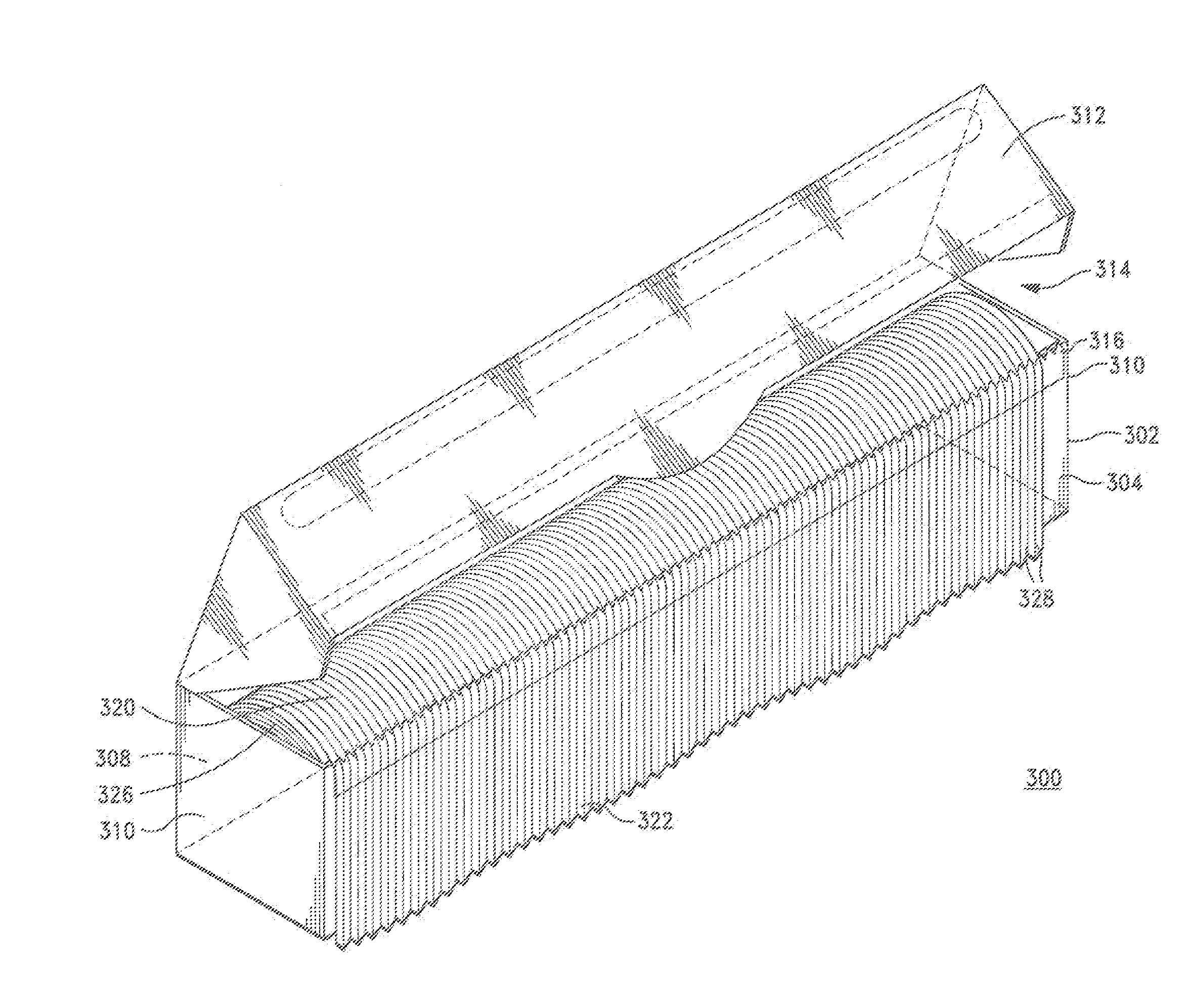

Preparation method of soft line-suction microfiber leather without thickness loss

PendingCN110130118AShort development cycleSoft touchHeat resistant fibresGrip property fibresEngineeringMicrofiber

