Patents

Literature

87results about How to "Reduce the degree of reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

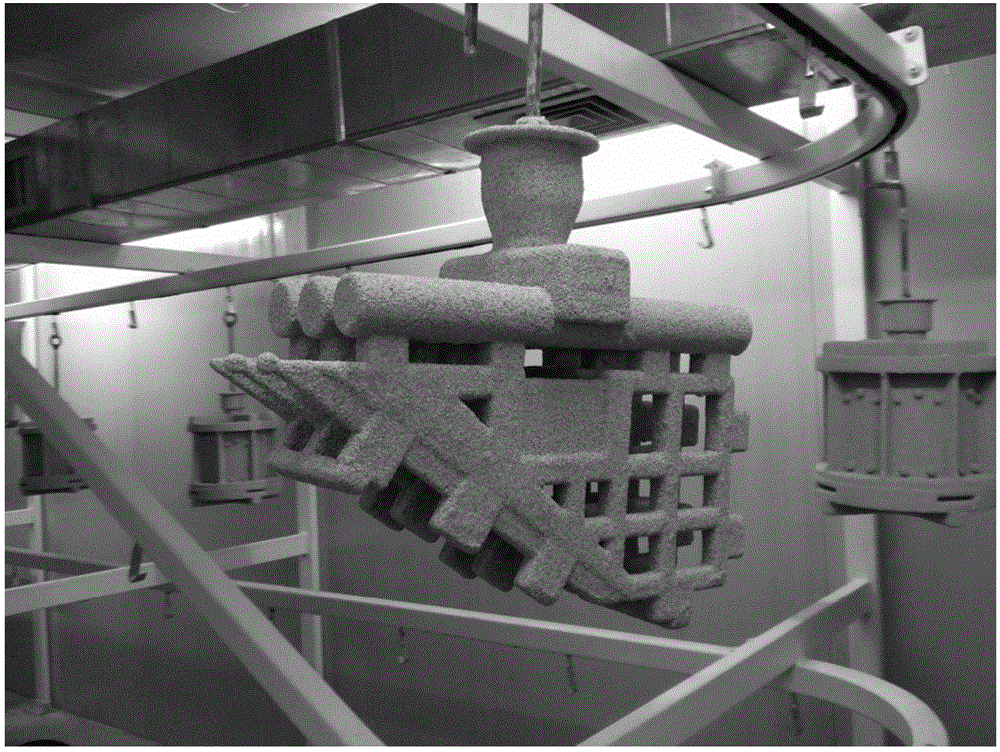

Preparation method of boron nitride ceramic shell for titanium and titanium alloy precision casting

InactiveCN1876272AReduce the degree of reactionReduce thicknessFoundry mouldsFoundry coresWaxTitanium

The invention relates to a method for preparing boron nitride ceramic molding shell, which is used for titanium and titanium alloy accurate casting. It belongs to field of shaping thermo-stable ceramic molding shell material. The invention comprises following steps: preparing coating slurry with refined boron nitride powder and binding agent zirconium acetate or silica sol according to proportion by weight of 3:1; immersing wax tank into said coating slurry to make slurry be coated on wax mold evenly; spreading sand, spreading boron nitride powder on wax mold; repeating said dip-coating and sand-spreading steps for 1 to 2 times after drying and hardening; preparing slurry with binding agent and mullet powder, back coating with prepared slurry for 3-5 times; drying, demolding, and sintering wax mold with several coating layers under condition of 900-1100 Deg. C and nitrogen; getting boron nitride ceramic molding shell material.

Owner:SHANGHAI UNIV

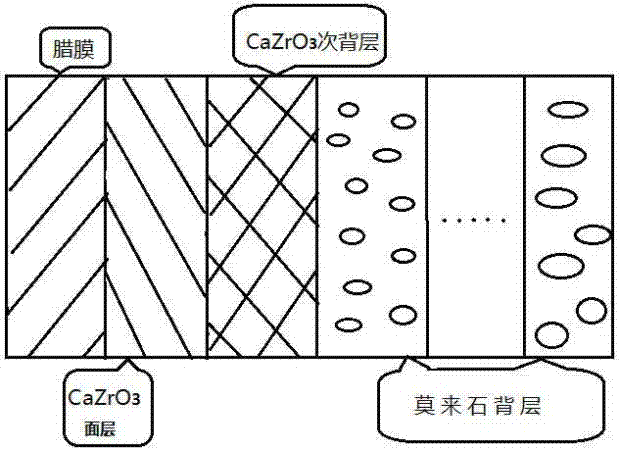

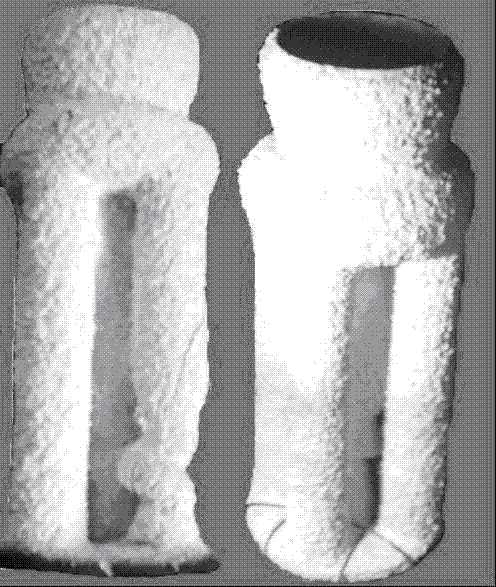

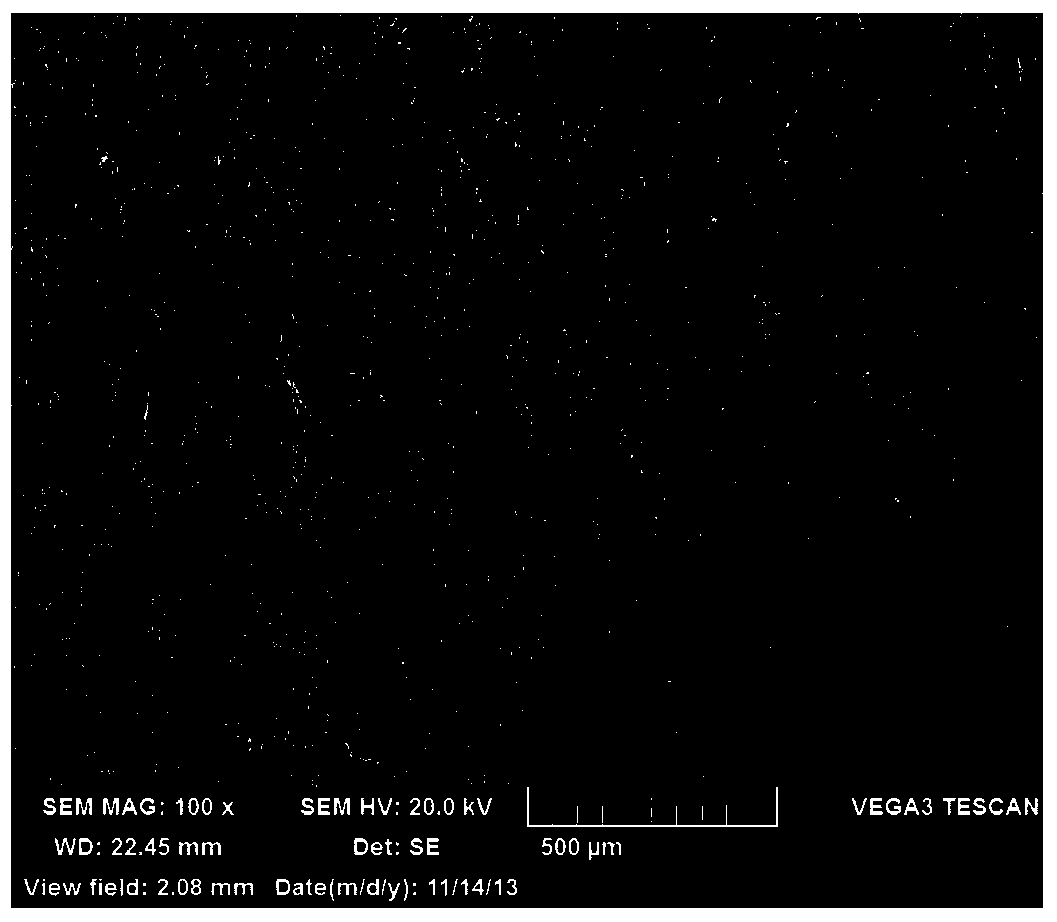

CaZrO3 mold shell used for titanium and titanium alloy precision casting and preparation method

ActiveCN103071764AHighlight substantiveSignificant progressFoundry mouldsFoundry coresZirconateTitanium

The invention discloses a CaZrO3 mold shell used for titanium and titanium alloy precision casting and a preparation method, which is characterized in that calcium zirconate is taken as a filling material, binders which are not reacted with a titanium alloy such as zirconium acetate or yttrium sol are pretreated, molded, hardened, roasted and the like to prepare the mold shell. The mold shell has small reaction degree with titanium and the titanium alloy, the thickness of contamination formed on the casting surface is small; the calcium zirconate ceramic mold shell has high strength, the casting surface has high fineness; a paint containing calcium zirconate is stable and is not easy to be gelled, the suspensibility is good, and the preservation time is long.

Owner:SHANGHAI UNIV +1

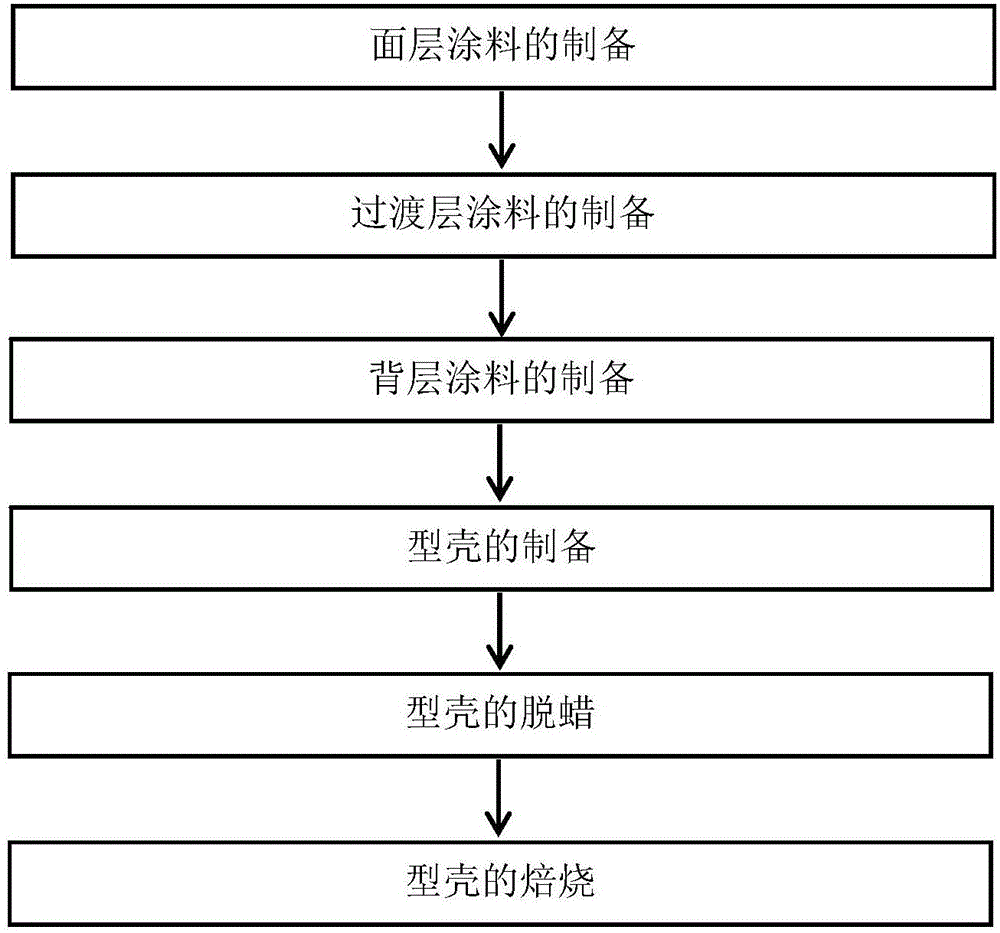

A kind of mold shell preparation method of precision casting titanium alloy

InactiveCN102284678AChemically stableOxygen controlFoundry mouldsFoundry coresSurface layerShell molding

The invention discloses a method for preparing a precision casting titanium alloy mold shell. The method comprises four steps of preparing a surface layer, preparing a transition layer, preparing a reinforcement layer, dewaxing and sintering. The shell-making process of the invention is simple, the cost of the shell mold is low, and the reaction between the titanium alloy casting and the surface layer material of the shell mold can be effectively controlled, the oxygen intake amount of the alloy can be reduced, and the titanium alloy casting is suitable for casting.

