Water-based color removing agent and preparation and use method and application thereof

A water-based technology, applied in the field of coatings, can solve the problems of too fast drying, flammability of oil-based color-based paint, and easy color difference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

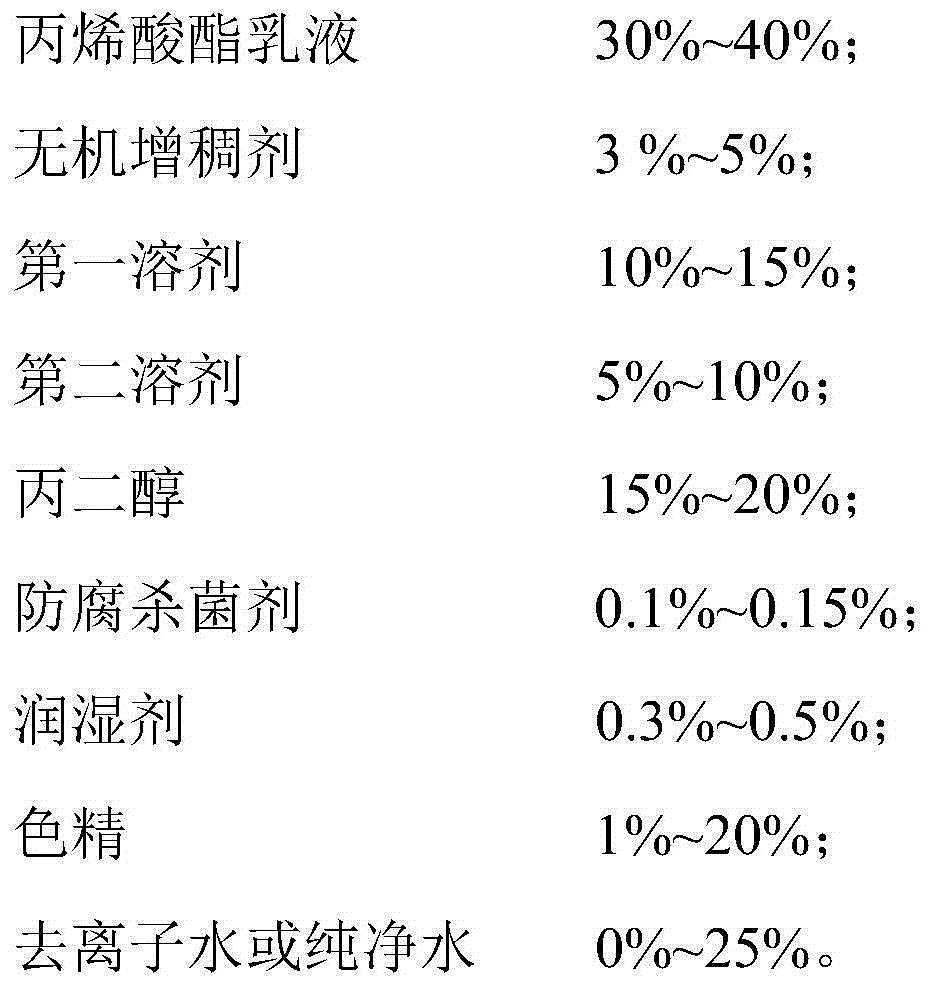

[0052] Correspondingly, the embodiment of the present invention also provides a preparation method of the above-mentioned water-based color rubbing treasure. In one embodiment, the preparation method of described water-based rubbing treasure comprises the following steps:

[0053] Step S01. Weigh the acrylate emulsion, inorganic thickener, first solvent, second solvent, propylene glycol, antiseptic and bactericide, wetting agent, color essence and deionized water according to the above-mentioned water-based rubbing treasure formula components or purified water;

[0054] Step S02. adding the weighed inorganic thickener and the first solvent into the acrylate emulsion, and performing mixing treatment to obtain a first mixed solution;

[0055] Step S03. Adding the weighed second solvent and propylene glycol into the first mixed solution for mixing to obtain a second mixed solution;

[0056] Step S04. adding the weighed antiseptic and bactericide and wetting agent into the secon...