The invention discloses a preparation method of soft line-suction microfiber leather without thickness loss. The preparation method comprises following steps: S1, base fabric is subjected to softeningtreatment; S2, dry surface making is performed, and microfiber leather is obtained; S3, printing treatment is performed, and a printing layer is obtained; S4, a line-suction process is adopted, a vacuum line suction machine is utilized for sucking lines, a heating hood passes through two heating areas, the first heating area is used for heating a main body, the second heating area is used for supplementing heat, and cooling is performed; the soft line-suction microfiber leather without thickness loss is obtained. The thickness of the line-suction microfiber leather prepared with the method ofthe soft line-suction microfiber leather without thickness loss is increased by about 0.05 mm; the product which is 1.0 mm-1.5 mm touches soft and full; the lines are natural and are copied from genuine leather directly, a line-suction roller is made, the lines are transferred to the surface of the product by the line-suction roller, and the lines have a short development cycle and change fast compared with release paper.

Owner:ZHEJIANG HEXIN NEW MATERIAL CO LTD

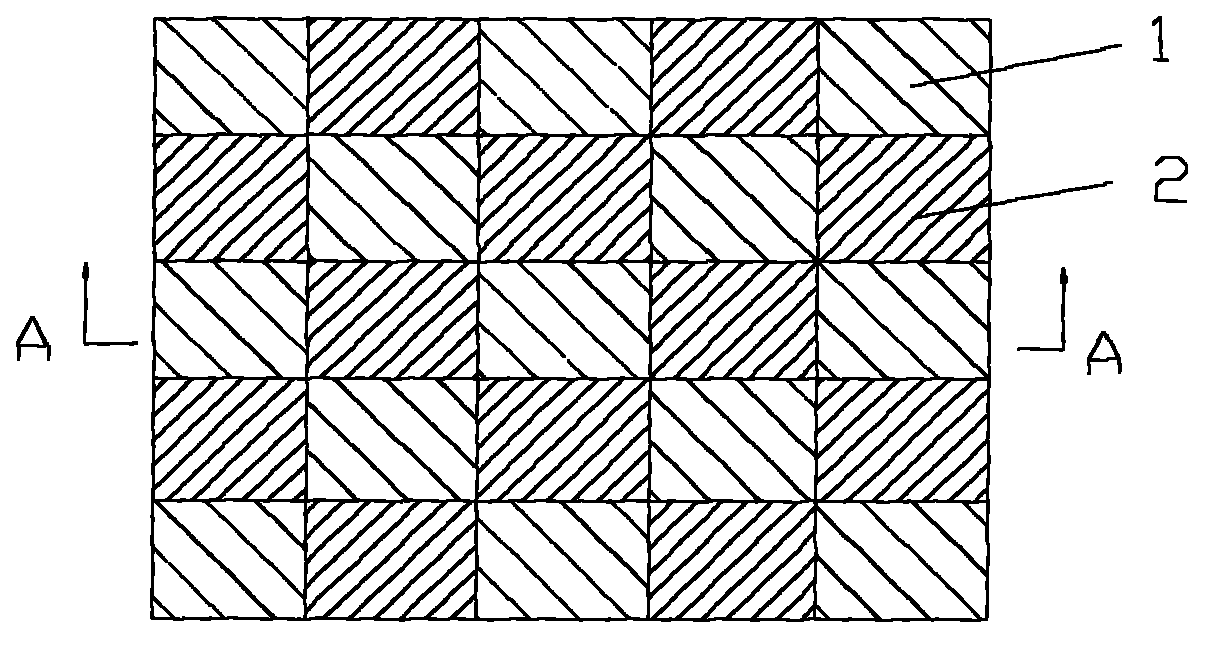

Double-sided wear-resistant stripe fabric

ActiveCN109706585AImprove wear resistanceImprove breathabilityMulti-ply fabricsSurface layerWear resistant