Owner:WUXI HUAYE IRON & STEEL

Preparation method of oxide doped and modified Y2O3+YSZ high-temperature-resisting shell

InactiveCN103949590AHigh strengthReduce interface reactionFoundry mouldsFoundry coresSlurryDoped oxide

The invention relates to a preparation method of an oxide doped and modified Y2O3+YSZ high-temperature-resisting shell. The preparation method comprises the following steps: preparing mixed powder of yttrium oxide and doped oxide and yttrium sol into slurry; coating, coating, stuccoing and drying; repeating the above steps for many time; then dewaxing so as to prepare a shell, and then sintering so as to form a finished product. The shell or a cruicible is suitable for smelting, precision casting and directional solidification of high-activity alloys and refractory metal at a high temperature of 1500-2000 DEG C, has the characteristics of low interface reaction, good deformability, high intensity, easy forming and capability of selecting types of doped oxides and dopping content according to the actual alloy components, and is more economical and has better technology property and thermal shock resistance as compared with pure yttrium oxide shells.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Passivating treatment method for stainless steel rare earth conversion coatings

InactiveCN102586773AImprove corrosion resistanceChange recipe concentrationMetallic material coating processesPhysical chemistryCerium

The invention belongs to the technical field of stainless steel surface treatment, and particularly relates to a passivating treatment method for stainless steel rare earth conversion coatings, which comprises the steps of soaking a stainless steel sample in a passivation solution of cerous nitrate, hydrogen peroxide and citric acid with proper concentration to be treated within a low temperature range, judging passivation time through changes of matrix surface colors, and then fetching out the sample to be cooled and dried so as to obtain a compact, smooth and golden rare earth oxide film on the stainless steel surface. The concentration of cerous nitrate is 0.01-0.05 mol / L, the volume fraction of hydrogen peroxide with 30% of mass fraction is 30-70%, and the mass fraction of citric acid is 0.1-4%. The passivation treatment temperature is 20-75 DEG C. The method can effectively improve pitting corrosion resistance and has important value.

Owner:SHANGHAI UNIV

Preparation method of waterborne polyurethane material with resistance to yellowing

InactiveCN102604039AGood yellowing resistanceImprove aging resistanceFibre treatmentPolymer scienceEmulsion

The invention relates to a preparation method of a waterborne polyurethane composite material with high resistance to yellowing. The preparation method comprises the following steps of: well dispersing nano-TiO2 in DMF (dimethylformamide) in a way of adding a dispersant; compounding MDI (diphenyl-methane-diisocyanate) with IPDI (isophorone diisocyanate), and reacting with polycarbonate diol to reduce the reaction degree of the MDI so as to get a waterborne polyurethane emulsion with higher stability; and adding nano-powder TiO2 into the polyurethane emulsion before emulsification, improving the dispersion stability of the nano-powder TiO2 in polyurethane, and adding an antioxidant 1010 and an ultraviolet absorbent UV-327 into the waterborne polyurethane emulsion to achieve better resistance to yellowing, wherein the yellowing grade is improved by 1-1.5 grades.

Owner:王全杰

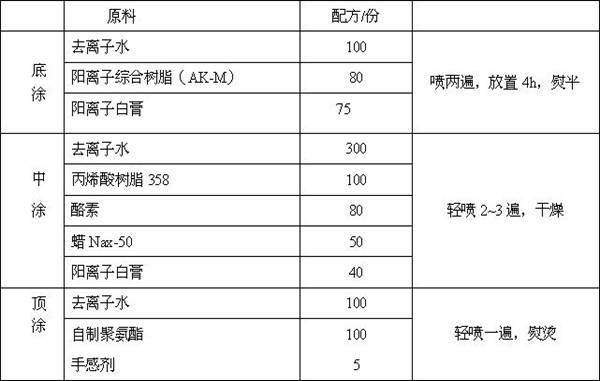

Preparation method of yttrium oxide moulding shell used for casting

ActiveCN106493287ASolve the problem of water back dissolutionSolve the breathability problemFoundry mouldsFoundry coresHuman healthTitanium alloy

The invention discloses a preparation method of an yttrium oxide moulding shell used for titanium alloy precision casting. A moulding shell surface layer coating comprises yttrium oxide refractory powder, ammonium zirconium carbonate binder, a wetting agent and a defoaming agent. The preparation method includes the steps of preparation of the surface layer coating, preparation of a back layer coating, preparation of the moulding shell, dewaxing, calcinations and the like. By means of the yttrium oxide moulding shell used for titanium alloy precision casting and the preparation method thereof, the problems that an existing moulding shell is prone to redissolution under the influence of water in the preparation and dewaxing processes, and steam dewaxing cannot be achieved are solved. The binder used for the coating is made of ammonium zirconium carbonate and is low in price, and the prepared coating is stable and reliable and cannot generate redissolution after being dried under the influence of water. The prepared surface layer coating is good in smearing performance and high in refractoriness, steam dewaxing is adopted, no pollution is caused to the environment, and the prepared surface layer moulding shell has no influence on the human health. The prepared yttrium oxide moulding shell is wide in application range, an interface reaction layer is small, titanium alloy casts are high in precision, performance is excellent, and later-period finishing is conducted easily.

Owner:SHANGHAI SPACE PRECISION MACHINERY RES INST

Aluminum-magnesium casting material for ladle liner and preparation method thereof

The invention relates to an aluminum-magnesium casting material for a ladle liner and a preparation method thereof. ACcording to the technical scheme, the method comprises the following steps: preparing 50-65wt% of microporous alumina particles serving as aggregate; preparing 10-15wt% of fine corundum particles, 15-30wt% of fine corundum powder, 2-8wt% of magnesium oxide powder, 2-8wt% of alpha-A12O3 powder and 2-8wt% of aluminum powder silica gel which are used as base materials; adding water which accounts for 3-10wt% of the sum of the aggregate and the base materials; evenly agitating, and molding in a vibrating manner; carrying out heat preservation at 100-150 DEG C for 12-36 hours, so as to prepare the aluminum-magnesium casting material for the ladle liner. The aluminum-magnesium casting material for the ladle liner prepared by the method has excellent slag resistance and thermal shock stability, and the service life of the aluminum-magnesium casting material for the ladle liner can be effectively prolonged.

Owner:WUHAN UNIV OF SCI & TECH

Geopolymer-based artificial flood control stone prepared from all wastes and preparation method thereof

The invention discloses a geopolymer-based artificial flood control stone prepared from all wastes and a preparation method of the geopolymer-based artificial flood control stone. The geopolymer-basedartificial flood control stone comprises the following raw materials in parts by weight: 288-412 parts of a waste silicon-aluminum material; 85-150 parts of alkali-containing waste; 29-75 parts of waste sulfate mineral; 1501-1860 parts of recycled aggregate; 216-241 parts of reclaimed water; 0-2 parts of waste fiber; and 0-5 parts of crop waste. The process is simple, the prepared artificial flood control stone has no appearance defect; the stone has the advantages of large volume density, high strength (more than 34 MPa), good weathering resistance, freezing resistance and abrasion resistance and the like, is convenient to throw, good in integrity, strong in stability, freeze-thaw resistance, weathering resistance and high-speed sand-containing water flow abrasion resistance in the usingprocess, is not easy to lose under high-speed water flow, and is an ideal substitute product for natural stone standby stone prevention.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER +1

