Poly siloxane leather coating material and its preparation method

A technology of polysiloxane and polysiloxane emulsion, which is applied in coatings, textiles and papermaking, etc., can solve the problems of difficult stirring operation, easy migration, large amount of emulsifier, etc., and achieve simple process flow and less pollution The effect of substance generation and less emulsifying dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

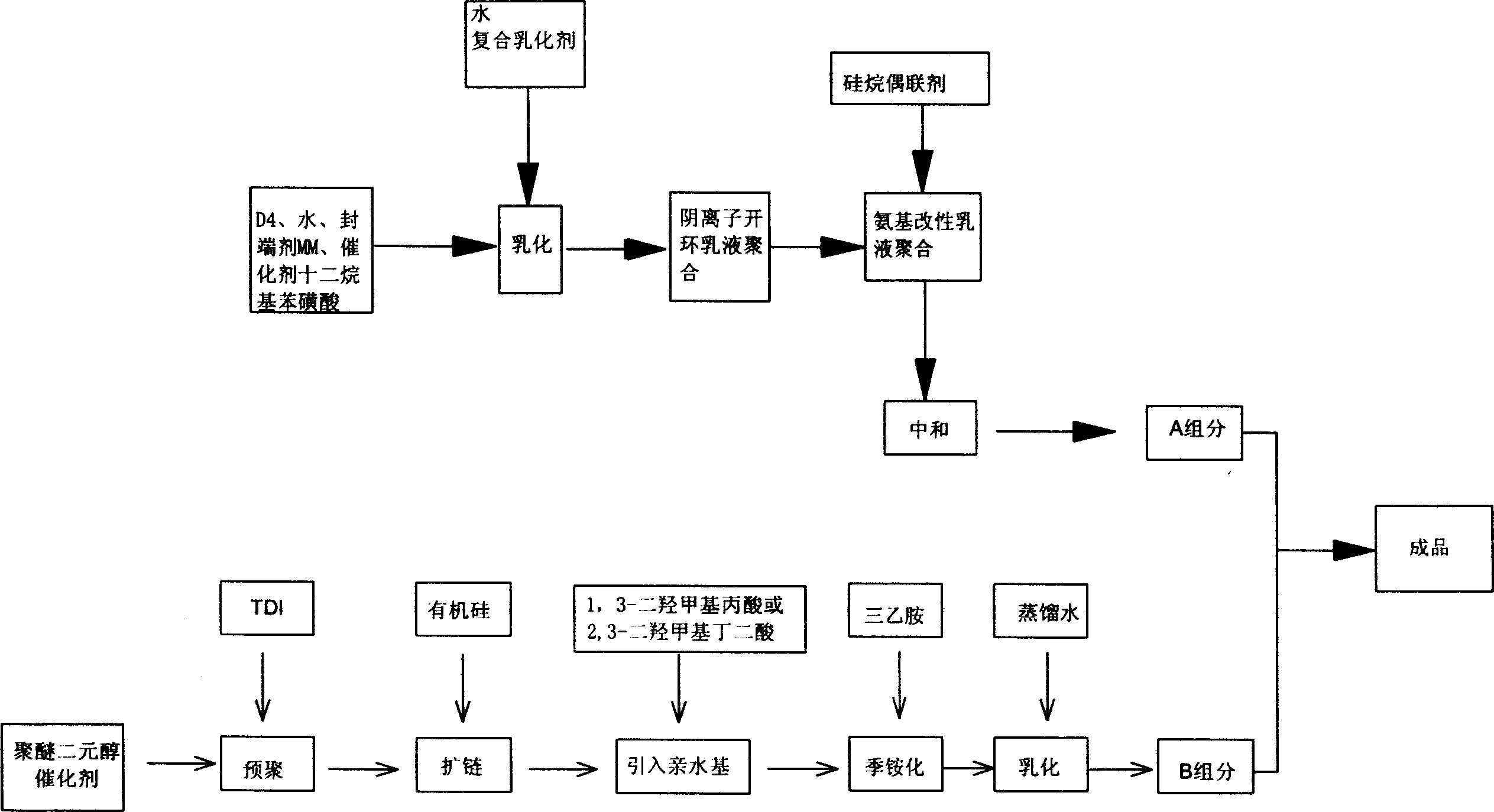

Method used

Image

Examples

Embodiment 1

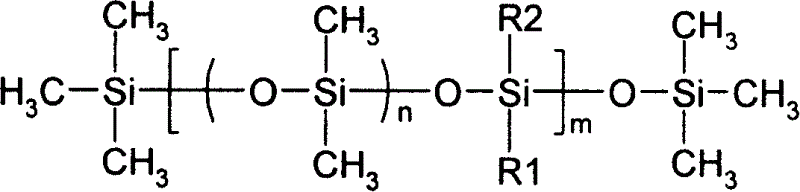

[0053] Preparation of component A: 6 grams of dodecylbenzenesulfonic acid (DBSA), 4 grams of sodium dodecylbenzenesulfonate (SDBS), 1.0 grams of anionic compound emulsifier OP-10, D 4 Add 60 grams and 180 grams of water into the reactor of the stirrer, raise the temperature, when the temperature rises to 80 ° C, keep it warm for 1 hour, add N-(β-aminoethyl)-γ-aminopropyltriethoxysilane 2.5 gram, keep warm for 4 hours, cool down to 50°C, keep warm for 5 hours, adjust the pH value to 6.5-7.5, and make an amino-modified polysiloxane emulsion with a solid content of about 28.8%.

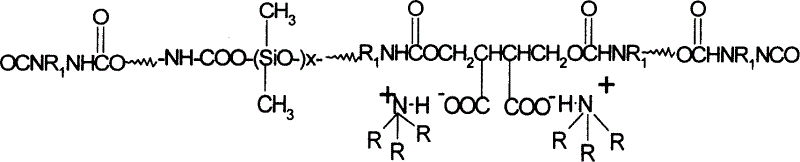

[0054] Preparation of component B: add 30 grams of polyether glycol with a number average molecular weight of 1500, 10 grams of polyether glycol with a number average molecular weight of 400, and 0.2 grams of dibutyltin dilaurate into a reactor with a stirrer, Introduce dry nitrogen protection, start the agitator, add 18 grams of TDI dropwise with a constant pressure dropping funnel, and then raise the t...

Embodiment 2

