Patents

Literature

42 results about "Durable press" patented technology

Efficacy Topic

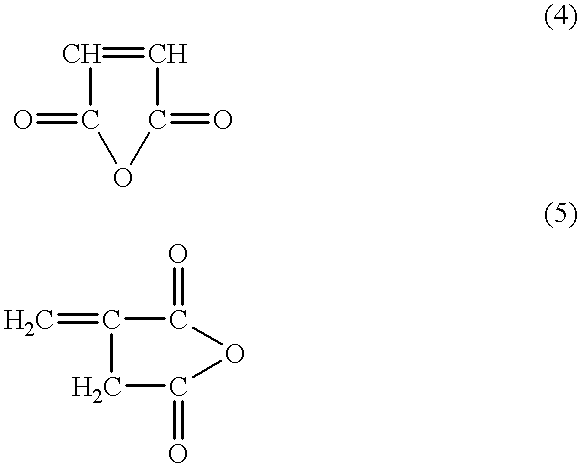

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

• DURABLE PRESS (noun) The noun DURABLE PRESS has 1 sense: 1. a fabric that has been chemically processed to resist wrinkles and hold its shape. Familiarity information: DURABLE PRESS used as a noun is very rare.

Strength and abrasion resistance of durable press finished cellulosic materials

InactiveUS20060272102A1Improves abrasionImproves strength retentionOrganic dyesWrinkle resistant fibresCross-linkCellulose

The invention relates to a method for improving the abrasion resistance and tensile strength of durable press finished cellulosic materials, such as cotton. According to the method of the present invention the cellulosic material is treated with an enzyme composition capable of removing cross links from the cellulosic material, especially cross links on the material surface.