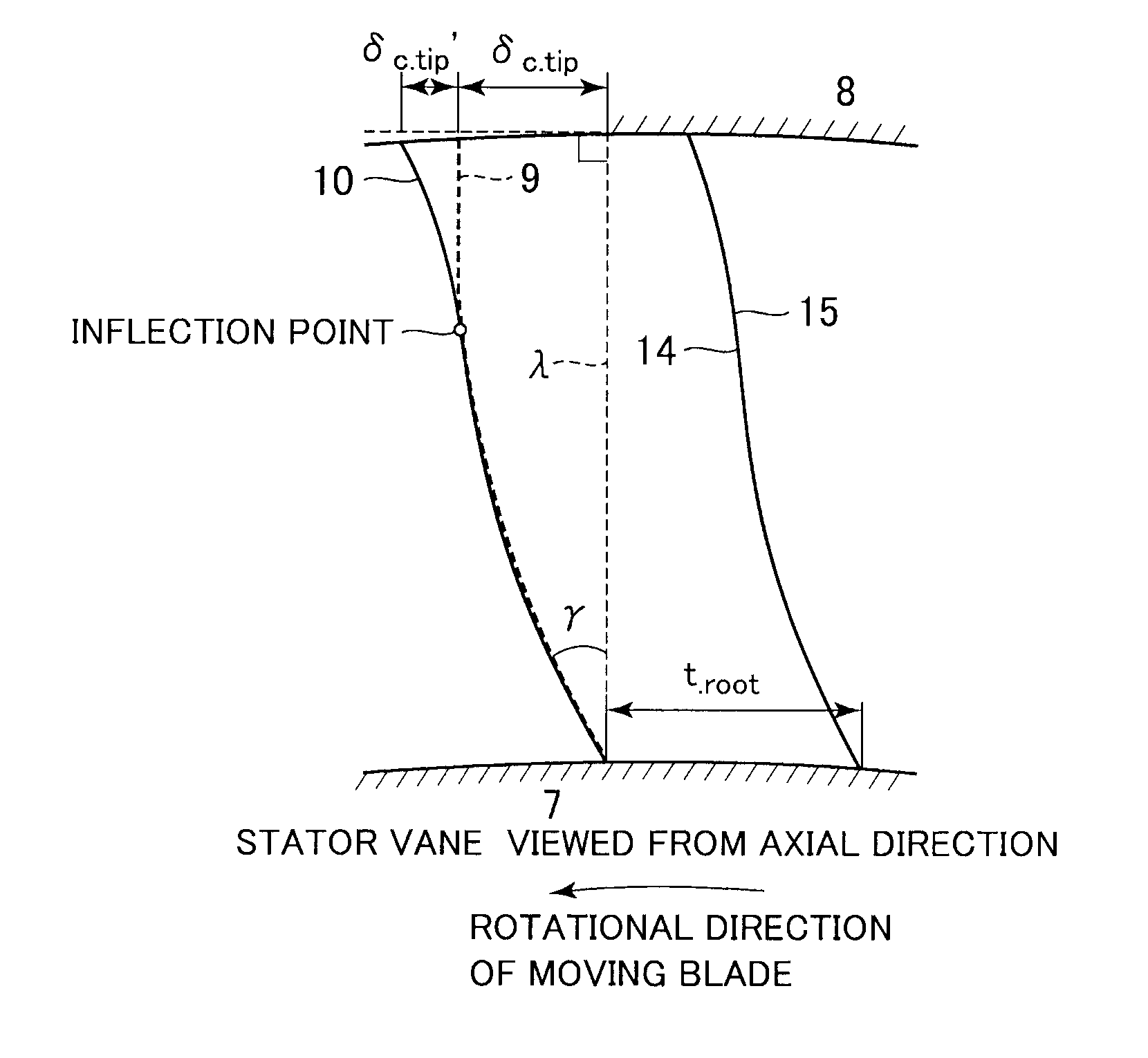

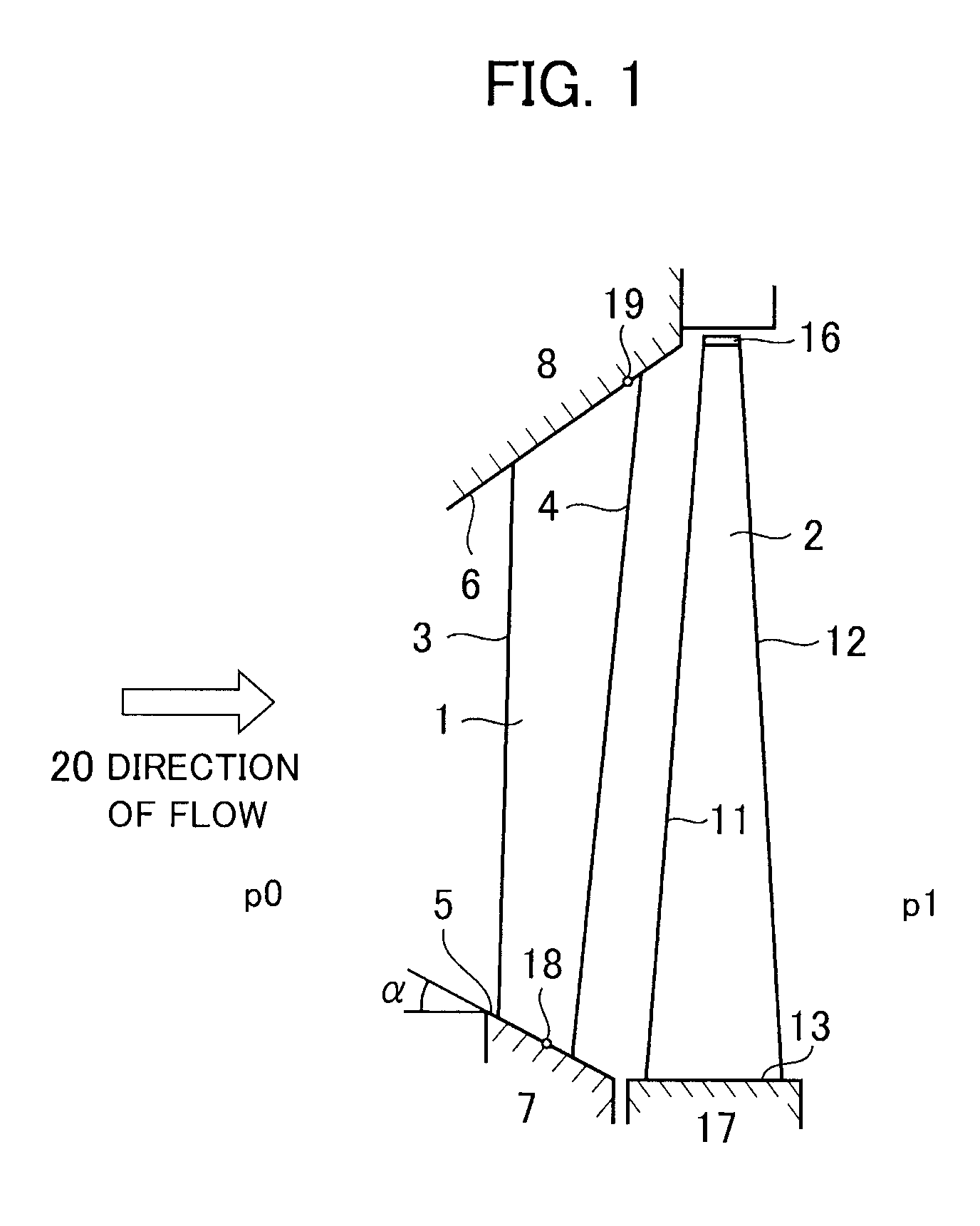

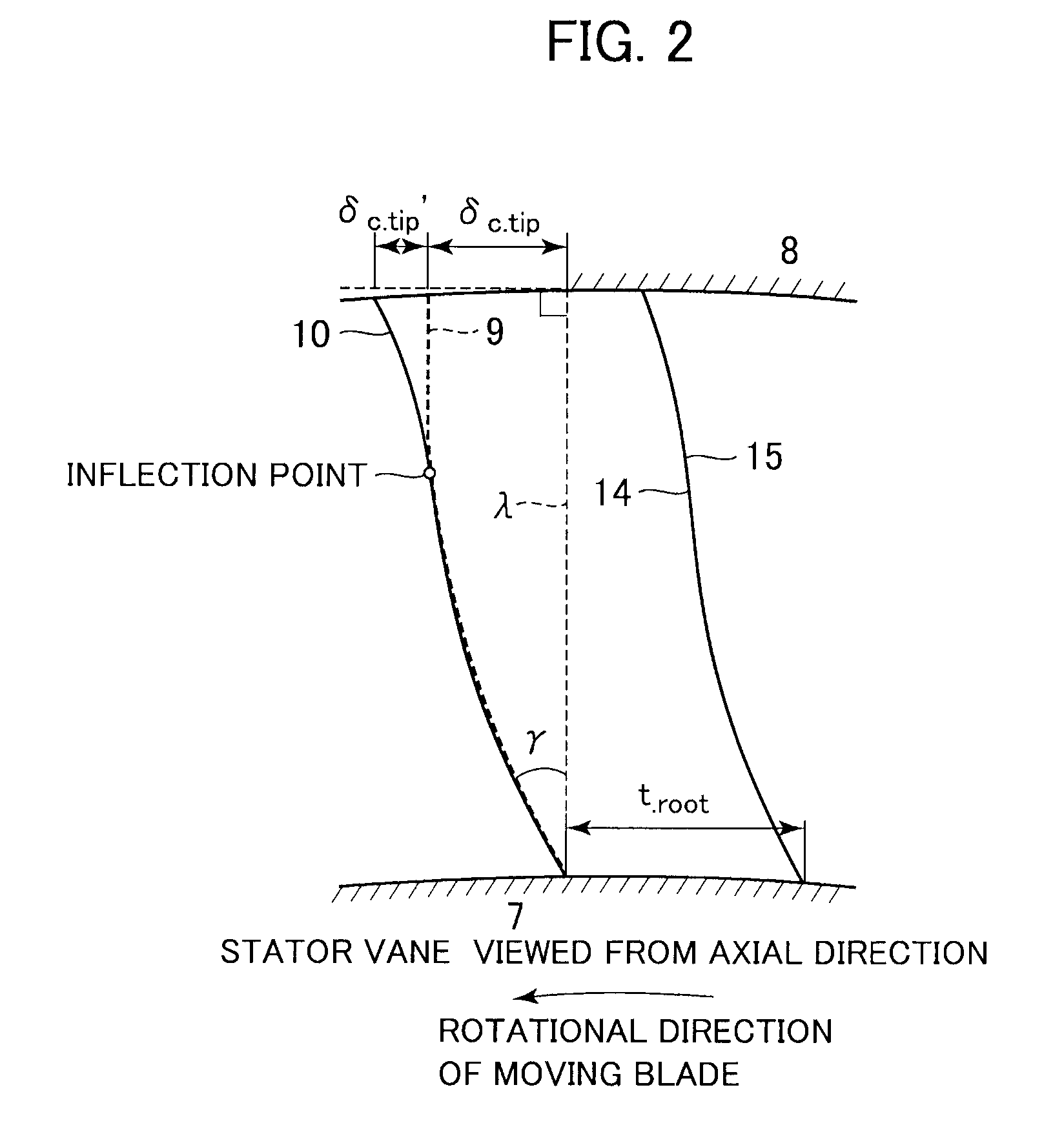

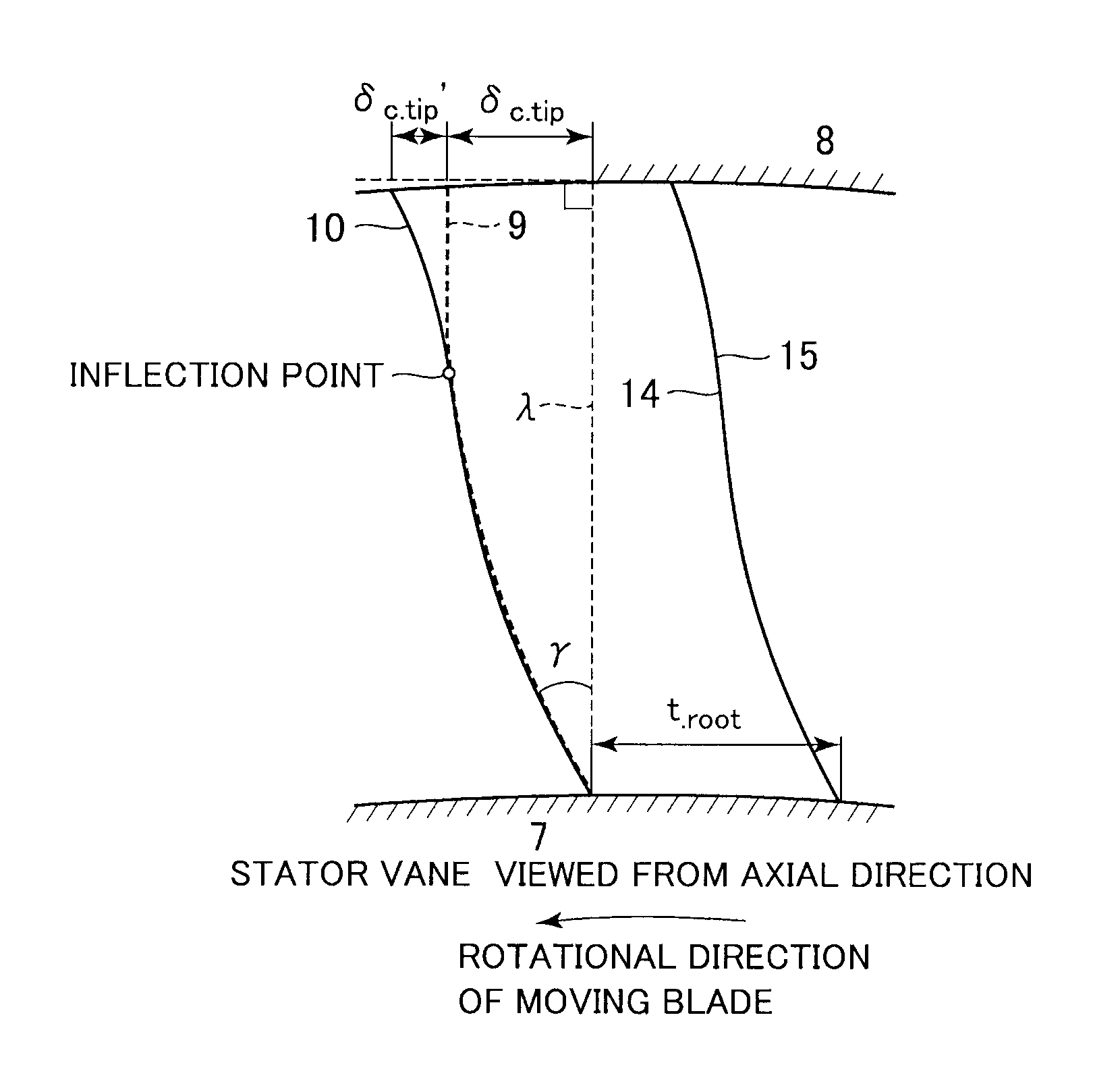

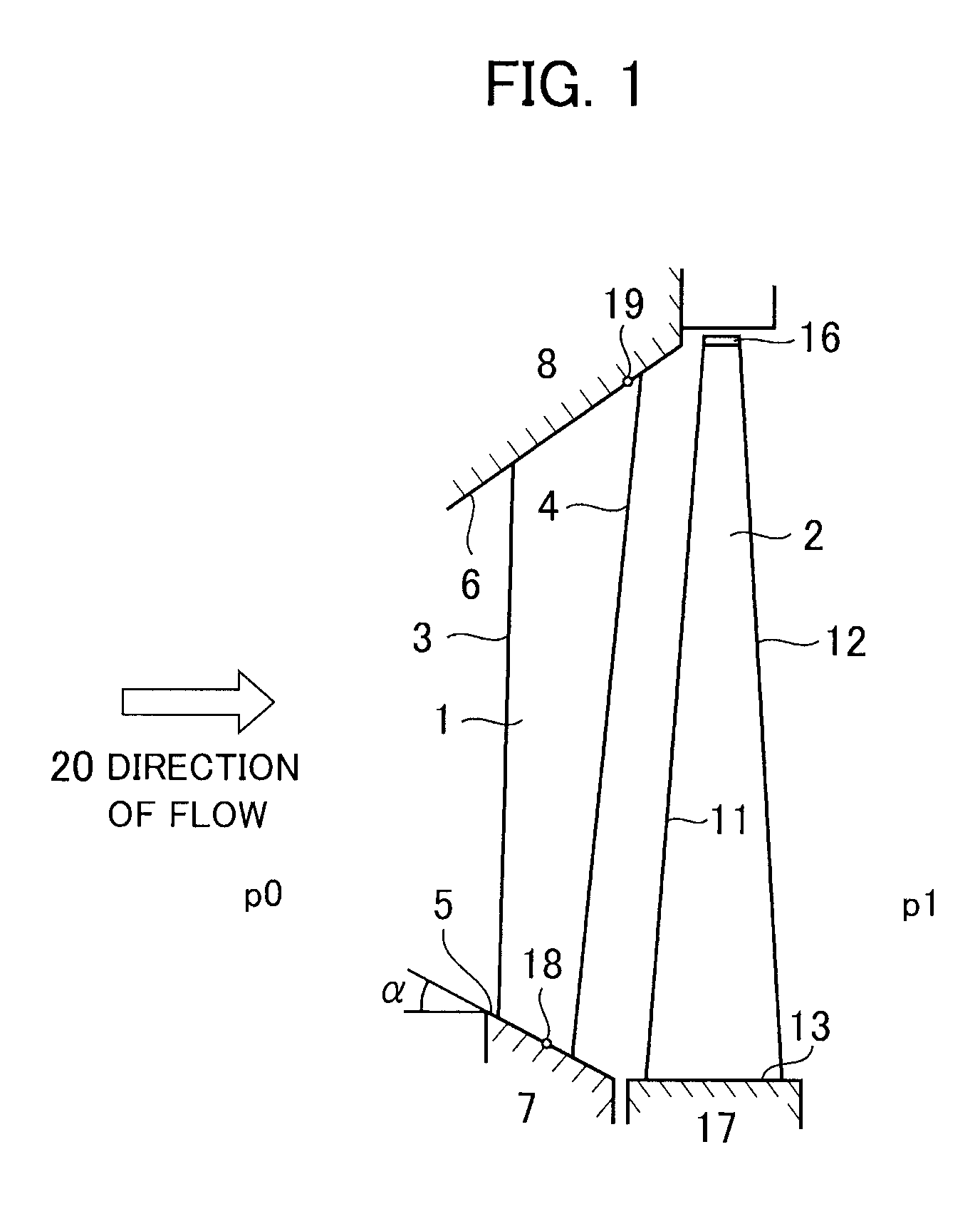

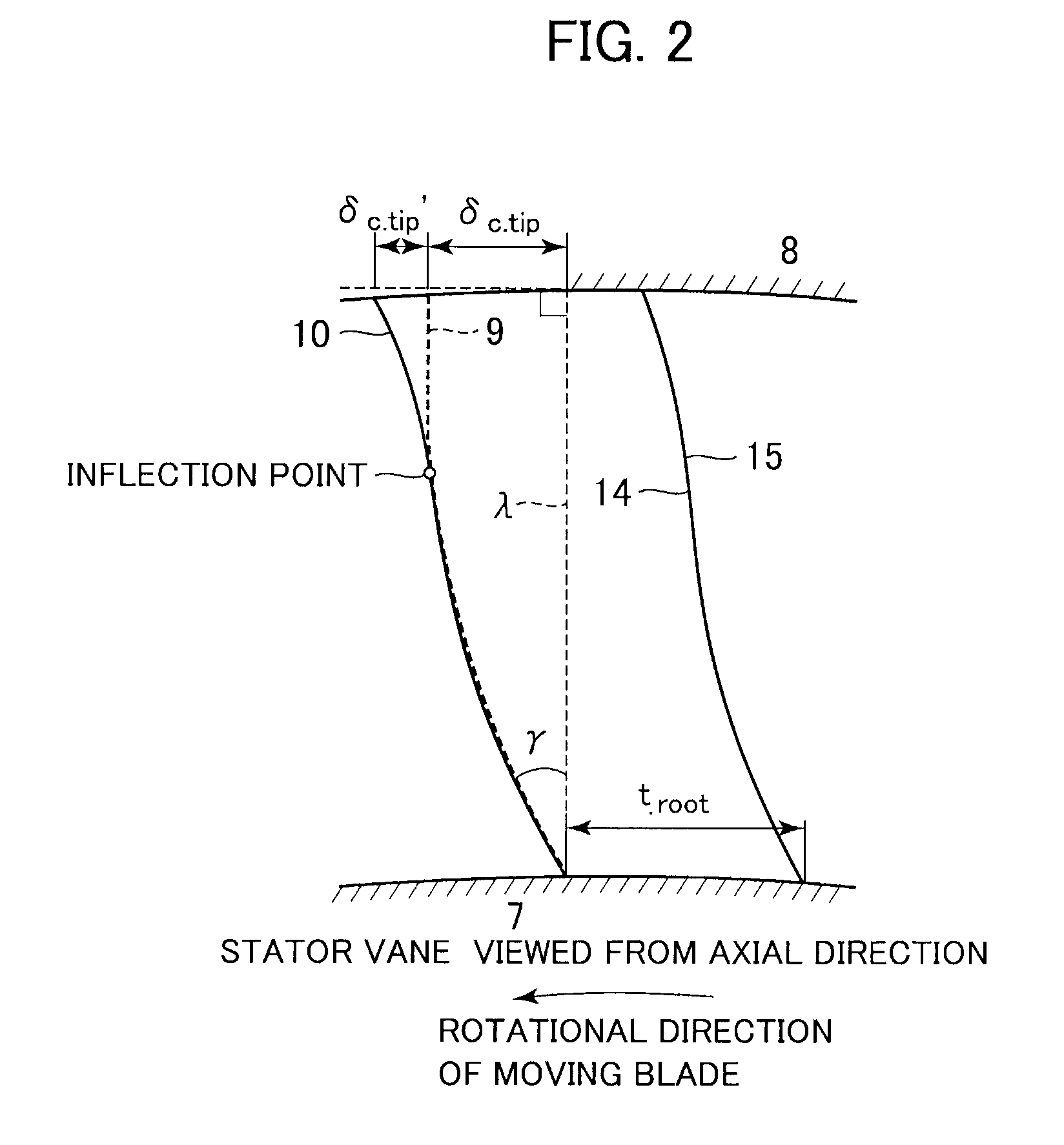

Steam Turbine Stator Vane and Steam Turbine Using the Same

ActiveUS20120076646A1Improve efficiency of turbineLength of moving is increasedSupersonic fluid pumpsEngine manufactureTrailing edgeStator

Suppressing profile loss of a moving blade due to radial flow without an increase in the length of a shaft of a turbine is disclosed. The degree of reaction on an inner circumferential side is set to an appropriate degree, reducing profile loss due to supersonic inflow, and improving turbine efficiency. A steam turbine stator vane has a trailing edge with a curved line when the stator vane is viewed from a downstream side in the axial direction. The curved line has an inflection point located on an outer circumferential side with respect to the center of the stator vane in the height direction of the stator vane. An inner circumferential portion of the curved line is located on the inner circumferential side with respect to the inflection point. An outer circumferential portion of the curved line is located on the outer circumferential side with respect to the inflection point.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

A mold shell for precision casting titanium alloy

The invention discloses a mold shell for precision casting titanium alloy. The mold shell is composed of 1 layer layer, 2 layers of transition layer, 4 layers of reinforcement layer and a sand layer between each layer, wherein the surface layer contains 200-400 Boron nitride powder, the sand layer between the surface layer and the transition layer is fused mullite sand with a particle size of 40-100 mesh; the first transition layer contains 200-400 mesh Y2O3 powder, and the second transition layer Contains 200-400 mesh Al2O3 powder, the sand layer between the first transition layer and the second transition layer and between the second transition layer and the reinforcement layer is fused mullite sand with a particle size of 40-80 mesh; The 4 reinforcement layers all contain bauxite, and the 3 sanding layers between the 4 reinforcement layers are coal gangue sands of 16-24 mesh.

Owner:WUXI HUAYE IRON & STEEL

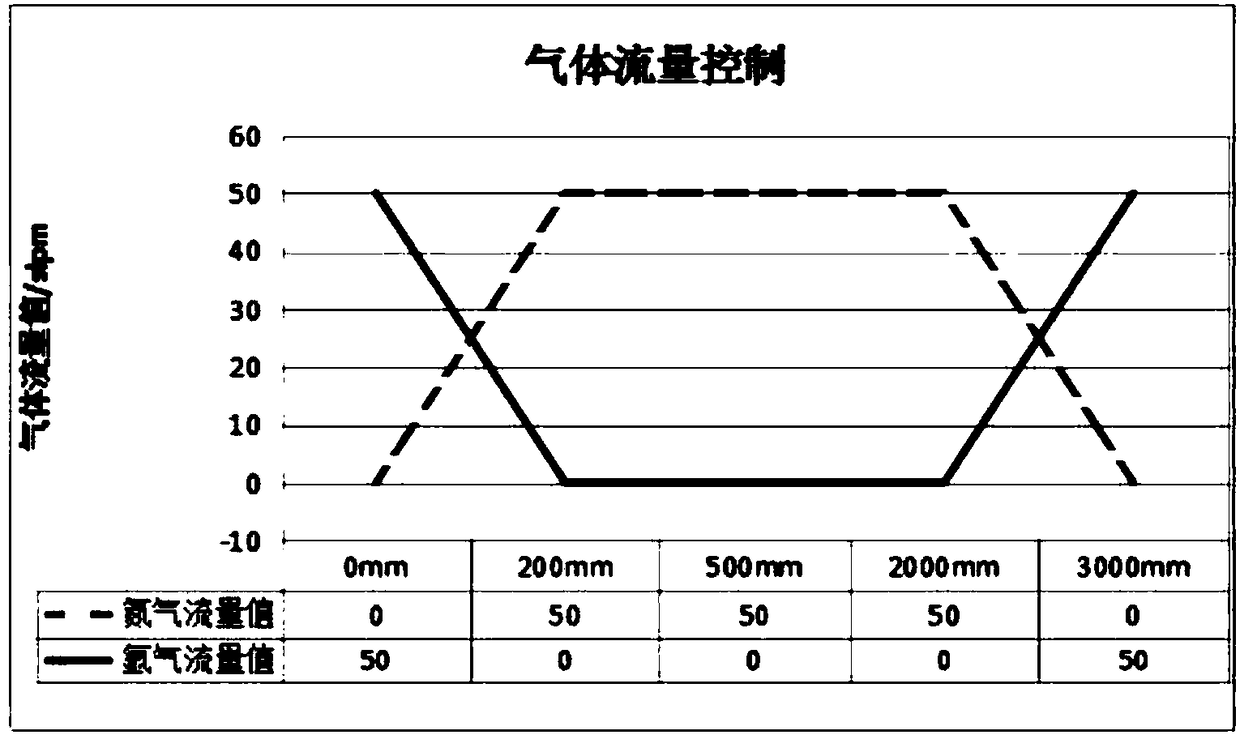

Method for growing cz si crystal in total nitrogen environment

InactiveCN108411360AImprove throughputReduce throughputPolycrystalline material growthBy pulling from meltThree stageTotal nitrogen

The invention provides a method for growing a cz si crystal in a total nitrogen environment. The method comprises the steps of melting, temperature stabilizing, seeding, shouldering, shoulder circuit,diameter equalizing, closing and the like, the method is characterized in that the diameter equalizing step is divided into three stages, wherein the second stage is diameter equalizing is conductedto reach 200mm to 2000mm, the injected gas is all nitrogen, and the growth speed of the crystal is higher than 84mm / hr. The method has the beneficial effects that the fraction rate of a battery pieceprepared from cz si crystals which are manufactured by adopting the production method is reduced by 2%, the lumen depreciation is lower than 1.7%, the conversion rate is higher than 21% and conforms the industry standard, the nitrogen crystal pulling crystallization rate is improved while the production cost is reduced, the using requirement is met, and the cost is reduced by at least 6.25%.

