Preparation method of side chain hydrophilically-modified block silicone oil for cotton

A technology of block silicone oil and hydrophilic modification, applied in the direction of improved hand-feeling fibers, textiles and papermaking, fiber processing, etc., can solve the problems of inability to meet diversified handfeel, unsatisfactory washing resistance, poor fabric handfeel, etc. , to achieve the effect of improving the hydrophilic ability, improving the washing resistance and improving the hand feeling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

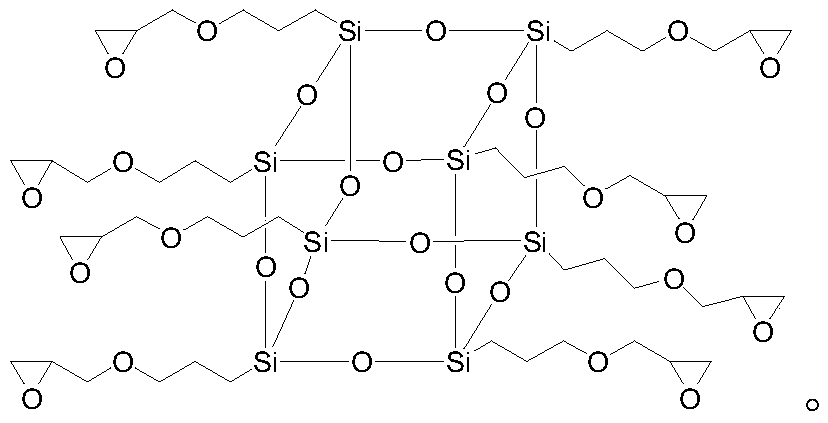

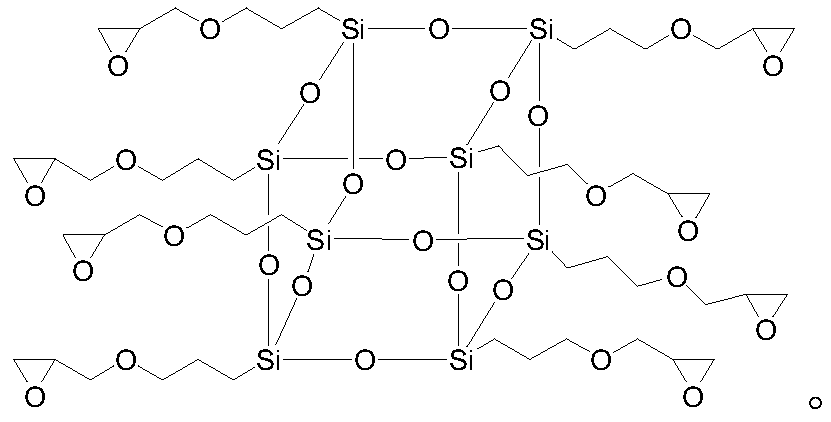

[0013] Example 1: 100 grams of side chain hydrogen-containing silicone oil with a number average molecular weight of 6000, 35 grams of allyl epoxy polyether with a number average molecular weight of 300, and 55 grams of isopropanol are added to a reaction vessel equipped with a condensation reflux device In the process, the temperature of the reaction vessel was raised to 78°C, 0.005 g of chloroplatinic acid was added, and the reaction was carried out at 80°C for 2 hours to obtain a side chain polyether epoxy silicone oil, the temperature was lowered to 20°C, and 37 g of double-ended polyether with a number average molecular weight of 300 was added. Aminopolyethylene glycol, 1.5 g of glycidyl cage silsesquioxane, heating the reaction vessel to 81° C., and keeping it warm for 9 hours to prepare side chain hydrophilic modified block silicone oil for cotton.

Embodiment 2

[0015] 100 grams of side chain hydrogen-containing silicone oil with a number average molecular weight of 8000, 40 grams of allyl epoxy polyether with a number average molecular weight of 400, and 60 grams of isopropanol were added to a reaction vessel equipped with a condensation reflux device, and the reaction vessel Raise the temperature to 79°C, add 0.007 g of chloroplatinic acid, and keep the temperature at 81°C for 3 hours to prepare side chain polyether epoxy silicone oil, cool down to 30°C, add 45 g of double-ended aminopolyethylene glycol with a number average molecular weight of 400 Alcohol, 1.8 grams of glycidyl cage silsesquioxane, the reaction vessel was heated to 83 ° C, and kept for 10 hours for reaction to obtain side chain hydrophilic modified block silicone oil for cotton.