Owner:NOVOZYMES NORTH AMERICA INC

Assembly process for glue-free hinge

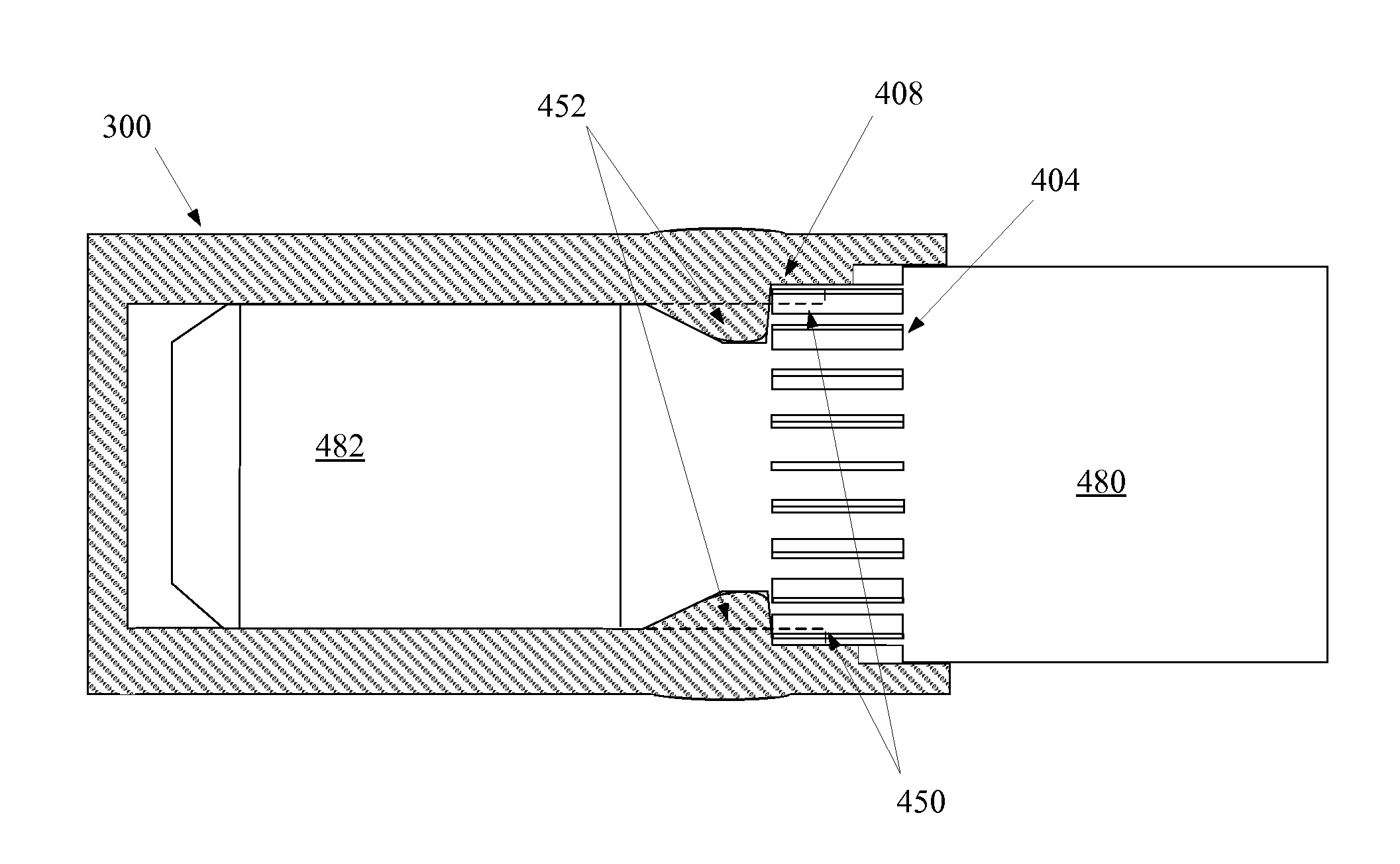

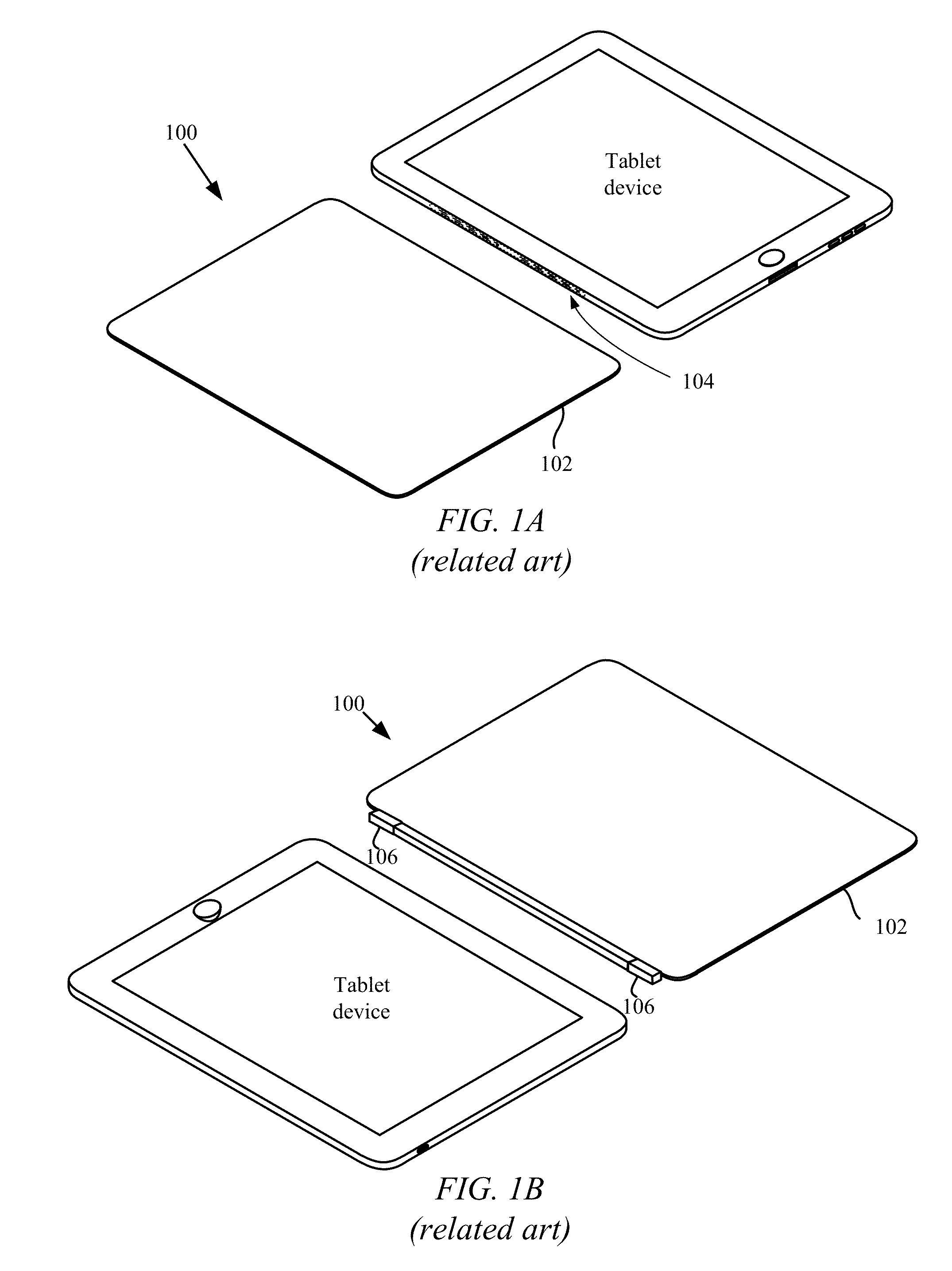

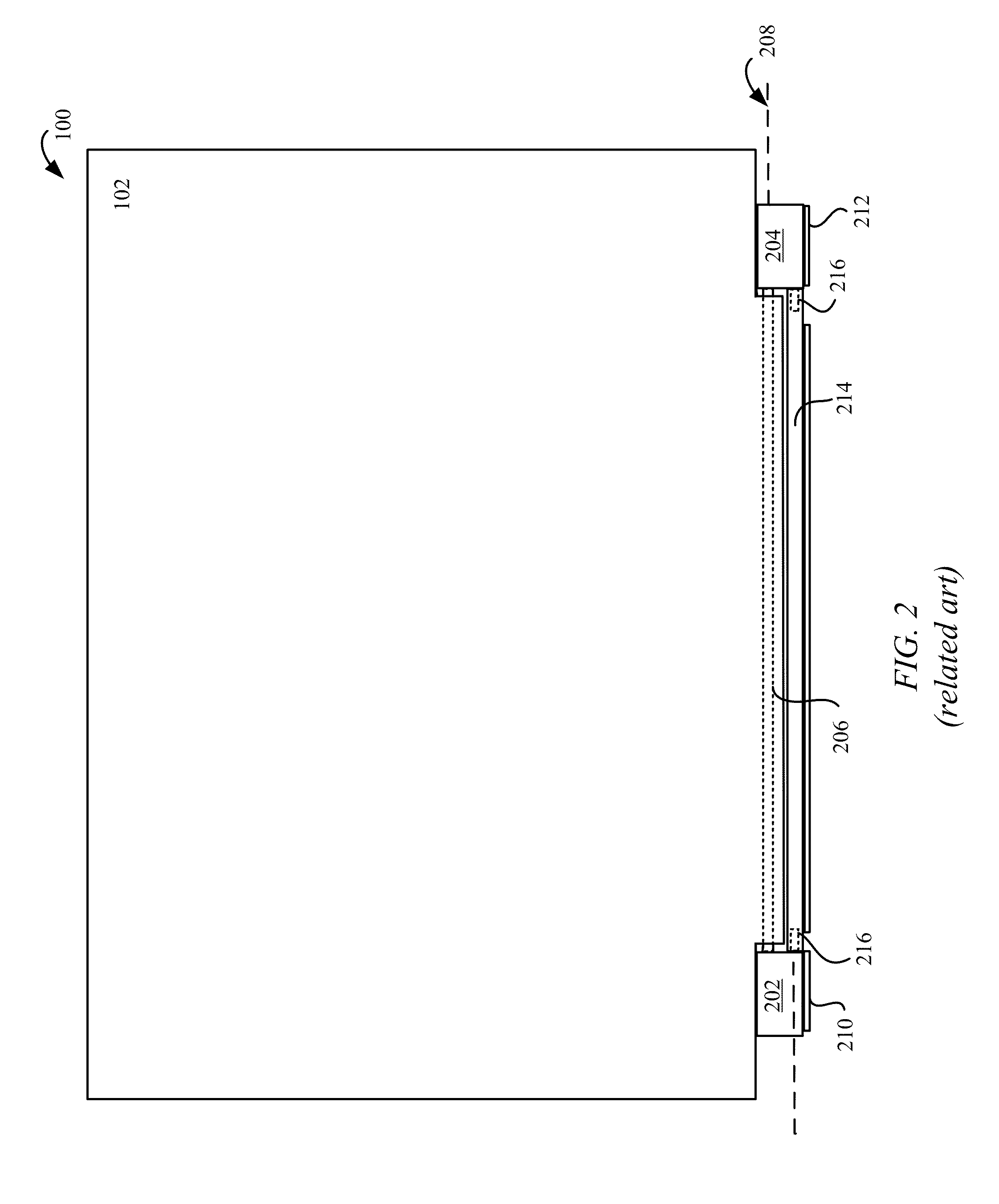

The described embodiment relates generally to the field of press-fit technology. Press-fit technology results in deformation of one component to lock another component in place. This deformation commonly causes surface strain to occur on the deforming component. When a component is anodized surface strain can result in anodization cracking; this ruins the finished appearance of cosmetic surfaces, generally resulting in ghosting lines and splotches appearing on the surface of a component. The described embodiment achieves a careful balance between component deformation and surface strain. By utilizing specific press-fit geometries and assembly methods, surface strain can be sufficiently limited to eliminate anodization cracking while also achieving a durable press-fit joint.

Owner:APPLE INC

Dyeing and finishing method for durable press bombasine yarn dyed fabric

ActiveCN103451917ALittle strengthHigh surface finishBiochemical fibre treatmentDyeing processFiberCellulose

Belonging to the application technology field of yarn dyed fabric dyeing and finishing in the textile industry, the invention provides a dyeing and finishing method for a durable press bombasine yarn dyed fabric, and aims to solve the technical problems of easy fiber damage, undesirable antiwrinkling effect and poor washfastness, easy generation of formaldehyde residue and other ecological pollution. The method provided in the invention combines a chemical technique and a biological enzyme technique to carry out scouring and bleaching and dyeing on a bombazine fabric, that is to say, caustic soda, cellulose and catalase are taken for cotton fiber scouring and bleaching, soda ash, protease and lipase are taken for raw silk degumming and dyeing, and an active dye and laccase are employed to perform bombazine fiber dyeing and aftertreatment. Meanwhile, formaldehyde-free antiwrinkling resin is employed to perform liquid ammonia moist crosslinking on the fabric so as to improve the wrinkle resilience of the fabric. By applying the method provided in the invention to perform dyeing and finishing on the bombasine yarn dyed fabric, the fabric has a smooth surface and soft handfeel, also, the chroma of a dyeing waste liquid is reduced. When high antiwrinkling performance is acquired, the fabric strength is less reduced. The treatment process is safe and environment-friendly, thus being in line with the processing requirements of ecological textiles.

Owner:NANTONG XINLAI SILK GARMENTS

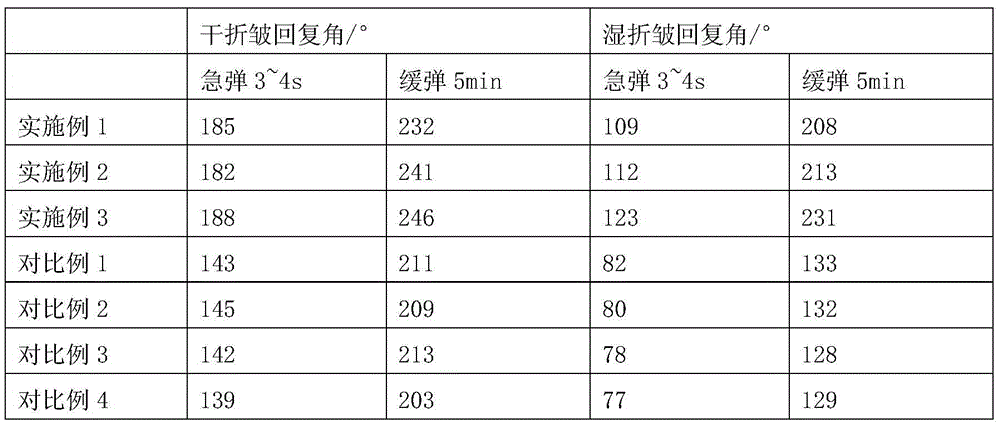

Anti-crease finishing agent for ramie fabric

ActiveCN103696258AAvoid strength lossGood effectBiochemical fibre treatmentVegetal fibresAlkylphenolSorbitan

The invention discloses an anti-crease finishing agent for ramie fabric, which comprises the following components in parts by mass: 1-2 parts of nonylphenol polyoxyethylene ether, 10-20 parts of amino silicon oil, 2-4 parts of sorbitan fatty acid ester, 2-6 parts of alkylphenol polyoxyethylene ether, 10-16 parts of Nipuwei SDP, 8-10 parts of diepoxy triethylene glycol glycidyl ether, 20-40 parts of chitosan and 5-10 parts of glutamine transaminase. The anti-crease finishing agent for ramie fabric, disclosed by the invention, performs anti-crease finishing on ramie, and realizes a relatively good effect; the anti-crease finishing agent performs finishing under neutral conditions, and the strength loss of ramie is avoided; after finishing, the crease delay elastic recovery angle exceeds 240 degrees, and the durable press resistance level reaches 4.0-4.5.

Owner:NANTONG CITY TONGZHOU DISTRICT DADA HEMP TEXTILE

Technique for fabricating shirts durable press and ironing

ActiveCN1796641AImprove stylingHeating/cooling textile fabricsTextile parts treatmentFiberEngineering

A process for preparing shirt of pressing free includes cutting as per patter, spraying edge loosing proof agent, spraying resin, pressing folded line, washing by water, drying and sewing. It the process, liquid ammonia + moist cross ¿C linked plus material is applied for preparing shirt, line made by folding is treated by spraying resin on and by pressing it with certain pressure to form the line to be permanent folded line for pressing free.

Owner:LUTAI TEXTILE

Improvement of strength and abrasion resistance of durable press finished cellulosic materials

InactiveCN1653227AWrinkle resistant fibresBiochemical treatment with enzymes/microorganismsCross-linkCellulose

The invention relates to a method for improving the abrasion resistance and tensile strength of durable press finished cellulosic materials, such as cotton. According to the method of the present invention the cellulosic material is treated with an enzyme composition capable of removing cross links from the cellulosic material, especially cross links on the material surface.