Owner:INNER MONGOLIA ZHONGHUAN SOLAR MATERIAL

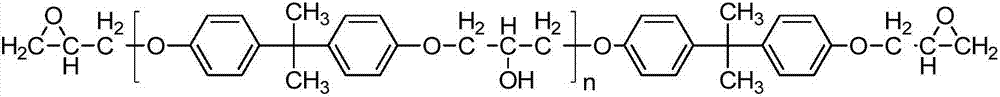

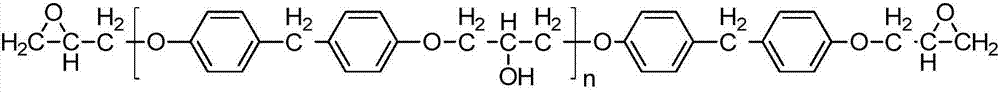

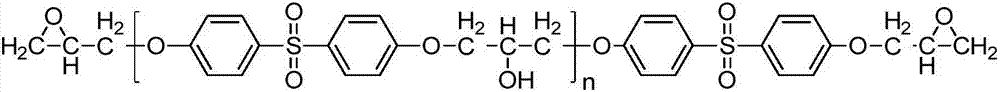

Preparation method and application of epoxy resin modified polyamide resin and powder coating

ActiveCN108003782AWell mixedReduce the degree of reactionPowdery paintsPolyamide coatingsCarbon numberEpoxy

The invention discloses a preparation method and application of epoxy resin modified polyamide resin and powder coating. The resin is prepared from raw materials containing polyamide resin and bifunctional epoxy resin. A terminal group of the polyamide resin is a carboxyl group, molecular weight of the polyamide resin is 1000-8000 g / mol, the dosage of the epoxy resin is 5-50% of the mass of the polyamide resin, and the mass of monomers having a carbon number of ten or more in polymerized monomers accounts for 50-100% of total monomer mass. The preparation method includes the step that the polyamide resin and the epoxy resin are subjected to melt mixing or homogenate dispersion mixing. By using the epoxy resin modified polyamide resin, the powder coating can be prepared, and a polymer coating layer with high-strength and excellent characteristics can be obtained after baking heat treatment.

Owner:WANHUA CHEM GRP CO LTD

Ladle castable

The invention relates to ladle castable, particularly to castable for ladle linings or working layers. In order to solve the technical problems, hte invention provides the ladle castable used at the direct lining where a ladle is in direct contact with molten steel; the ladle castable comprises the following components in percentage by weight: 8-20% of sintered microporous aluminum spinel of 12-8mm, 11-15% of sintered microporous aluminum spinel of 8-5mm, 12-15% of sintered microporous aluminum spinel of 5-3mm, 10-15% of sintered microporous aluminum spinel of 3-1mm, 30-35% of sintered microporous aluminum spinel smaller than or equal to 1mm, 0-15% of modified magnesia-calcium clinker smaller than or equal to 1mm, 1% of chromium carbide powder, 3-5% of compound gel powder, 1% of hydrated alumina micropowder, 1% of nacrite powder, 0.5% of bismuth germanate powder, 3-5% of modified pure calcium aluminate cement, 0.1% of C7H10N2O2S, 0.1% of C2H14Na2O6S2, and 0.05% of 4-morpholineethanesulfonic acid. Through the adoption of the ladle castable disclosed by the invention, the reacting degree of the material of the ladle lining and slags can be lowered; the high-temperature performance and the slag corrosion resistance of slag-resistance ladle products are improved; the thermal shock resistance of ladles is greatly improved; the service life of whole casting ladles is effectively prolonged, and compared with conventional ladles of the same type, the service life of ladles using the castable disclosed by the invention is prolonged by 30% and more.

