Ramie finishing liquid and durable press finishing process thereof

A technology of ramie fiber and finishing solution, which is applied in the field of printing and dyeing technology, can solve the problems of affecting the health of operators, stimulating human skin, respiratory tract mucous membrane, and inducing skin cancer, etc., achieving strong loss control, significant effect, and improving application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] 1. Test part:

[0040] The specific embodiment of the present invention comprises four parts such as the synthesis of polymer, the research of structure and fabric application finishing process and fabric performance test, involves equipment and material and includes:

[0041] 1. Main instruments and equipment

[0042] ① constant temperature bath;

[0043] ②Magnetic stirrer or electric stirrer;

[0044] ③Electric rolling car;

[0045] ④Baking machine;

[0046] ⑤Universal strength machine;

[0047] ⑥ Wrinkle recovery angle measuring instrument;

[0048] ⑦Tear strength machine;

[0049] ⑧PH meter;

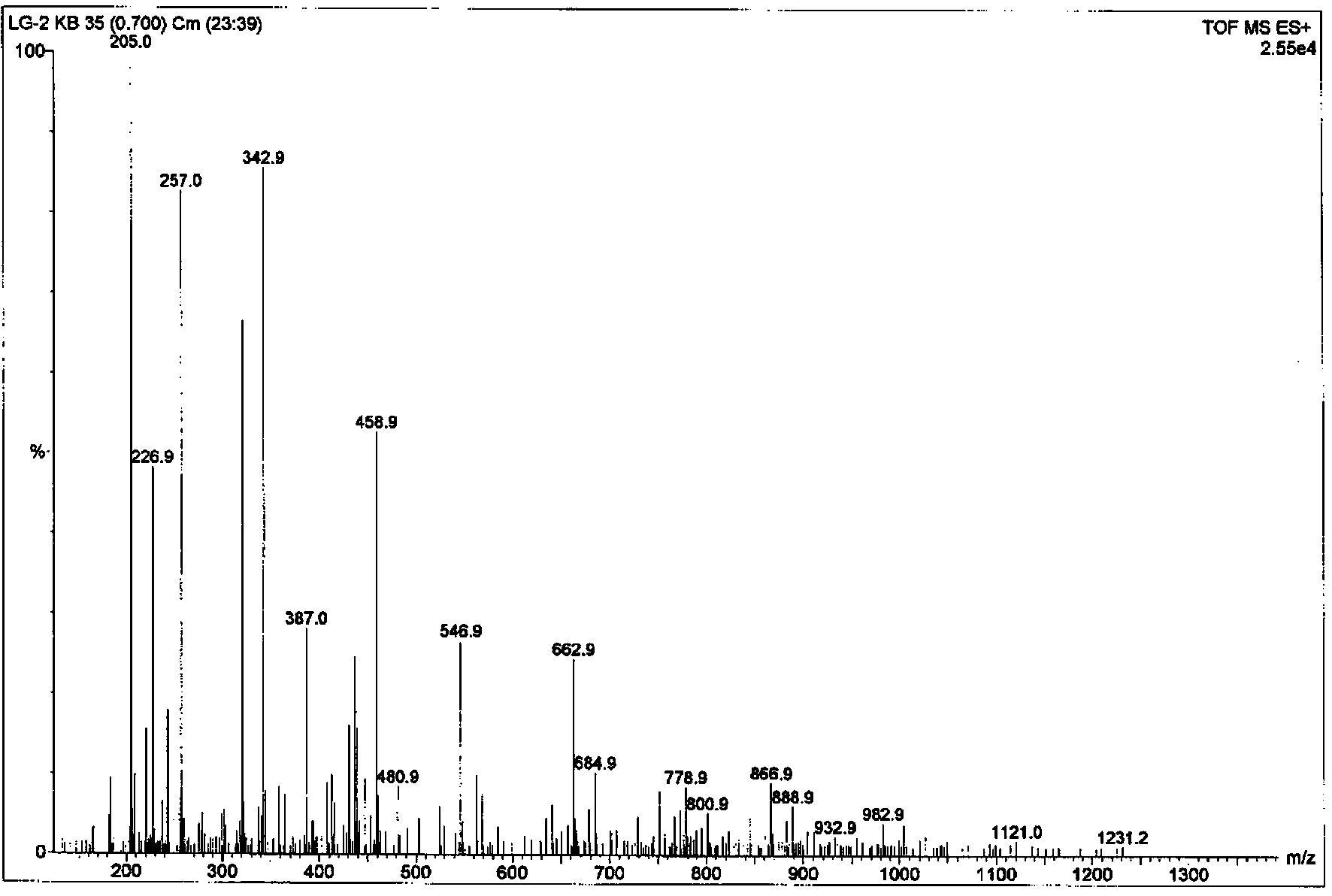

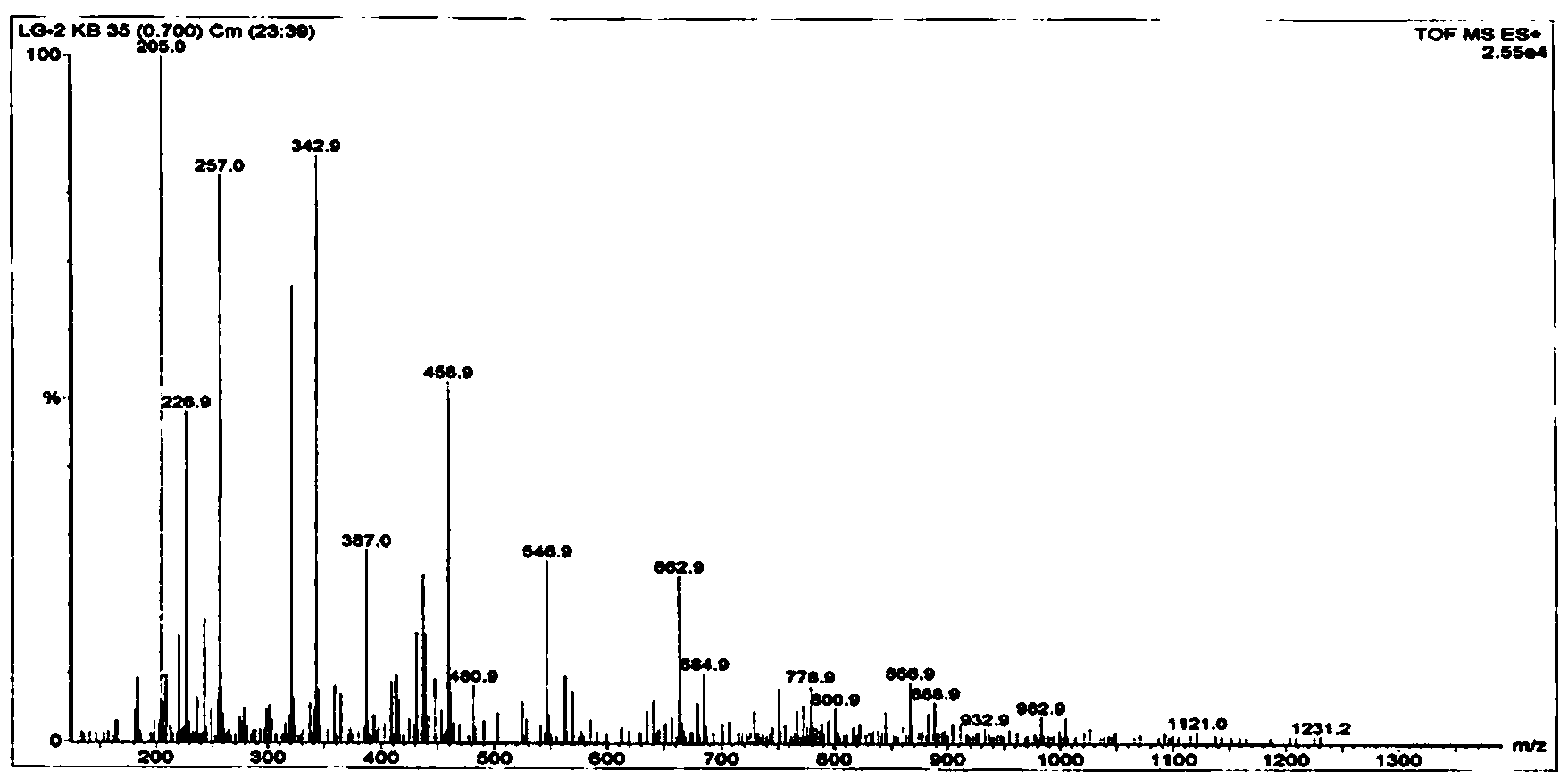

[0050] ⑨LCT chromatography-mass spectrometer (Micromass);