Owner:NOVOZYMES NORTH AMERICA INC

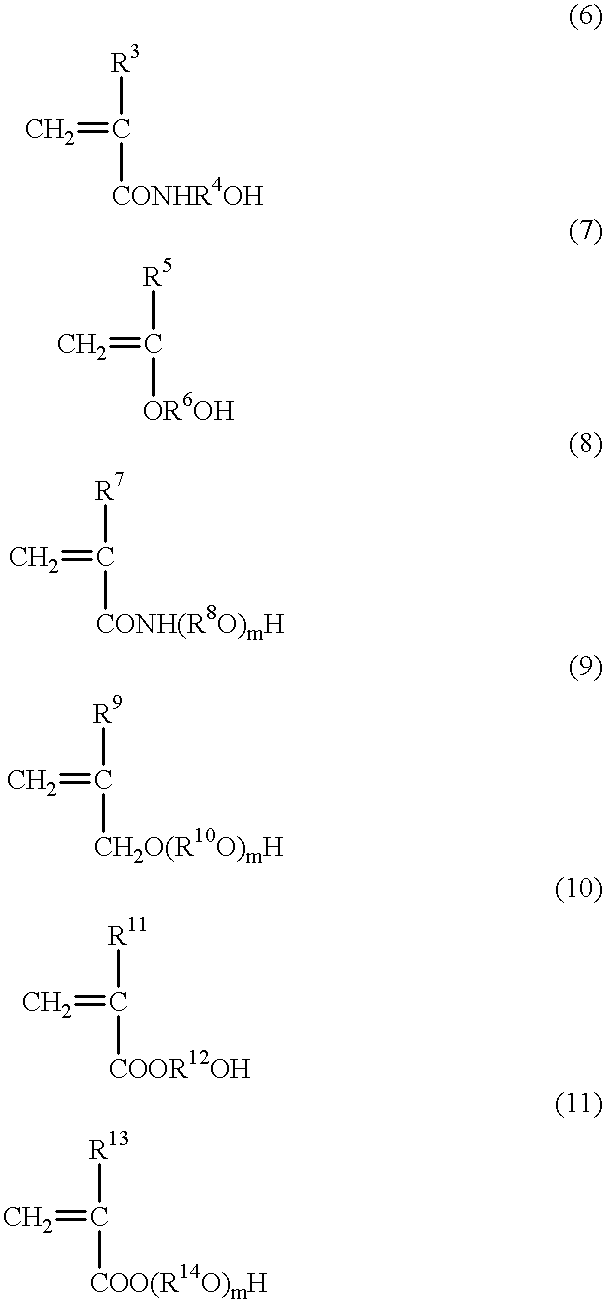

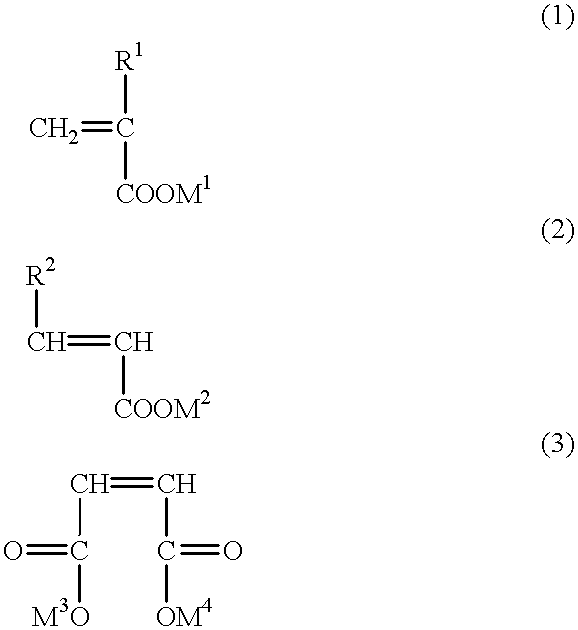

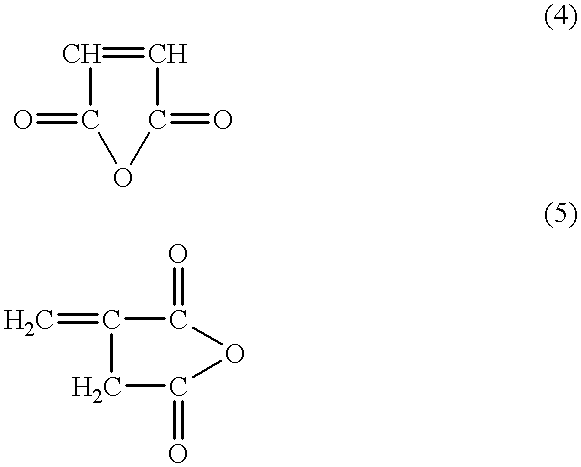

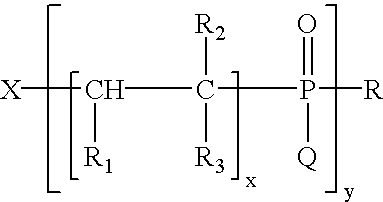

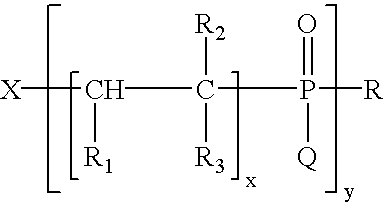

Fiber product-treating agents

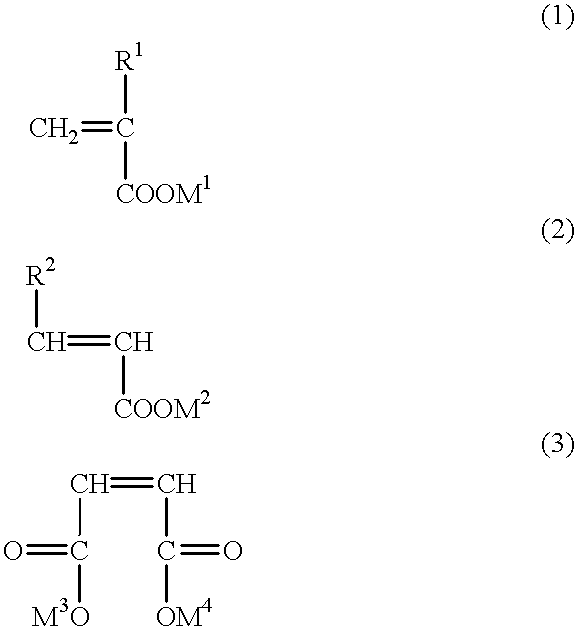

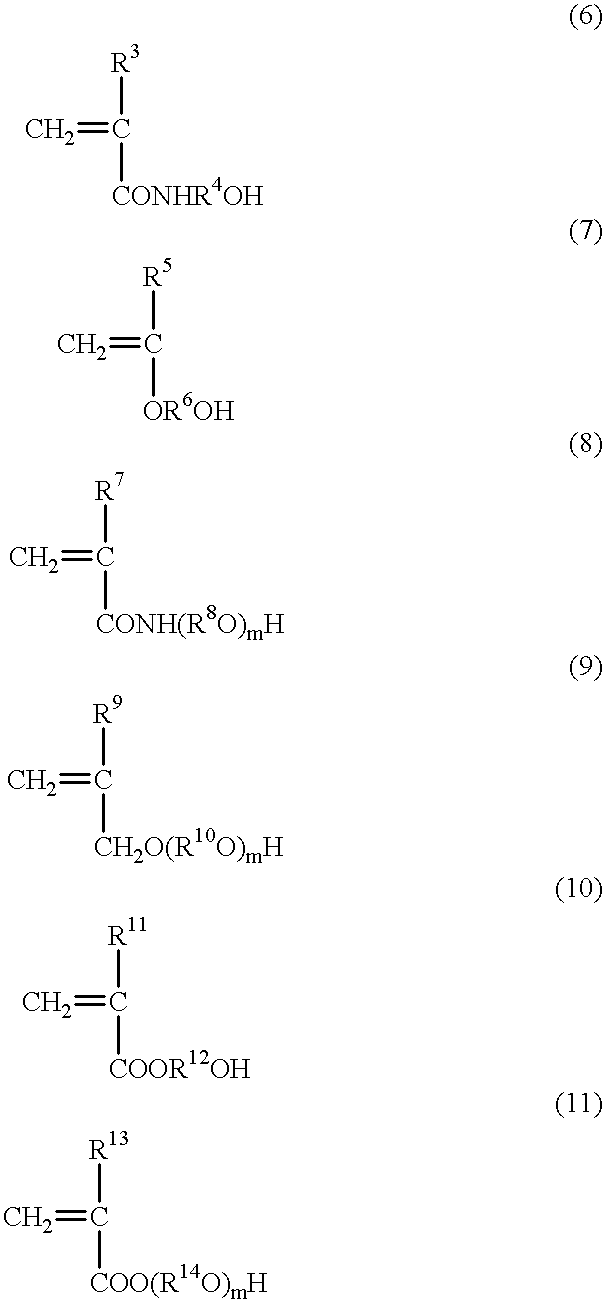

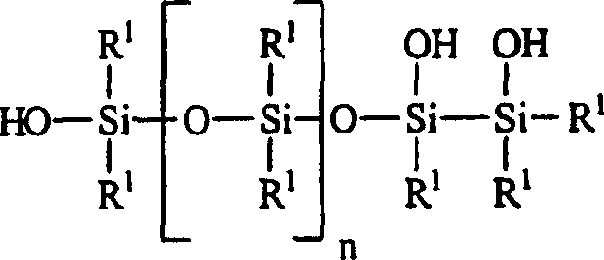

InactiveUS20010037529A1Excellent durable press configurationEasily impartedOrganic detergent compounding agentsPhysical treatmentFiberMedicine

The present invention provides a fiber product-treating agent which can impart an excellent wrinkle-resistant effect and an excellent durable press effect to the fiber product capable of being heated and being hardly effected with not only during wearing but also after washing. That is, the present invention provides the treating agent for imparting the durable press configuration on a fiber product by a heating treatment with e.g. an iron, which comprises a specific amount of (i) two or more compounds forming mutually a crosslinked structure by heating and / or (ii) a compound forming a self-crosslinked structure by heating, and water, wherein the content of a nonvolatile matter is 0.01 to 30%.