Owner:徐州国隆电力配件铸造有限公司

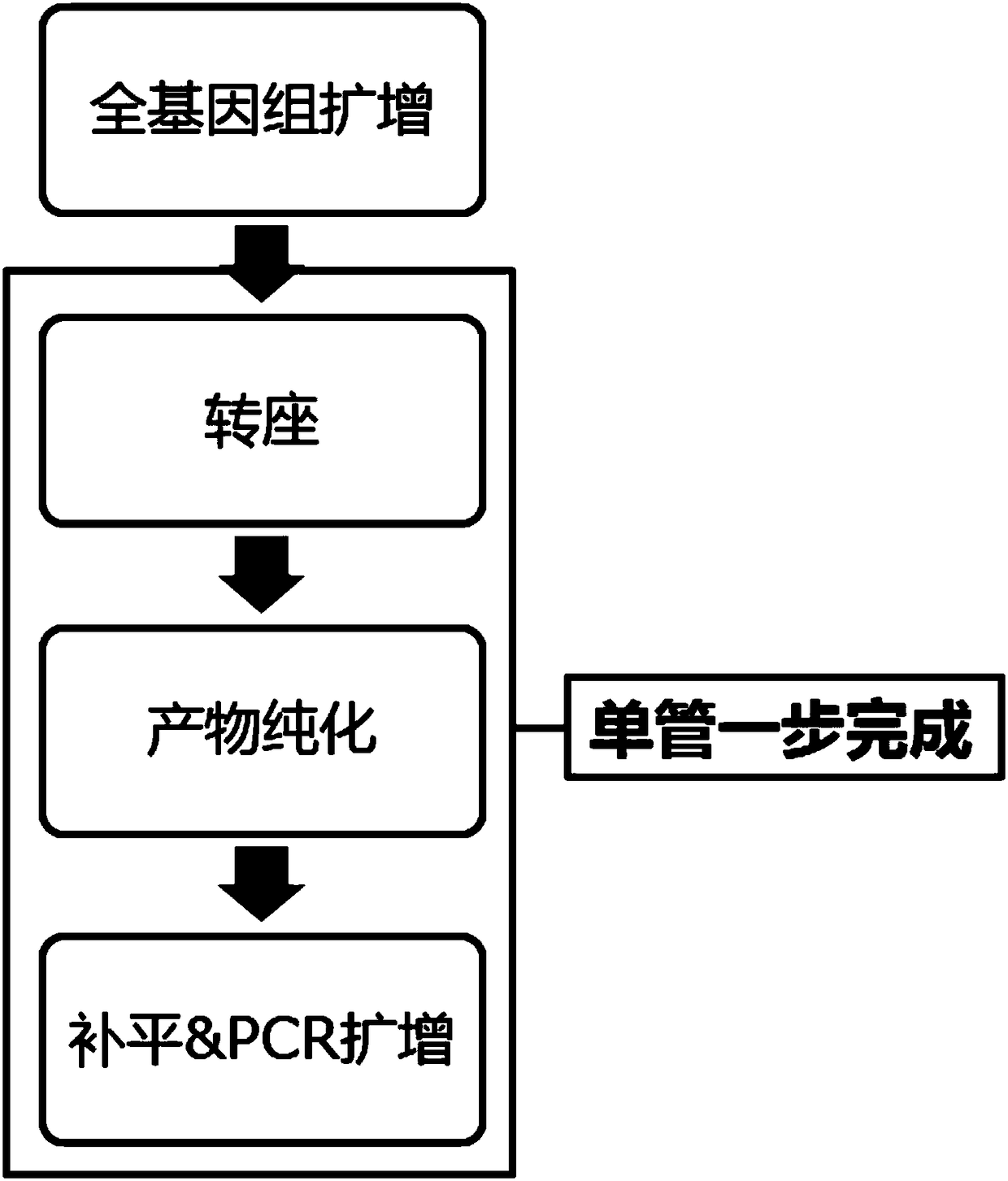

Single-cell genome copy number variation detection method and kit

InactiveCN108410970ALower reaction costReduce the degree of reactionMicrobiological testing/measurementLibrary creationInformation analysisPollution

The invention relates to the technical field of biology, in particular to a combination, a kit and application of the kit. The application includes a solution of single-cell genome copy variation detection, comprising single cell amplification, library construction, high-throughput sequencing and information analysis; library construction based on transposase is applied to single cell sequencing;the use of single-tube one-step library construction process helps relieve operational complexity, thus avoiding pollution. In addition, the invention also provides optimal window length according tothe requirement on CNV (copy number variation) lowest detection resolution; run test is performed to count distribution differences, relative to coverage, of CNV area and normal area sequencing data;significance P value of each candidate CNV is output in final results; detection accuracy is effectively improved.

Owner:CAPITALBIO CORP

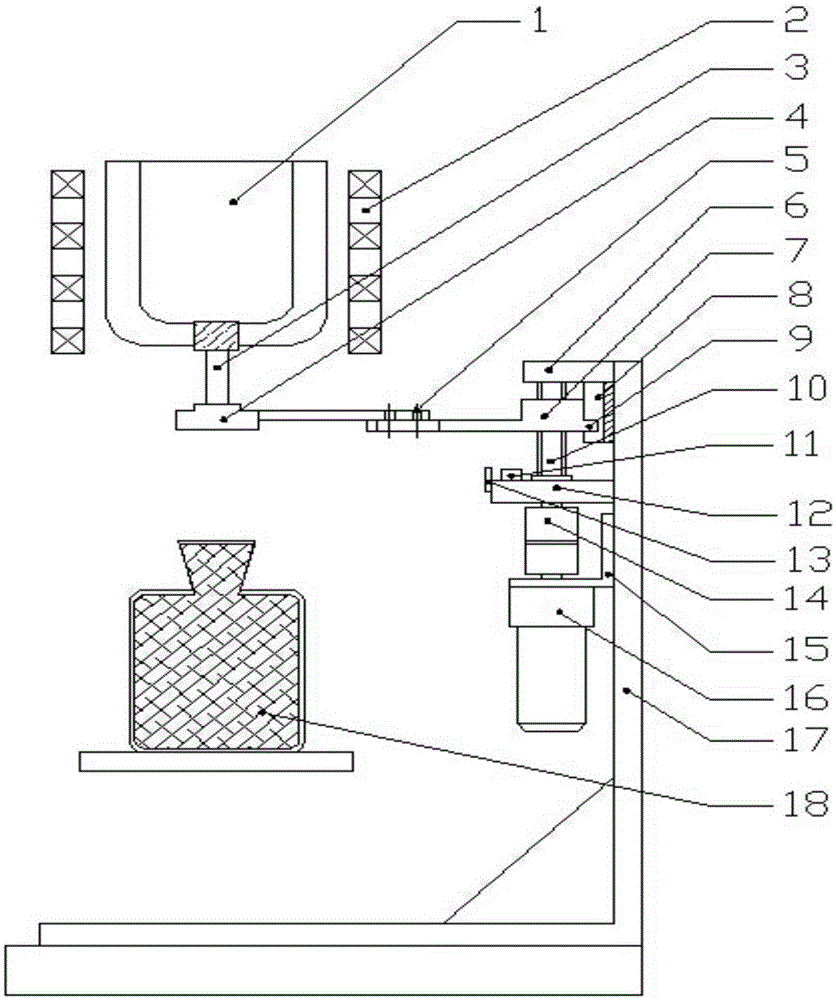

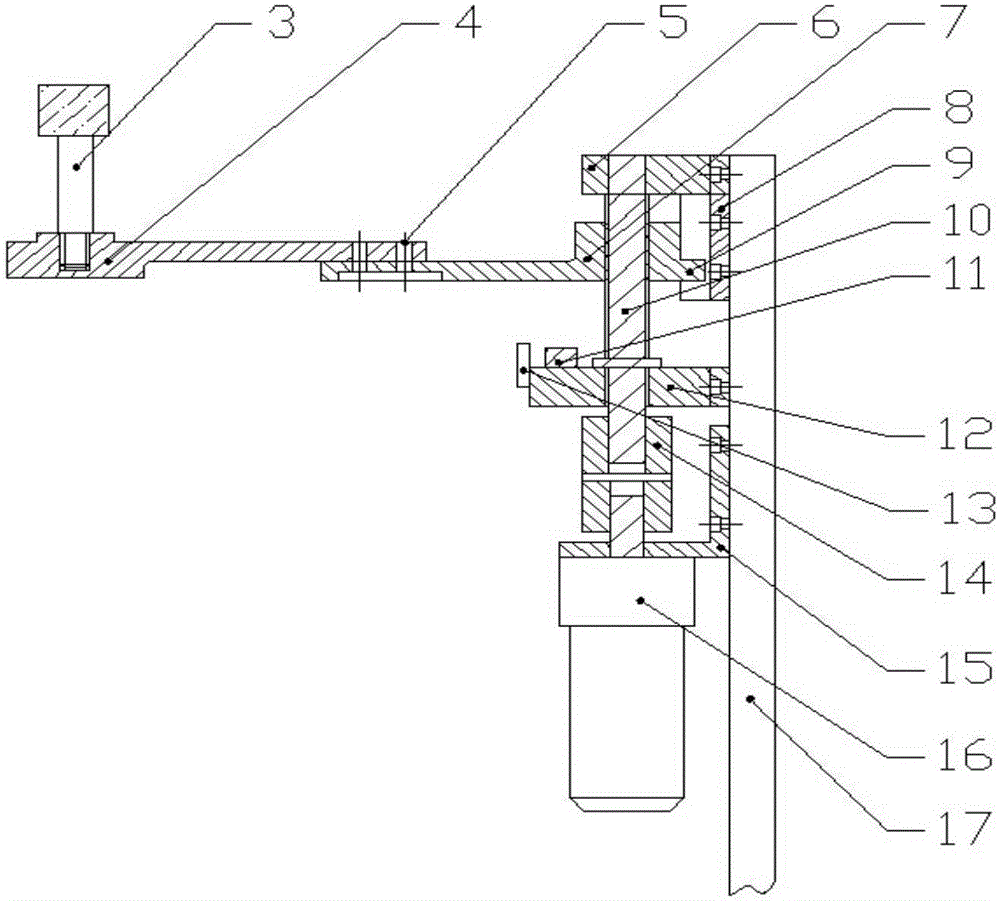

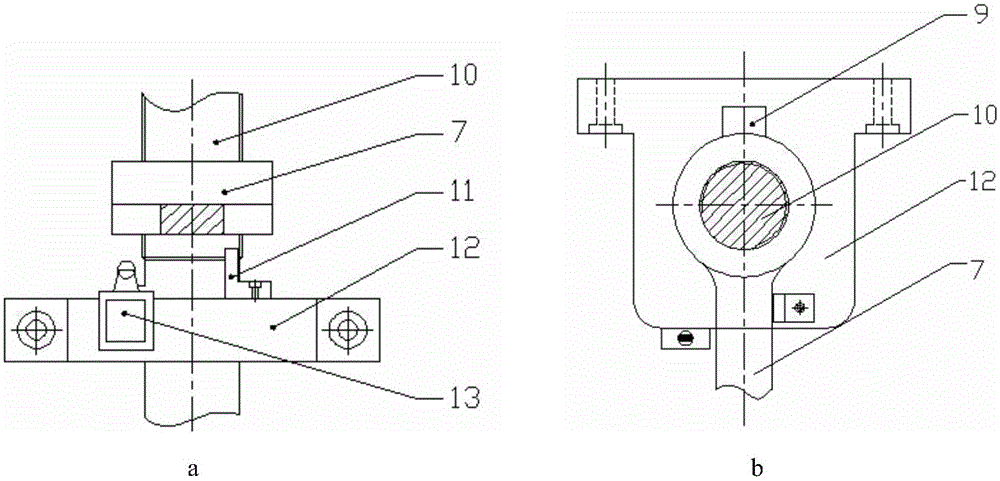

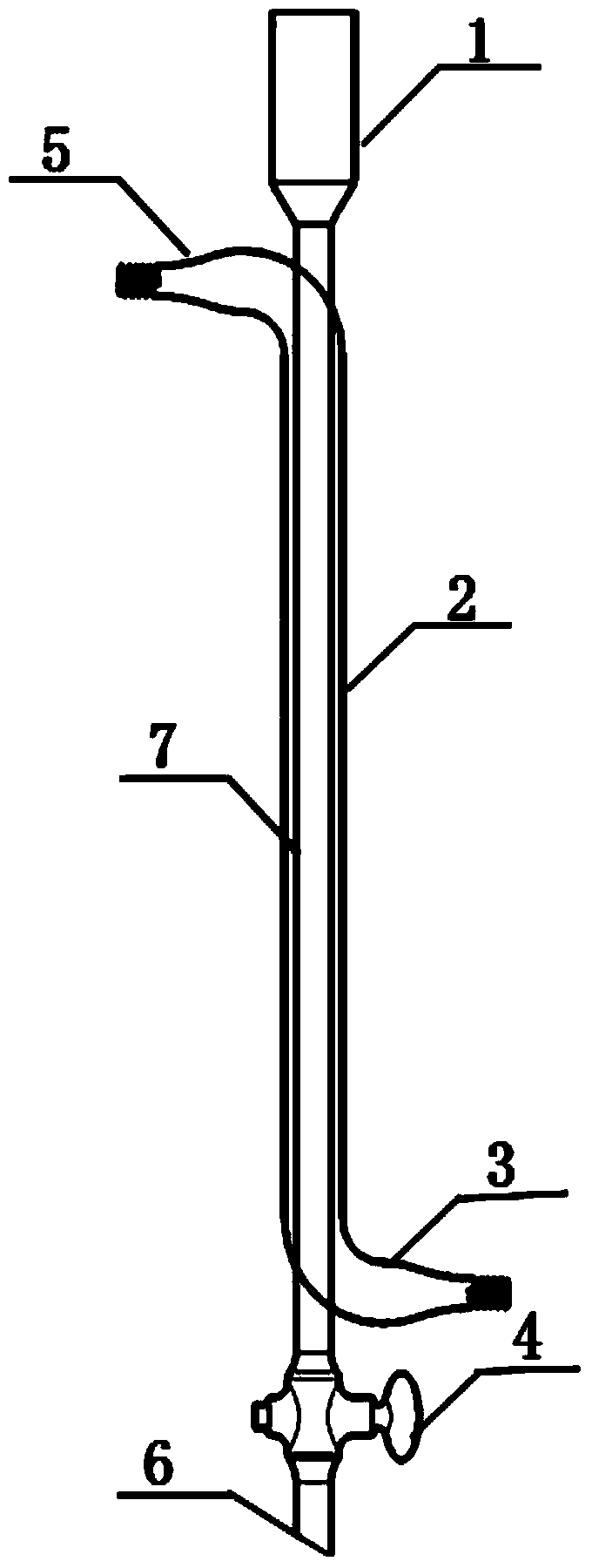

Bottom cork pulling type vacuum induction melting and casting control device

ActiveCN105081302AImprove interchangeabilityReduce the degree of reactionMelt-holding vesselsContact timeCrucible