[0057] Preparation of component A: 7 grams of DBSA, 3 grams of SDBS, 1 gram of TX-10, D 4 , 50 grams, and 180 grams of water, mix and add in the reactor with agitator, heat up while stirring, when the temperature rises to 90 ° C, keep warm for 6 hours, add N-(β-aminoethyl)-γ-aminopropyl dropwise 2.2 g of methyldiethoxymethylsilane, heat preservation for 4 hours, lower the temperature to 50°C, heat preservation for 3 hours, adjust the pH value to 6.5-7.5, and prepare an amino-modified polysiloxane emulsion with a solid content of about 22%.

[0058] Preparation of component B: Add 25 grams of polyether diol with a number average molecular weight of 1000 and 15 grams of polyether diol with a number average molecular weight of 1500 into a reactor with a stirrer, and feed Dry under nitrogen protection, start the stirrer, add 16 grams of TDI dropwise with quantitative addition, and then raise the temperature to 80 ° C, after the heat preservation reaction for 5 hours, add 5 grams o...

Embodiment 3

[0061] A component prepared DBSA 6.5 grams, SDBS 2.0 grams, AEO-10 1.5 grams, D 4 , 50 grams of mixed solution, 1 / 3 of the mixed solution and 200 grams of water were added to a reactor with a stirrer, stirred for 30 minutes, emulsified, heated to 60°C while stirring, and then the remaining 2 / 3 mixed solution was added dropwise for 2 hours After the internal addition is completed, continue to keep warm for 5 hours, add 2 grams of N-(β-aminoethyl)-γ-aminopropyltrimethoxysilane dropwise, keep warm for 5 hours, adjust the pH value to 6.5-7.5, and obtain a solid content of about It is a 23.6% amino-modified polysiloxane emulsion.

[0062] Preparation of component B: Add 15 grams of polyether diols with a number average molecular weight of 400, 25 grams of polyether diols with a number average molecular weight of 2000, and 0.1 grams of catalyst into a reactor with a stirrer, and pass into Dry under nitrogen protection, start the stirrer, add 17 grams of TDI dropwise, and then rai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com