Owner:KAO CORP

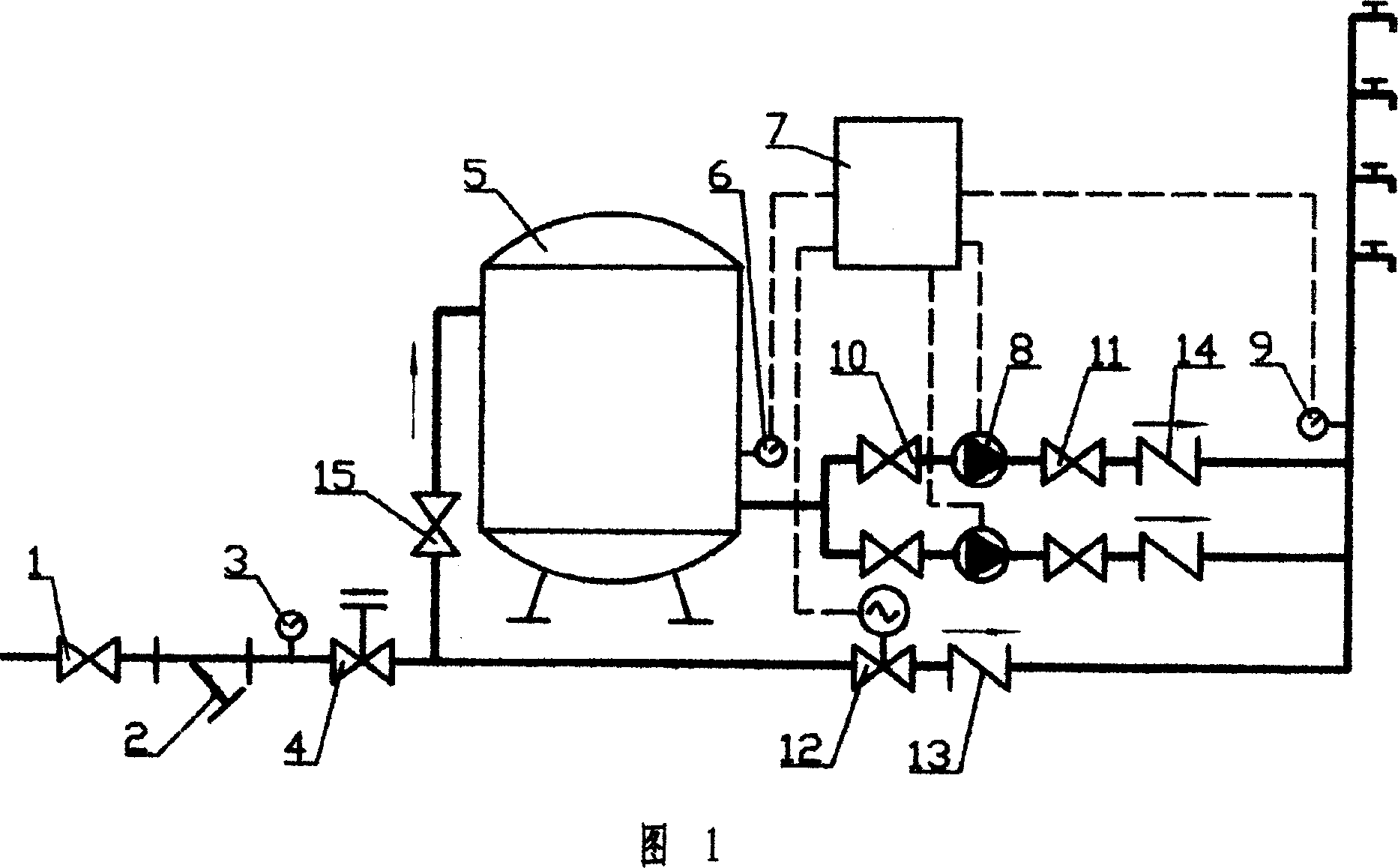

Pressure superposition water supply system for pressure-continuous type pipe network

InactiveCN101012657AImprove efficiencySave electricityService pipe systemsWater mainsEngineeringVariable frequency control

The invention discloses a durable-pressing pressure-superposed water supply system in pipe network, comprising inverter controller (7) and water supply circuit, characterized in that the water supply circuit is constituted by connecting the parallel circuit between the pressure-holding valve (4) and the remote pressure gauge (9) at the location of water outlet. The parallel circuit is constituted by booster loop and reserving by-pass. The booster loop comprises an inverter pump (8) or multiple parallel inverter pumps (8) and a diaphragm pressure jug (5) in series. There is an electromotive valve (12) in the reserving by-pass. In pressure-superposed water supply in pipe network, the invention controls the lowest pressure of municipal pipe network accurately. When the installing height of equipment is lower than the one of municipal pipe network, there is no influence to municipal pipe network and peripheral user. The secondary pollution of system generated by groundwater infiltration can also be avoided and multiple inverter pumps with different height are switched to decrease the energy saving.

Owner:GUANGZHOU UNIVERSITY

Novel formaldehyde-free crease-resist finishing agent and finishing process thereof

InactiveCN105484027AImprove wrinkle resistanceImprove wash resistanceFibre treatmentIsooctyl acrylateResist

The invention discloses a novel formaldehyde-free crease-resist finishing agent. The novel formaldehyde-free crease-resist finishing agent is prepared from acryloyl succinic acid monomers, iso-octyl acrylate, styrene, methyl methacrylate, high-density polyethylene wax emulsion, dimethyl silicone oil, a non-phosphorus catalyst, N-beta-aminoethyl-gamma-aminopropyl methyl dimethoxy silane, etherified dihydroxyl ethylene urea, chitosan, polyethylene glycol and itaconic acid. The invention provides a formaldehyde-free phosphorus-free crease-resist finishing agent for a cotton fabric and a finishing method of the finishing agent. The problems that a traditional unsaturated carboxylic acid finishing agent is prone to yellowing, low in power, poor in polymerization effect and the like are solved, damage of phosphorus-containing wastewater to the environment can further be reduced, environment protection and industrial production are facilitated, and after crease-resist and durable pressing finishing is conducted, a treated fabric has good crease resistance, shape memorizing property and washing fastness.

Owner:湖州市千金丝织厂(普通合伙)

Permanent press finishing process of wool fabric

The invention provides a permanent press finishing process of a wool fabric. The process comprises the following steps: firstly, performing pad-roll treatment on a finishing solution consisting of 80g / L-100g / L of a 2D resin finishing agent, 1g / L-3g / L of a penetrating agent, 20g / L-50g / L of a softening agent and 10g / L-15g / L of a catalyst at room temperature for two times, wherein the padding rate is 70%-80%; secondly, folding and pressurizing by using a heavy hammer; thirdly, pre-drying at 80-90 DEG C for 3-5 minutes; fourthly, baking at 120-160 DEG C for 60-90 seconds; fifthly, steaming at 90-100 DEG C for 8-10 minutes; lastly, drying and doffing. The wool fabric treated with the finishing process provided by the invention has an excellent wash and wear effect, and is outstanding in rebound resilience and durable press performance, full in hand feel, smooth, thick and free from color change and color fading.