The invention discloses a bottom cork pulling type vacuum induction melting and casting control device. A cork pulling mechanism is mounted on a support; a casting mould is located below a choke plug; and the choke plug in the cork pulling mechanism is mounted in a casting hole of a crucible and is matched with a screw rod by a cork pulling rod. According to the bottom cork pulling type vacuum induction melting and casting control device, bottom injection type casting is adopted, and no electrodes and no crucible oblique rotation mechanisms are needed, so that the structural complexity of apparatuses and the complexity of melting and casting working procedures are reduced. Meanwhile, the cork pulling rod is not in contact with a melt, so that the contact time of the melt and the crucible is shortened and the contact area of the melt and the crucible is reduced, and the reaction speed of metal and the melt is reduced; and the casting position of the metal melt is accurately positioned in the lower part, so that no splashing and casting missing conditions occur.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

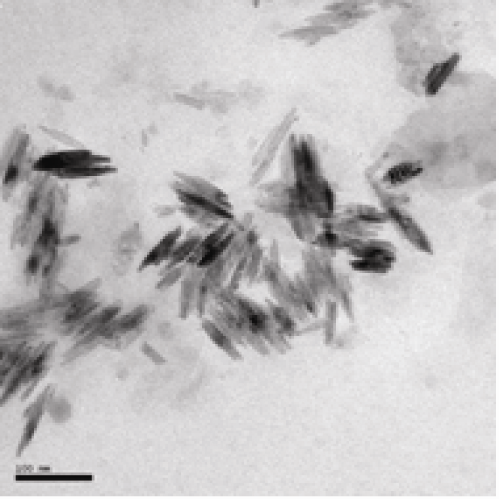

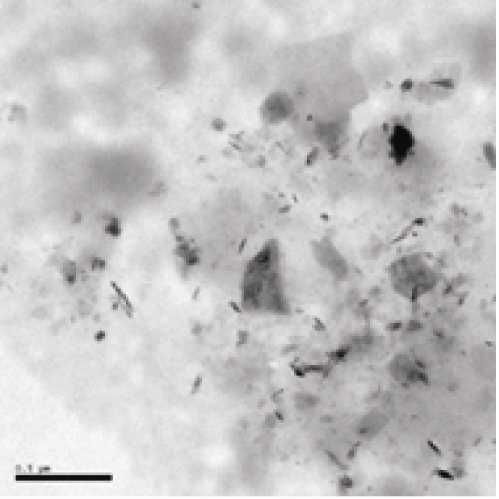

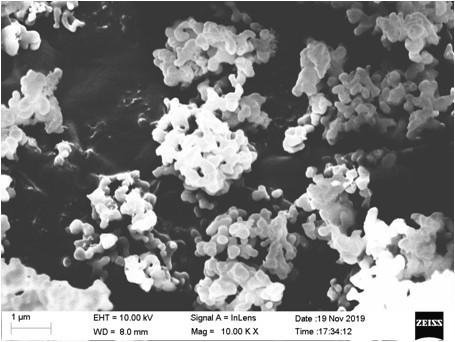

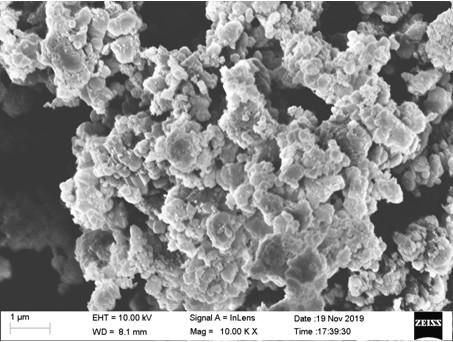

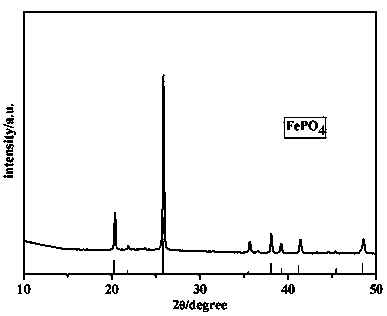

Preparation method of anhydrous iron phosphate nanoparticles

ActiveCN111377426ASlow reaction speedReduce the degree of reactionMaterial nanotechnologyCell electrodesIron phosphateOxidizing agent

The invention provides a preparation method of anhydrous iron phosphate nanoparticles, which belongs to the technical field of inorganic synthesis. The preparation method comprises the following stepsof adding iron powder into a phosphoric acid solution, heating to about 40 DEG C, preserving heat, adding an oxidant, continuously preserving heat, and filtering to obtain a dark brown filtrate, adding an oxidant into the filtrate, and stirring at normal temperature, filtering, washing and drying to obtain faint yellow powder, and carrying out high-temperature treatment on the powder at 500-700 DEG C to obtain the anhydrous iron phosphate nanoparticles. In the preparation method, the oxidation of ferrous ions is completed at normal temperature, and iron phosphate does not need to be crystallized and aged, so that the cost for preparing iron phosphate is further reduced. In addition, the anhydrous iron phosphate obtained by the preparation method is of a micron secondary structure formed by agglomeration of nanoparticles, and the lithium iron phosphate obtained by lithiation of the anhydrous iron phosphate with the morphology is large in capacity and high in compaction density.