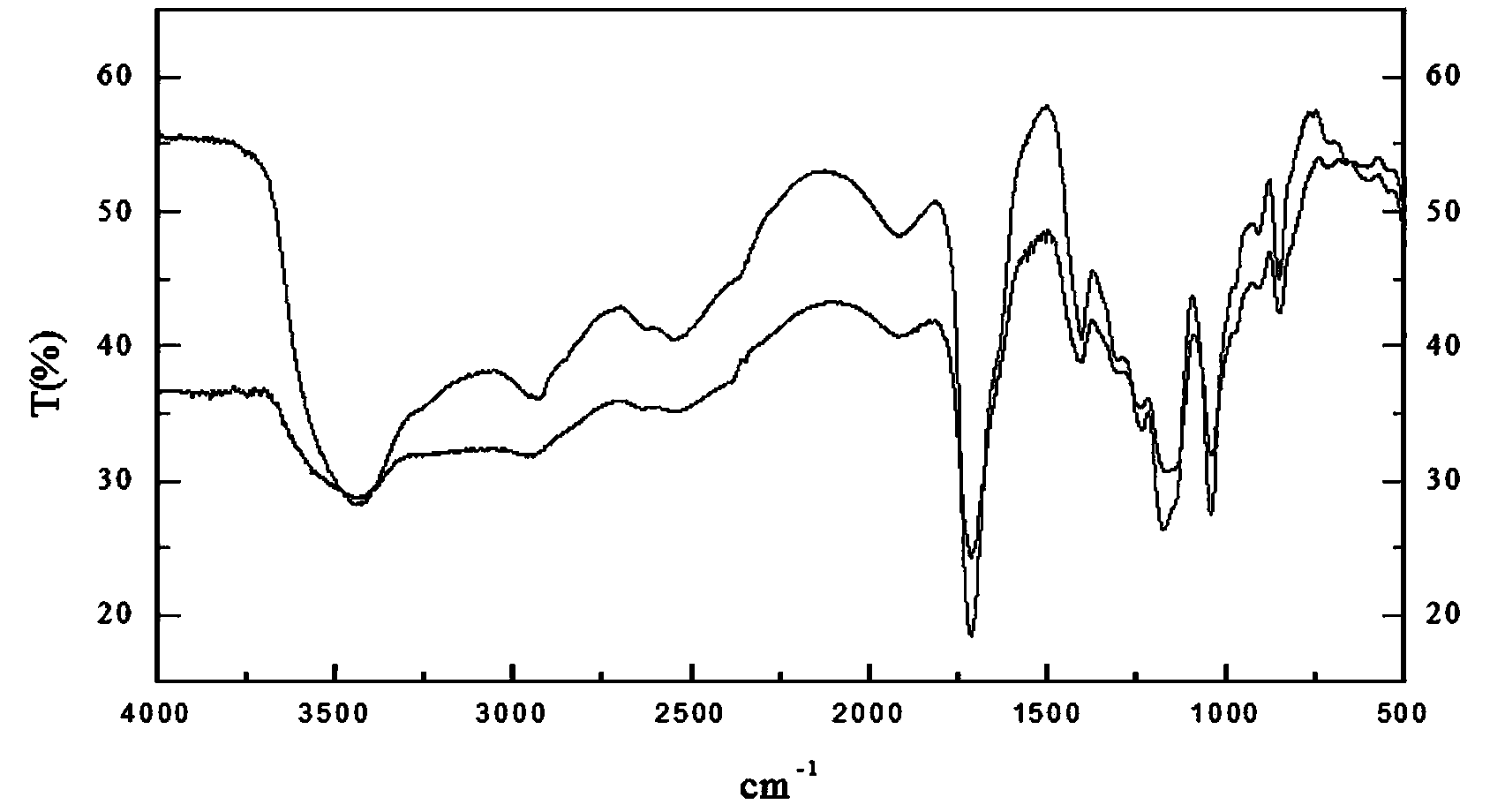

[0051] ⑩Fourier transform infrared spectrometer (PE company).

[0052] 2. Main material

[0053] ①Maleic acid (maleic acid);

[0054] ② fumaric acid (fumaric acid);

[0055] ③ peroxide;

[0056] ④ Desalted water (conductivity ≤ 10 micro Siemens / cm, pH = 5.0-8.5, SiO 2 ≤0.2mgSiO2 2 / L);

[0057] ⑤ Sil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com