The invention relates to a double-sided wear-resistant stripe fabric. The fabric comprises a wear-resistant thick weaving section and a breathable thin weaving section which are woven by warp yarn andweft yarn. In the wear-resistant thick weaving section, outer-layer weft yarn is interwoven with outer-layer warp yarn into a wear-resistant surface layer, middle-layer weft yarn is interwoven with middle-layer warp yarn into a middle base layer, and inner-layer weft yarn is interwoven with inner-layer warp yarn into a wear-resistant inner layer; first connecting warp yarn is interwoven with theouter-layer weft yarn and the middle-layer weft yarn in a drifting way, so that the wear-resistant surface layer is connected with the middle base layer into a whole part; second connecting warp yarnis interwoven with the middle-layer weft yarn and the inner-layer weft yarn in the drifting way, so that the middle base layer is connected with the wear-resistant inner layer into a whole part. In the breathable thin weaving section, the outer-layer warp yarn, the middle-layer warp yarn, the inner-layer warp yarn, the first connecting warp yarn and the second connecting warp yarn are combined into single-strand monolayer warp yarn, and the single-strand monolayer warp yarn is interwoven with monolayer weft yarn in the drifting way. Compared with the prior art, the double-sided wear-resistantstripe fabric has excellent wear resistance and air permeability and is thick in hand feeling, high in strength and very suitable for preparing various high-grade coats.

