Vertical type steam iron

A steam and vertical technology, used in hand irons, iron pads, washing devices, etc., can solve the problems of coexistence of liquid water and steam, reduced steam efficiency, and falling liquid water, etc. Improve filtration efficiency and improve the effect of ironing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0085] Preferred embodiments of the present invention will be described below with reference to the drawings, in which the same reference numerals are assigned to the same parts as conventional ones, and detailed description thereof will be omitted.

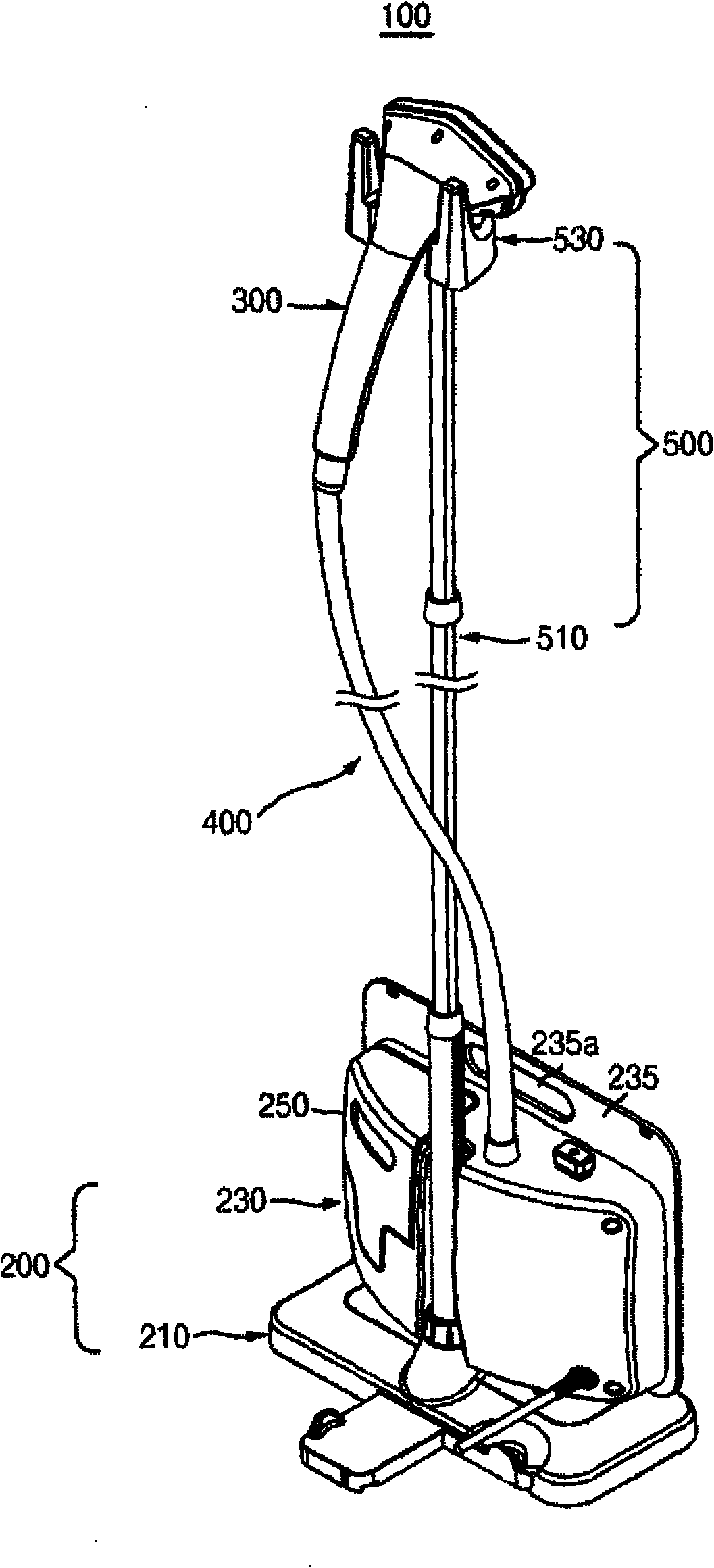

[0086] figure 1 is a perspective view showing the appearance of an upright steam iron according to a preferred embodiment of the present invention.

