Patents

Literature

285 results about "Methacrylic monomers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Methyl methacrylate (MMA) is a monomer that’s also known as methacrylic acid, methyl ester. A key building block for acrylic-based polymers, MMA has applications that include safety glazing, exterior paints, vinyl impact modifiers, adhesives, illuminated light displays, and more.

Curable liquid resin composition

PCT No. PCT / JP97 / 01871 Sec. 371 Date Feb. 3, 1998 Sec. 102(e) Date Feb. 3, 1998 PCT Filed Jun. 2, 1997 PCT Pub. No. WO97 / 46601 PCT Pub. Date Dec. 11, 1997A curable liquid resin composition containing 100 parts by weight of the following (meth)acrylic liquid resin (A) and 1 to 1,000 parts by weight of a (meth)acrylic monomer (B) having an unsaturated double bond in its molecule and having a number average molecular weight of 1,000 or less, the (meth)acrylic liquid resin (A) being a liquid resin which is obtained by polymerizing monomers containing an alkyl (meth)acrylate monomer (a-1-1) of the formula (1),CH2 C(R1)COO-R2(1)wherein R1 is a hydrogen atom or CH3 and R2 is an alkyl group, and / or an alkylene glycol (meth)acrylate monomer (a-1-2) of the formula (2),CH2=C(R1)COO(CnH2nO)mR3(2)wherein R1 is a hydrogen atom or CH3, R3 is an alkyl group or a phenyl group, n is an integer of 1 to 3, and m is an integer of 3 to 25, and other polymerizable vinyl monomer (a-2), an average of molecular weights of all the monomers being 100 to 1,500, the liquid resin having a number average molecular weight of 10,000 to 200,000 and a viscosity of 1 to 10,000 poise (measured at 50 DEG C.), or a modified product of the above liquid resin, the curable liquid resin composition can form a film as a film-forming material or as a resin for an adhesive without using a solvent and give a cured film.

Owner:TOYO INK SC HOLD CO LTD

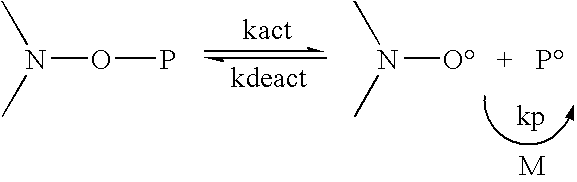

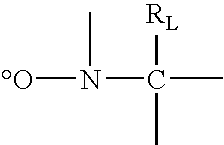

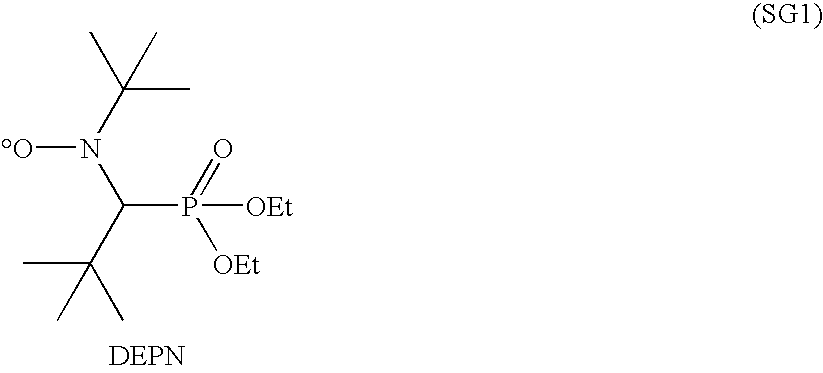

Low Surface Energy Block Copolymer Preparation Methods and Applications

Methods for the preparation of low surface energy block co-polymers are disclosed. The block co-polymers comprise at least two blocks, each of which comprises, in polymerized form, an acrylic monomer, a methacrylic monomer, or a mixture thereof. At least one block is a low surface energy block, which comprises, in polymerized form, a low surface energy monomer Low surface energy macroinitiators useful in forming the block co-polymers are also disclosed. The block co-polymers may be prepared by nitroxide mediated controlled free radical polymerization.

Owner:ARKEMA INC

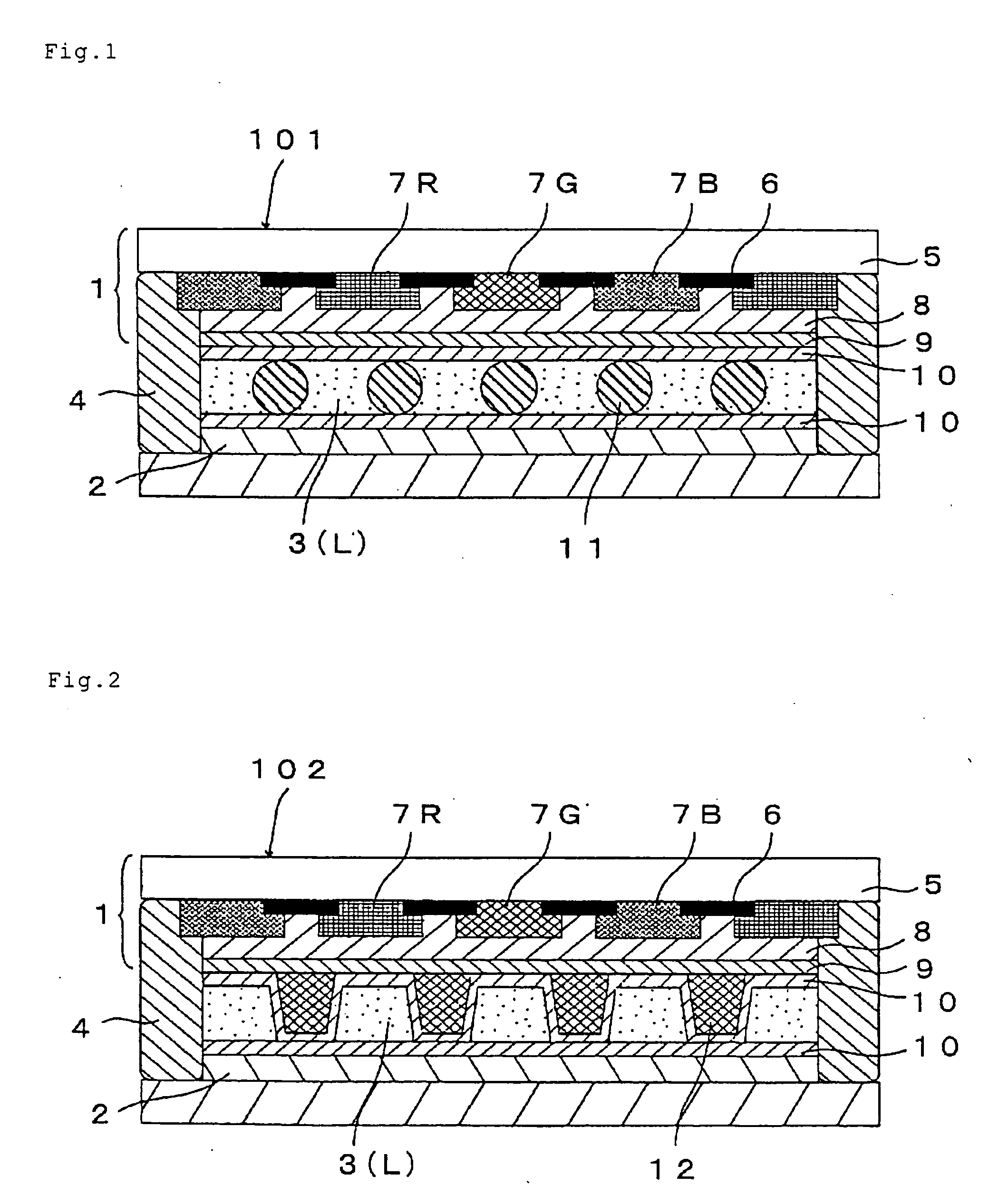

Alkali-soluble maleimide copolymer and liquid crystal display comprising the same

InactiveUS20050074563A1Improve the immunityHigh hardnessLiquid crystal compositionsOrganic chemistrySolubilityLiquid-crystal display

It is an object of the present invention to provide an alkali-soluble maleimide-based copolymer excellent in resistance for thermally yellowing, high in hardness, excellent in solubility in solvents and capable of readily forming uniform coat films and, in addition, capable of being satisfactorily dissolved in alkali water when remaining uncured, as well as a pigment dispersion composition comprising such copolymer and an ionizing radiation-curable resin composition comprising such copolymer. Another object of the present invention is to provide a color filter and a liquid crystal display which are formed by using the ionizing radiation-curable resin composition. The present invention is related to an alkali-soluble maleimide-based copolymer which comprises, as essential constituents, 5 to 50% by mass of a maleimide monomer unit which is at least one unit selected from the group consisting of a N-cyclohexylmaleimide monomer unit, a N-benzylmaleimide monomer unit and a substituted N-benzylmaleimide monomer unit, 8 to 30% by mass of the (meth)acrylic acid monomer unit and 30 to 87% by mass of a (meth)acrylic acid ester monomer unit and which satisfies the condition represented by the formula: 0.4×X≦Y≦0.5×X+10 where X is the content, in % by mass, of the N-cyclohexylmaleimide monomer unit, the N-benzylmaleimide monomer unit and the substituted N-benzylmaleimide monomer unit and Y is the content, in % by mass, of the (meth)acrylic acid monomer unit.

Owner:NIPPON SHOKUBAI CO LTD +1

Nanoparticles for delivery of a pharmacologically active agent

InactiveUS20060280798A1Hinder recognitionPowder deliveryMicroencapsulation basedActive agentWater insoluble

Core-shell nanoparticles comprising: (a) a core which comprises a water insoluble polymer or copolymer, and (b) a shell which comprises a hydrophilic polymer or copolymer; said nanoparticles being obtainable by emulsion polymerization of a mixture comprising, in an aqueous solution, at least one water-insoluble styrenic, acrylic or methacrylic monomer and specific hydrophylic monomers or copolymers.