Owner:劲霸男装(上海)有限公司

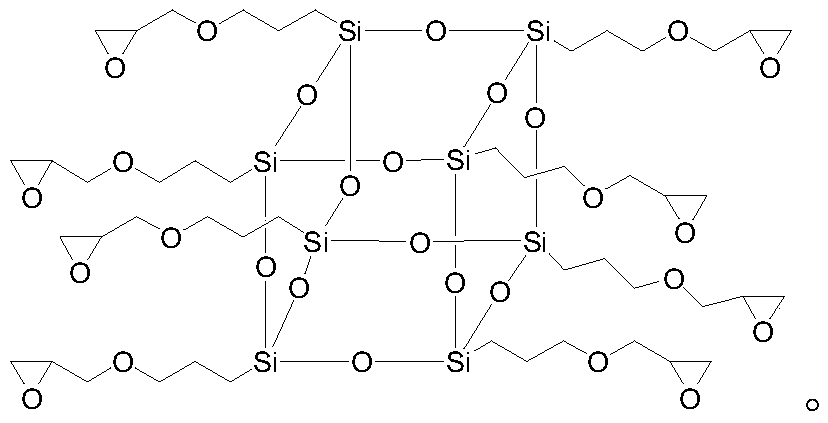

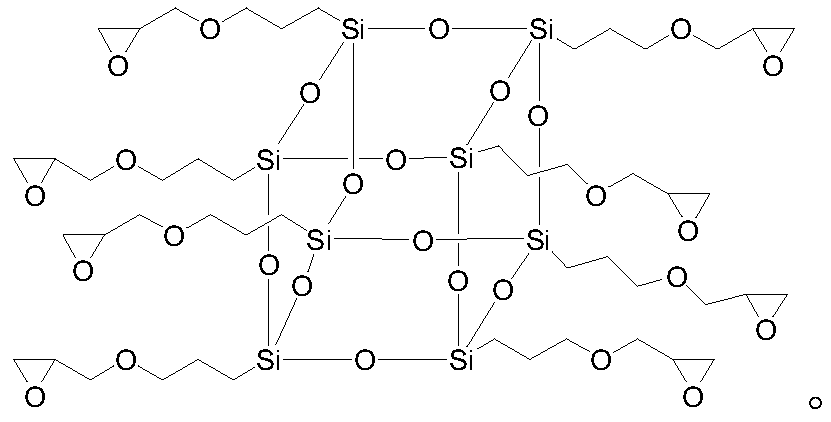

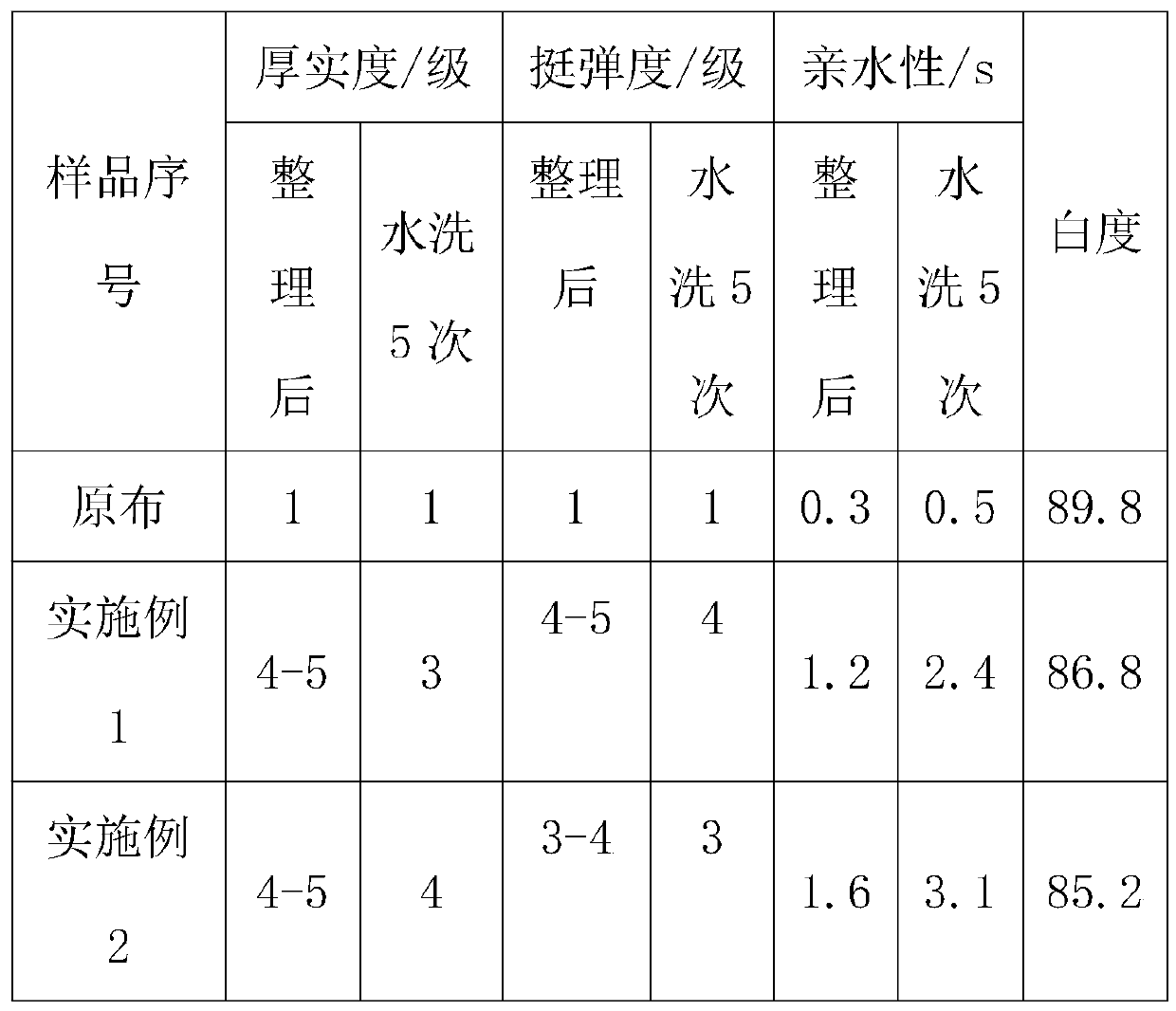

Preparation method of side chain hydrophilically-modified block silicone oil for cotton

ActiveCN111499872AImprove hydrophilicityFeel goodGrip property fibresVegetal fibresEpoxyPolymer science

The invention relates to the field of textile assistants, and especially relates to a preparation method of side chain hydrophilically-modified block silicone oil for cotton. The side chain hydrophilically-modified block silicone oil is prepared by a reaction of side chain hydrogen-containing silicone oil, allyl epoxy polyether, amino-terminated polyethylene glycol, glycidyl polyhedral oligomericsilsesquioxane, isopropanol and the like. The modified monomer is glycidyl polyhedral oligomeric silsesquioxane with multiple functional groups, so that the prepared side chain hydrophilically-modified block silicone oil for cotton has a polyhedral oligomeric frame structure, and a finishing agent prepared from the side chain hydrophilically-modified block silicone oil for cotton can endow cottonfabrics with excellent hydrophilicity, yellowing resistance, thickness, stiffness, elasticity and washing resistance.