[0087] Such as figure 1 As shown, the upright steam iron 100 according to the preferred embodiment of the present invention includes a base assembly 200 , a nozzle assembly 300 and a hose 400 connecting the base assembly 200 and the nozzle assembly 300 . Moreover, the upright steam iron 100 may further include a shelving assembly 500 for shelving the nozzle assembly 300 for easy storage and use. Of course, when the shelving assembly 500 is not provided, it can also be shelved in a place where it can be hung around for storage.

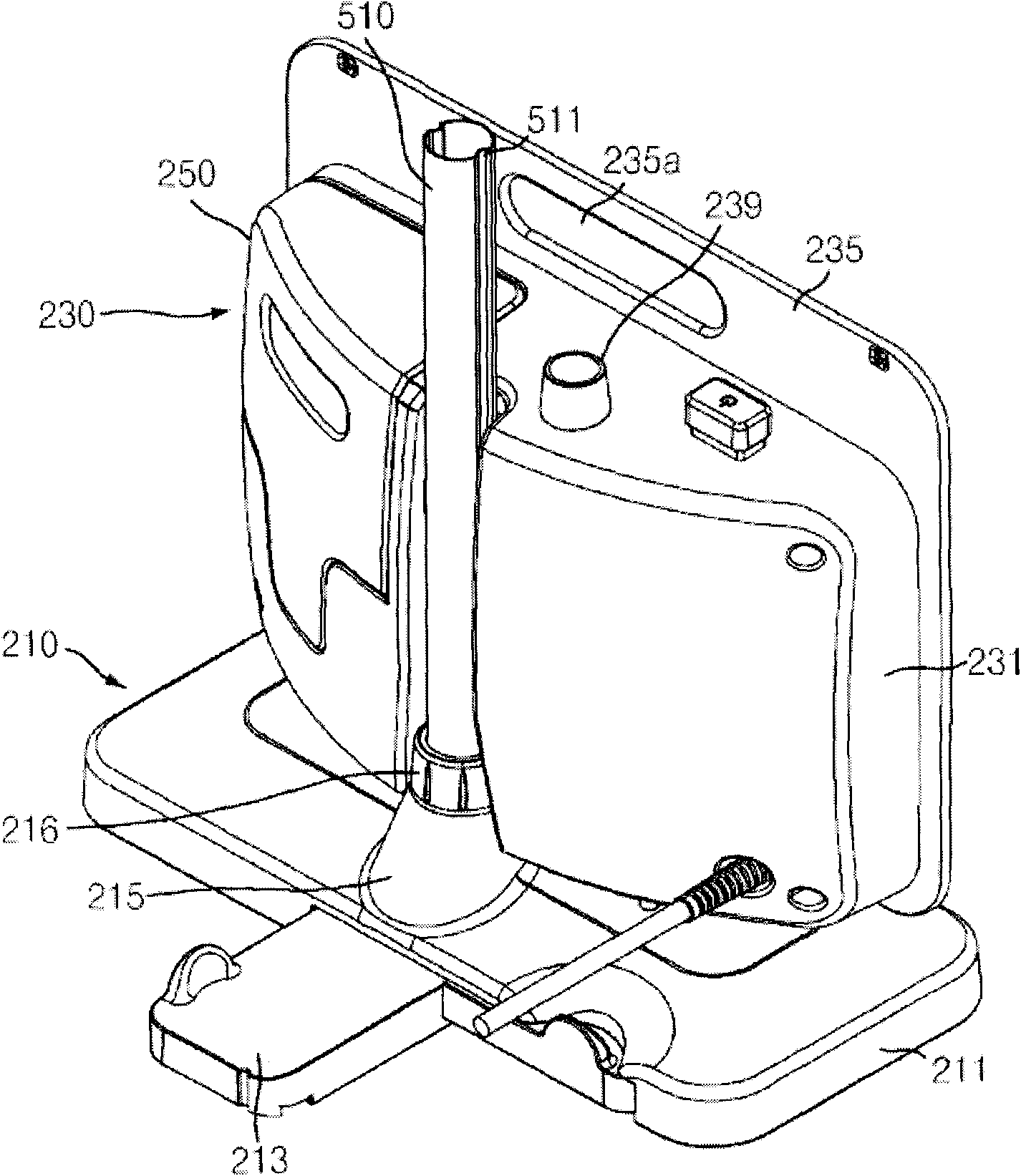

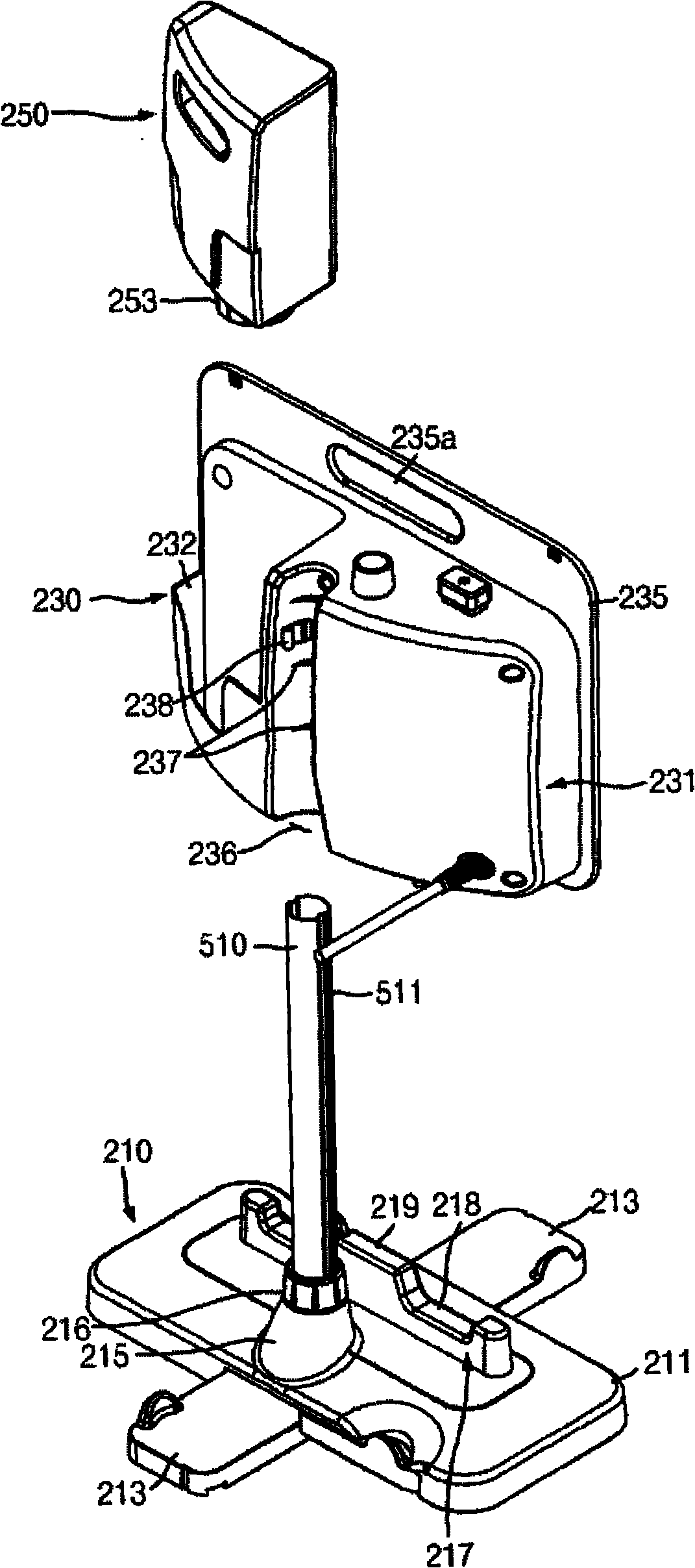

[0088] Such as figure 2 and image 3 As shown,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com