Owner:INST SUPERIORE DI SANITA

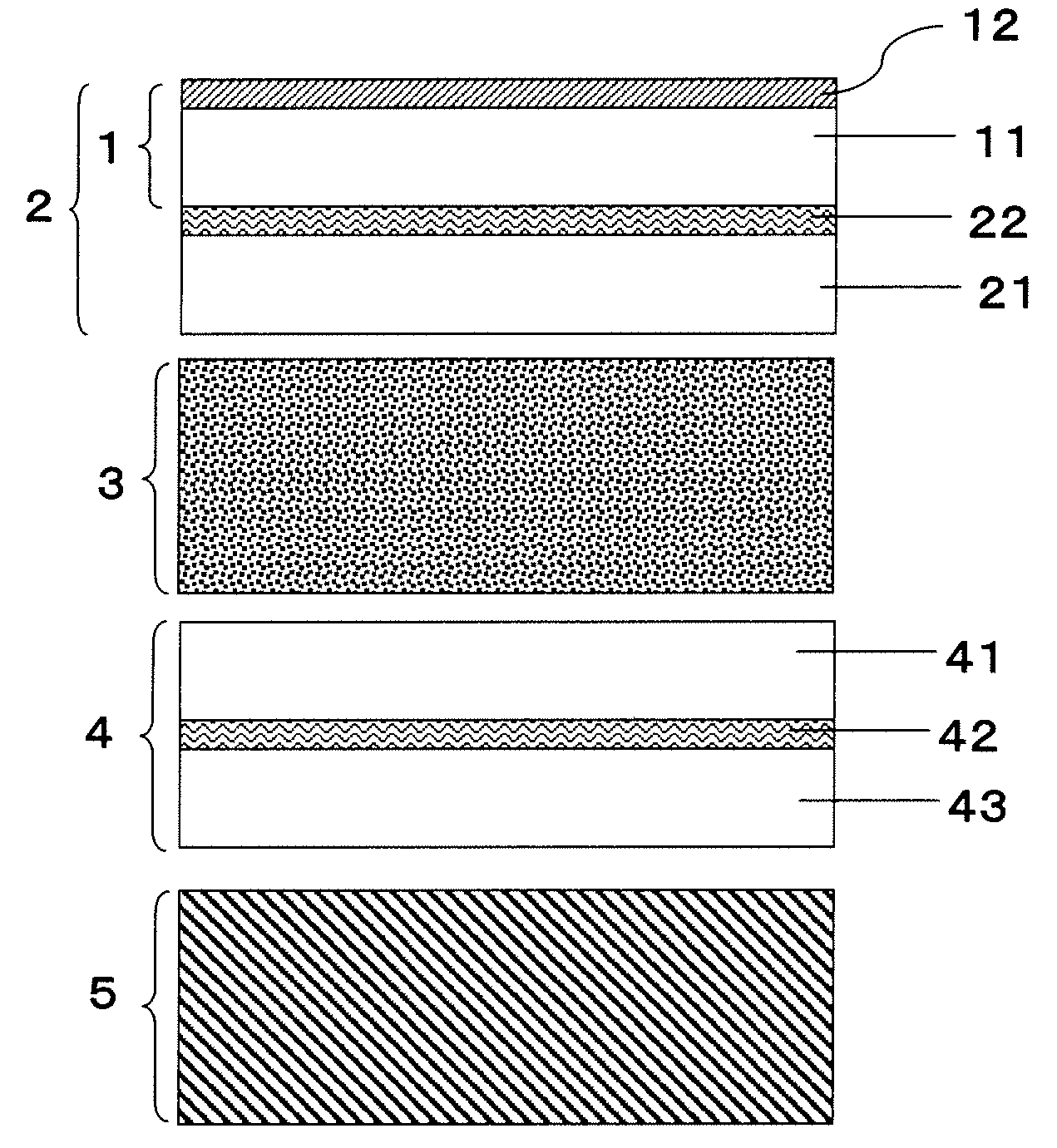

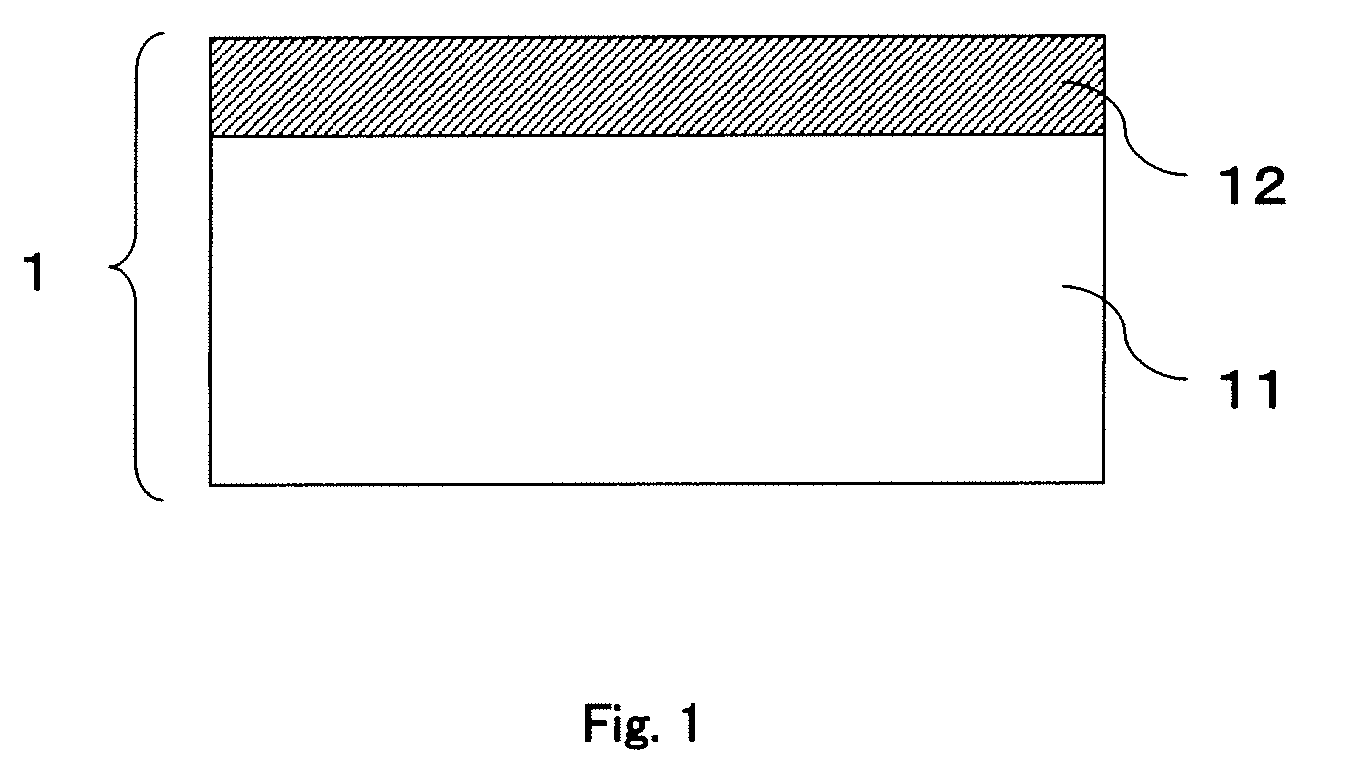

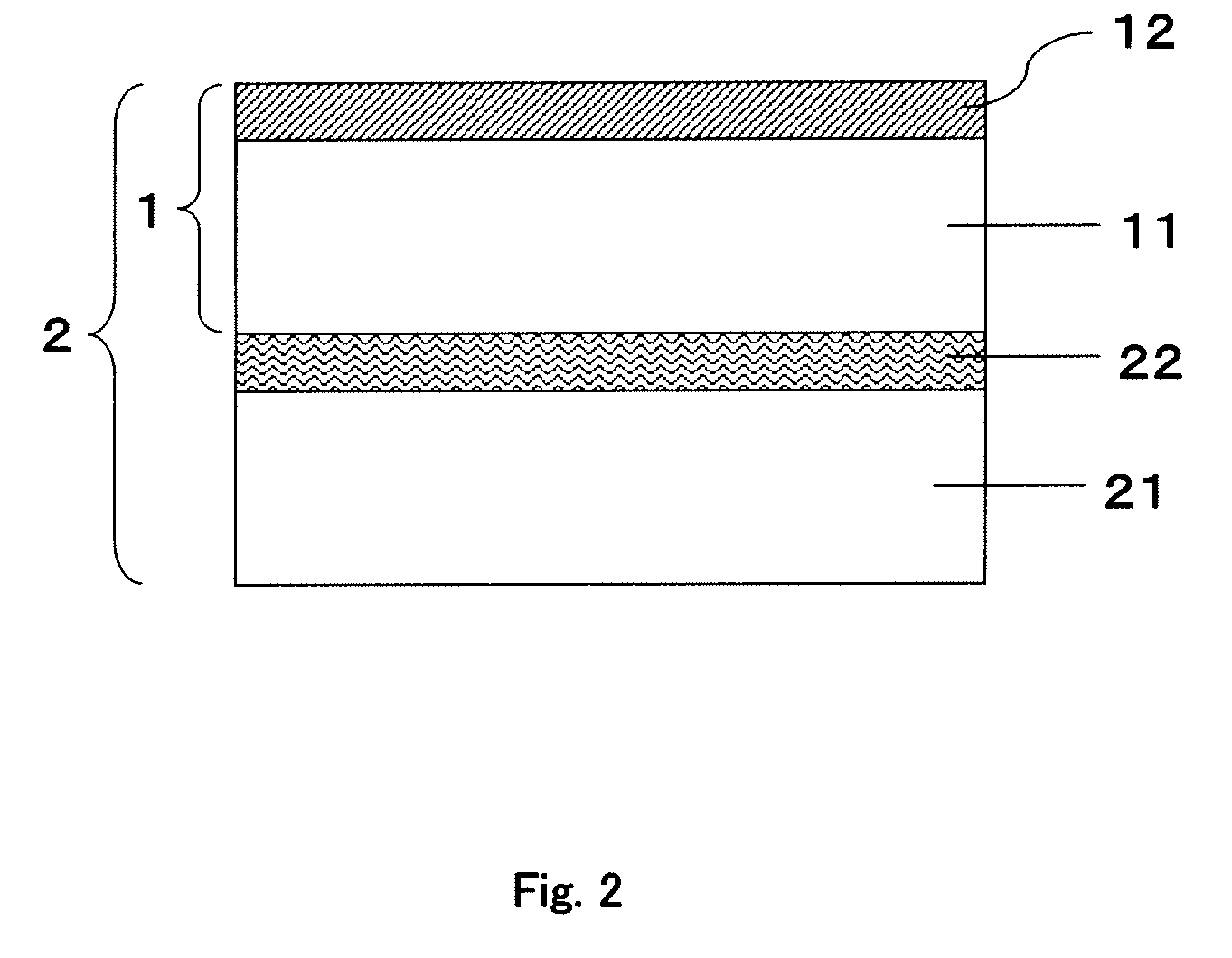

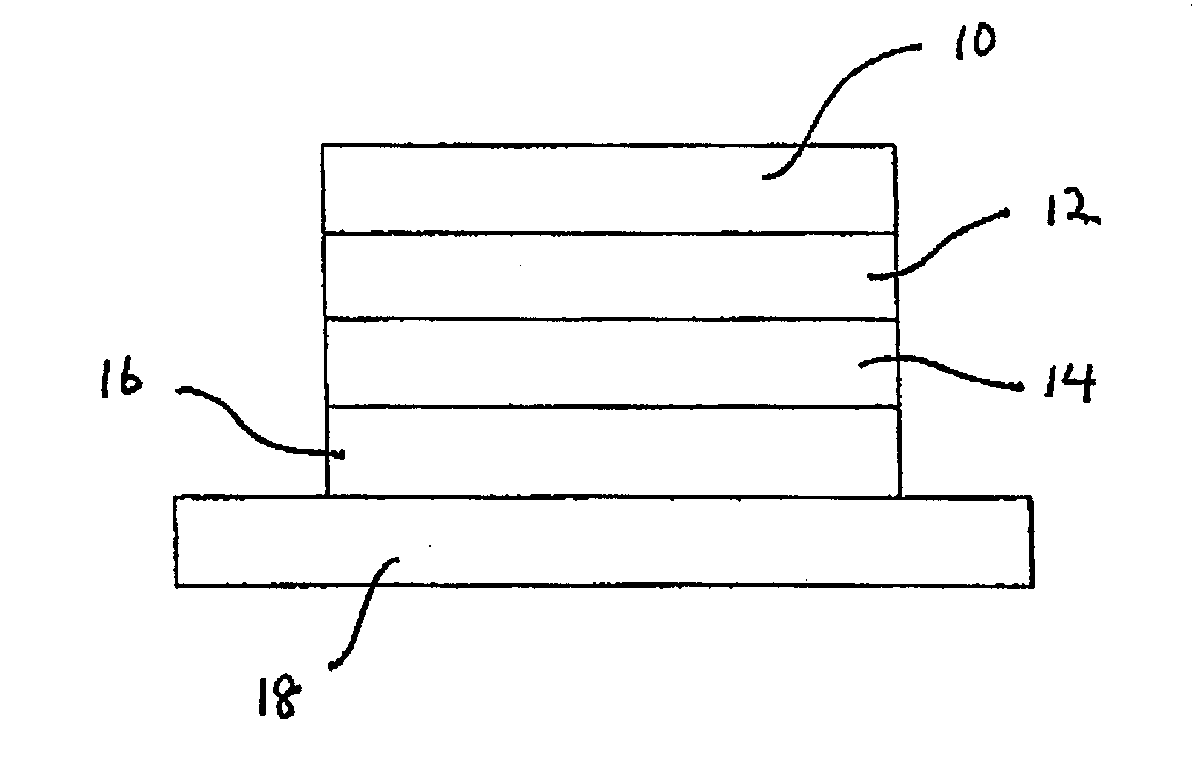

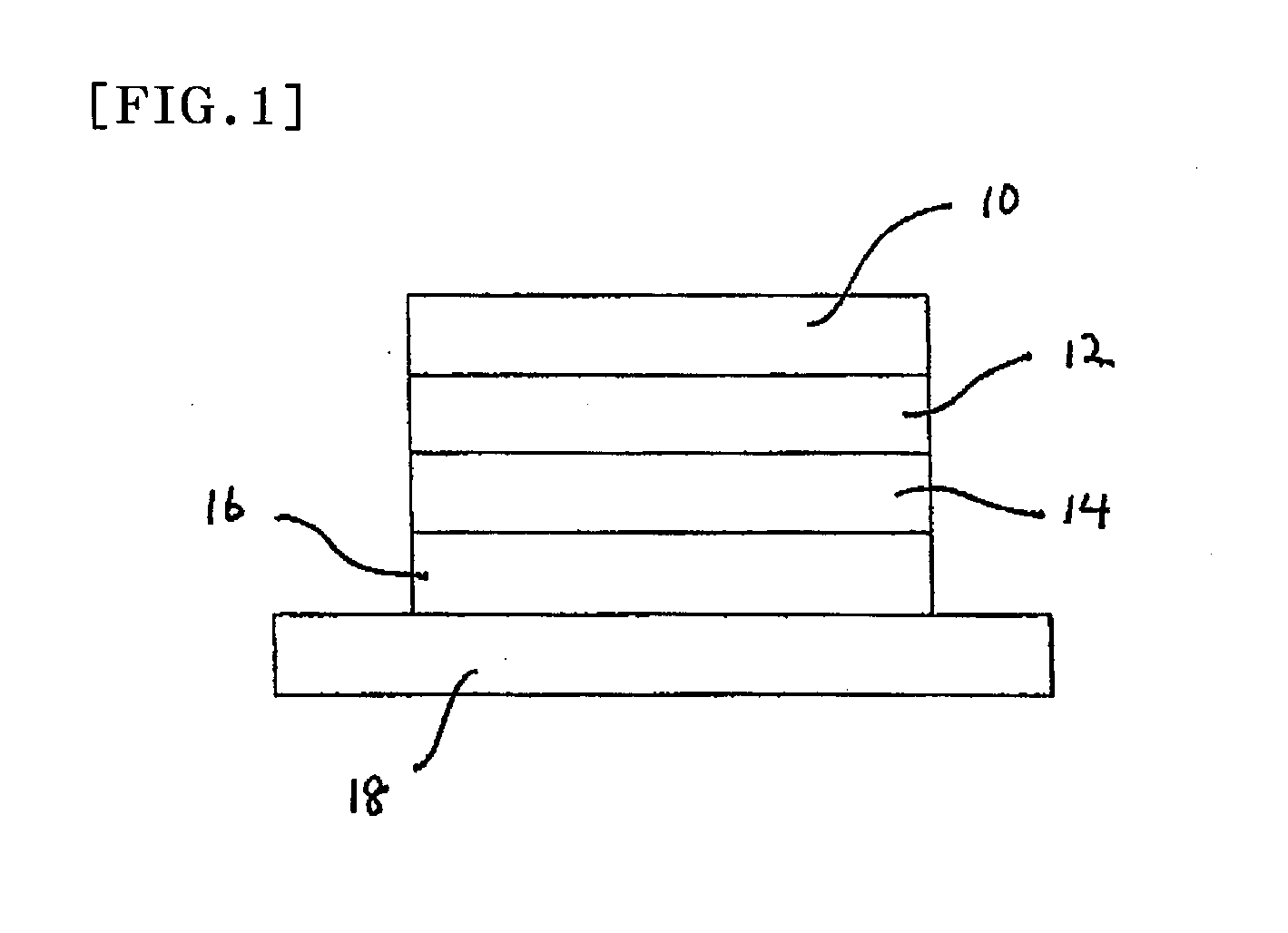

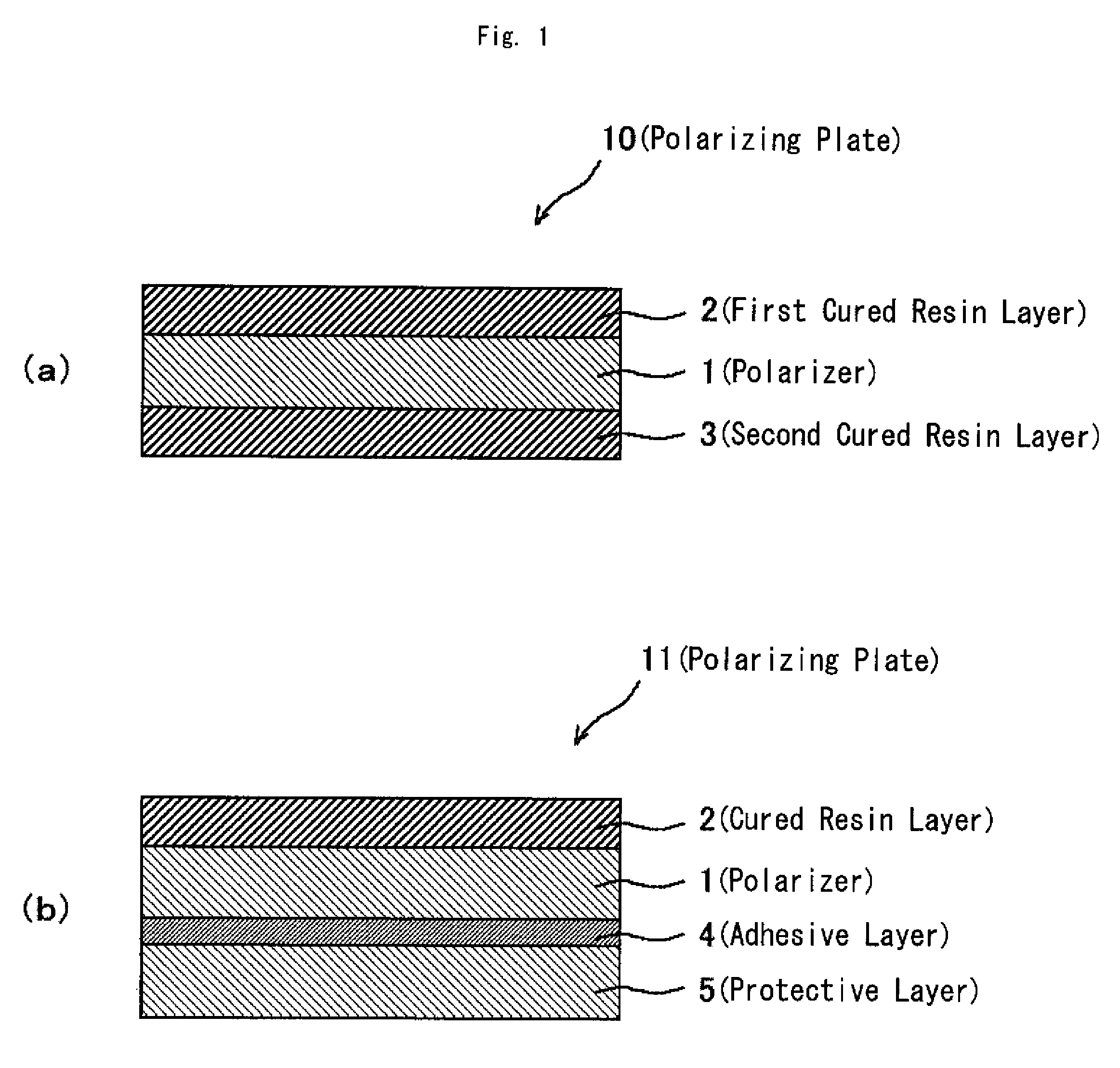