Owner:HANGZHOU MEIGAO HUAYI CHEM

Weaving process for multicolour warp towel quilt product

InactiveCN101696527ARich and colorful color matchingRich high-end marketWoven fabricsYarnEngineering

The invention discloses a weaving process for a multicolour warp towel quilt product weaved by a jacquard satin loom. A cutting machine order for cutting a heald yarn and reeding in a mixed area of wool wraps and ground wraps is adopted; and the ratio of the number of the wool wraps to that of the ground wraps is more than 1. The produced multicolour warp towel quilt product has rich and varied colour assortment, good standing property and firm handfeel of a terry, and exquisite and clear pattern, and extremely high visual and use values, and greatly enriches the high-end market of towel quilt products.

Owner:SUNVIM GROUP

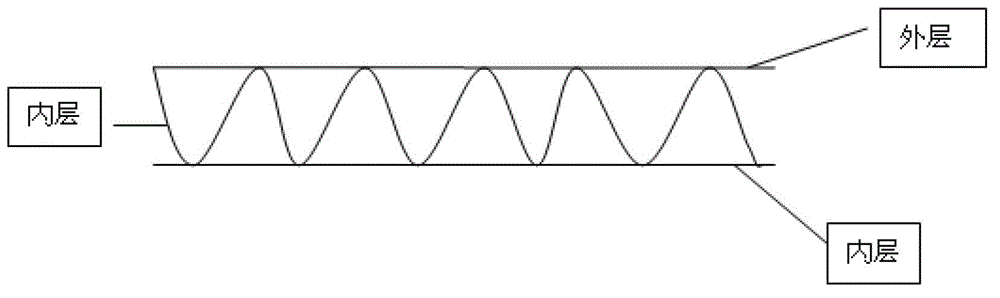

A kind of three-dimensional warm knitted fabric and its preparation method

ActiveCN103382618BImprove crispnessGood snagging resistanceWeft knittingHeating/cooling textile fabricsPolyesterFiber

The invention relates to three-dimensional thermal insulation knitted fabric and a preparation method thereof. The fabric comprises an outer layer, an inner layer and connecting silk yarns, wherein the outer and the inner layer are formed through the twice loop formation mode, and the connecting silk yarns are wound between the outer layer and the inner layer in a reciprocating manner to enable the outer layer and the inner layer to be connected together; the outer layer is formed by micro-thin polyester fiber, the inner layer is formed by non-circular cross-section fiber, and the connecting silk yarns are polyester filaments. The preparation method comprises the following steps: obtaining fabric via knitting of yarns, presetting, dyeing, functional finishing, drying, secondary setting, and obtaining the thermal insulation knitted fabric. The thermal insulation knitted fabric has the characteristics of excellent stiff and smooth effect, lightness, thermal insulation, firm handfeel, excellent snagging prevention and the like, overcomes the defects of easiness in snagging, infirm handfeel, poor thermal insulation and the like, is simple in structure and low in cost, and has excellent application prospects.