Owner:朱文潮

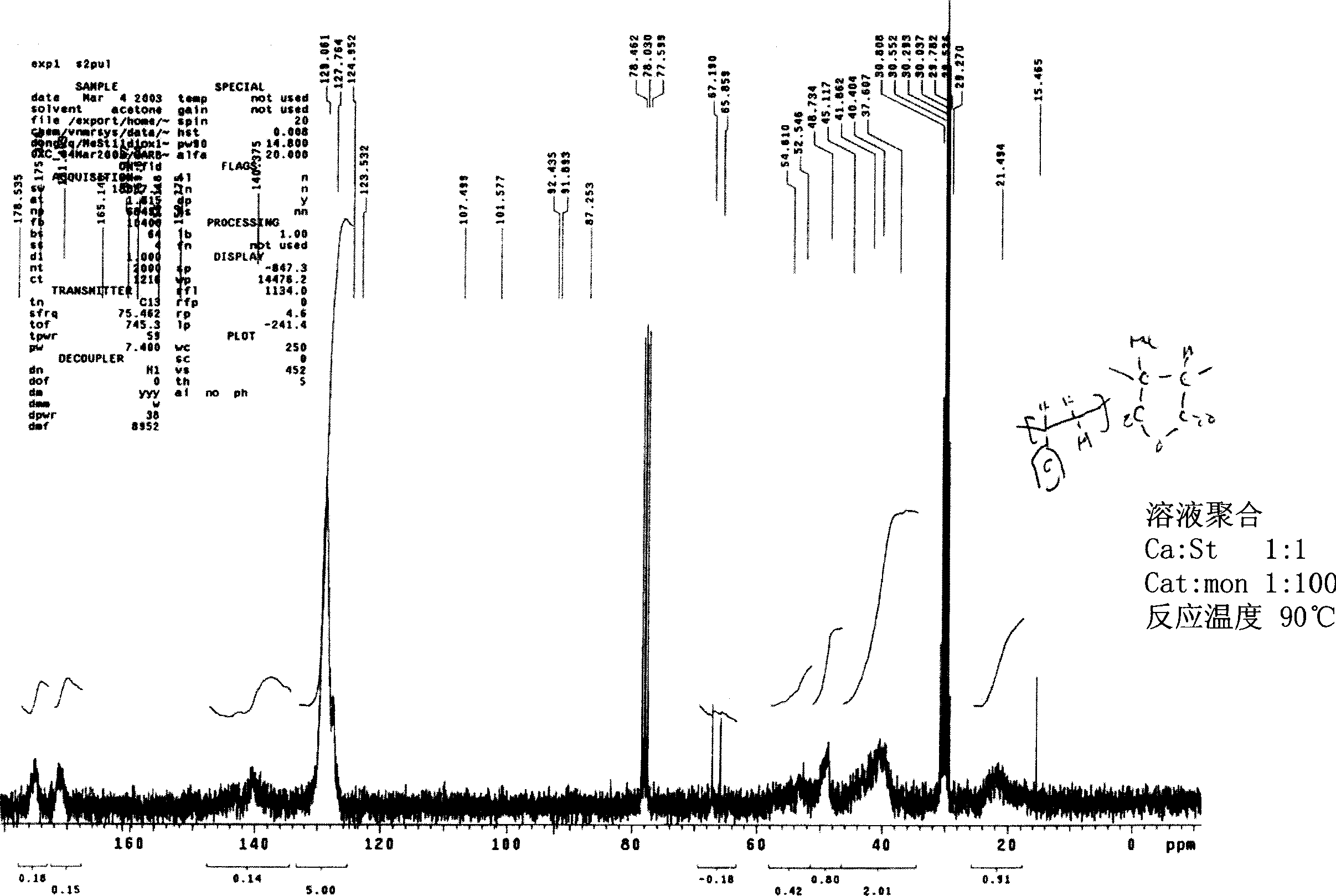

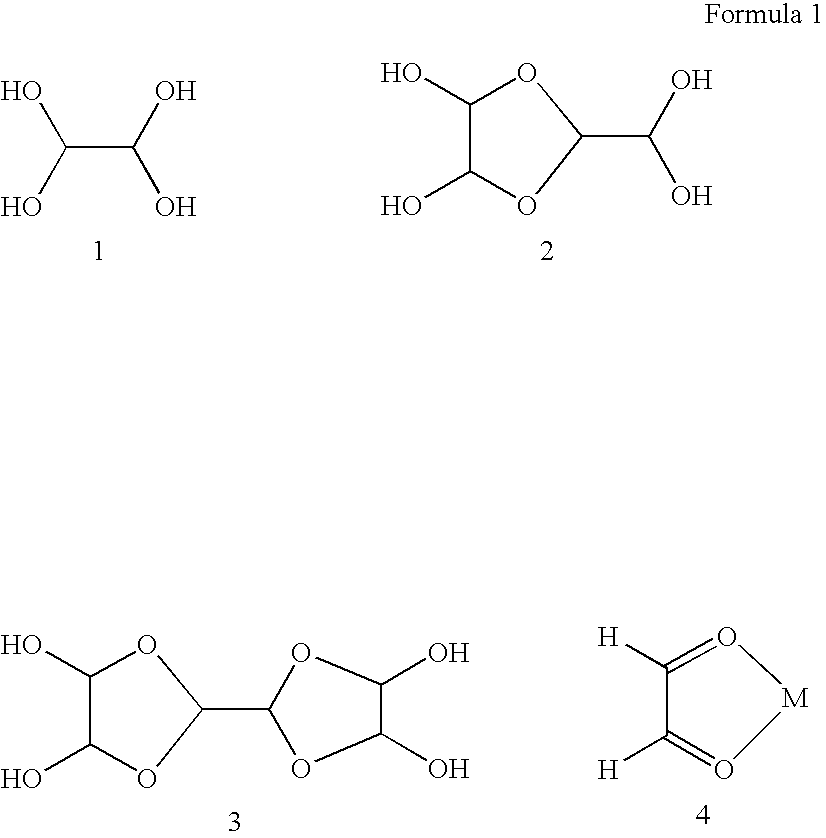

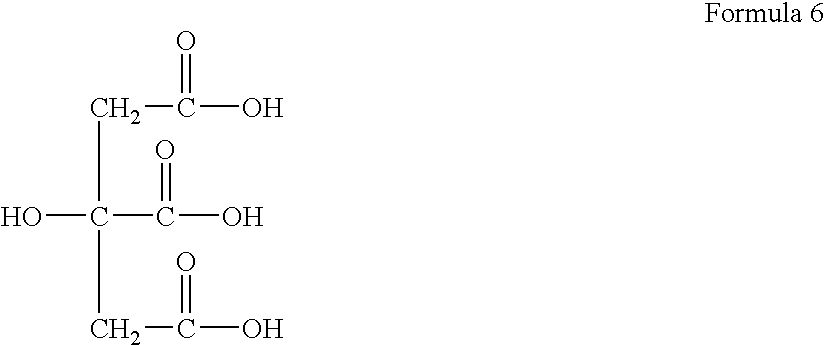

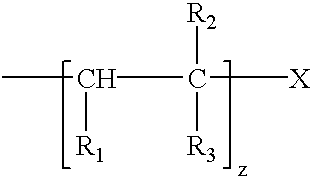

Anticreasing treating method for cotton fabrics with poly C (carboxylate acid) nano particles

The present invention relates to a method capable of utilizing poly (carboxylic acid) nano particles to implement anti-crease treatment of cotton fabric. Said invention designs and synthesizes polycarboxylic acid, and provides its property for raising crease resistance of cellulose fabrics. Said invention utilizes the emulsification and polymerization of vinyl monomer to prepare the described nano particles. Said nano particles can be used for raising durable press property of cotton fabrics.

Owner:ESQUEL ENTERPRISES LTD +1

Durable press/wrinkle-free process

InactiveUS20010001331A1Physical treatmentSynthetic resin layered productsWrinkle skinSilicone Elastomers

Cellulosic fiber-containing fabrics are made wrinkle resistant by a durable press wrinkle-free process which comprises treating a cellulosic fiber-containing fabric with formaldehyde, a catalyst capable of catalyzing the crosslinking reaction between the formaldehyde and cellulose and a silicone elastomer, heat-curing the treated cellulose fiber-containing fabric, preferably having a moisture content of more than 20% by weight, under conditions at which formaldehyde reacts with cellulose in the presence of the catalyst without a substantial loss of formaldehyde before the reaction of the formaldehyde with cellulose to improve the wrinkle resistance of the fabric in the presence of a silicone elastomeric softener to provide higher wrinkle resistance, and better tear strength after washing, with less treatment.

Owner:AMERICAN TEXTILE SOLUTIONS +1

Ramie finishing liquid and durable press finishing process thereof

The invention discloses ramie finishing liquid and a durable press finishing process thereof. The ramie finishing liquid comprises a polymer solution, a silicone softener, a fabric protector, PEG 400, and penetrant JFC. The durable press finishing process comprises the following steps: (1), immersing and tying a fabric in the finishing liquid for two times; (2), drying; (3), baking; (4), cooling to place; and (5), testing performance of the fabric. After finishing is performed on pure ramie fabrics and finished clothes through a synthesized fumaric acid polymer provided by the invention and by a certain fabric finishing process, the ironing-free effect is obvious, and the strength loss is also controlled; simultaneously, the application prospect of the ramie finishing liquid disclosed by the invention is also propelled and widened because the ramie finishing liquid is free from formaldehyde.