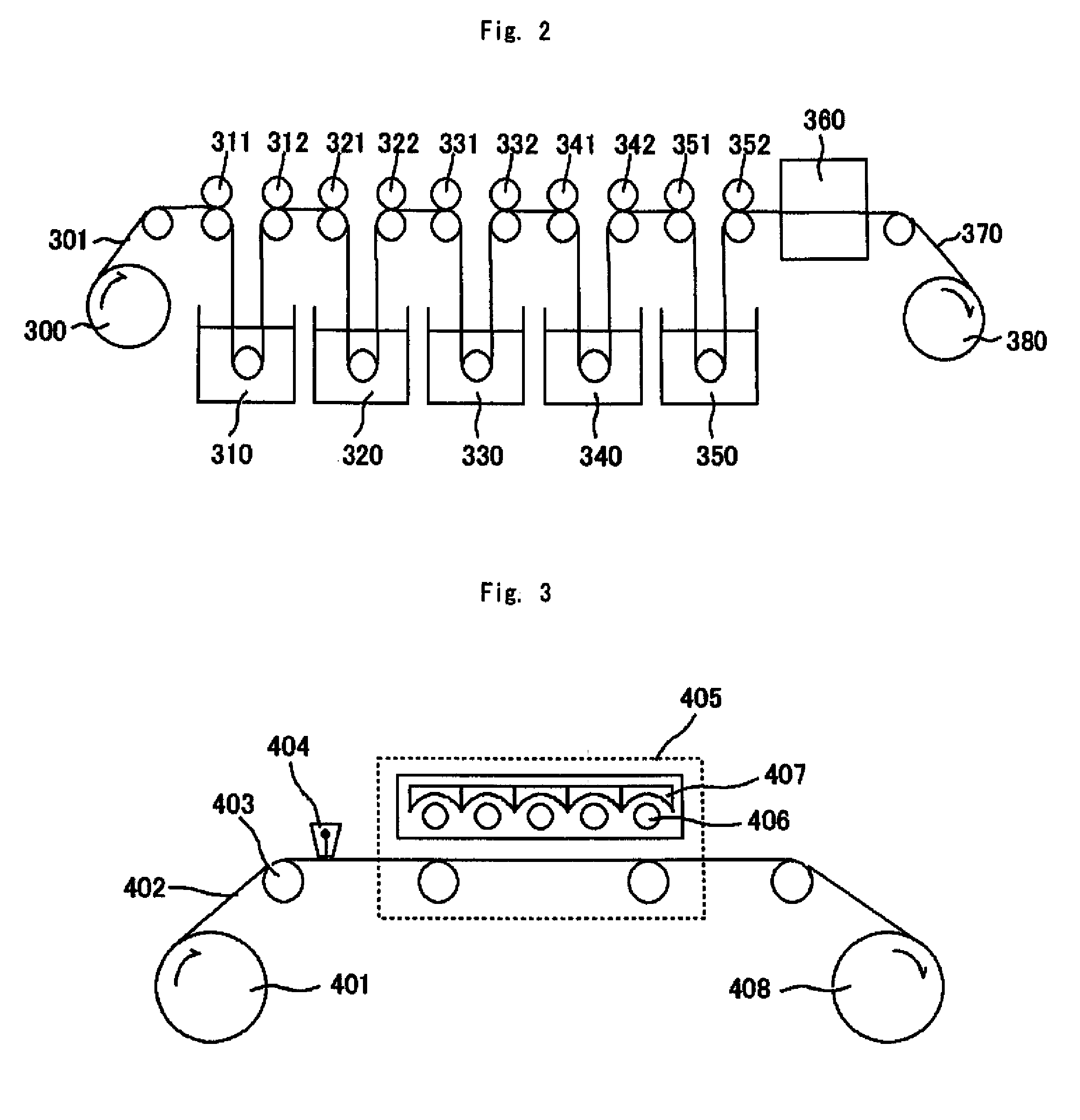

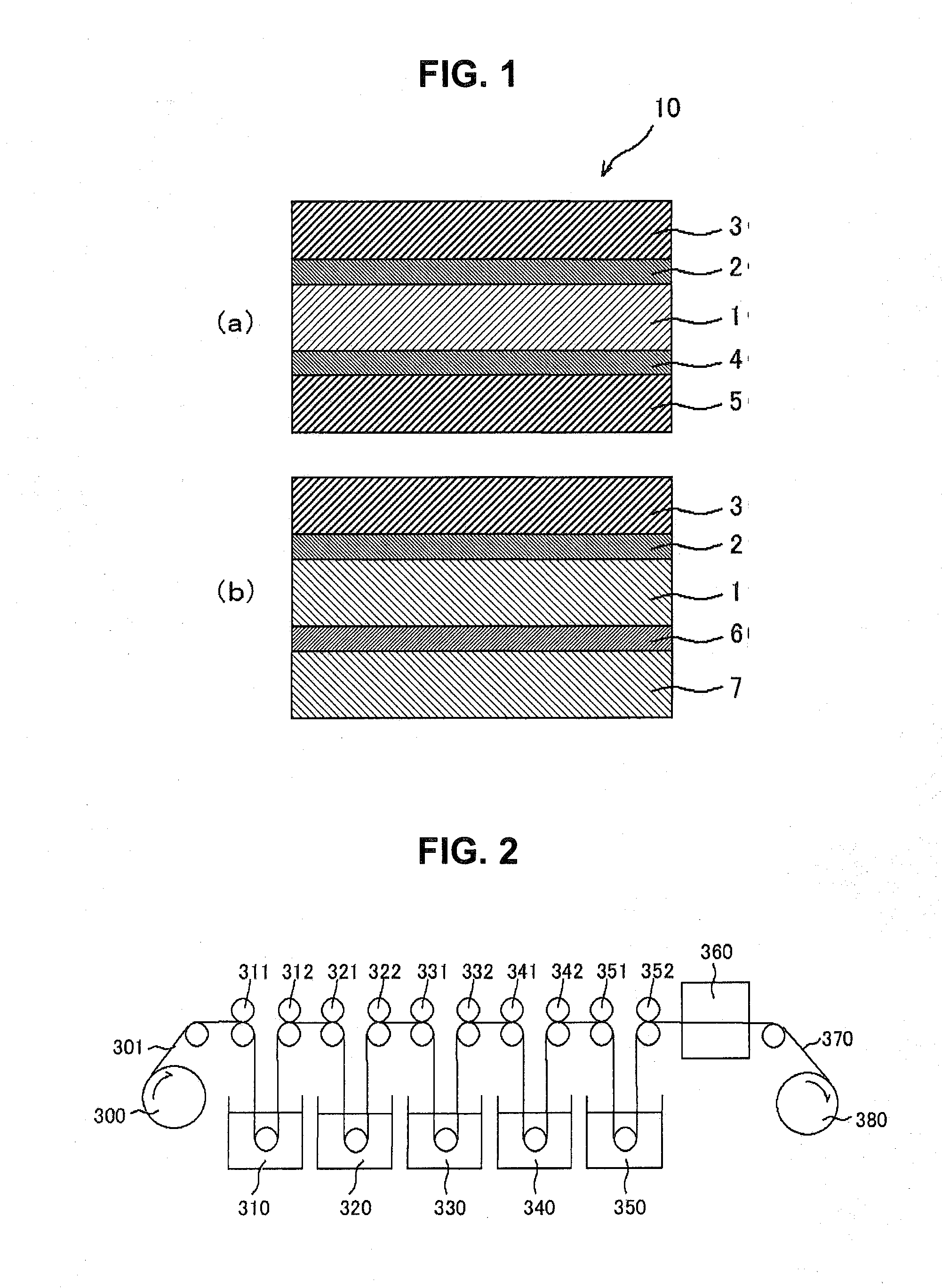

Polarizing plate and image display including the same

InactiveUS20070269616A1High hardnessReduce thicknessLiquid crystal compositionsPolarising elementsDisplay devicePolarizer