Owner:黄冈林立新能源科技有限公司

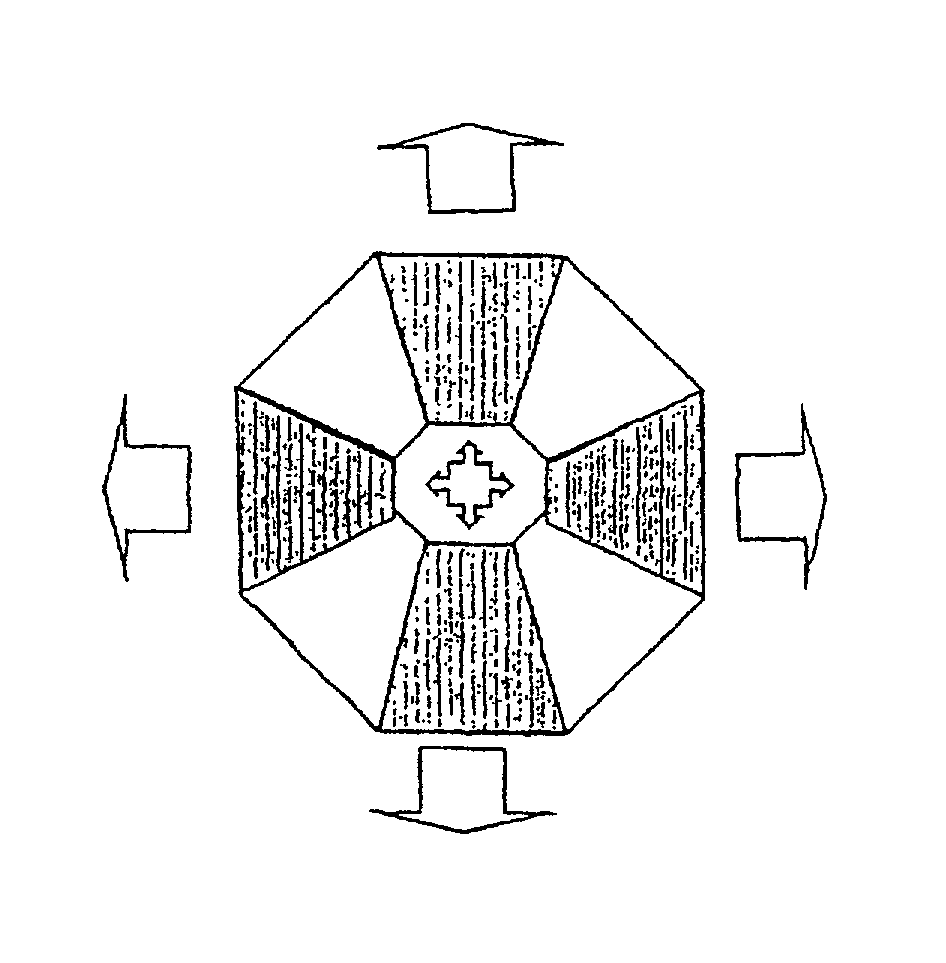

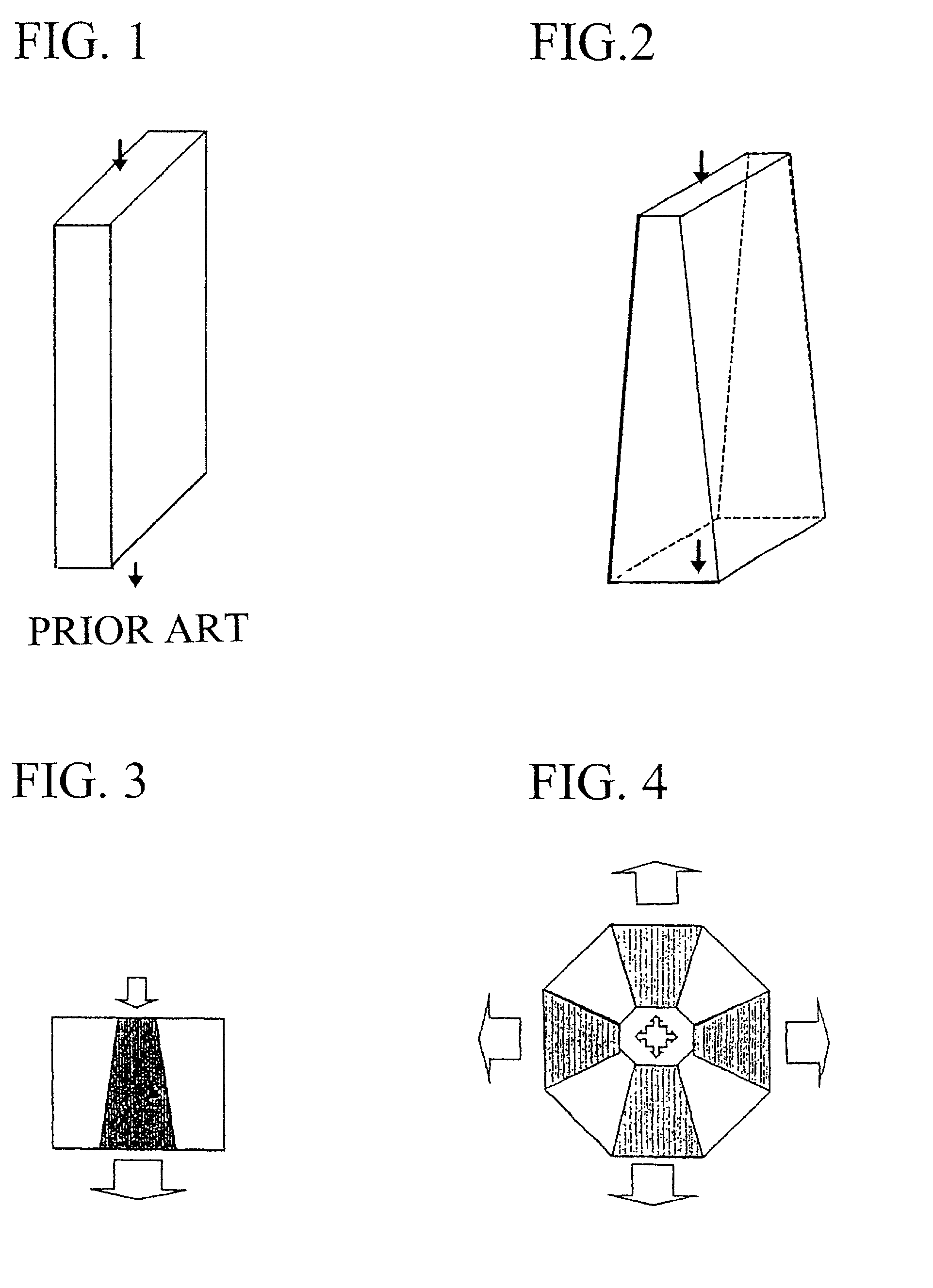

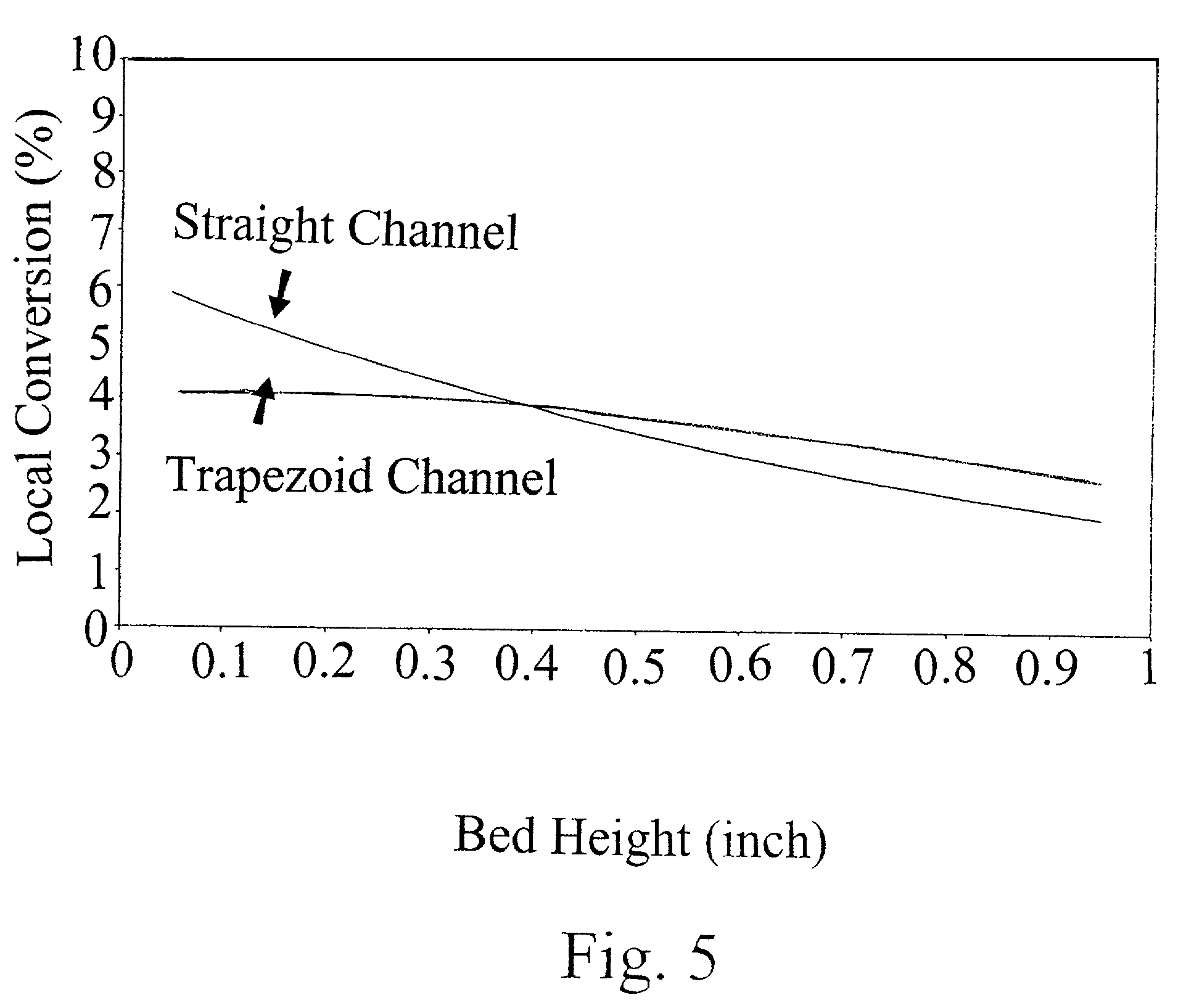

Reactors having varying cross-section, methods of making same, and methods of conducting reactions with varying local contact time

ActiveUS8206666B2Uniform temperature distributionHigh product selectivityChemical analysis using catalysisPhysical/chemical process catalystsChemical reactionContact time

The present invention provides methods of conducting chemical reactions in a reaction channel that has an varying cross-sectional area such that a chemical reactant or reactants experience varying local contact time as the reactant(s) flow through the channel. The invention also provides reactors having reaction channels with varying cross-sectional areas. In a particularly preferred embodiment, the reaction channel section has a trapezoidal shape that becomes broader from the inlet toward the outlet.

Owner:BATTELLE MEMORIAL INST

Process for preparing high-molecular aliphatic polyester

The present invention relates to the preparation process of high molecular weight aliphatic polyester. Aliphatic diatomic acid and aliphatic diatomic alcohol are made to react in decalin solvent with catalyst of stannous chloride, stannous zincate, n-butyl titanate, isopropyl titanate, etc at 100-200 deg.c for 1-14 hr to obtain the high molecular weight aliphatic polyester. The preparation process of the present invention is simple, low in cost, easy to control and high in yield, and the product has high molecular weight and high purity.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Periclase-calcium-containing spinel brick for cement rotary kiln burning zone and preparation method thereof

The invention in particular relates to a periclase-calcium-containing spinel brick for a cement rotary kiln burning zone and a preparation method thereof. The preparation method is characterized by firstly mixing 60-95wt% of magnesia and 5-40wt% of calcium-containing spinel as raw materials, then adding pulp waste liquid accounting for 2-5wt% of the raw materials, mulling, forming and baking the materials and then insulating the product at 1500-1800 DEG C for 2-5 hours, thus obtaining the periclase-calcium-containing spinel brick for the cement rotary kiln burning zone. A preparation method of calcium-containing spinel is characterized by firstly grinding 55-75wt% of raw material aluminium oxide, 20-40wt% of raw material magnesium oxide and 1-10wt% of raw dolomite together, drying and mixing the powder and extruding the mixture into a green body; then insulating the green body at 110-200 DEG C for 12-48 hours, putting the green body in a high temperature kiln to be calcined at 1600-1850 DEG C and then breaking the product after calcination, thus obtaining calcium-containing spinel. The periclase-calcium-containing spinel brick prepared by the preparation method has excellent performance of sticking to kiln coatings and prolongs the service lives of refractory materials.

Owner:WUHAN UNIV OF SCI & TECH

Steam turbine stator vane and steam turbine using the same

InactiveUS9011084B2Increase in profile lossReduce the degree of reactionSupersonic fluid pumpsEngine manufactureDegree of reactionTrailing edge

Suppressing profile loss of a moving blade due to radial flow without an increase in the length of a shaft of a turbine is disclosed. The degree of reaction on an inner circumferential side is set to an appropriate degree, reducing profile loss due to supersonic inflow, and improving turbine efficiency. A steam turbine stator vane has a trailing edge with a curved line when the stator vane is viewed from a downstream side in the axial direction. The curved line has an inflection point located on an outer circumferential side with respect to the center of the stator vane in the height direction of the stator vane. An inner circumferential portion of the curved line is located on the inner circumferential side with respect to the inflection point. An outer circumferential portion of the curved line is located on the outer circumferential side with respect to the inflection point.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

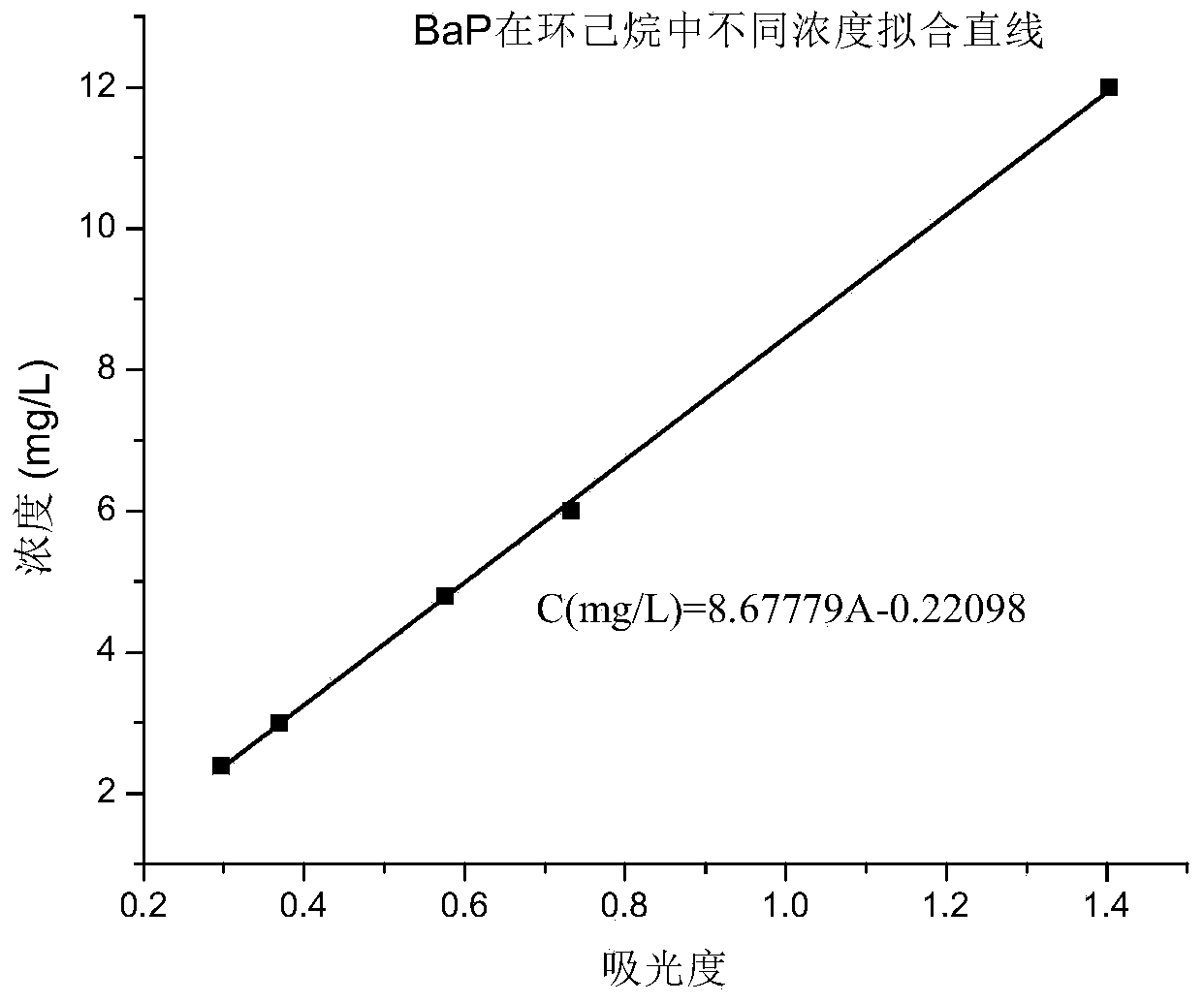

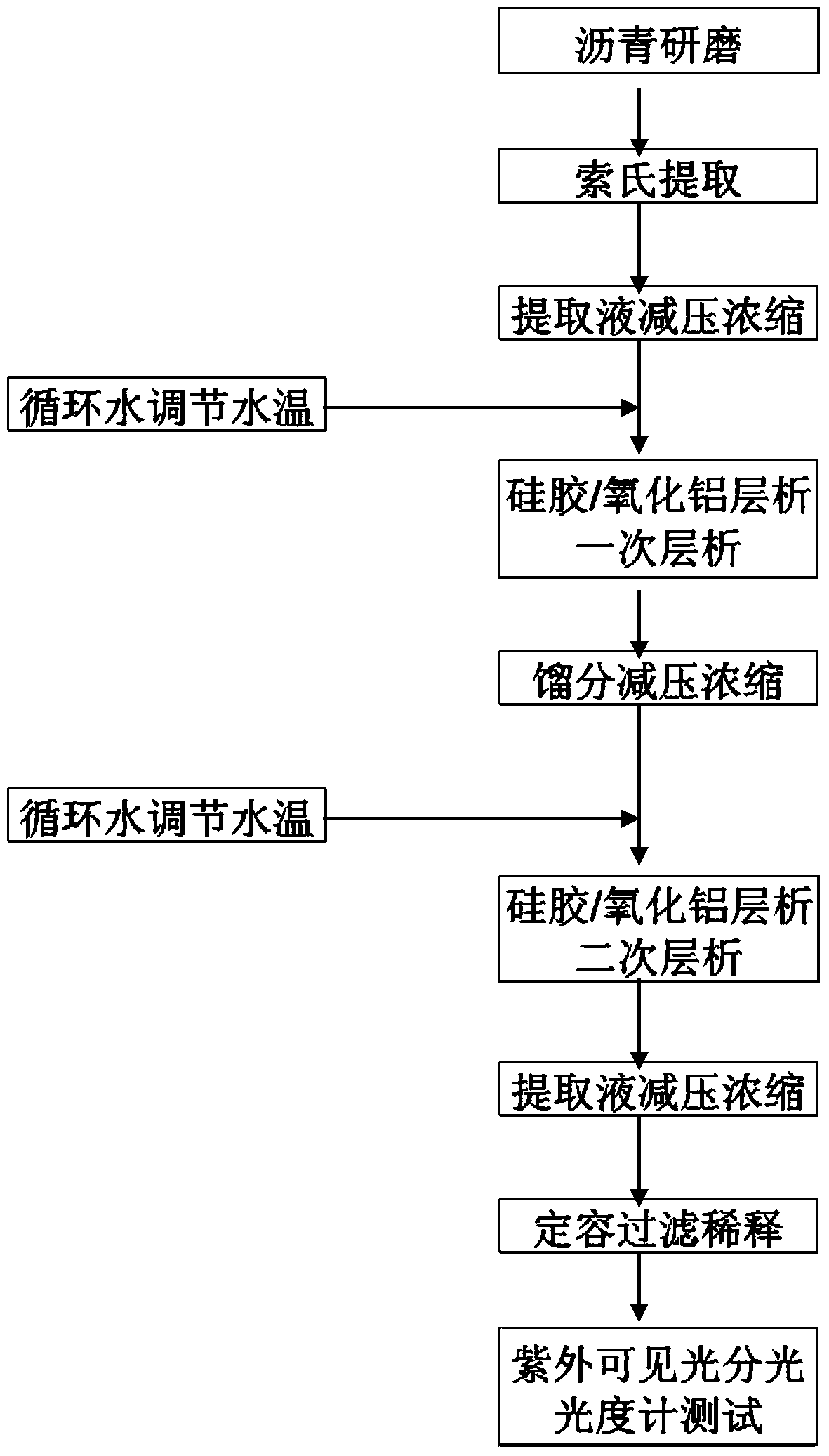

Method for detecting benzo (a) pyrene in medium and high-temperature coal pitch

ActiveCN104316484AEfficient removalAccurate measurementPreparing sample for investigationColor/spectral properties measurementsTemperature controlVisibility

The invention discloses a method for detecting benzo (a) pyrene in medium and high-temperature coal pitch. The method comprises the steps of firstly constructing a standard working curve for analyzing benzo (a) pyrene, performing Soxhlet extraction on a medium or high-temperature coal pitch sample, performing chromatography on concentrated liquid in a photosensitive temperature control type glass chromatographic column to obtain a sample, and analyzing the sample by a UV1601 ultraviolet visible spectrophotometer to obtain the content of benzo (a) pyrene in the medium and high-temperature coal pitch. The method has the advantages of accuracy and visibility.

