A kind of three-dimensional warm knitted fabric and its preparation method

A knitted fabric, three-dimensional technology, which is applied in the directions of knitting, weft knitting, fabric surface trimming, etc., can solve the problems of unstable quality of three-dimensional warm knitted fabrics, poor anti-hooking ability, and insufficient stiffness, and achieves good application prospects and cost. Low, good stiffness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Raw material selection

[0025] The outer layer of the fabric is made of fine denier polyester fiber with a linear density of 150D, a single fiber fineness of 1.1dtex, and a Z-twisted filament twist. The linear density of the cross-shaped polyester fiber in the inner layer is 150D, and the twist direction of the filament is Z twist. The density of polyester filaments in the middle connecting thread is 75D, and the twist direction of the filaments is untwisted.

[0026] (2) Weaving process

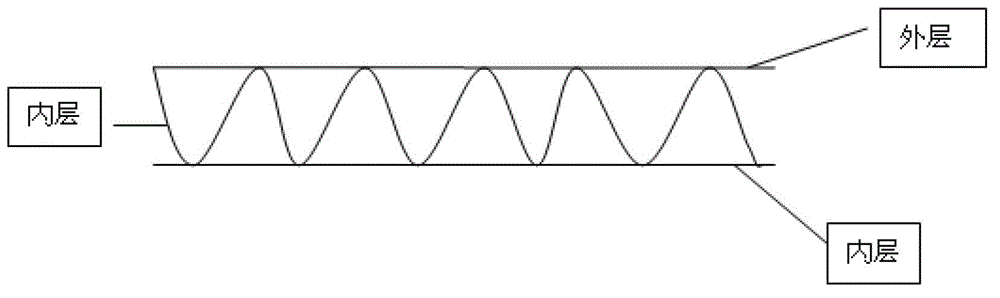

[0027] A three-dimensional warm-keeping knitted fabric comprises an outer layer, an inner layer and a middle layer. The structure described was obtained by the following method.

[0028] The cylinder needles go through 1, 3, 5, 7....... Odd-numbered needles form a circle first, followed by 2, 4, 6, 8........... ..Even numbered stitches form a loop.

[0029] Then the dial needles pass through 1, 3, 5, 7...... odd numbered needles to form a circle first, followed by 2, 4, 6, 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com