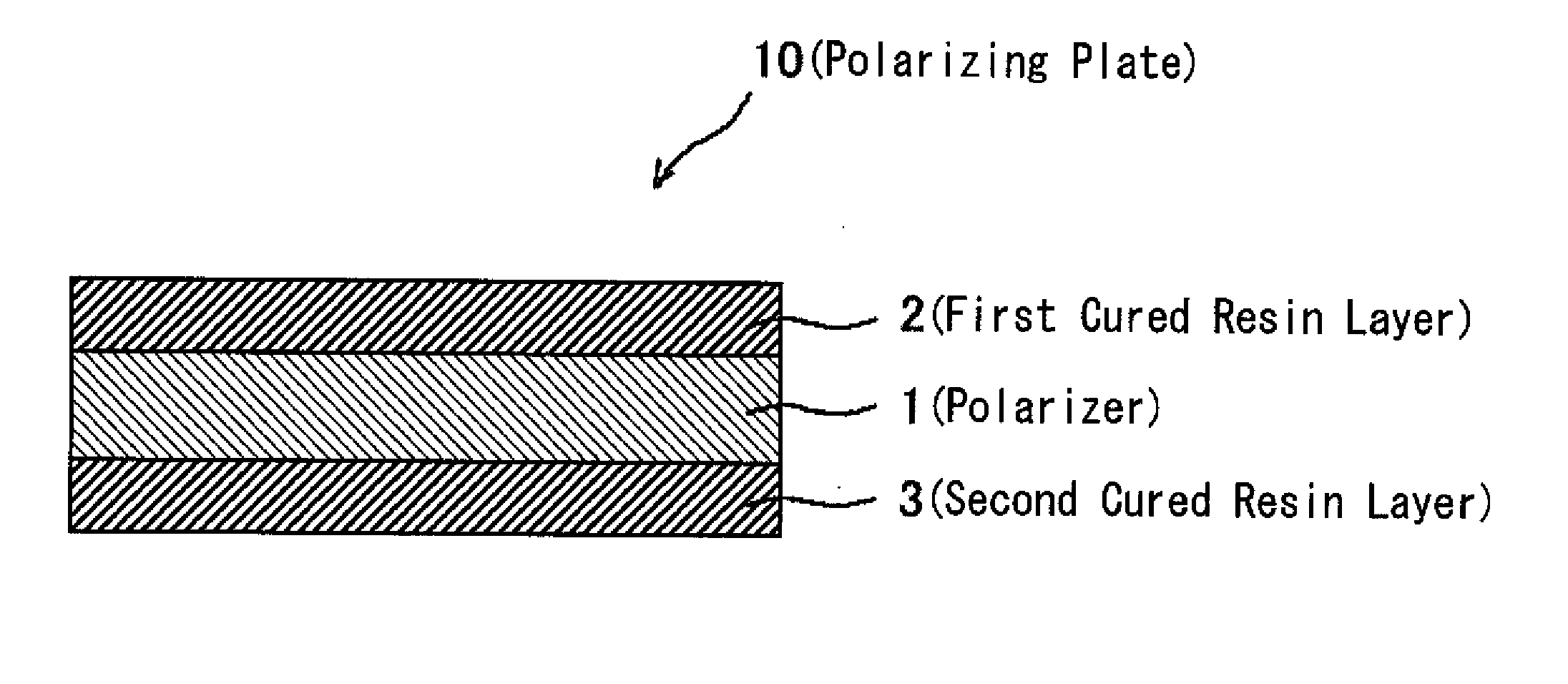

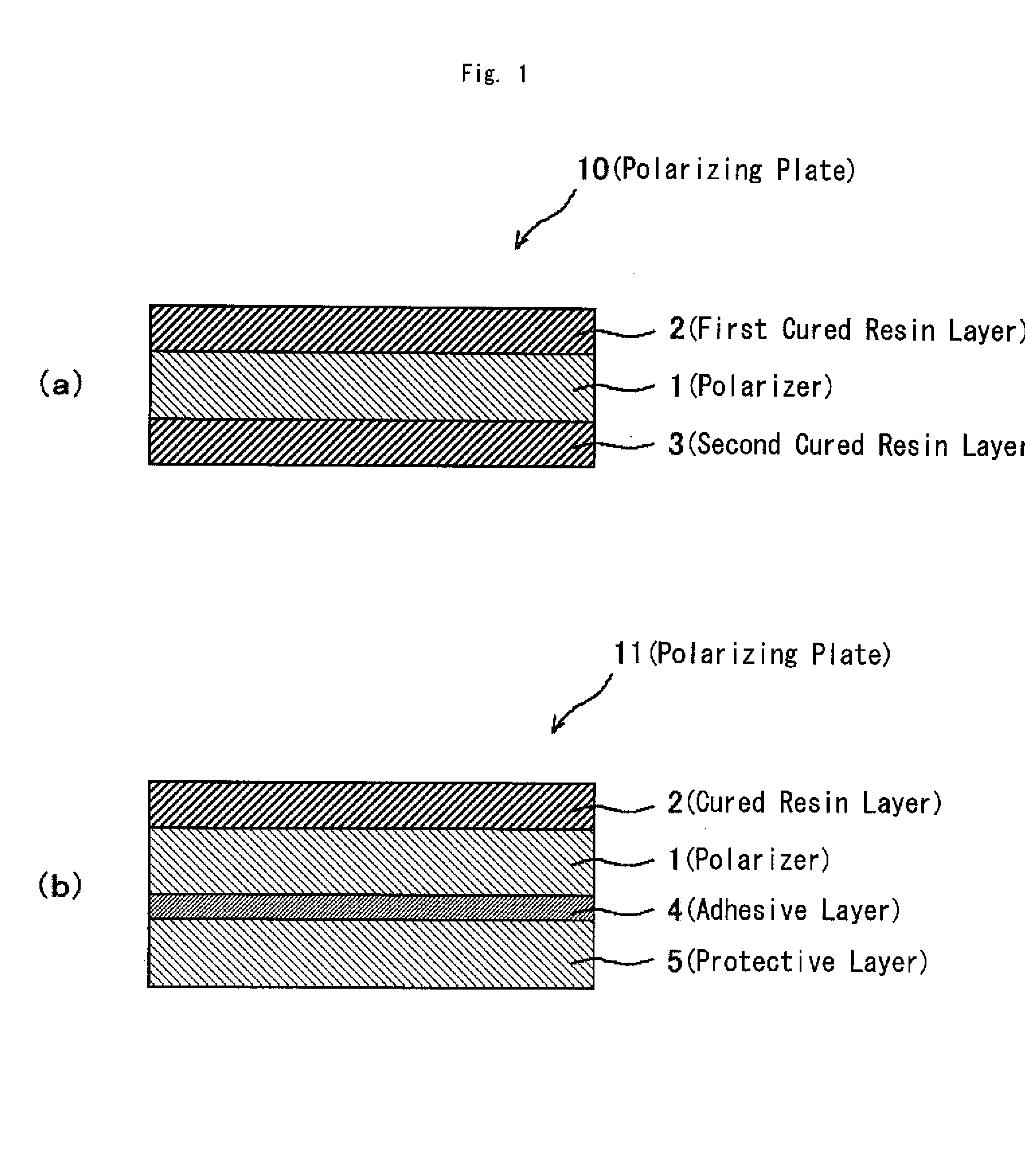

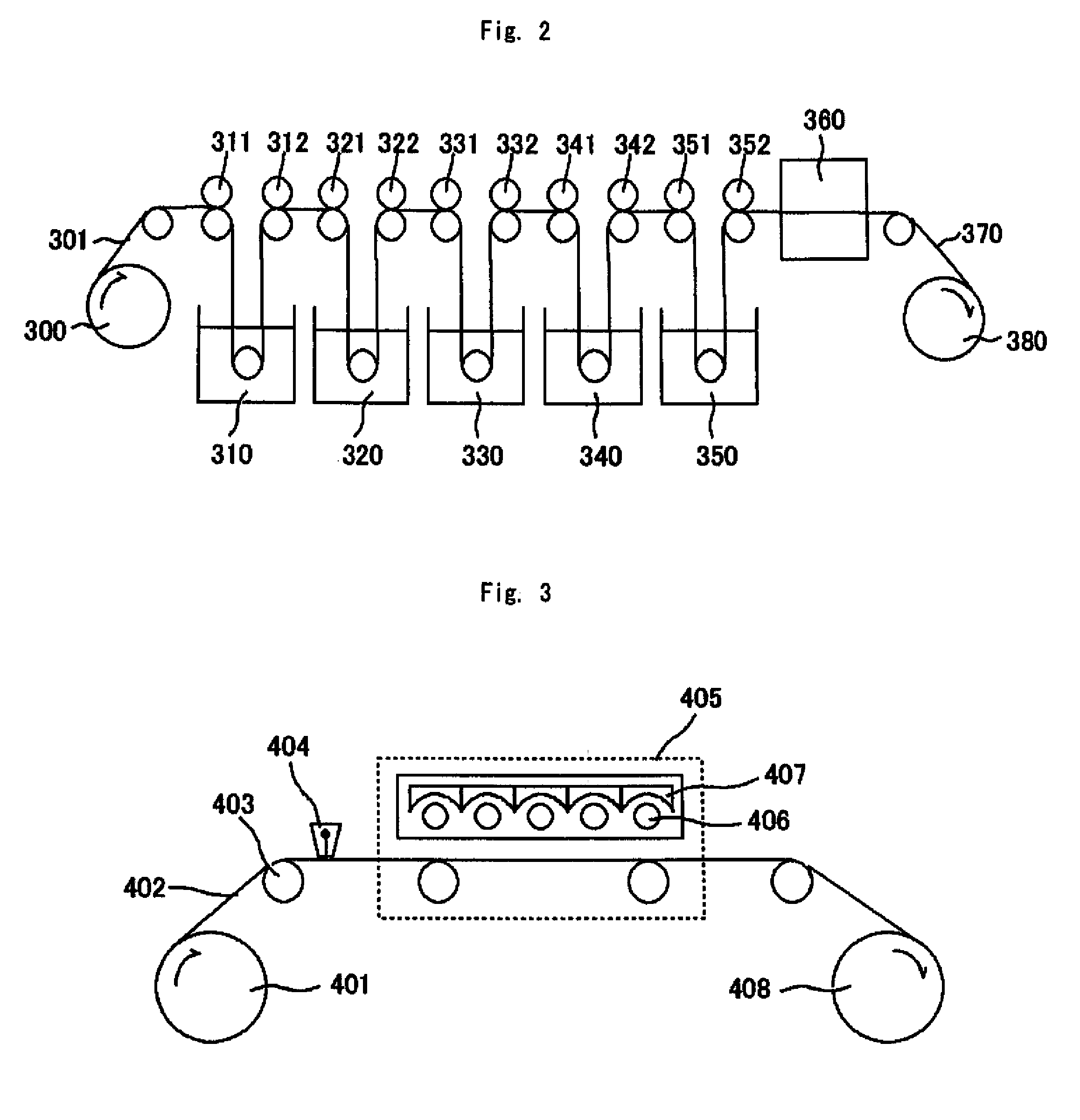

A polarizing plate is provided that has excellent polarization properties and high surface hardness and can have a reduced thickness. The polarizing plate includes a polarizer and a cured resin layer. The cured resin layer is formed directly on at least one surface of the polarizer. The cured resin layer is formed of a solventless photocurable composition containing the following components (A), (B), and (C): (A) at least one of a polyfunctional acrylic monomer and a polyfunctional methacrylic monomer; (B) a photocurable prepolymer; and (C) a photopolymerization initiator.

Owner:NITTO DENKO CORP

Composite polymer composition

A composite polymer composition comprising the emulsion polymerization product of: (i) an aqueous dispersion comprising the melt kneading product of one or more polyolefins, from 2 to 25 wt % of one or more dispersion stabilizing agents, water and optionally a neutralizing agent, and (ii) one or more (meth)acrylic monomers; wherein the one or more polyolefins have a Tg equal to or less than 50° C. and comprise from 0.5 to 100 wt % functionalized polyolefin; and wherein the melt kneading product (i) comprises polymer particles having a volume average particle size between 150 nm and 2000 nm dispersed in the water; and wherein the one or more (meth)acrylic monomers polymerize onto the polymer particles form composite polymer particles using an emulsion polymerization process is provided.

Owner:ROHM & HAAS CO

Clearcoat paint composition

A coating composition including a copolymerization product of a mixture of monomers including one or more carbamate-functional monomers and (meth)acrylic monomers, some having carboxylic acid-functionality. The monomer mixture is essentially free of hydroxyl monomers. The coating composition may be a solvent-borne clearcoat coating composition, preferably an automotive clearcoat coating composition, that may be applied over a water-borne basecoat coating composition.

Owner:BASF CORP

Preparation method of flame-retardant core-shell-type acrylic resin

ActiveCN102875723AGood compatibilityImprove the defect of "hot sticky and cold brittle"Fibre treatmentCoatingsPolymer scienceEmulsion

The invention relates to a preparation method of flame-retardant core-shell-type acrylic resin, which comprises the following steps of: adding deionized water, emulsifying agent, methacrylic acid and monomers A for emulsification, starting to drop initiator when temperature reaches 75DEG C, keeping dropping time to be 1-3h, preserving heat for reaction for 3-5h, dropping ester compounds and keeping reaction time to be 1-3h to obtain core-layer emulsion; and simultaneously adding monomers B and initiator into the core-layer emulsion, keeping dropping time to be 1-3h, preserving heat at 75-85DEG C for reaction for 2h, dropping bentonite dispersion liquid with mass percent being 20 percent, preserving heat for reaction for 1-3h, dropping cross-linking agent, preserving heat for reaction for 1-2h, decreasing temperature to 50DEG C, adding emulsifying agent into a reaction system, keeping reaction time to be 30min, and adding ammonia water to regulate pH (potential of hydrogen) to 7-8 to obtain the flame-retardant core-shell-type acrylic resin. The obtained acrylic resin has the advantages that not only can the defect of hot sticking and cold shortness of the traditional acrylic resin be improved, but also the flame retardation of the acrylic resin can be improved.

Owner:北京世纪蓝箭防水材料有限公司

Hard Coat Layer Composition and Hard Coat Film

InactiveUS20090274902A1Easy to disassembleImprove adhesionSynthetic resin layered productsPolarising elementsCoated membranePolymer science

The present invention provides a hard coat film and a hard coat layer forming composition which forms a hard coat layer adhering well to a substrate, which does not curl up easily and having antifouling properties, excellent abrasion resistance, surface hardness, and a high level of visibility. The present invention has a specific feature in that a hard coat layer forming composition which includes polyfunctional acrylic (or methacrylic) monomer (A), acrylic monomer having a hydroxyl group (B), radical photopolymerization initiator (C), and fluorocompound having a polymerizable group (D) is used. The hard coat film of the present invention has the hard coat layer which is formed by curing the hard coat layer forming composition on a transparent substrate and has a surface free energy less than 20 mN / m and the thickness in the range of 5-25 μm.

Owner:TOPPAN PRINTING CO LTD

Pressure-sensitive adhesive composition, pressure-sensitive adhesive layer, process for producing the pressure-sensitive adhesive layer, and optical member with pressure-sensitive adhesive

InactiveUS20090042004A1Excellent pressure-sensitive adhesive propertyIncreased durabilityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesDisplay deviceLayer thickness

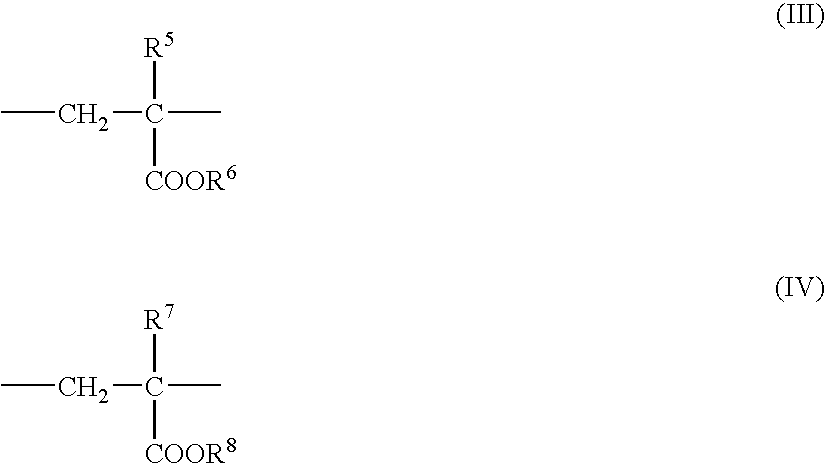

This invention provides a pressure-sensitive adhesive composition that exhibits excellent pressure-sensitive adhesive properties after crosslinking treatment, does not cause lifting or lifting upon heat treatment or treatment under high-humidity conditions particularly even in the case of a pressure-sensitive adhesive layer having a reduced layer thickness, and has excellent durability. A pressure-sensitive adhesive layer formed using the pressure-sensitive adhesive composition, and a process for producing the same are also provided. Further, an optical member with pressure-sensitive adhesive comprising the pressure-sensitive adhesive layer and an image display using the same are provided. The pressure-sensitive adhesive composition is characterized by comprising 100 parts by weight of an (meth)acrylic polymer and 0.02 to 2 parts by weight of a peroxide, and 0.02 to 2 parts by weight of an isocyanate crosslinking agent, the (meth)acrylic polymer comprising as monomer units 50 to 98% by weight of an (meth)acrylic monomer represented by general formula CH2═C(R1)COOR2, wherein R1 represents hydrogen or a methyl group and R2 represents an alkyl group having 2 to 14 carbon atoms, and 0.1 to 35% by weight of a nitrogen-containing monomer.

Owner:NITTO DENKO CORP

Styrene-acrylic emulsion for priming paint as well as preparation method and application thereof

ActiveCN101704913AImprove surface strengthImprove the phenomenon of hair loss and powder lossPaper coatingCoatingsCross-linkAccelerant

The invention provides a styrene-acrylic emulsion for priming paint as well as a preparation method and an application thereof. The preparation method comprises the following steps: by using a surfactant compound from an anionic surfactant and a nonionic surfactant as an emulsifier and using peroxide as an initiator, carrying out free-radical emulsion polymerization on (methyl) acrylic monomer, (methyl) acrylate monomer, (methyl) styrene, cross-linking monomer and an accelerant under the conditions of 50-95 DEG C and normal pressure to obtain an emulsion; and then, neutralizing the obtained emulsion with aqueous alkali, and regulating the pH value to be 7-10 to obtain a finished product. The styrene-acrylic emulsion for priming paint is a product which can be used for paper-making paint and has high performance and environmental protection. When the product is applied to the priming paint of coated paper, the surface strength of the coated paper can be obviously increased, and the phenomena of fur falling and powder falling can be improved.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

