Double-sided wear-resistant stripe fabric

A technology of stripes and fabrics, applied in the direction of fabrics, textiles, textiles and papermaking, etc., can solve the problems of difficult to apply high-grade clothing fabrics, sense of grade and poor air permeability, and achieve environmental protection, safety and health, excellent wear resistance and breathability, and strength big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

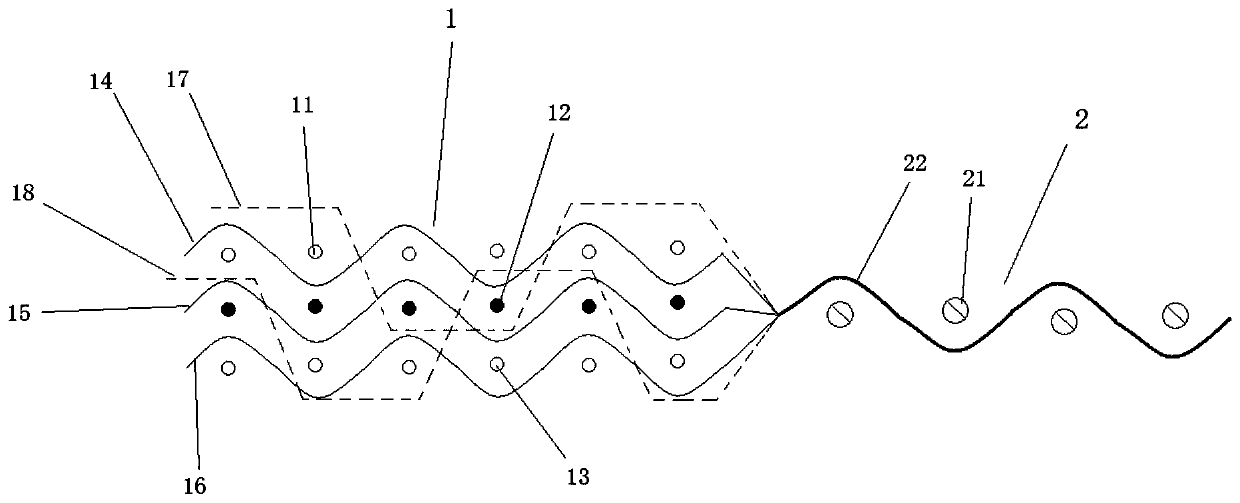

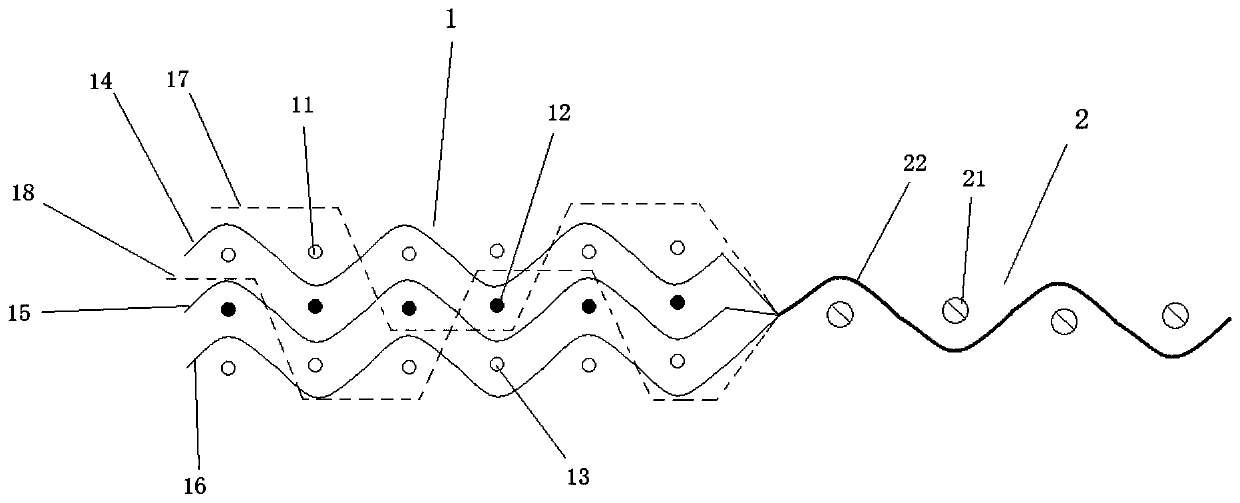

[0028] A double-sided wear-resistant striped fabric, its structure see figure 1 As shown, it includes a wear-resistant thick weaving section 1 and an air-permeable thin weaving section 2 woven by warp and weft yarns, wherein,

[0029] In the wear-resistant thick weaving section 1, the weft yarn is divided into three layers, namely the outer layer weft yarn 11, the middle layer weft yarn 12 and the inner layer weft yarn 13, and the warp yarn is divided into the outer layer warp yarn 14, the middle layer warp yarn 15, the inner layer warp yarn 16, the first connecting Warp yarn 17 and second connecting warp yarn 18, wherein, outer layer weft yarn 11 interweaves with outer layer warp yarn 14 to form a wear-resistant surface layer, middle layer weft yarn 12 interweaves with middle layer warp yarn 15 to form an intermediate base layer, and inner layer weft yarn 13 interweaves with inner layer warp yarn 16 to form Wear-resistant inner layer, the first connecting warp yarn 17 interwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com