Owner:芜湖艾特纺织科技有限公司

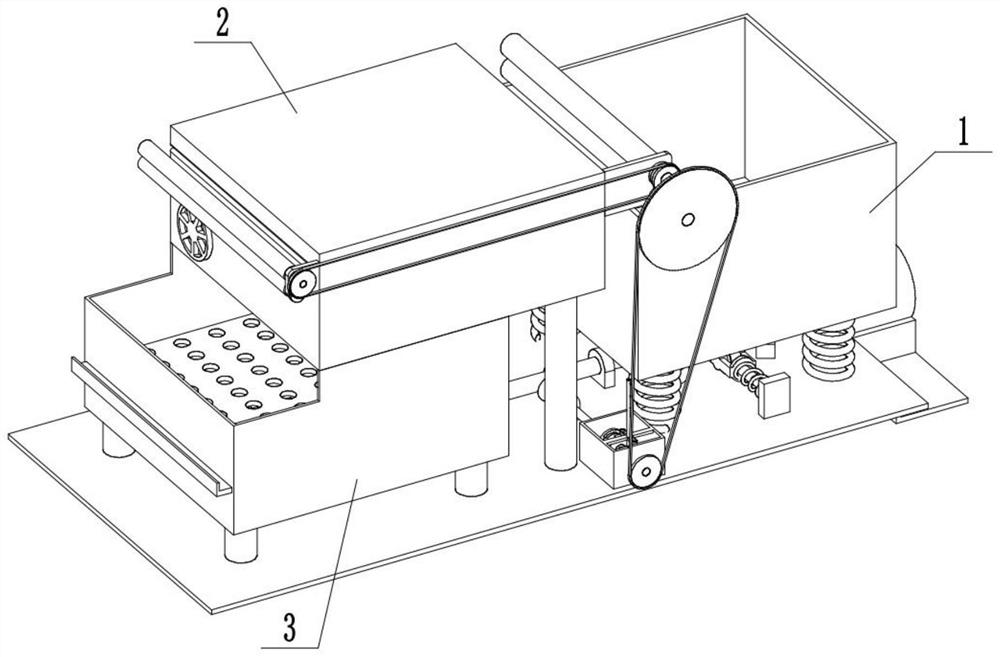

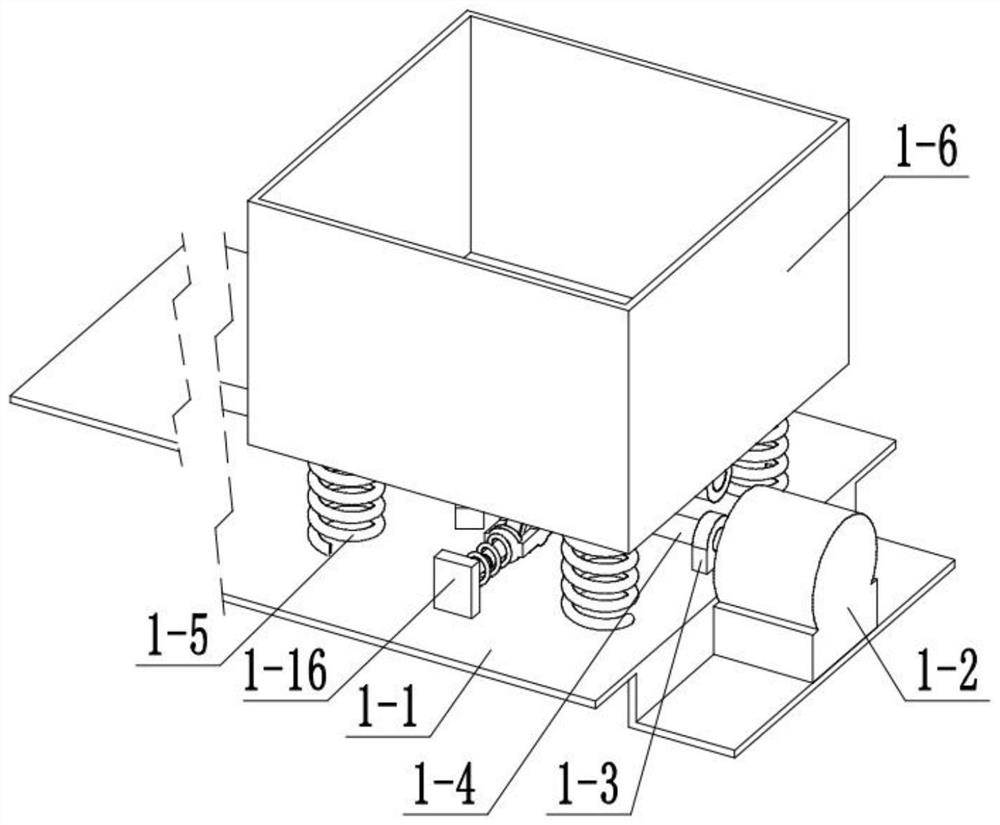

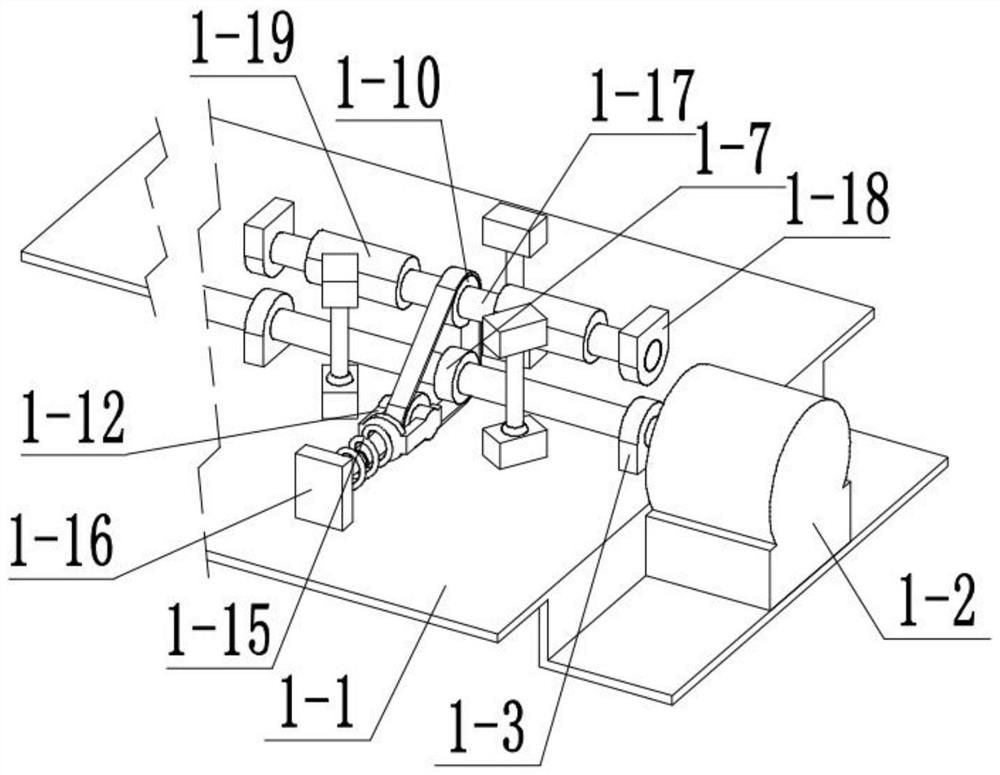

Fabric resin treatment equipment

InactiveCN111778663AGood for condensationControl rotationLiquid/gas/vapor treatment machines driving mechanismsLiquid/gas/vapor removal by squeezing rollersFiberPolymer science

The invention relates to the field of spinning, in particular to fabric resin processing equipment. Many excellent properties can be given to the fabric through resin treatment of the fabric; the fabric can obtain the performances of crease resistance, shrink resistance, non-ironing property, durable pressing property, flame retardance, good gloss, comfortable hand feeling and the like; traditional treatment equipment is treated by a plurality of pieces of equipment; the automation degree and the procedure fluency degree are too low. The fabric resin processing equipment solves the problems; the fabric is put into an oscillation box filled with resin; reciprocating vibration of the oscillation box promotes resin to be fully impregnated into fabric fibers; after impregnating is finished, the fabric is enabled to pass through a rolling roller, a fabric channel and a conveying roller; a heating column is started, the heating column emits heat to promote condensation of resin among fabricfibers, the rolling roller and the conveying roller are controlled to rotate, the fabric slowly moves in a drying chamber at a low speed, the fabric falls into the cleaning chamber after being dried,and resin residues are cleared away through reciprocating forward and reverse rotation cleaning.

Owner:单东霞

Durable press cellulosic fibrous substrates with improved physical properties

This invention is directed to a finishing method and composition for greatly increasing the tear strength and flex abrasion resistance of durable press cellulosic (including cotton) fabric, often greater than that of the untreated cellulosic fabric, without sacrificing its durable press properties.

Owner:NANO TEX

Non-ironing post-finishing technique for cotton fabric

The invention relates to a fabric finishing process, in particular to a non-ironing finishing process of a woven cotton fabric. The non-ironing post-finishing process includes the steps of fabric preparation, resin padding, tenter drying, baking, pre-shrinking, and rolling, wherein the fabric preparation includes gray fabric seaming, singeing, desizing, alkali mercerizing, dyeing, and drawing. The steps of web setting and liquid ammonia finishing, wherein, the step of resin padding includes two resin padding steps, and also includes a ventilation step after resin padding and before tenter drying. Due to the adoption of the above-mentioned technical solution, the contradiction between the anti-wrinkle performance of cotton fabric and the strength and wear resistance of the fabric is completely resolved, so that the hand feeling, air permeability and hygroscopicity of cotton fabric continue to maintain the characteristics of cotton fabric, and the anti-wrinkle performance is greatly improved. Improvement, formaldehyde residues are greatly reduced, and energy consumption and sewage discharge can also be reduced.

Owner:上海白玉兰染整有限公司

Fiber product-treating agents

InactiveUS6660044B2Easily impartedReliable configurationOrganic detergent compounding agentsWrinkle resistant fibresFiberChemistry

The present invention provides a fiber product-treating agent which can impart an excellent wrinkle-resistant effect and an excellent durable press effect to the fiber product capable of being heated and being hardly effected with not only during wearing but also after washing. That is, the present invention provides the treating agent for imparting the durable press configuration on a fiber product by a heating treatment with e.g. an iron, which comprises a specific amount of (i) two or more compounds forming mutually a crosslinked structure by heating and / or (ii) a compound forming a self-crosslinked structure by heating, and water, wherein the content of a nonvolatile matter is 0.01 to 30%.

Owner:KAO CORP

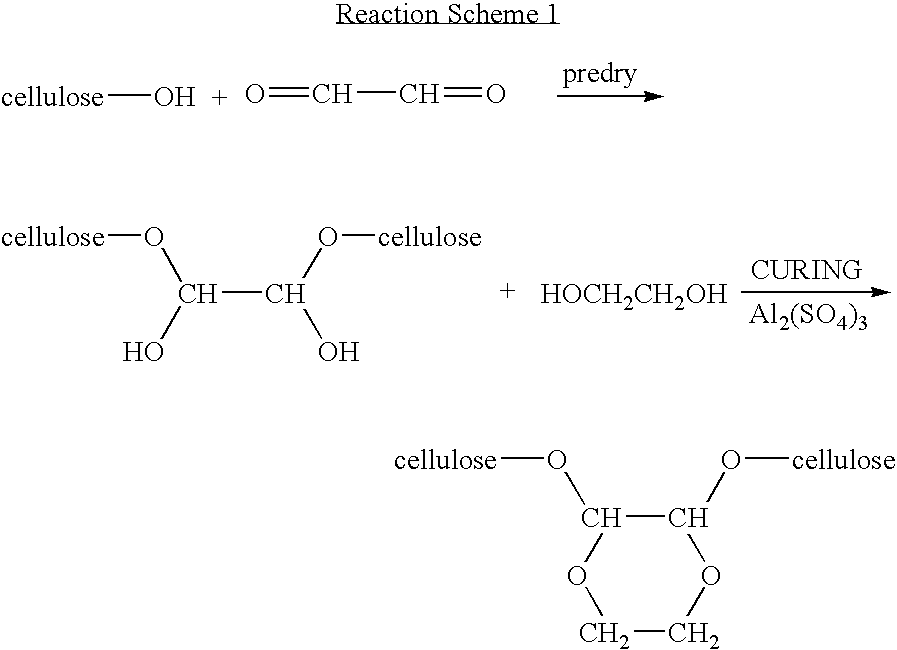

Formaldehyde-free durable press finishing agent

InactiveUS20050040360A1Give fabrics wrinkle-free performanceMinimize reduction in strength and whitenessPhysical treatmentWrinkle resistant fibresWrinkle skinHydrogen Sulfate

The present invention relates to a durable press finish composition, which contains a crosslinker for giving wrinkle-free performance to fabrics, a catalyst, and an additive allowing reductions in strength and whiteness of fabrics to be minimized. As the crosslinker, there is used glyoxal containing no formaldehyde. As the catalyst, there is used one selected from aluminum salt, magnesium salt, citric acid and a mixture thereof. As the additive, there is used sodium tetraborate, sodium peroxoborate, sodium chlorite, or sodium hydrogen sulfate.

Owner:GREEN TEX CHEM

Durable press treatment of fabric

A post mill or post manufacturing process for reducing wrinkle and crease problems in fabric articles is provided. The process involves the domestic or commercial laundry application of a phosphonate- and phosphinate-containing polycarboxylate cross-linking agent followed by at least partial curing of the cross-linking agent via the application of heat to the article. The present invention also includes an article of manufacture or product comprising the treatment composition, at least one container for the treatment composition and accompanying text instructing the user of the product on application of the treatment.

Owner:STRIKE INVESTMENTS

A kind of processing method of natural non-ironing pure cotton fabric

ActiveCN105350286BWith non-iron effectLittle impact on hand feelingBiochemical fibre treatmentDyeing processYarnPulp and paper industry

The invention discloses a processing method of a natural non-ironing pure cotton fabric. The whole processing process is as follows: yarn selection → yarn dyeing → sizing → weaving → singeing → desizing → mercerizing → liquid ammonia → biological enzyme treatment → drying → Non-ironing resin finishing → Pre-shrinking; the advantage is that the non-ironing grade of pure cotton fabrics processed by this method can reach above 3.0, realizing the application of silicone in the actual production of pure cotton non-ironing fabrics, and the obtained pure Cotton fabric has a non-ironing effect, does not contain formaldehyde, is environmentally friendly, and is harmless to the human body; in addition, the strong damage to the fabric during the processing process has little impact on the feel of the fabric, and the processed fabric feels very smooth and soft.