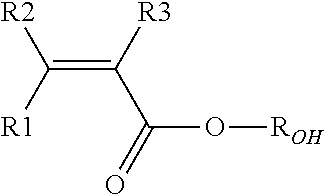

Vinylidene fluoride copolymers

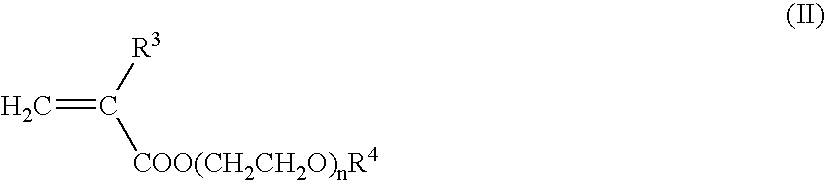

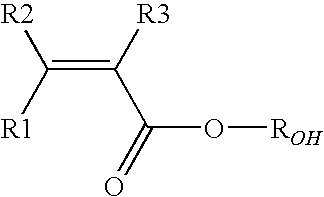

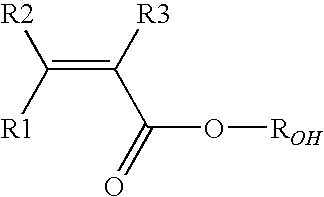

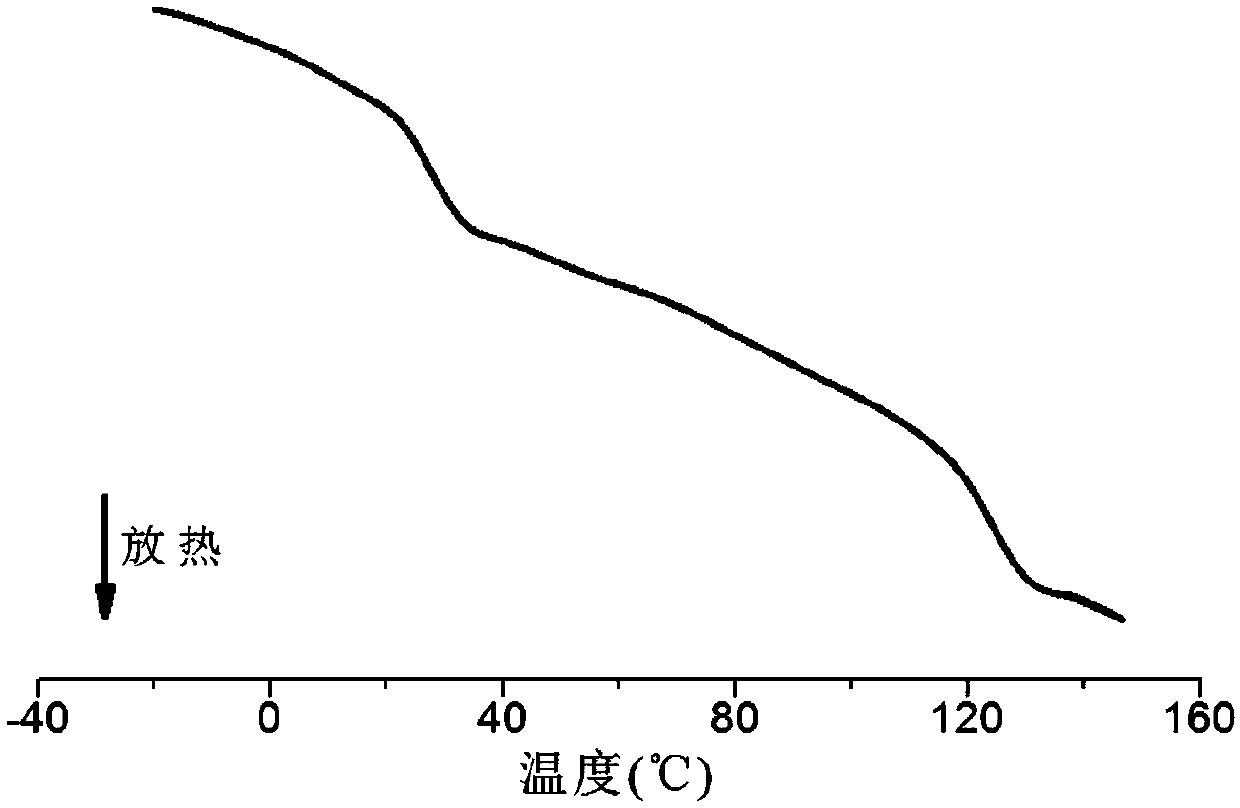

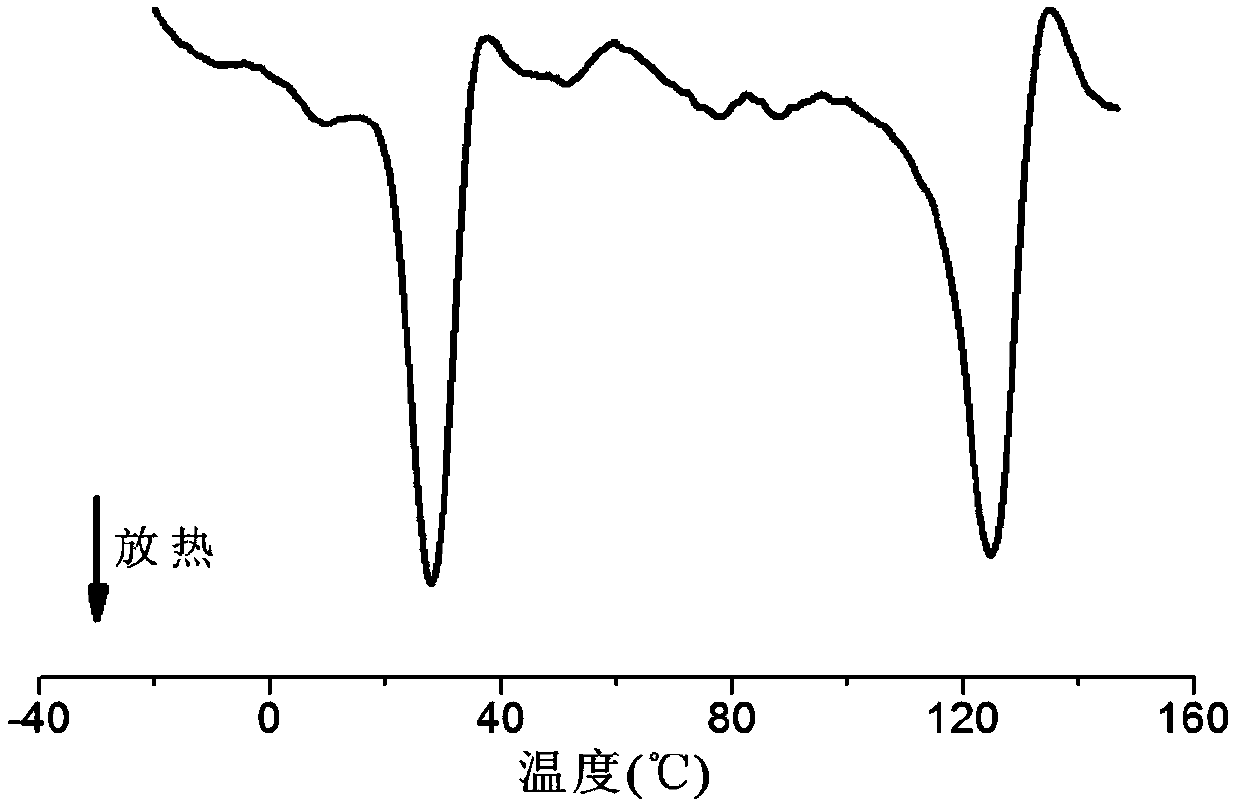

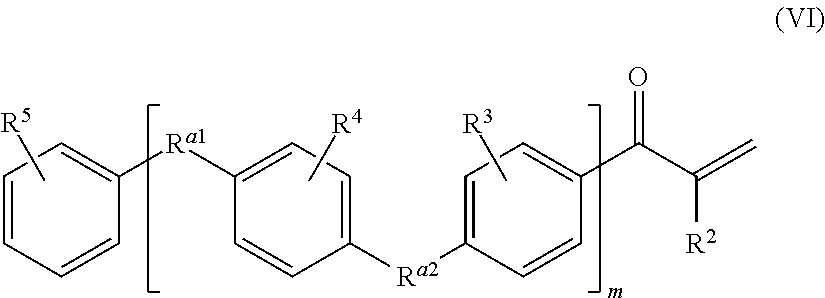

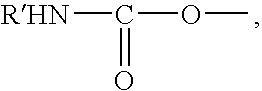

The present invention pertains to a linear semi-crystalline copolymer [polymer (A)] comprising recurring units derived from vinylidene fluoride (VDF) monomer and at least one hydrophilic (meth)acrylic monomer (MA) of formula:wherein each of R1, R2, R3, equal or different from each other, is independently an hydrogen atom or a C1-C3 hydrocarbon group, and ROH is a hydrogen or a C1-C5 hydrocarbon moiety comprising at least one hydroxyl group,said polymer (A) comprising from 0.05 to 10% by moles of recurring units derived from said hydrophilic (meth)acrylic monomer (MA) and being characterized by a fraction of randomly distributed units (MA) of at least 40%, having improved thermal stability, to a process for its manufacture, to a composition comprising the same, and to its use as binder in batteries or for the manufacture of hydrophilic membranes.

Owner:SOLVAY SOLEXIS

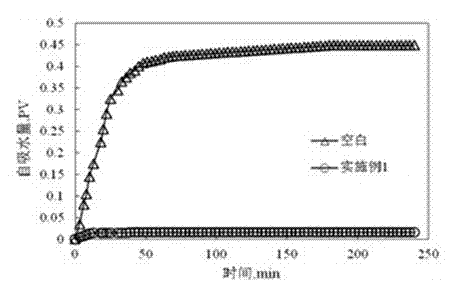

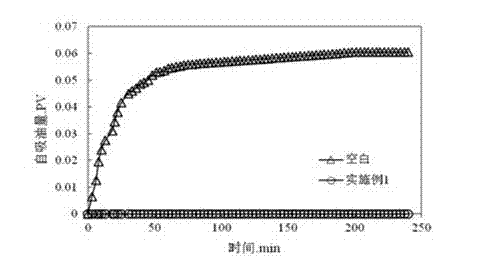

Anti-water-blocking agent for drilling fluid and preparation method thereof

ActiveCN102887974AGood weather resistanceImprove performanceDrilling compositionGas phaseWater block

The invention relates to an anti-water-blocking agent for drilling fluid and a preparation method thereof. The anti-water-blocking agent is a polymer containing a butyl acrylate (BA) monomer, a methyl methacrylate (MMA) monomer, a methacrylic acid (MAA) monomer, an acrylamide (AM) monomer and a 2-(perfluorohexyl)ethyl methacrylate (G06B) monomer, wherein the mol percent of a is 35.8-36.5%, the mol percent of b is 27.0-30.5%, the mol percent of c is 7.5-9.0% and the mol percent of d is 7.5-9.0%. According to the invention, the anti-water-blocking agent effectively reduces filtrate surface tension and oil-water interfacial tension, improves gas-phase relative permeability, has a good invading fluid draining effect and is beneficial to driving away resident fluid in near wellbore formations in a draining manner so as to better relieve the water blocking effect. The preparation method of the anti-water-blocking agent is safe and economic and has a high conversion rate; and a batch feeding method is used, so that the requirements for low dosage and high performance are met.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Multiphase Acrylic Adhesives

ActiveUS20080302479A1Improve fracture toughnessLiquid surface applicatorsPolyureas/polyurethane adhesivesMeth-Polymer science

The invention relates to cured (meth)acrylate based adhesive composition, comprising at least two co-continuous phases of interpenetrating networks and at least two types of polymeric inclusions, in which one of the co-continuous phases comprises a polymer or copolymer based on at least one acrylic or methacrylic acid monomer or a derivative thereof. These compositions exhibit better facture toughness, especially at low temperatures.

Owner:HUNTSMAN INT LLC

Electrode binding agent of novel lithium ion battery and preparation method of electrode binding agent

ActiveCN108417836AReduce electrode polarizationHigh discharge specific capacityCell electrodesSecondary cellsCyclic processInterface impedance

The invention discloses an electrode binding agent of a novel lithium ion battery. The electrode binding agent is an ABA-type three-block polymer, wherein polyacrylic acid blocks are arranged at two ends, a polyacrylate block is arranged at a middle part, each polyacrylic acid block is formed by polymerizing a methacrylic acid monomer and / or an acrylic acid monomer, and the polyacrylate block is formed by polymerizing one or more of methyl acrylate, butyl acrylate, hydroxyethyl acrylate and hydroxypropyl acrylate. The invention also discloses a preparation method for the electrode binding agent of the novel lithium ion battery. The block copolymer binding agent provided by the invention is small in electrode polarization and high in discharging specific capacity, the capacity retention ratio during the circulation process is high, and the binding agent is small in interface impedance, can be simultaneously applicable to a positive electrode and a negative electrode and has huge application prospect in the field of the lithium ion battery.

Owner:MINNAN NORMAL UNIV

Preparation method of flame resistance core-shell type aqueous acrylic ester resin coating

ActiveCN104031514AImprove the defect of "hot sticky and cold brittle"Improve flame retardant performanceFireproof paintsPolymer sciencePhosphonium salt

The invention relates to a preparation method of a flame resistance core-shell type aqueous acrylic ester resin coating. Water, emulsifiers, methacrylic acid and a monomer A are added and emulsified, an initiator starts to be added dropwise for 1-3 hours when the temperature is 75 DEG C, reaction is carried out for 3-5 hours with the temperature kept at 75 DEG C, quaternary phosphonium salt is added to react for 1-3 hours, and core layer emulsion is obtained; a monomer B and an initiator are added into the core layer emulsion dropwise for 1-3 hours at the same time and react for 2 hours with the temperature kept at 75-85 DEG C, borane is added dropwise, reaction is carried out for 1-3 hours with the temperature kept at 75-85 DEG C, then cross-linking agents are added dropwise, reaction is carried out for 1-2 hours with the temperature kept at 75-85 DEG C, the temperature is decreased to be 50 DEG C, an emulsifier is added into a reaction system, the reaction time is 30 minutes, ammonium hydroxide is added to adjust the pH value to be 7-8, and the flame resistance core-shell type aqueous acrylic ester resin coating is obtained. The flame resistance of obtained flame resistance core-shell type aqueous acrylic ester resin can be greatly improved, and the defect that traditional acrylic ester resin is sticky at high temperature and crisp at low temperature is also overcome.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD +1

Ink for aqueous inkjet recording, inkjet recording method, and inkjet printed matter

InactiveUS20150050467A1High discharging reliabilityMeasurement apparatus componentsDecorative surface effectsOrganic solventWater soluble

Ink for aqueous inkjet recording contains water, a hydrosoluble organic solvent; a pigment; and an acrylic-modified polycarbonate-based urethane resin that contains at least one of an acrylic monomer, a methacrylic monomer, and an alkylester thereof as components.

Owner:RICOH KK

Building exterior wall-coating emulsion compositions and building exterior walls

InactiveUS20060069198A1Increase elasticityIncrease flexibilityCoatingsGraft polymer adhesivesPolymer chemistryFree-radical reaction

An emulsion composition for building exterior walls is provided comprising in admixture, [A] a graft copolymerized emulsion obtained by adding to (1) an oil-in-water type emulsion containing at least one organopolysiloxane having an organic group containing a radical reactive group or SH group, (2) a monomer or monomeric mixture containing at least 70 wt % of at least one monomer selected from acrylic and methacrylic monomers and effecting emulsion graft polymerization of component (2) to the organopolysiloxane, and [B] a silicone resin-containing emulsion. The emulsion composition is capable of forming an elastic, flexible coating which is endowed with water resistance, weather resistance, water repellency, adhesion and heat resistance and maintains these properties over a long period of time. It can thus be used as a base in a variety of paints and coating agents.

Owner:NISSHIN CHEM IND CO LTD

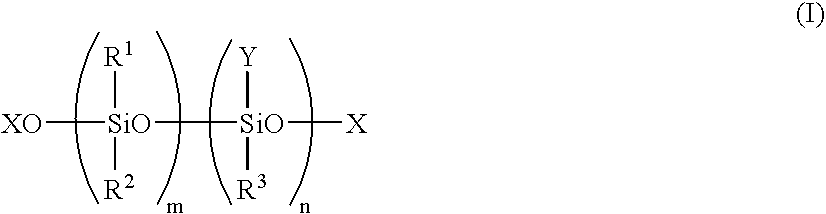

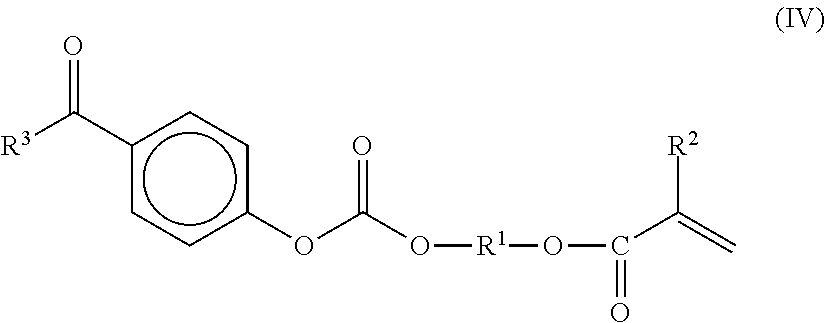

UV-curable composition and pressure sensitive adhesive having breathability derived therefrom, as well as method for manufacturing the same

ActiveUS20150152297A1Improve balanceHigh viscosityFilm/foil adhesivesEster polymer adhesivesPolymer scienceHydrogen

The present invention relates to a polymerizable composition, comprising a polymerizable monomer of formula (I), a copolymerizable UV-initiator, at least one copolymerizable (meth)acrylic monomer:R1—(OCH2CH2)n-L-OC(O)—CR2═CH2 Formula (I)wherein R1 is hydrogen or a C1-C6 alkyl group, n is an integer from 1 to 100, L is a single bond or a divalent linking group, preferably a single bond or a C1-6 alkylene group, and R2 is hydrogen or a CH3 group; andoptionally (d) at least one copolymerizable non-acrylate monomer;wherein the amount of the polymerizable monomer of formula (I) is between 2.5 and 40% by weight of the total of all polymerizable monomers (a), (b), (c) and (d).The invention also relates to a random copolymer obtained by reacting the polymerizable composition, a crosslinked product of the random copolymer and an adhesive composite material comprising the random copolymer or the crosslinked product on a substrate.

