Knitted fabric containing cotton and having silky luster, handfeel and cool feeling and manufacturing method thereof

A knitted fabric and luster technology, which is applied in knitting, weft knitting, fabric surface trimming, etc., can solve the problem of drapability, hand feeling, gloss, and coolness that cannot be obtained closer, increase production processes and production costs, and knitted fabrics Weaving research and other issues to achieve the effect of production feasibility, excellent stiffness, and improvement of shrinkage problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

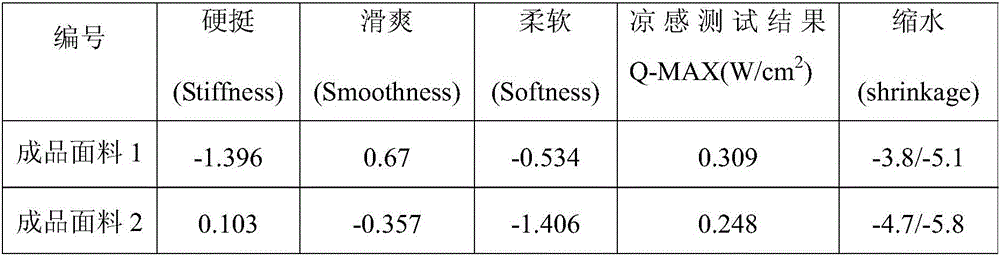

Embodiment 1

[0040] The present embodiment provides a cotton-containing knitted fabric with silky luster, feel and cool feeling, and the preparation method of the fabric is as follows:

[0041] 1) Use the circular weft machine to weave the yarn into two different gray cloths (respectively marked as gray cloth 1 and gray cloth 2): the yarns used in the two different gray cloths are 100% cotton yarns, and the structure of the gray cloths They are also plain weave, and the gray cloth design and weaving parameters are shown in Table 1.

[0042] Table 1 Gray cloth design and weaving parameters

[0043] serial number

Yarn length 50C

Contacts

door width

Gram weight

Gray cloth 1

40S / 1

115mm

32

56 inches

135g / m 2

Gray cloth 2

40S / 1

120mm

24

54 inches

120g / m 2

[0044] 2) Mercerizing: use open-width mercerizing machine to mercerize the above two kinds of gray fabrics respectively, speed: 15m / min,...

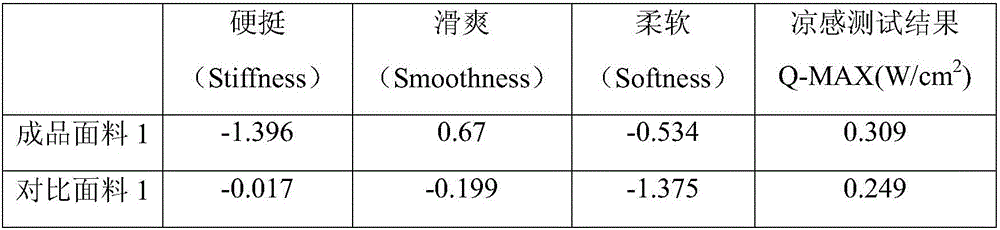

Embodiment 2

[0062] The present embodiment provides a cotton-containing knitted fabric with silky luster, feel and cool feeling, and the preparation method of the fabric is as follows:

[0063] 1) Use the circular weft machine to weave the yarn into gray cloth: the yarn used is 100% cotton yarn, the texture of the gray cloth is cotton wool cloth, and the gray cloth design and weaving parameters are shown in Table 6.

[0064] Table 6 gray cloth design and weaving parameters

[0065] yarn count

Yarn length 50C

Contacts

door width

Gram weight

60S / 1

130mm

32

60 inches

170g / m 2

[0066] 2) Mercerizing: Use an open-width mercerizing machine to mercerize the gray cloth, with a speed of 15 m / min and a temperature of 20°C at room temperature. The composition of the mercerizing working fluid is shown in Table 7.

[0067] 3) Scouring: adopting conventional techniques for scouring.

[0068] The composition of table 7 mercerizing working solution...

Embodiment 3

[0079] 1) Use the circular weft machine to weave the yarn into gray cloth: the yarn used is 100% cotton yarn, the texture of the gray cloth is piqué, and the design of the gray cloth and the weaving parameters are shown in Table 10.

[0080] Table 10 gray cloth design and weaving parameters

[0081] yarn count

[0082] 2) Mercerizing: Use an open-width mercerizing machine to mercerize the gray cloth, with a speed of 15 m / min and a temperature of 20°C at room temperature. The composition of the mercerizing working fluid is shown in Table 11.

[0083] 3) Scouring: adopting conventional techniques for scouring.

[0084] The composition of table 11 mercerizing working solution

[0085] components

[0086] 4) Arrange the billets in the enzyme washing working solution (pH value 5-7), control the bath ratio to 1:15, treat at 55°C for 60 minutes, and then place the billets in an 80°C water bath for 10 minutes to kill enzymes; enzyme washing work The composition o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com