Anticreasing treating method for cotton fabrics with poly C (carboxylate acid) nano particles

A nanoparticle, cotton fabric technology, applied in fiber processing, textiles and papermaking, etc., can solve problems such as color enhancement, unsatisfactory performance, loss of fabric strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

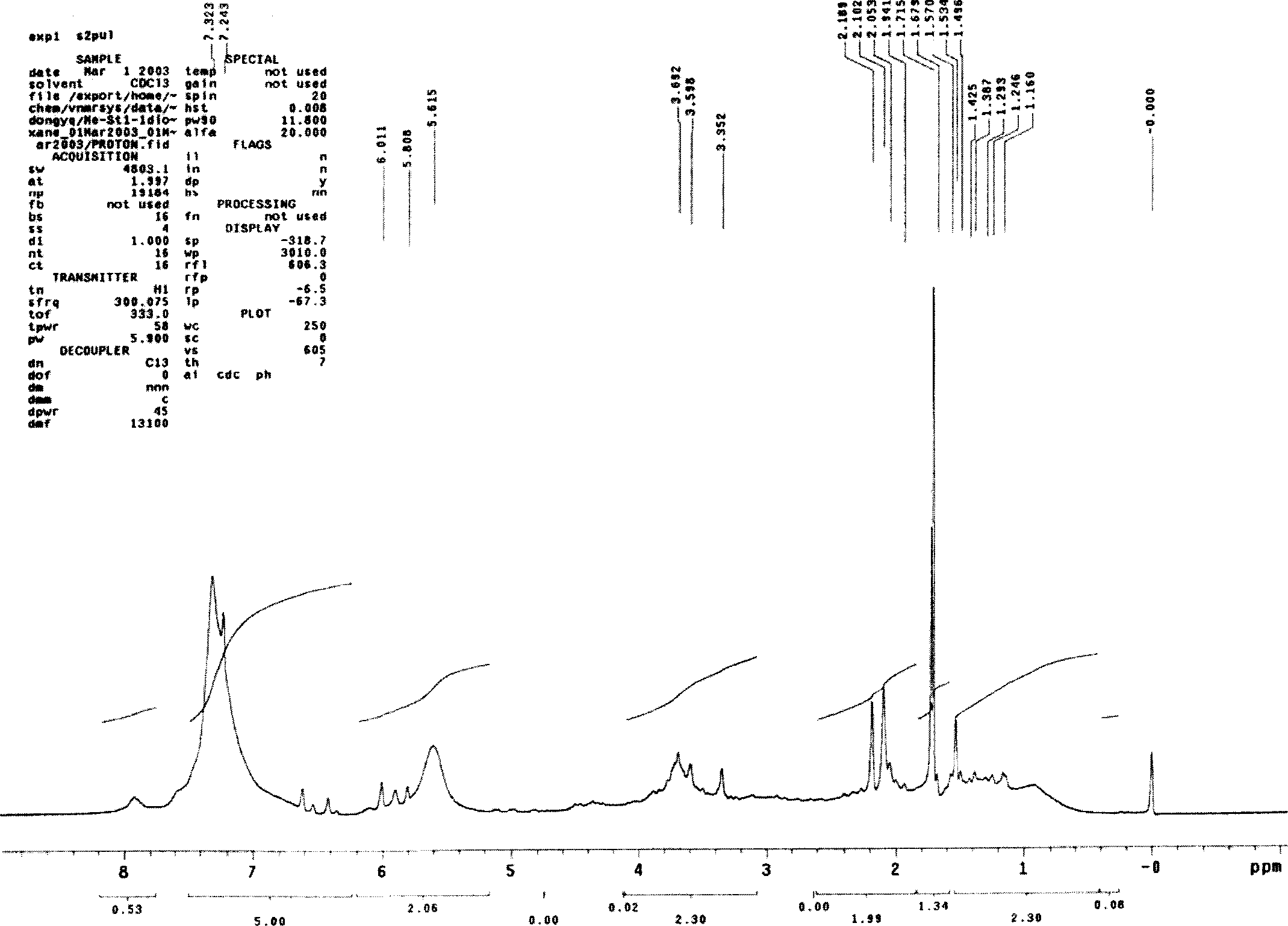

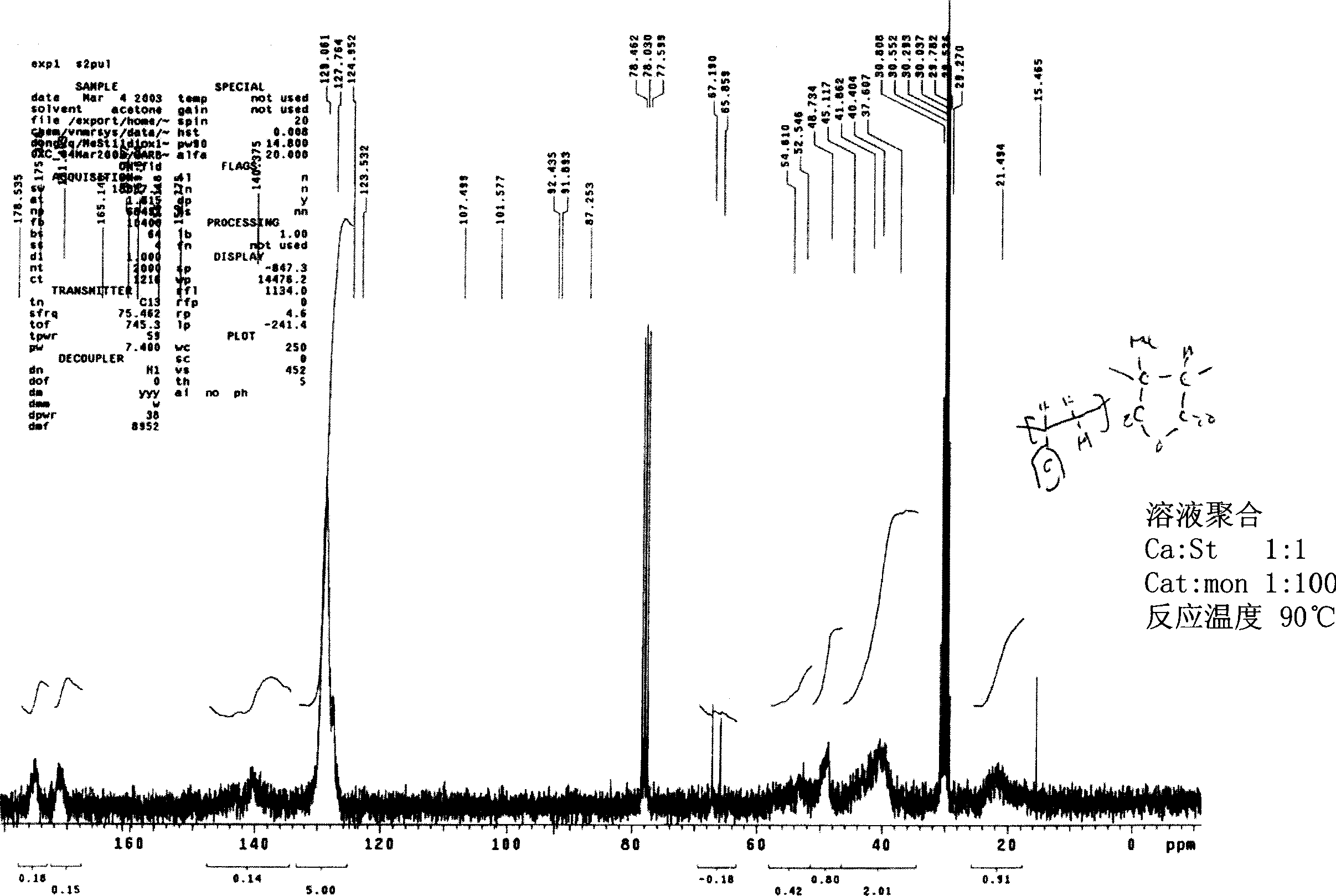

[0055] emulsion polymerization

[0056] Polymerization is accomplished in an aqueous medium. In a typical implementation, at N 2 6 ml of deionized water, 0.02 g of SDS and 0.01 mol of monomer 1 were stirred under atmosphere for 30 min. After further stirring for 5 minutes at 60 °C, the initiator (0.0001 mol Na 2 S 2 o 8 ). in N 2 Polymerization was carried out at 60°C for 24 hours under air.

Embodiment 2

[0058] emulsion polymerization

[0059] except in N 2 0.01 mol of monomer 2 was stirred under gas for 30 minutes and the process of Example 1 was repeated. Add the initiator (0.003mol Na 2 S 2 o 8 ). in N 2 Polymerization was carried out at 90°C for 24 hours under air.

Embodiment 3

[0061] emulsion polymerization

[0062] except in N 2 0.01 mol of monomer 4 was stirred under gas for 30 minutes and the process of Example 1 was repeated. Add the initiator (0.004mol Na 2 S 2 o 8 ). in N 2 Polymerization was carried out at 80°C for 24 hours under air.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com