Owner:ICAP SIRA

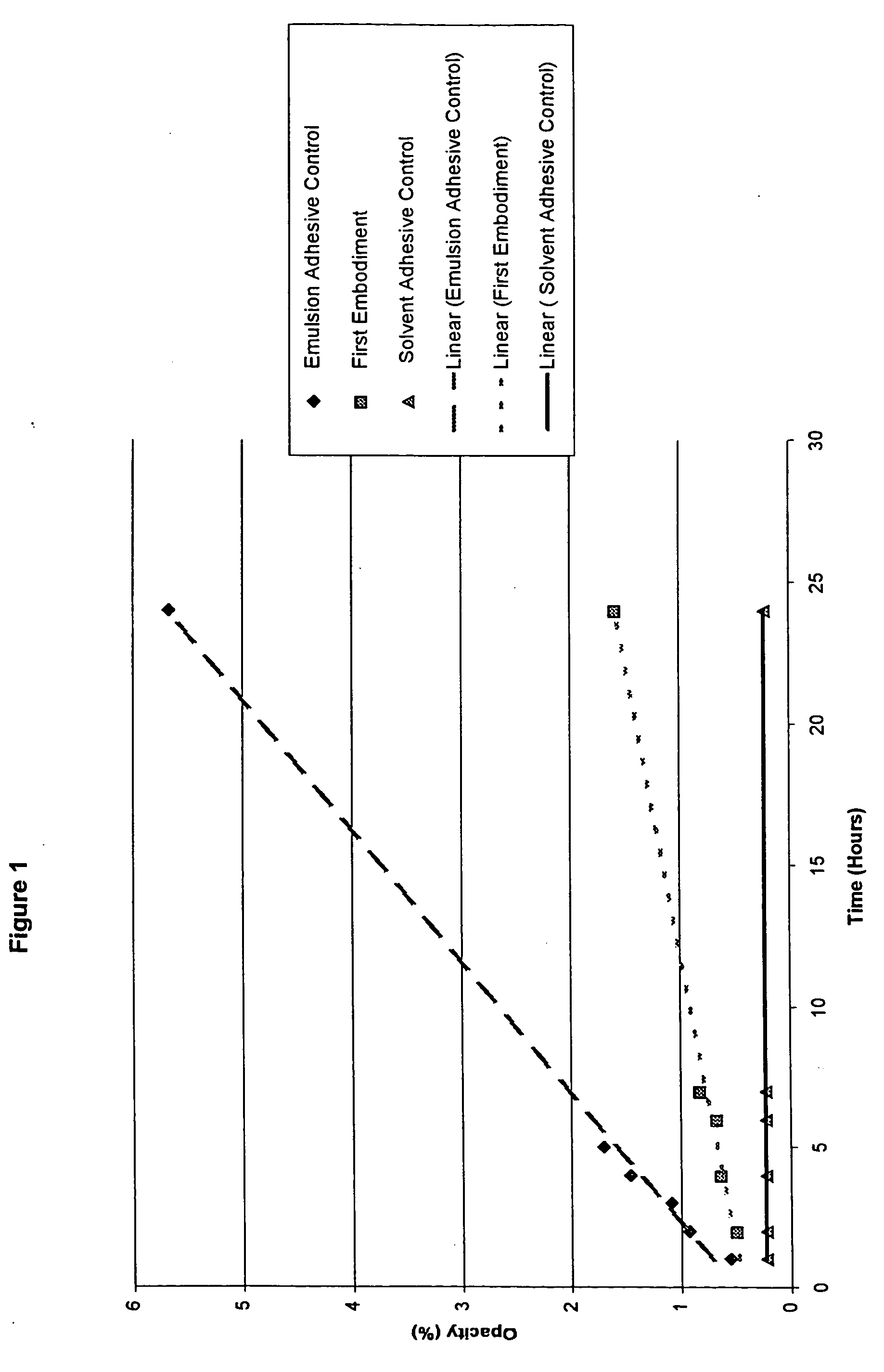

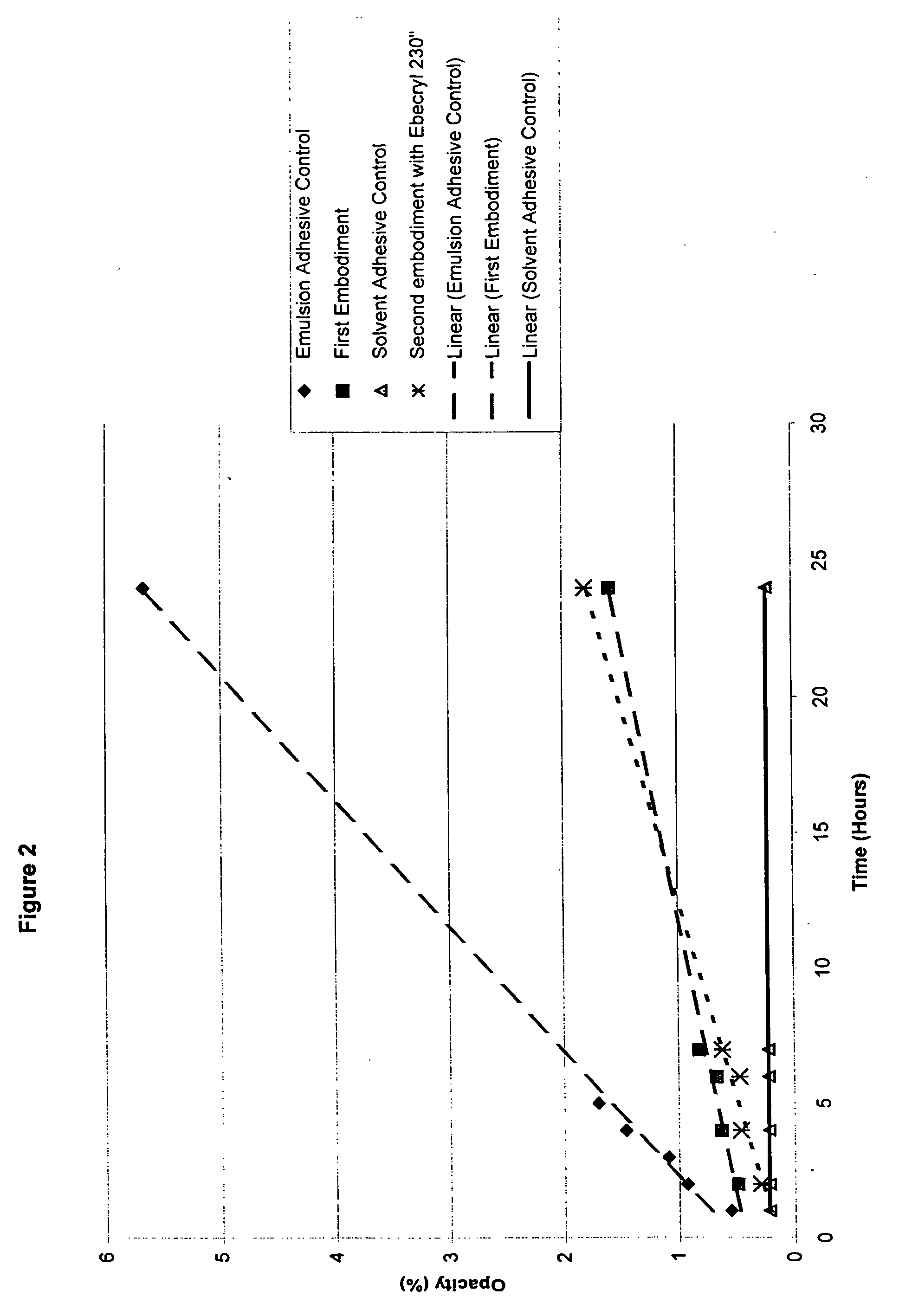

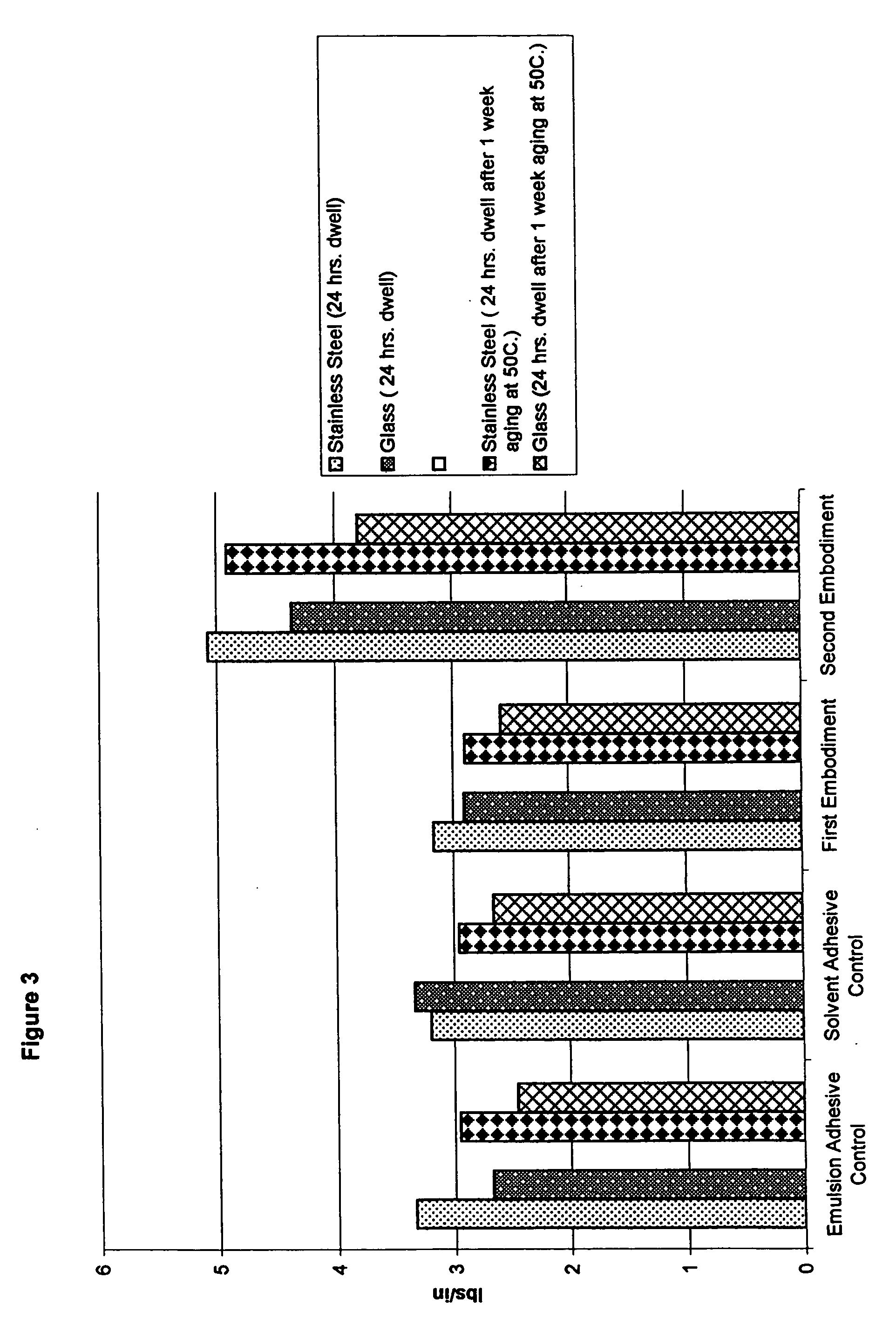

Water-whitening resistant pressure-sensitive adhesive

InactiveUS20050176876A1Improve abilitiesImprove propertiesEster polymer adhesivesEmulsion paintsPolymer scienceMeth-

Pressure-sensitive adhesive compositions that resist water-whitening are provided. The compositions comprise emulsion copolymers formed from a plurality of monomers that includes a plurality of (meth)acrylic monomers, at least one trifluoroalkyl(meth)acrylate monomer, and at least one alkylimidazolidone (meth)acrylate monomer. Preferably, the (meth)acrylic monomers comprise a plurality of soft monomers, at least one hard monomer and at least one acid monomer. The plurality of monomers may further include at least one aliphatic urethane di(meth)acrylate, an oligomer. The pressure-sensitive adhesive composition also comprises a surfactant system including at least one surfactant.

Owner:AVERY DENNISON CORP

Polarizing plate and image display including the same

InactiveUS7622055B2High hardnessReduce thicknessLiquid crystal compositionsPolarising elementsDisplay deviceHigh surface

A polarizing plate is provided that has excellent polarization properties and high surface hardness and can have a reduced thickness. The polarizing plate includes a polarizer and a cured resin layer. The cured resin layer is formed directly on at least one surface of the polarizer. The cured resin layer is formed of a solventless photocurable composition containing the following components (A), (B), and (C):(A) at least one of a polyfunctional acrylic monomer and a polyfunctional methacrylic monomer;(B) a photocurable prepolymer; and(C) a photopolymerization initiator.

Owner:NITTO DENKO CORP

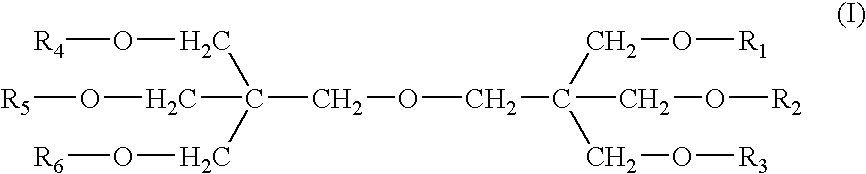

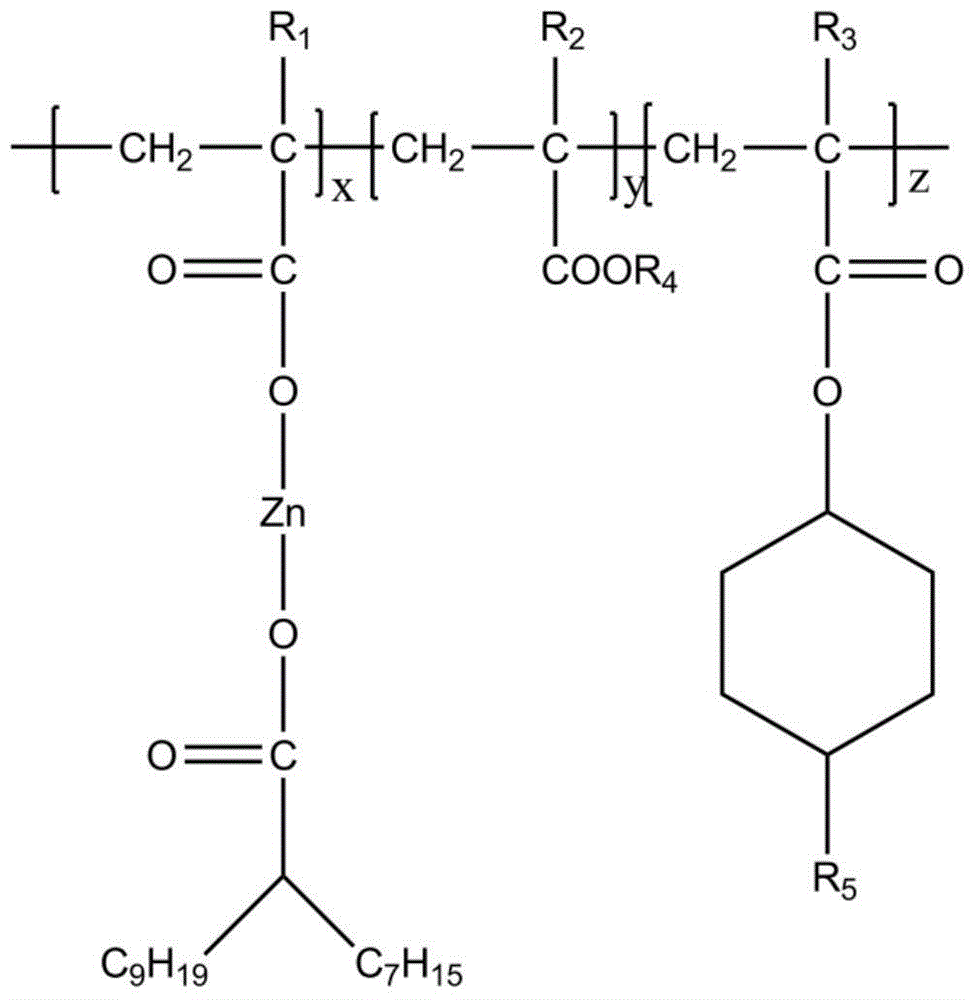

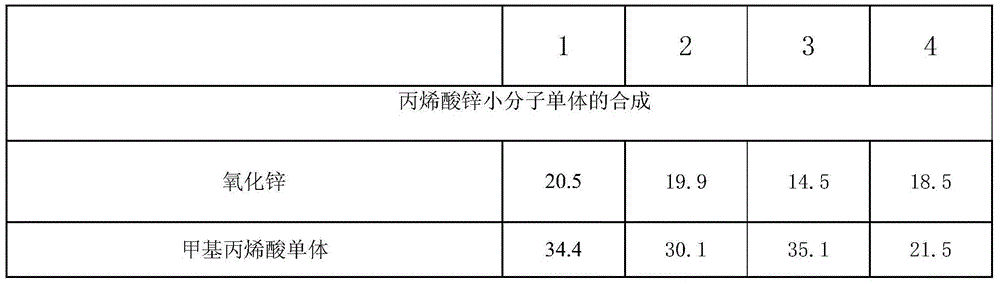

Preparation method of anti-cracking zinc acrylate antifouling paint

ActiveCN104629567AWith antifouling effectImprove crack resistanceAntifouling/underwater paintsPaints with biocidesCarboxylic acidPolymer solution

The invention discloses a preparation method of an anti-cracking zinc acrylate antifouling paint. The preparation method comprises synthesis of a zinc acrylate small-molecular monomer, synthesis of a zinc acrylate polymer and preparation of zinc acrylate antifouling paint, wherein the zinc acrylate small-molecular monomer contains a first solvent, zinc oxide, a methacrylic acid monomer and monocarboxylic acid; the zinc acrylate polymer contains a second solvent, a zinc acrylate small-molecular monomer, a methacrylate monomer and an initiator; the zinc acrylate antifouling paint contains a zinc acrylate polymer solution, pigment filler, a third solvent, an antifouling agent and an auxiliary; the structural formula of the synthesized zinc acrylate polymer is shown in the specification; the long branch of isostearic acid in monocarboxylic acid has relatively good internal plasticization function so that the synthesized zinc acrylate polymer has relatively good flexibility; and the methacrylate monomer is of a aliphatic six-membered ring structure with a cyclohexyl structure, the damage of the antifouling paint caused by excessive internal stress can be avoided, and the anti-cracking performance of the antifouling paint is enhanced.