Embodiment 3

[0017] 100 grams of side chain hydrogen-containing silicone oil with a number average molecular weight of 10,000, 50 grams of allyl epoxy polyether with a number average molecular weight of 600, and 65 grams of isopropanol were added to a reaction vessel equipped with a condensation reflux device, and the reaction vessel Raise the temperature to 80°C, add 0.009 g of chloroplatinic acid, and keep the temperature at 81°C for 4 hours to prepare side chain polyether epoxy silicone oil, cool down to 35°C, add 55 g of double-ended aminopolyethylene glycol with a number average molecular weight of 600 Alcohol, 2 grams of glycidyl cage silsesquioxane, the reaction vessel was heated to 85° C., and kept for 12 hours, to obtain side chain hydrophilic modified block silicone oil for cotton.

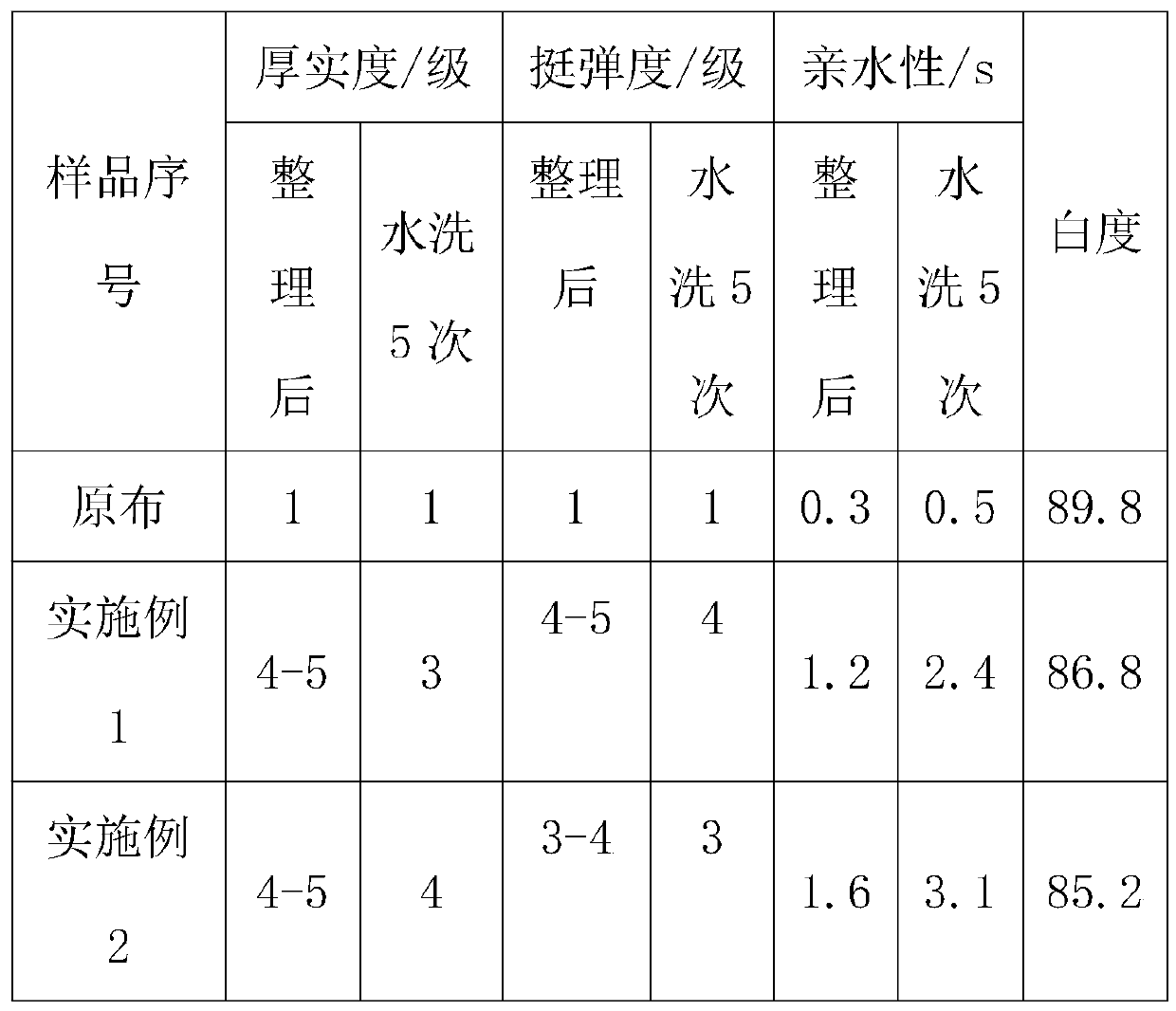

[0018] Application and finishing process of side chain hydrophilic modified block silicone oil for cotton:

[0019] 1. Preparation of side chain hydrophilic modified block silicone oil emulsion for c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com