Owner:盛泰智造集团股份有限公司

Durable press finishing agent

InactiveCN102011312AReasonable formulaImprove work performanceFibre treatmentAluminium carbonateFibroin

Owner:袁建辉

Technique for fabricating shirts durable press and ironing

ActiveCN100340710CImprove stylingHeating/cooling textile fabricsTextile parts treatmentFiberCross-link

A process for preparing shirt of pressing free includes cutting as per patter, spraying edge loosing proof agent, spraying resin, pressing folded line, washing by water, drying and sewing. It the process, liquid ammonia + moist cross-linked plus material is applied for preparing shirt, line made by folding is treated by spraying resin on and by pressing it with certain pressure to form the line to be permanent folded line for pressing free.

Owner:LUTAI TEXTILE

Moisture-controlled curing durable press process

InactiveUS6121167ABetter water absorbencyLess strength-lossUltra-high-frequency fibre heatingRadio/micro wave fibre treatmentCross-linkCellulose fiber

A wrinkle-free / wrinkle-resistant cellulosic fiber-containing fabric which retains tensile-, tear- and abrasion-strength due to the reduction of hydrogen bonding in the fabric is obtained by a process which comprises pretreating the fabric with the processes to reduce and control hydrogen bonding in the fabric, and treating a cellulosic fiber-containing fabric with aqueous formaldehyde and a catalyst in liquid form capable of catalyzing the cross-linking reaction between the formaldehyde and cellulose. Such cross-linking is carried out by heat-curing the cellulosic fiber-containing fabric under saturated steam with or without high pressure and / or infrared or far-infrared radiation and / or high frequency (induction) radio waves. Under such conditions the formaldehyde reacts with cellulose in the presence of catalyst with no substantial loss of formaldehyde prior to said reaction so as to improve the wrinkle-free or wrinkle-resistant property of the fabric without substantial strength loss. This is accomplished by maintaining the moisture level during curing high enough to prevent detrimental increase in hydrogen bonding above the reduced level of hydrogen bonding by the prior process of liquid ammonia treatment and / or aqueous wetting. Such precise control of moisture and formaldehyde at curing is also achieved by superheated steam cure, moist-cure, which controls the same level of moisture throughout the curing process, or mild-cure with steam lower than 212 DEG F. (100 DEG C.).

Owner:OKAMOTO HIROHARU

Durable press finishing agent

A durable press finishing agent comprises components in parts by mass as follows: 15-25 parts of polyurethane resin, 25-35 parts of polyhydric alcohol, 3-8 parts of a metal-salt catalyst, 1-5 parts of poly-methylsiloxane silicone bodies and 20-35 parts of water, wherein the metal-salt catalyst adopts basic aluminum chloride or aluminum chloride hexahydrate; and polyhydric alcohol adopts ethylene glycol or diethylene glycol. The provided durable press finishing agent doesn't take formaldehyde as a resin cross-linking agent for synthesizing raw materials, no formaldehyde is left over when the durable press finishing agent is used for processing clothes, and the use is safe.

Owner:NANTONG CITY TONGZHOU DISTRICT DADA HEMP TEXTILE

Enhanced fabric comprising substrates and process to provide same

InactiveCN1398309AImprove performanceImprove water absorptionLight resistant fibresWrinkle resistant fibresHydrogenPolyethylene glycol

The present invention relates to substrate comprising fabric, the substrate treated with a composition comprising: a) an aldehyde, said aldehyde a mono-functional aldehyde, a di-functional aldehyde, or mixtures thereof; b) a polyethylene glycol having the formula: R(OCH2CH2)xOR wherein R is hydrogen, C1-C4 alkyl, and mixtures thereof, and the index x has a value of 15 to 45; c) an acid catalyst; and d) optionally, a surface modifying agent; wherein the treated substrate has at least three enhanced fabric benefits, said benefits selected from the group consisting of: i) durable press; ii) hand feel; iii) anti-abrasion; iv) anti-shrinkage; and v) anti-yellowing. The present invention further relates to a system and a process for providing a substrate having the above described enhanced fabric benefits.

Owner:STRIKE INVESTMENTS

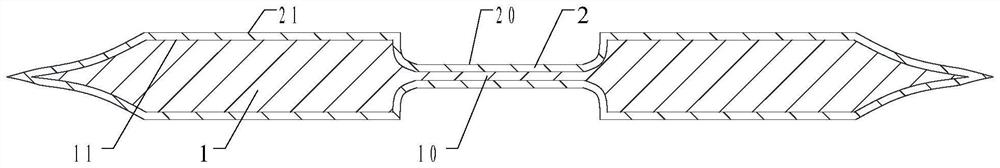

Durable press-fit cleaning block and production process thereof

PendingCN114209259APlay the role of fixing the filling coreCarpet cleanersFloor cleanersMechanical engineeringIndustrial engineering

The invention discloses a durable press-fit cleaning block which comprises a cleaning block base body composed of a filling core and an outer cover wrapping the outer side of the filling core, and the filling core and the outer cover are formed in a press-fit mode. The filling core comprises a core body inner concave part and a core body outer convex part; the outer cover comprises a cover body inner concave part and a cover body outer convex part which are respectively arranged corresponding to the core body inner concave part and the core body outer convex part; and the outer cover is in press fit with the inner concave part of the core body of the filling core at the inner concave part of the cover body. According to the durable press-fit cleaning block with the structure, part of the filling core is adhered to the outer cover through the press-fit cleaning block base body, the function of fixing the filling core is achieved, and meanwhile the press-fit pattern (Logo) can also achieve the effects of attractiveness and publicity.

Owner:日照美添生活用品有限公司

Preparation method of fabric hand-improving non-ironing resin

ActiveCN108892762BEasy to prepareLow formaldehyde residueWrinkle resistant fibresGrip property fibresAlcoholProcess engineering

The invention belongs to the technical field of textile auxiliary agents and specifically relates to a preparation method for a fabric hand feel improved type easy-care resin. The preparation method comprises the following steps: successively adding glyoxal, formaldehyde and urea into a reactor to react under certain conditions; adding alcohols materials and organic amines materials for reacting;and finally, performing reduced pressure distillation, cooling and then discharging, thereby acquiring an end product. The preparation method for the easy-care resin provided by the invention is simple; the fabric after the easy-care treatment with the resin prepared according to the invention has high easy-care level and less residual formaldehyde; compared with the fabric finished with common 2Dresin, the fabric feels soft and smooth, has the characteristics of durability and pressing resistance, overcomes the defect of hard easy-care fabric and promotes the quality of the end product of clothing.

Owner:ZIBO LURUI FINE CHEM CO LTD

Enhanced fabric comprising substrates and process to provide same

The present invention relates to substrate comprising fabric, the substrate treated with a composition comprising: a) an aldehyde, said aldehyde a mono-functional aldehyde, a di-functional aldehyde, or mixtures thereof; b) a polyethylene glycol having the formula: R(OCH2CH2)xOR wherein R is hydrogen, C1-C4 alkyl, and mixtures thereof, and the index x has a value of 15 to 45; c) an acid catalyst; and d) optionally, a surface modifying agent; wherein the treated substrate has at least three enhanced fabric benefits, said benefits selected from the group consisting of: i) durable press; ii) hand feel; iii) anti-abrasion; iv) anti-shrinkage; and v) anti-yellowing. The present invention further relates to a system and a process for providing a substrate having the above described enhanced fabric benefits.