Owner:XIAMEN SUNRUI SHIP COATING

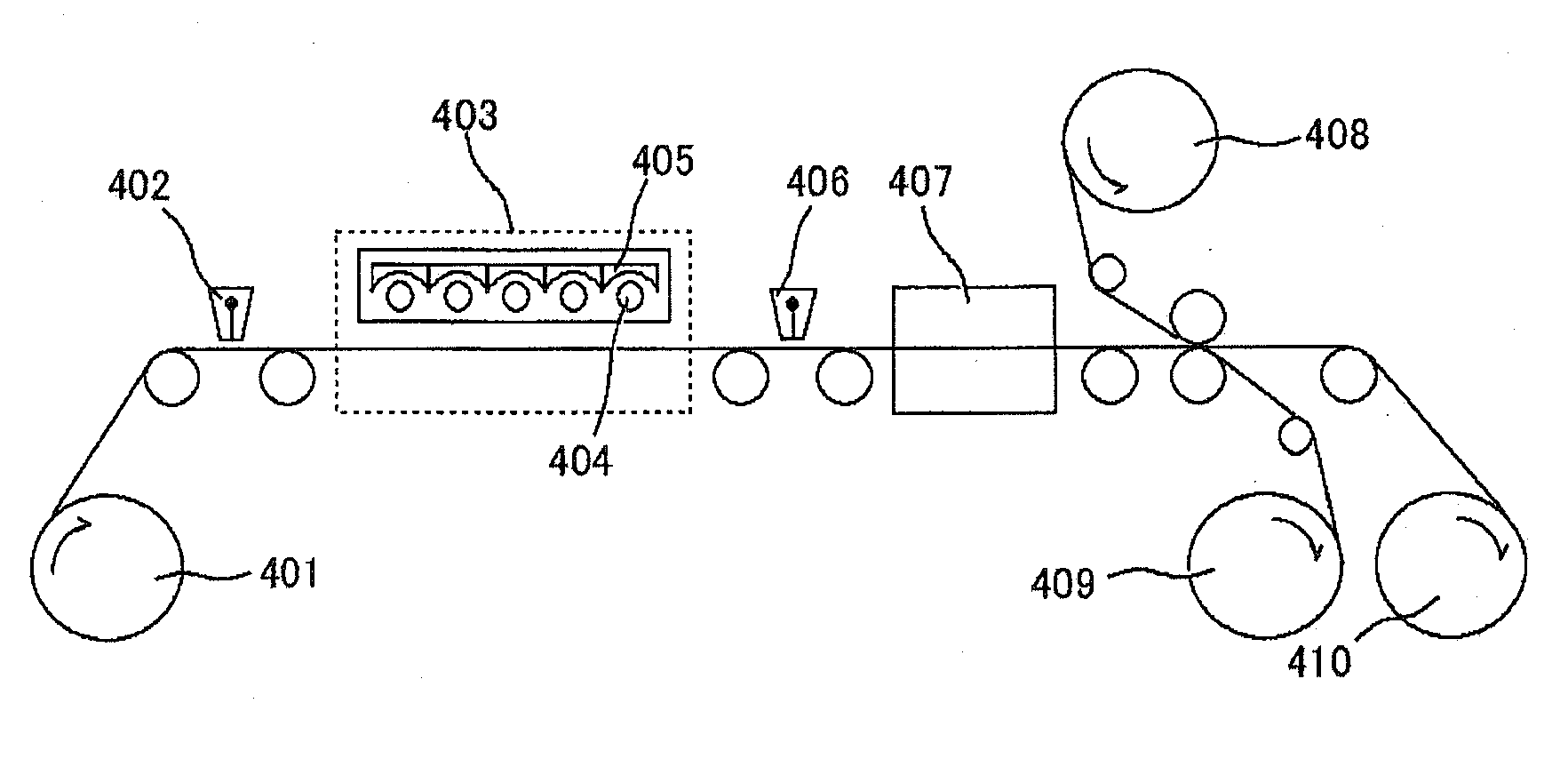

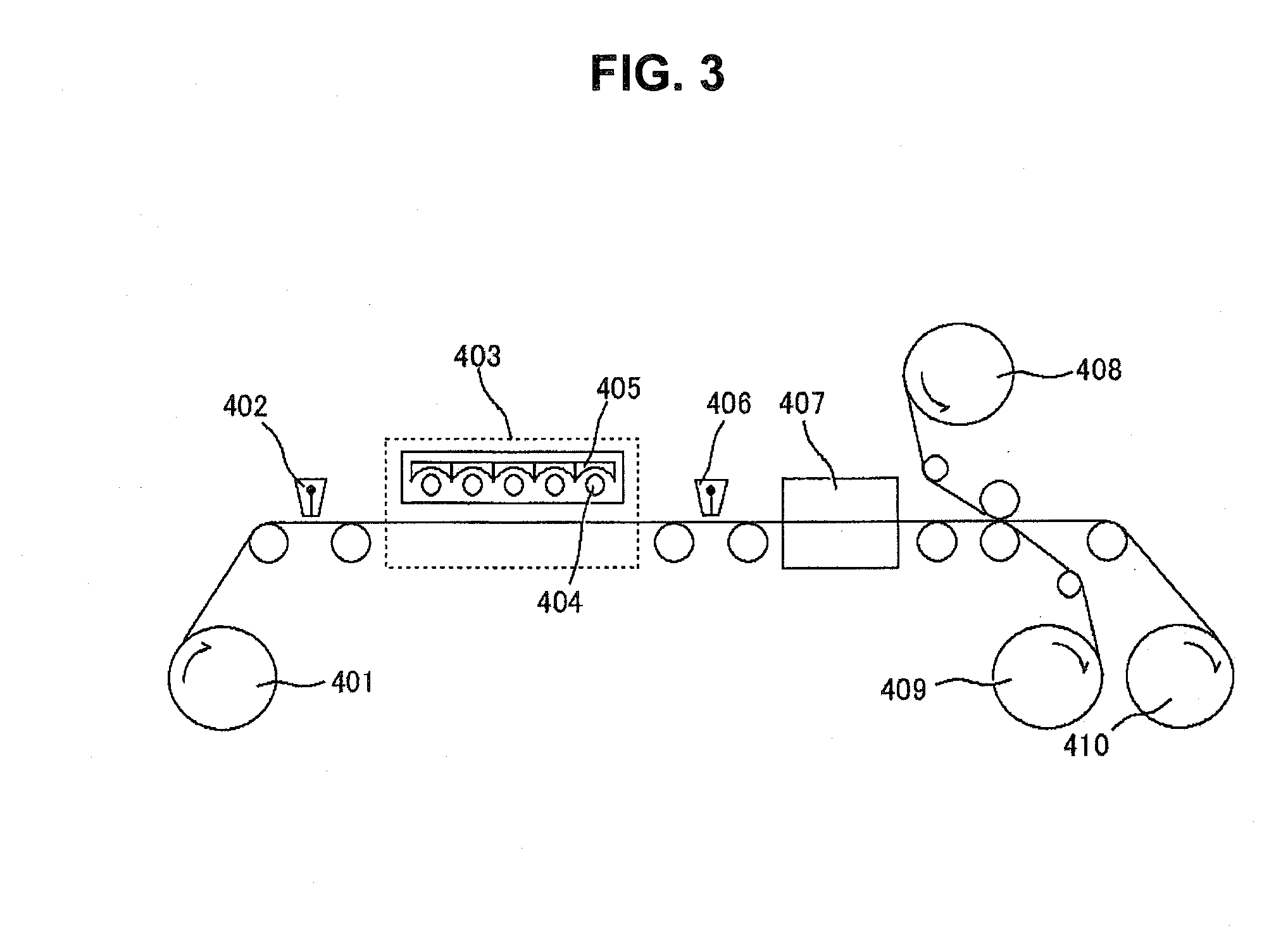

Polarizing plate, image display, and method of manufacturing polarizing plate

InactiveUS20100238383A1High hardnessImprove adhesionLamination ancillary operationsSynthetic resin layered productsHardnessPolarizer

A polarizing plate is provided that has high hardness, can have a reduced thickness, and has excellent in polarization properties. The polarizing plate includes a polarizer, an adhesive layer, and a cured resin layer. The adhesive layer is stacked on at least one surface of the polarizer. The cured resin layer is stacked on the surface of the adhesive layer located on the opposite side to the polarizer. The adhesive layer has a thickness in the range of 0.1 μm to 10 μm. The cured resin layer is formed of a solventless photocurable composition containing component (A) and component (B), with component (A) being at least one of a polyfunctional acrylic monomer and a polyfunctional methacrylic monomer and component (B) being a photocurable prepolymer.

Owner:NITTO DENKO CORP

Clearcoat paint composition

A coating composition including a copolymerization product of a mixture of monomers including one or more carbamate-functional monomers and (meth)acrylic monomers, some having carboxylic acid-functionality. The monomer mixture is essentially free of hydroxyl monomers. The coating composition may be a solvent-borne clearcoat coating composition, preferably an automotive clearcoat coating composition, that may be applied over a water-borne basecoat coating composition.

Owner:BASF CORP

Inkjet ink and inkjet recording method

ActiveUS20120033011A1Excellent stabilityHigh glossinessDuplicating/marking methodsInksWater solubleOrganic solvent

Provided is an inkjet ink comprising at least water, a pigment, a resin, a water-soluble organic solvent, and a surfactant, wherein the resin comprises a copolymer resin synthesized from a monomer that includes a (meth)acrylic monomer, and the copolymer resin has an acid value of not less than 50 mgKOH / g and not more than 200 mgKOH / g, a glass transition temperature (Tg) not less than 20 and not more than 100° C., and a weight-average molecular weight (Mw) not less than 20,000 and not more than 100,000, and as a result, a high-quality image is formed in that abrasion resistance and adhesiveness on a non-absorptive recording medium are high, glossiness is high, and there is no ink mixing, and ejection performance is good and recovery through maintenance is excellent. Also provided is an inkjet recording method that uses the same.

