Anti-water-blocking agent for drilling fluid and preparation method thereof

A technology for waterproof locking agent and drilling fluid, which is applied in chemical instruments and methods, drilling compositions, etc., can solve the problem of unfavorable release of water locking effect of stagnant fluid near wellbore, and cannot effectively reduce filtrate surface tension and oil-water interfacial tension. , the problem of poor drainage effect of invading liquid, etc., to reduce the surface tension of the solution and the interfacial tension of oil and water, the preparation method is safe and economical, and the conversion rate is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

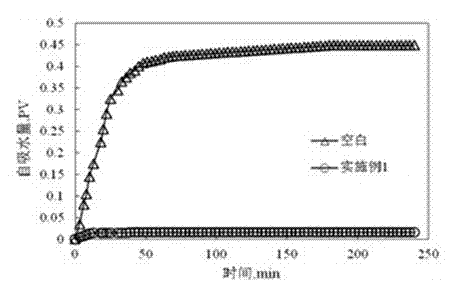

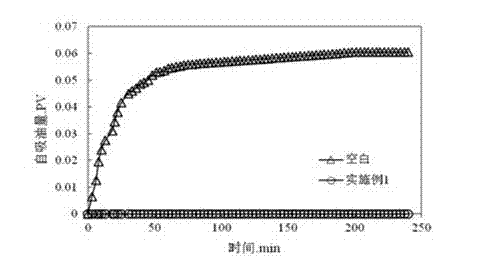

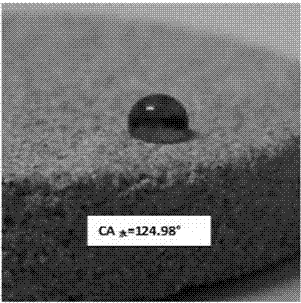

Examples

Embodiment 1

[0034] A preparation method for drilling fluid waterproof locking agent, it comprises the steps:

[0035] 1) Disperse the four monomers of butyl acrylate, methyl methacrylate, acrylamide and methacrylic acid in water at a ratio of 5:4:1:1, add 2% emulsifier, and shear and stir for 30 minutes to obtain a mixture Solution A, the mass concentration of A solution is 20%.

[0036] 2) The synthesis temperature of the mixed solution A is 70°C. Before the synthesis, nitrogen protection is introduced. When the temperature of the solution rises to 70°C, an initiator is added, and the reaction is kept for 1 hour. The initiator is potassium persulfate, and the dosage is 1% of the total amount of monomers. 0.02%. The resulting solution is B.

[0037] 3) Slowly add tridecafluorooctyl methacrylate with 18% of the total amount of monomers in step 1) dropwise to solution B, an emulsifier with 0.5% of the total amount of monomers in step 1) and the total amount of monomers in step 1) Add 0.0...

Embodiment 2

[0040] A preparation method for drilling fluid waterproof locking agent, it comprises the steps:

[0041]1) Disperse the four monomers of butyl acrylate, methyl methacrylate, acrylamide and methacrylic acid in water at a ratio of 4:4:1:1, add 2.25% emulsifier, and shear and stir for 30 minutes to obtain a mixture Solution A, the mass concentration of A solution is 25%.

[0042] 2) The synthesis temperature of the mixed solution A is 70°C. Before the synthesis, nitrogen protection is introduced. When the temperature of the solution rises to 70°C, the initiator is added, and the reaction is kept for 1 hour. The initiator is potassium persulfate, and the dosage is 1% of the total amount of monomers. 0.08%. The resulting solution is B.

[0043] 3) Slowly add tridecafluorooctyl methacrylate with 21% of the total amount of monomers in step 1) to solution B, an emulsifier with 0.4% of the total amount of monomers in step 1) and the total amount of monomers in step 1) The amount of...

Embodiment 3

[0046] A preparation method for drilling fluid waterproof locking agent, it comprises the steps:

[0047] 1) Disperse the four monomers of butyl acrylate, methyl methacrylate, acrylamide and methacrylic acid in water at a ratio of 4:3:1:1, add 2.5% emulsifier, and shear and stir for 30 minutes to obtain a mixture Solution A, the mass concentration of A solution is 30%.

[0048] 2) The synthesis temperature of the mixed solution A is 70°C. Before the synthesis, nitrogen protection is introduced. When the temperature of the solution rises to 70°C, the initiator is added, and the reaction is kept for 1 hour. The initiator is potassium persulfate, and the dosage is 1% of the total amount of monomers. 0.1%. The resulting solution is B.

[0049] 3) Slowly add tridecafluorooctyl methacrylate of 25% of the total amount of monomers in step 1) to solution B, an emulsifier of 0.6% of the total amount of monomers in step 1) and the total amount of monomers in step 1) Add 0.05% of the i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com