Owner:STRIKE INVESTMENTS

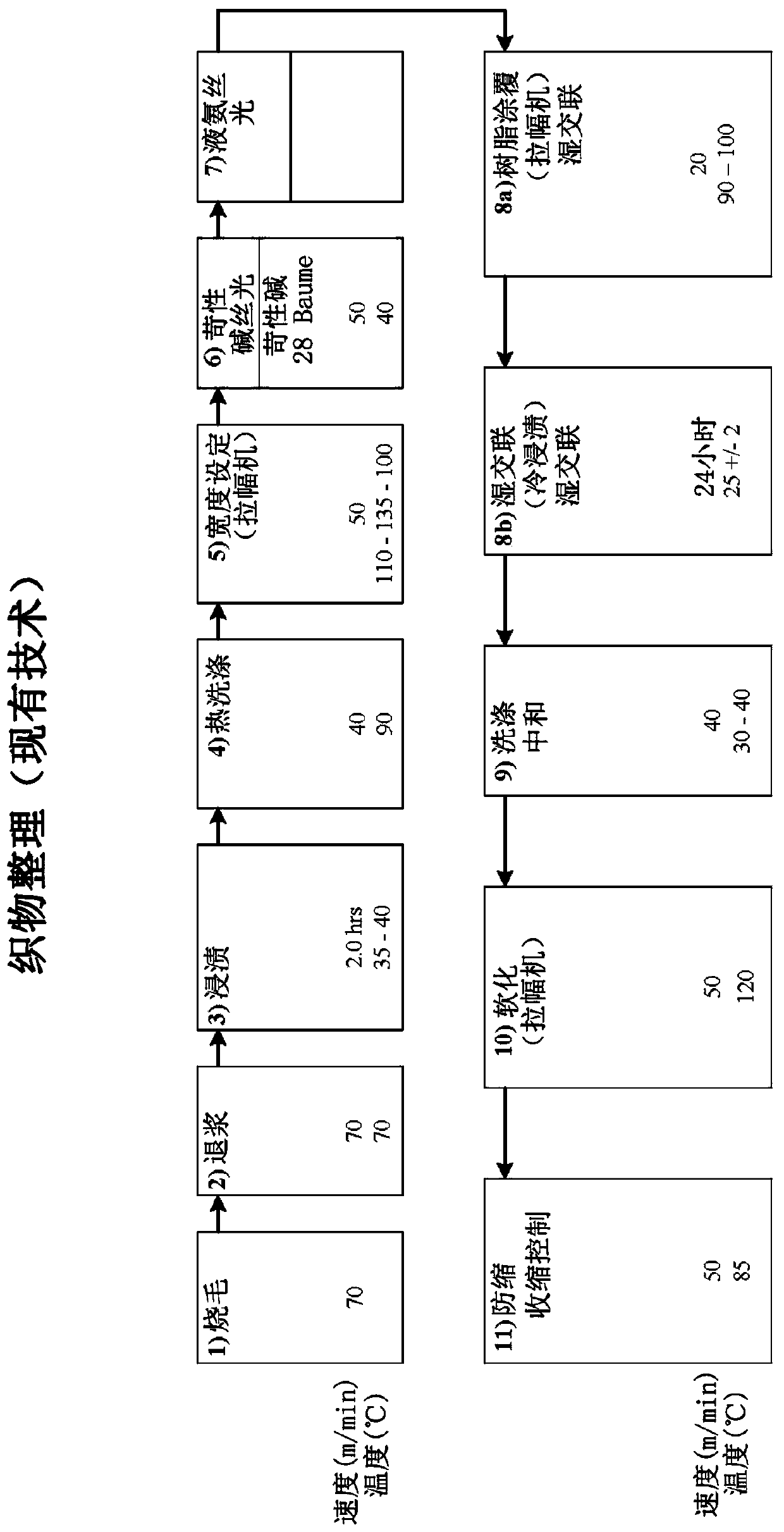

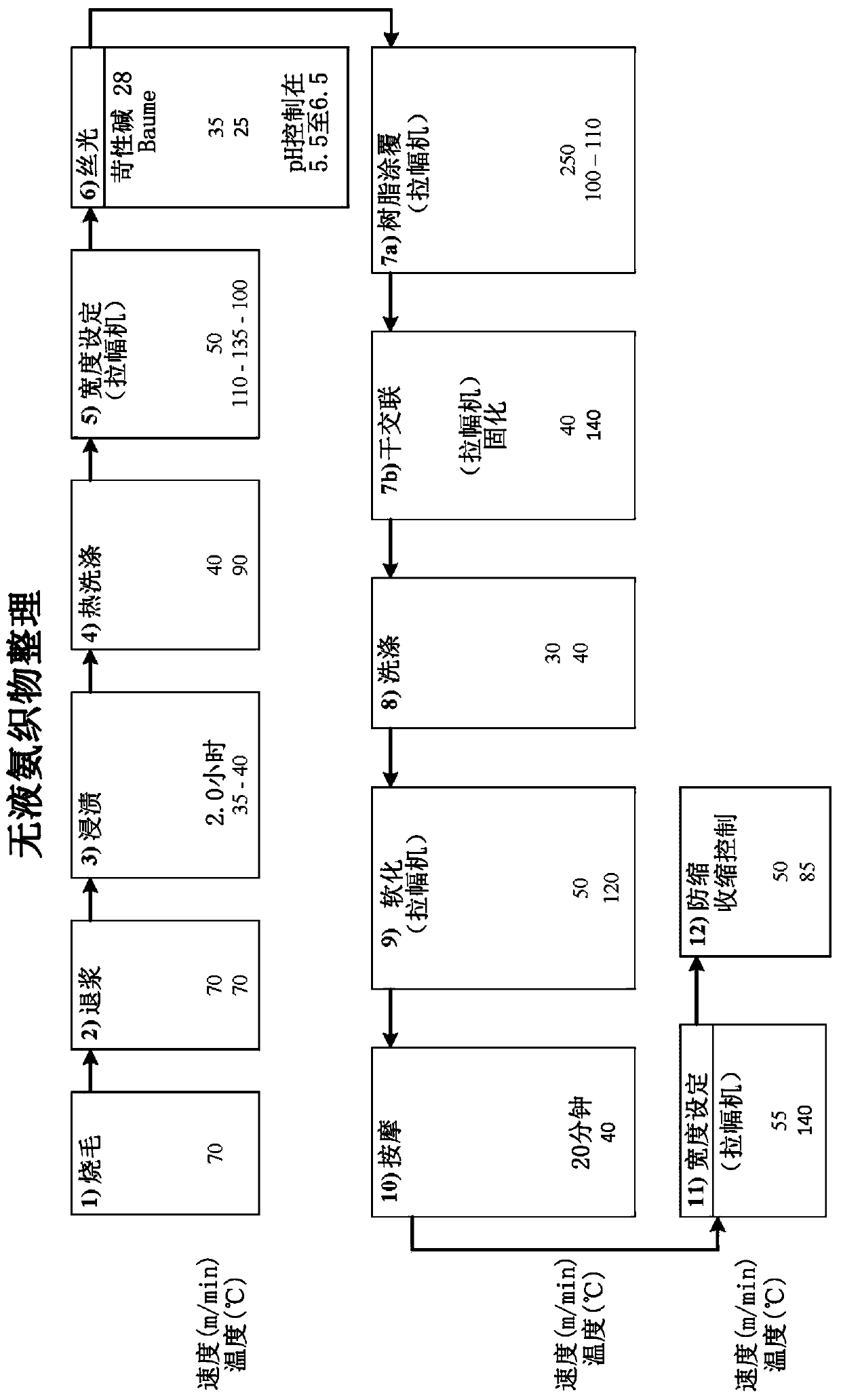

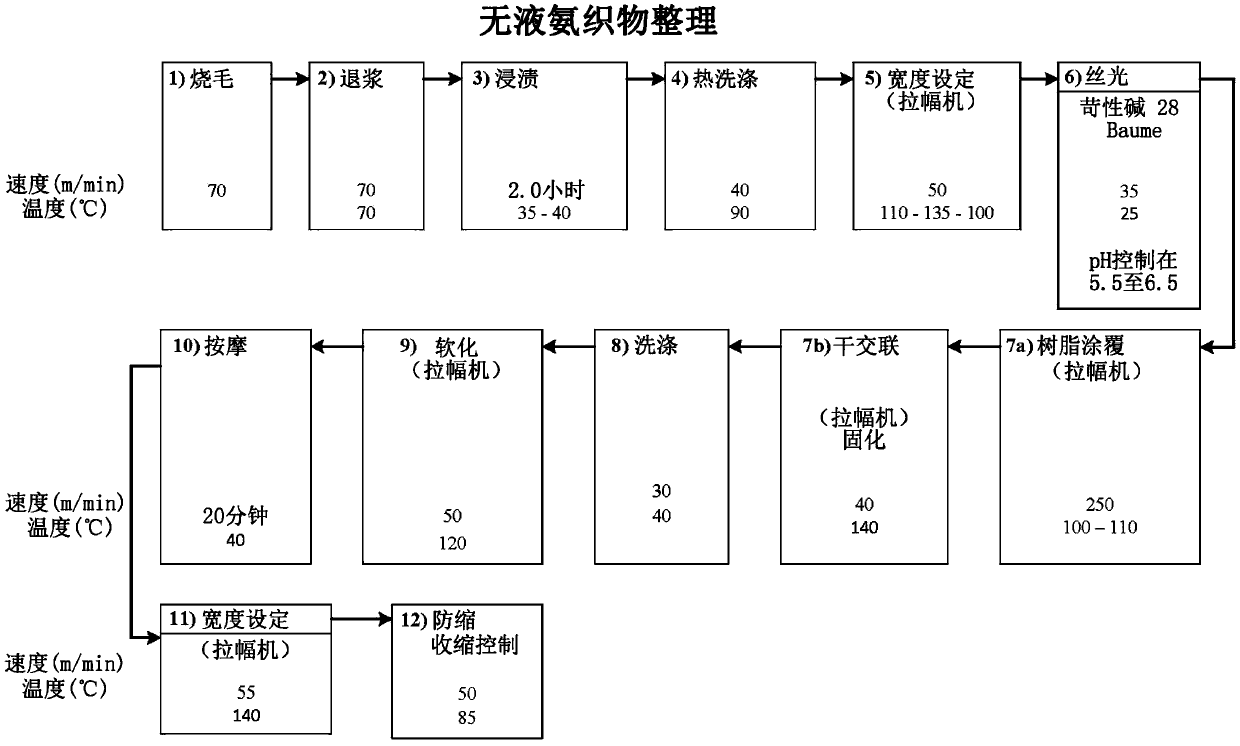

Non-iron fabrics and garments, and a method of finishing the same

The present disclosure relates to a method of finishing non-iron fabrics, and the non-iron fabrics made by this method, This method includes the steps of mercerizing a fabric without liquid ammonia; curing the fabric by applying a low temperature, low formaldehyde curing resin and dry cross linking it; and massaging the fabric using an air blast textile finishing machine. The non-iron fabrics (andgarments) produced according to this method have an improved durable press rating and reduced formaldehyde content or are even formaldehyde free when compared to similar products finished according to conventional liquid ammonia moisture-cure processing.

Owner:PVH +4

A kind of non-ironing finishing cross-linking reaction buffer and its application

ActiveCN104674548BReduce the degree of reactionGood storage stabilityVegetal fibresCelluloseNitrogen

The invention relates to a noniron finishing crosslinking reaction buffering agent and an application thereof. The buffering agent is formed by combining one or more of 1,4-diazabicyclo[2,2,2]octane, 1,8-diazabicyclo[5,4,0]undec-7-ene and ammonium hydroxide. The noniron finishing crosslinking reaction buffering agent is added to a noniron finishing solution containing a crosslinking agent, a catalyst and a softener and plays a role in buffering the Lewis acid catalyst at the temperature lower than 130 DEG C, the degree of reaction of the crosslinking agent with cellulose is obviously decreased, the buffering agent can be applied to a noniron delayed-curing reaction system, the storage stability of a sensitized fabric is improved, and the final noniron effect is slightly affected.

Owner:DONGHUA UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com