Owner:KONICA MINOLTA IJ TECHNOLOGIES INC

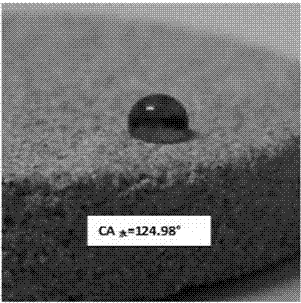

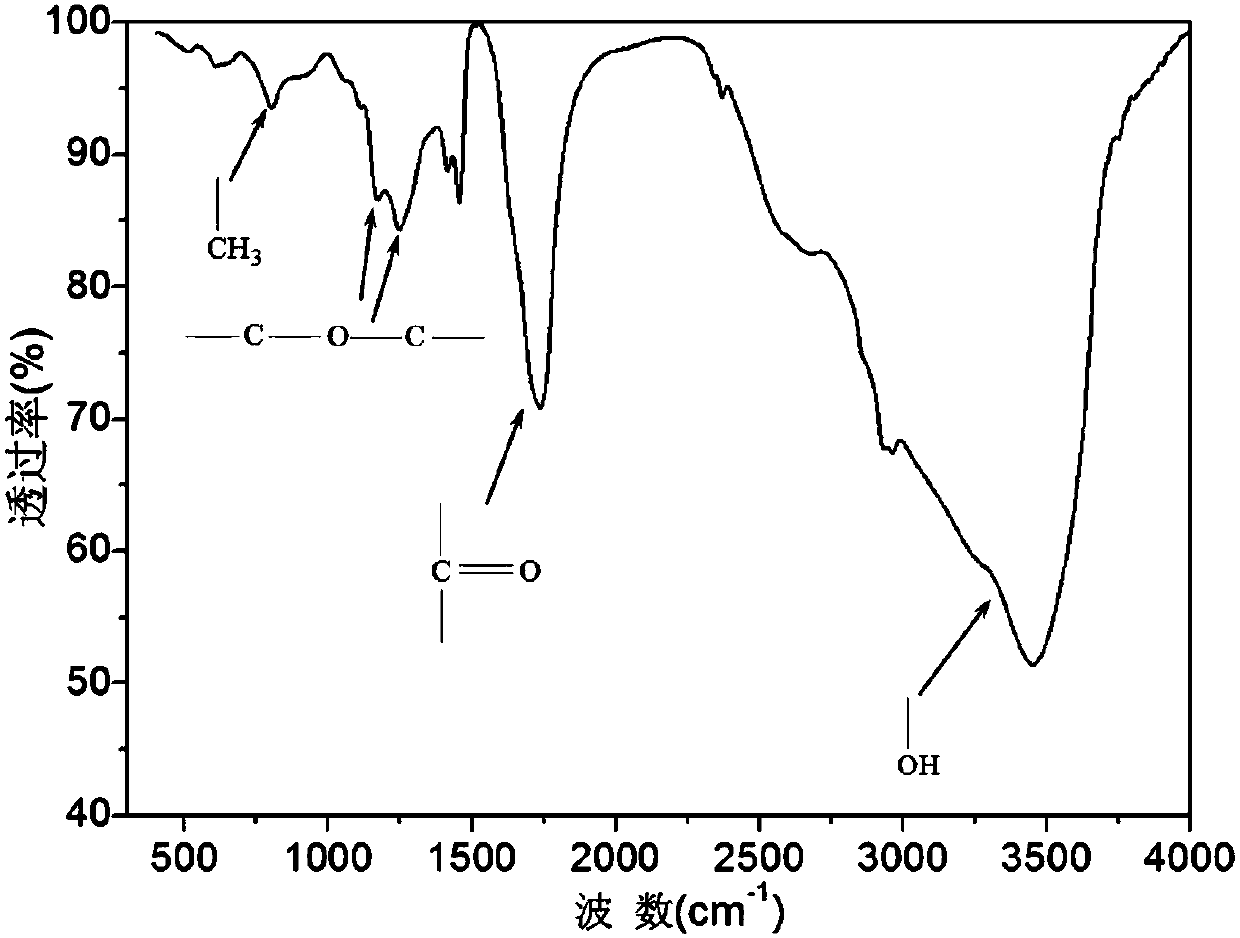

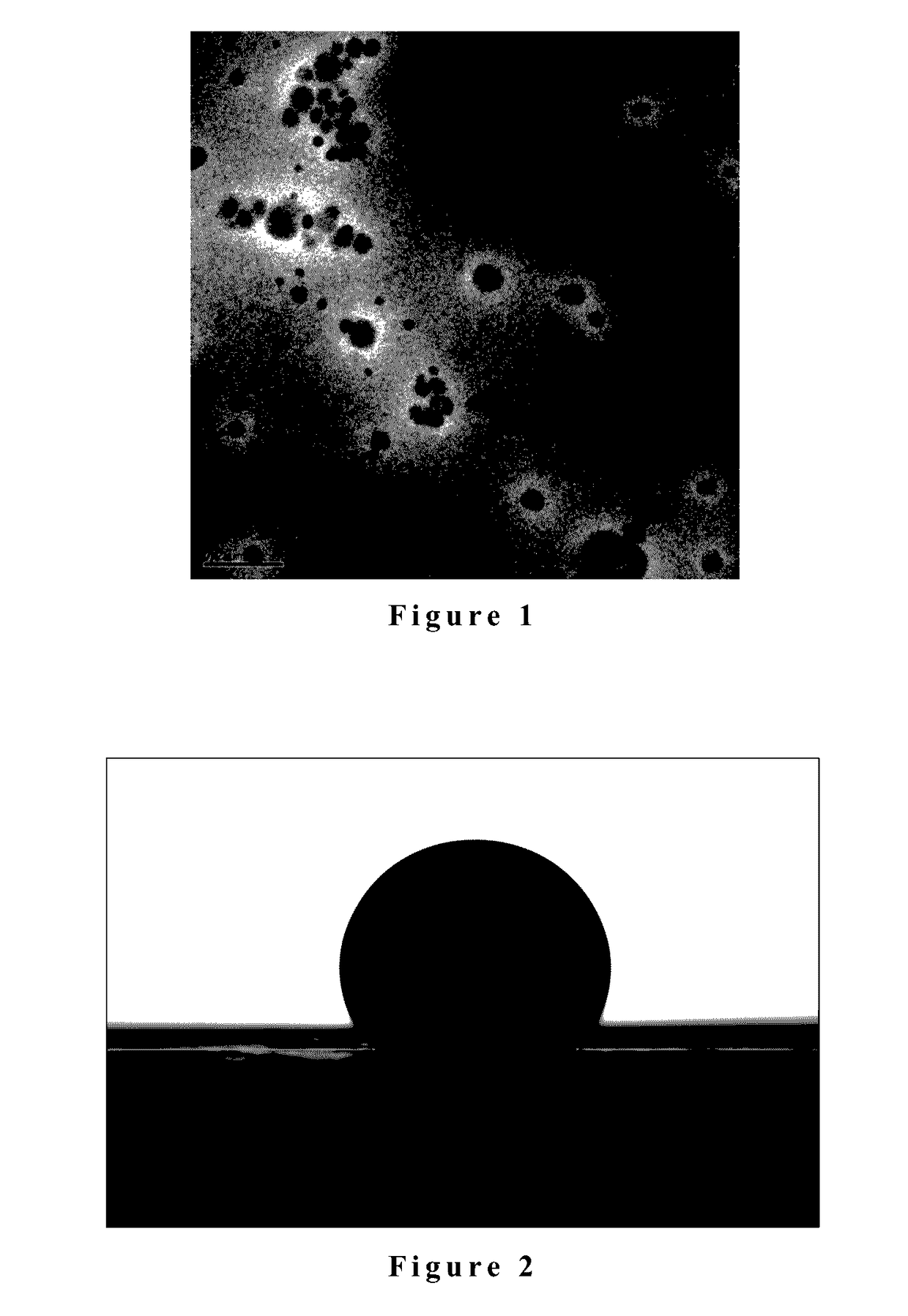

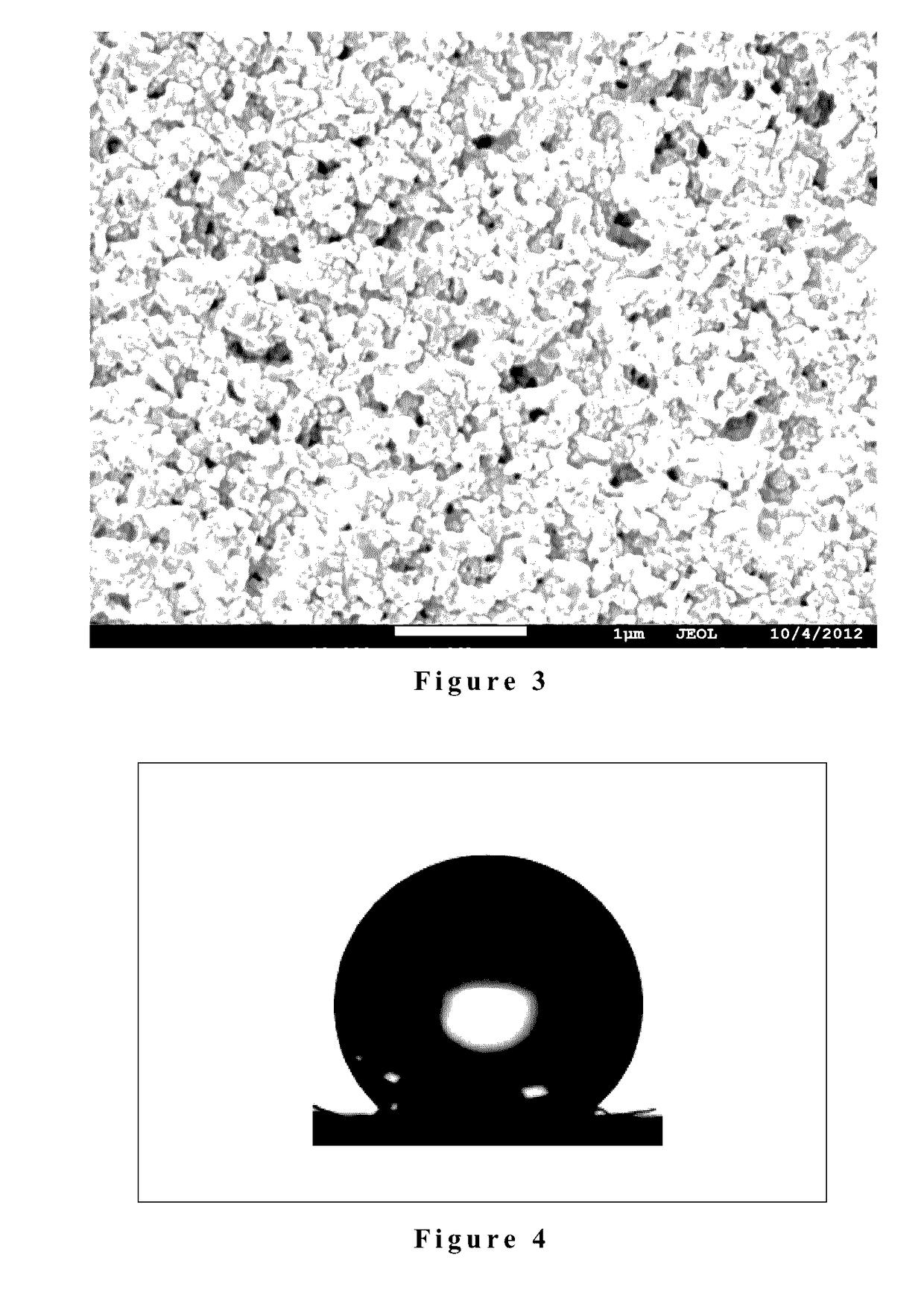

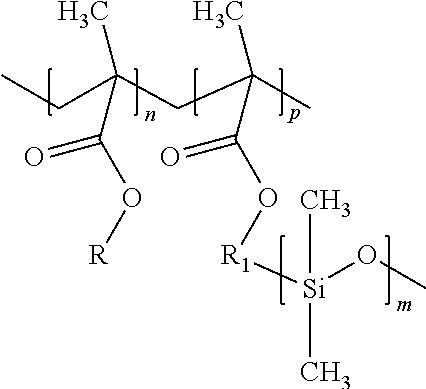

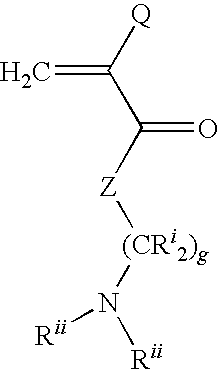

Method for Obtaining a Hybrid Latex and Use Thereof in Hydrophobic and Superhydrophobic Coatings

The present invention relates to a siliconized hybrid latex that consists of a polysiloxane methacrylic copolymer of the formula (I), starting with at least one methacrylic monomer that is partially soluble in water, and at least one functionalised silicone-based macromonomer that is insoluble in water and highly hydrophobic, and to the use of said latex in a water-based formula, free of fluorinated compounds, generating highly hydrophobic or superhydrophobic surfaces with self- or easy-cleaning properties.

Owner:CENT DE INVESTIGACION & POLIMEROS S A DE +1

Adhesive sheet for glass protection, and protective film for automotive glass

InactiveUS20090123739A1Improve heat resistanceHigh transparencyFilm/foil adhesivesSynthetic resin layered productsWeather resistancePolypropylene

Disclosed is an adhesive sheet for protecting a glass, which is excellent in weather resistance, adhesion reliability, transparency and impact resistance. Also disclosed is a protective film for an automotive glass, which is prepared using the adhesive sheet. The adhesive sheet comprises an adhesive layer and a substrate, wherein the adhesive layer comprises an adhesive composition containing, as a base polymer, a (meth)acrylic polymer comprising the following components (A) to (C) as monomer units: (A) 40 to 99.9% by weight of 2-ethylhexyl(meth)acrylate; (B) 0.1 to 10% by weight of a (meth)acrylic monomer having a functional group; and (C) 0 to 59.9% by weight of a vinyl monomer which can be copolymerized with the component (A) and / or (B), and wherein the substrate has a trilaminar structure composed of a propylene layer, a polyethylene layer and a polypropylene layer.

Owner:NITTO DENKO CORP

Crosslinked Polymer

The present invention provides a lubricating composition comprising: (a) an oil of lubricating viscosity; and (b) a crosslinked polymer derived from monomers comprising: (i) 0.001 wt % to 7 wt % of a di- or higher functional crosslinking monomer; (ii) 30 wt % or higher of a hydrocarbyl-substituted (meth)acrylic monomer, wherein each hydrocarbyl contains greater than 8 carbon atoms; and (iii) 0 wt % to 40 wt % of a hydrocarbyl-substituted (meth)acrylic monomer, wherein each hydrocarbyl contains 8 or fewer carbon atoms. The invention further provides a method of preparing the crosslinked polymer and its use in a lubricating composition for lubricating an internal combustion engine.

Owner:THE LUBRIZOL CORP

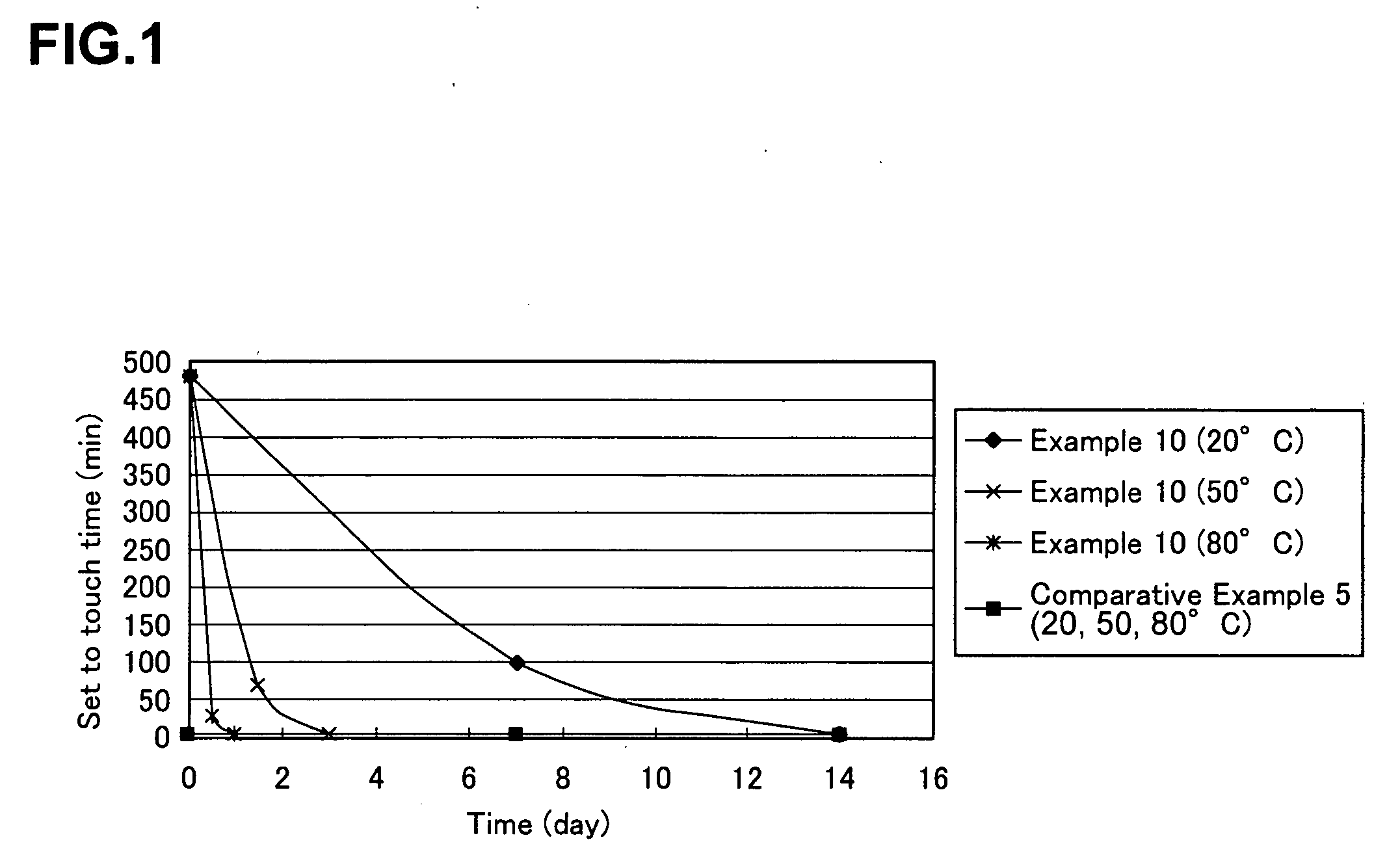

Curable composition and method for producing the same

Disclosed herein is a curable composition excellent in workability, adhesion properties, rubber-like properties, storage stability, and quick curability. The curable composition comprises (A) a crosslinkable silyl group-containing organic polymer and (B) a (meth)acrylic polymer obtained by polymerizing a (meth)acrylic monomer having a polymerizable unsaturated bond in the presence of a metallocene compound and a crosslinkable silyl group-containing thiol compound, at least one end of the (meth)acrylic polymer being bonded to a residue, —S—R3 (where R3 represents a group having a crosslinkable silyl group) obtained by removing a hydrogen atom from the crosslinkable silyl group-containing thiol compound.

Owner:CEMEDAINE CO LTD

Acrylic resin composition dispersed in water

InactiveUS20050221107A1Good lookingSufficient dispersion stabilityMeat/fish preservationSynthetic resin layered productsDispersion stabilityMeth-

It is an object to provide an acrylic resin composition dispersed in water. The composition has excellent appearance and sufficient dispersion stability, is stable even in one-package composition, exhibits physical properties of coating film excellent in water resistance, solvent resistance and weathering resistance, and sufficiently deals with recent environmental issues. It is also an object of the present invention to provide a coating film formed using such an acrylic resin composition dispersed in water. It is also an object of the present invention to provide a coating film formed using such an acrylic resin composition dispersed in water. The acrylic resin composition dispersed in water is an one-package composition obtained by combining a polymer comprising a monomer unit containing an aliphatic hydrocarbon group having 8 to 24 carbon atoms and a (meth)acrylic acid monomer unit, an oxazoline compound having two or more oxazoline rings and a specific amine compound.

Owner:NIPPON SHOKUBAI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com