Embodiment 1

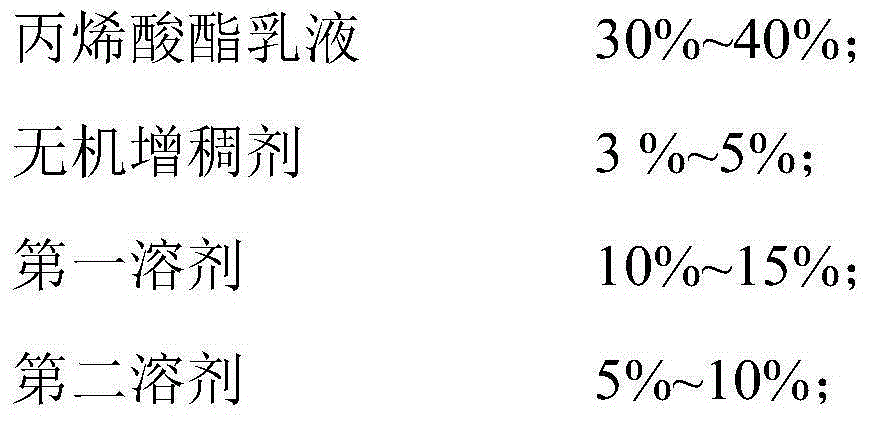

[0088] A water-based color rubbing treasure and a preparation method thereof. Wherein, the water-based rubbing treasure includes the following formula components in mass percentage:

[0089]

[0090] The preparation method of this water-based rubbing treasure comprises the steps:

[0091] First, water-based nano-scale acrylate emulsion, inorganic bentonite, ethylene glycol butyl ether, dipropylene glycol butyl ether, propylene glycol, isothiazolone, polyether siloxane copolymer, imitation mahogany water-based metal complex dye are provided according to Example 1 And deionized water, weigh each component;

[0092] Next, add the weighed inorganic bentonite and ethylene glycol butyl ether into the weighed water-based nano-scale acrylate emulsion, and stir for 15 minutes at a stirring speed of 400 rpm to prepare the first mixed solution;

[0093] Add the weighed dipropylene glycol butyl ether and propylene glycol into the above-mentioned first mixed solution, and stir for 10 ...

Embodiment 2

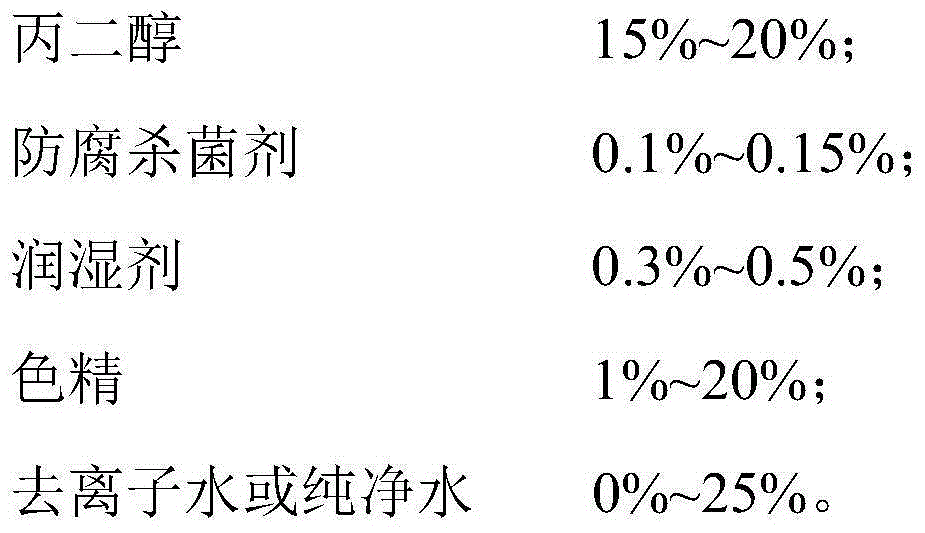

[0097] A water-based color rubbing treasure and a preparation method thereof. Wherein, the water-based rubbing treasure includes the following formula components in mass percentage:

[0098]

[0099] The preparation method of this water-based rubbing treasure comprises the steps:

[0100] First, water-based nano-scale acrylate emulsion, inorganic bentonite, ethylene glycol butyl ether, dipropylene glycol butyl ether, propylene glycol, isothiazolone, polyether siloxane copolymer, imitation mahogany water-based metal complex dye are provided according to embodiment 2 And deionized water, weigh each component;

[0101] Next, add the weighed inorganic bentonite and ethylene glycol butyl ether into the weighed water-based nano-scale acrylate emulsion, and stir for 20 minutes at a stirring speed of 600 rpm to prepare the first mixed solution;

[0102] Add the weighed dipropylene glycol butyl ether and propylene glycol into the above-mentioned first mixed solution, and stir for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com