Owner:NINGBO DAQIAN TEXTILE

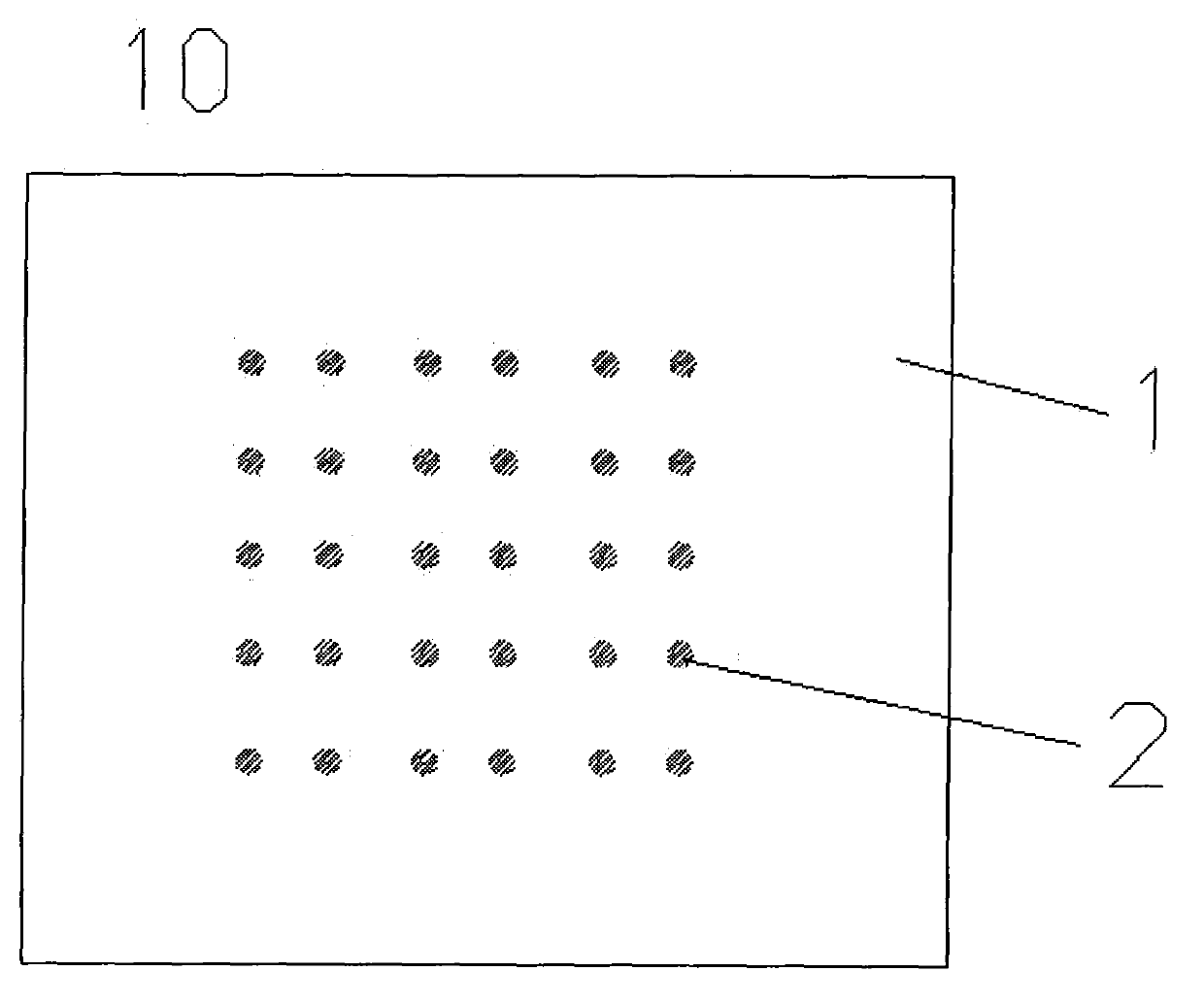

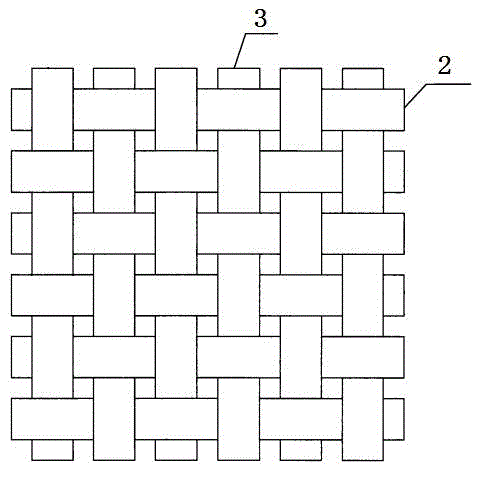

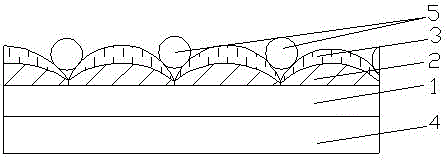

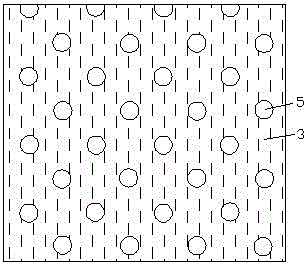

Looping fabric anti-skidding table cloth with salient points

The invention relates to looping fabric anti-skidding table cloth with salient points. The looping fabric anti-skidding table cloth with the salient points comprises a table cloth body (1), one side, facing the table top, of the table cloth body (1) is provided with the anti-skidding salient points (2), the anti-skidding salient points (2) are made of plastic or rubber and pasted to the table cloth body (1), the table cloth body (1) is made of fabric, the fabric is interwoven by warps and wefts, the warps comprise looping yarns and filling yarns, and the looping yarns form a fixed texture after spanning weft yarns in a certain number. Starting points and stopping points of loops formed by the looping yarns are arranged at three-weft-yarn interval, the filling yarns form a fixed texture, and three weft yarns are arranged between every two adjacent weaving points. The anti-skidding salient points are arranged, so that the friction coefficient between the table cloth and a table is increased, and the adhesive force between the table cloth and the table is accordingly improved. The looping fabric anti-skidding table cloth with the salient points is full, fluffy, soft and firm in hand feeling.

Owner:赵平宝

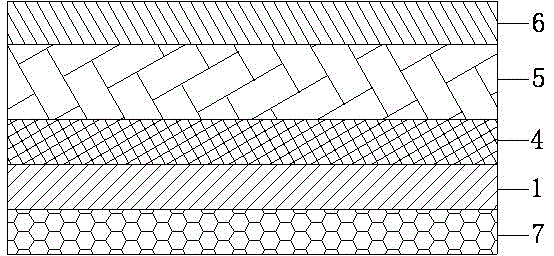

Looped fireproof fabric

InactiveCN106313718AFullness of productsFeel thickSynthetic resin layered productsFlax fiberFiber layer

The invention relates to a looped fireproof fabric. The fabric comprises a fabric body, the fabric body is a fenestral fabric formed through interweaving warp yarns and weft yarns, the weft yarns adopt memory fiber terylene, the front side of the fabric body is covered with a flax fiber core layer (3), the surface of the flax fiber core layer is covered with a ramie fiber layer (4), the surface of the ramie fiber layer is covered with a flame retardation layer (5), the flame retardation layer is adhered with flame retardation powder, and the surface of the flame retardation layer (5) is covered with a flocked layer (6). The back side of the fabric body is covered with a base layer, the base layer is made of a textile, the textile is formed by interweaving warp yarns and weft yarns, the warp yarns comprise looped yarns and base yarns, and the looped yarns cross a certain quantity of the weft yarns to form a fixed structure, wherein three filaments of the weft yarns exist between the start point and the end point of a looped pile formed by the looped yarns; and three filaments of the weft yarns exist between adjacent interlace joints of the fixed structure formed by the base yarns. The looped fireproof fabric has good air permeability and high comfort level, and allows products to have full, fluffy, soft and thick hand feeling.

Owner:黄文平

Stiffening agent and production method thereof

InactiveCN102454106BExcellent yarn cohesionDoes not affect shadeFibre treatmentEmulsionPolyvinyl acetate

Owner:南通斯恩特纺织科技有限公司

Preparation process of shaping liner for vamp

InactiveCN109610170AGood fabric stiffnessFabric stretch and feel thickSucessive textile treatmentsTwo or more solvent application treatmentComfort levelsPolyvinyl acetate

The invention provides a preparation process of a shaping liner for a vamp. The preparation process comprises the following steps: base cloth weaving, alkali-padding piling, oxygen bleaching treatment, stiffness treatment, two-point dispensing, baking treatment, baking treatment and winding inspection treatment. The base cloth is weaved by adopting 58tex*58tex all-cotton in the warp and weft; thedemand that the shaping liner for vamp has good shaping performance and air permeability and comfort level; the stiffness treatment is performed on the product by adopting the polyacrylate and polyvinyl acetate twice-padding and twice-rolling process; the settled fabric is good in stiffness and the fabric has good elastic and firm handfeel.

Owner:ZHEJIANG KINGSAFE INTERLINING

Chenille sofa fabric with high wear resistance and preparation method thereof

PendingCN112176496AImprove sparsityNot easy to hook off the lineLiquid/gas/vapor removalMulti-ply fabricsPolyesterWoven fabric

A chenille sofa fabric with high wear resistance belongs to the field of textile fabrics, and is formed by weaving warp yarn and weft yarn, wherein the warp yarn is polyester cotton blended yarn, theweft yarn is chenille yarn, the chenille yarn comprises core yarn and decorative fluff yarn, the core yarn is terylene, the decorative fluff yarn is polypropylene fibers, and the fabric has a soft, thick, elegant and noble fabric style; and meanwhile, wear resistance of the sofa fabric is improved, and the polyester cotton warp yarn and the chenille weft yarn are interwoven to form a bonded double-layer tissue structure, so that the fabric structure is more compact, the sparse condition of the fabric in a fluff-free area can be improved, and the thread of sofa fabric is not easy to loose by hooking.

Owner:YIXING ZHONGDA TEXTILE

Soft-bumped and looped fabric with anti-radiation fabric layer

InactiveCN104924702AEnhance layeringFeel thickSynthetic resin layered productsTextile decorationEngineeringWeft yarn

The invention relates to a soft-bumped and looped fabric with an anti-radiation fabric layer. The soft-bumped and looped fabric comprises a fabric body (1); the upper surface of the fabric body (1) is provided with an outer layer (3), and the lower surface of the fabric body (1) is provided with a jacquard layer (4); filler (2) is arranged between the outer layer (3) and the fabric body (1); in addition, the upper surface of the outer layer (3) is provided with a plurality of ornaments (5) which are arranged in a staggered manner; the jacquard layer (4) is fixed on the lower surface of the fabric body (1); the fabric body (1) is made of a textile fabric which is formed by interweaving warp yarns and weft yarns, wherein the warp yarns comprise loopy yarns and base yarns; the loopy yarns span over a certain quantity of weft yarns and then form fixed tissues. Wherein, three weft yarns are spaced between an origin and an end point of a loop formed by the loopy yarns; three weft yarns are spaced between every two adjacent interweaved points of the fixed tissues formed by the base yarns. By means of raised soft bumps and the ornaments, the layering sense of the soft-bumped and looped fabric with the anti-radiation fabric layer is enhanced.

Owner:JIANGYIN HULIAN DYEING & FINISHING

Checked looped fabric

InactiveCN103820920AAdd dimensionIncrease warmthSwivel-woven fabricsLappet-woven fabricsConvex structureEngineering

The invention relates to a checked looped fabric and belongs to the field of textile fabrics. The checked looped fabric comprises a fabric body (1) which is provided with a plurality of cells (2), the rectangular cells (2) are staggered and embedded in the plane of the fabric body (1). The cells (2) are integrally connected with the fabric body (1) to form a concave-convex structure. The back of the fabric body (1) and cells (2) is provided with a jacquard layer (3). The fabric body (1) is made of textile fabric made by interweaving warps and wefts; the warps include looped yarns and ground yarns; the looped yarns form fixed weave by crossing a certain amount of wefts. Three wefts are between the start and end of each loop formed by the looped yarns. The ground yarns form fixed weave; each two adjacent interweaving points are spaced by three wefts. The concave-convex structure of the checked looped fabric enables the fabric to be more three dimensional; meanwhile the jacquard layer on the back of the fabric body and cells enables the fabric to be better in warmth retention.

Owner:周忠平

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com