Owner:CHINA RES INST OF DAILY CHEM IND

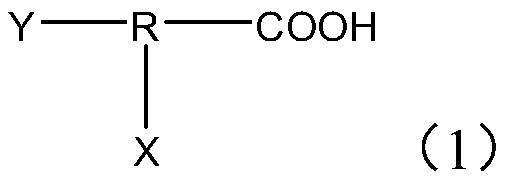

Composite coating used for titanium alloy investment precision casting, surface coating and preparation method and application thereof

ActiveCN110125326ASmall specific surface areaReduce hydrationFoundry mouldsFoundry coresOxide ceramicAdhesive

The invention discloses a composite coating used for the titanium alloy investment precision casting, a surface coating and a preparation method and application thereof. Preparation materials of the composite coating used for titanium alloy investment precision casting comprise a refractory material, an adhesive, an anti-hydration agent and a regulator, wherein the refractory material comprises yttrium oxide, and the anti-hydration agent is a derivative of a saturated fatty acid. The structural formula of the derivative of the saturated fatty acid is shown in the following formula (1) that R represents an alkyl group, X and Y independently represent a substituent group, wherein the substituent group contains one or more of an alkyl group, a hydroxyl group, a phenyl group or a carboxyl group. The surface coating comprises the composite coating, and further comprises a wetting agent and a defoaming agent. The composite coating used for the titanium alloy investment precision casting andthe surface coating have the advantages of being simple in component, stable in performance, not easy to gel, not easy to dissolve in water, long in service life and low in production cost, and the reaction degree of yttrium oxide ceramic type shell and the titanium alloy prepared by using the coating is small, and the formed alpha adhesion layer is small in thickness.

Owner:湖南洛兰新材料有限公司

Method for preparing titanium alloy mold shell

InactiveCN107695283AEnsure the firmness of the bondLow costFoundry mouldsMoulding machinesCeramicTitanium dioxide

The invention discloses a method for preparing a titanium alloy mold shell. The method for preparing the titanium alloy mold shell comprises the steps that firstly, titanium dioxide sol is prepared and serves as a binder, then is mixed with boron nitride powder and Al2O3 powder and slurry is prepared for manufacturing the titanium alloy mold shell, finally, dewaxing and sintering are conducted, and the environment-friendly titanium alloy mold shell with good stability is obtained. According to the method for preparing the titanium alloy mold shell, boron nitride is used as a surface layer, Y2O3 and Al2O3 are used as a transition layer, electro-melting mullite is used as a stuccoing layer, combination firmness of the surface layer and the back layer is ensured, selection and combination ofkinds of ceramics solve the problems of low precision, poor stability and existing of certain harm in existing titanium alloy mold shell preparing, and the cost is low.

Owner:BAOJI YONGSHENGTAI TITANIUM IND

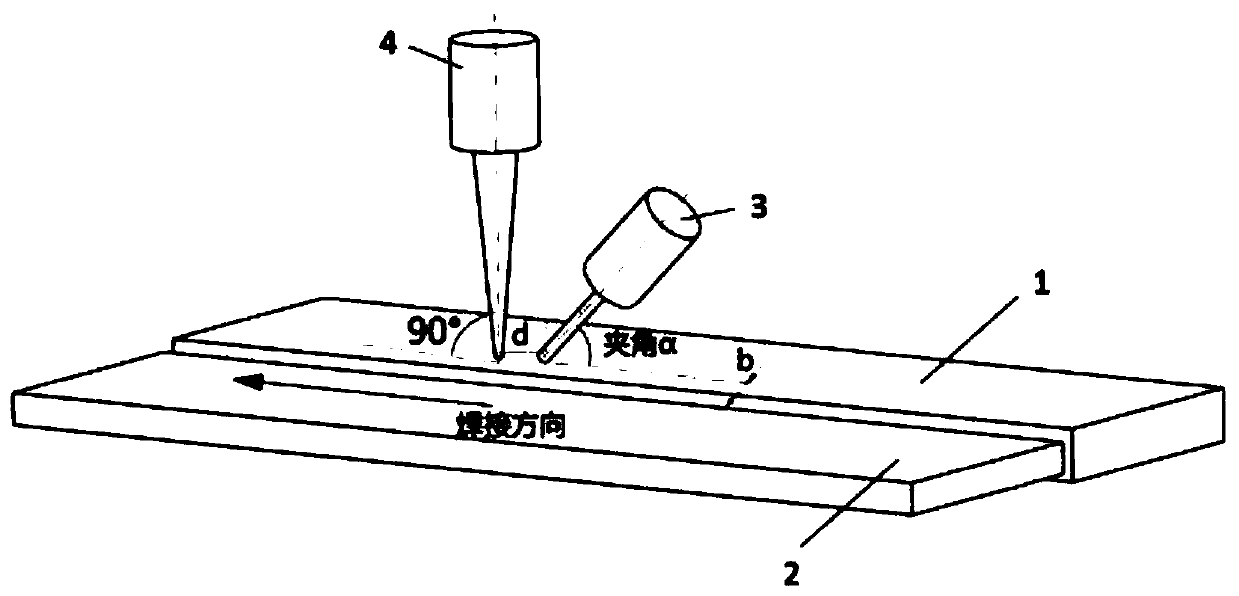

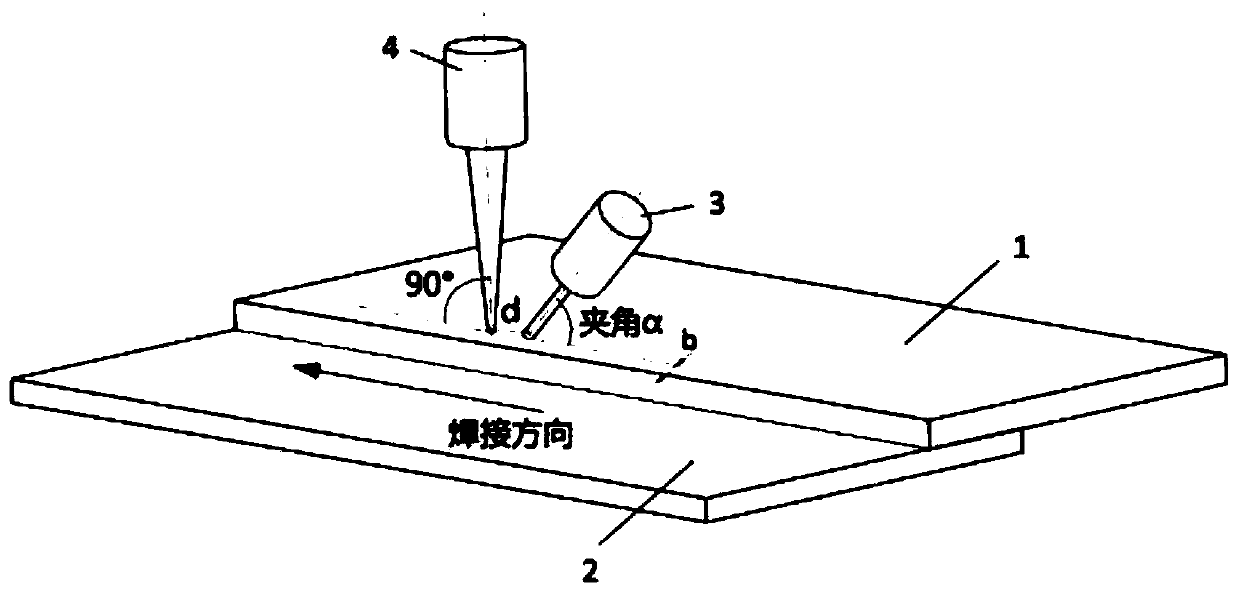

Aluminum/steel special metal low-power laser coupling DP-MIG welding-brazing method

InactiveCN109807420AImprove applicabilityStrong reliabilitySoldering apparatusWelding/soldering/cutting articlesGeneration rateHigh energy

The invention provides an aluminum / steel special metal low-power laser coupling DP-MIG welding-brazing method. The aluminum / steel special metal low-power laser coupling DP-MIG welding-brazing method comprises the following steps of polishing, washing and fixing an aluminium alloy and a steel material; and welding the fixed aluminium alloy and the fixed steel material, wherein the welding process comprises the steps of firstly, setting a compounding mode and a welding position; secondly, setting a laser incident angle and a laser parameter; thirdly, setting an electric arc welding gun angle andan electric arc parameter; fourthly, determining shielding gas and a welding wire; and fifthly, welding the aluminium alloy and the steel material at a welding speed of 0.1-1 m / min. According to thealuminum / steel special metal low-power laser coupling DP-MIG welding-brazing method, by using direct current double-pulse metal inert-gas welding, grain refinement and dendrite fragmentation are realized through periodical high energy pulse and low energy pulse alternative variation, and therefore, the pore generation rate and crack sensitivity are reduced; DP-MIG arc is also guided and stabilizedby using low power laser to be beneficial for inhibiting the growth of intermetallic compound layer; and therefore, the wettability and spreadability of a joint are improved so that the strength of the joint is enhanced.

Owner:CENT SOUTH UNIV

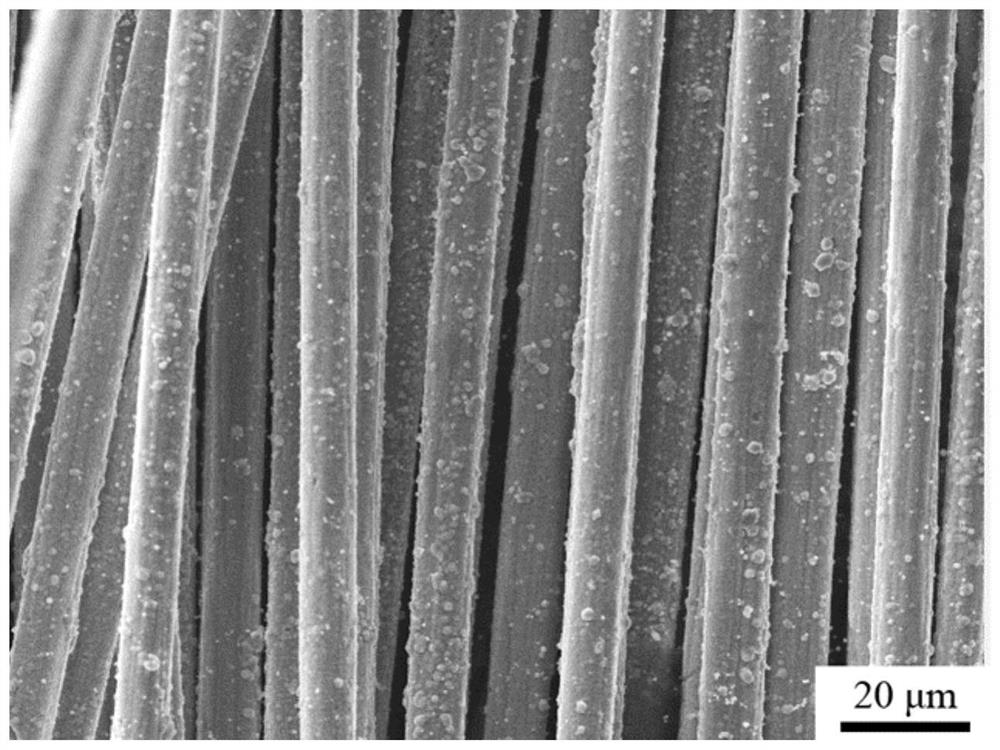

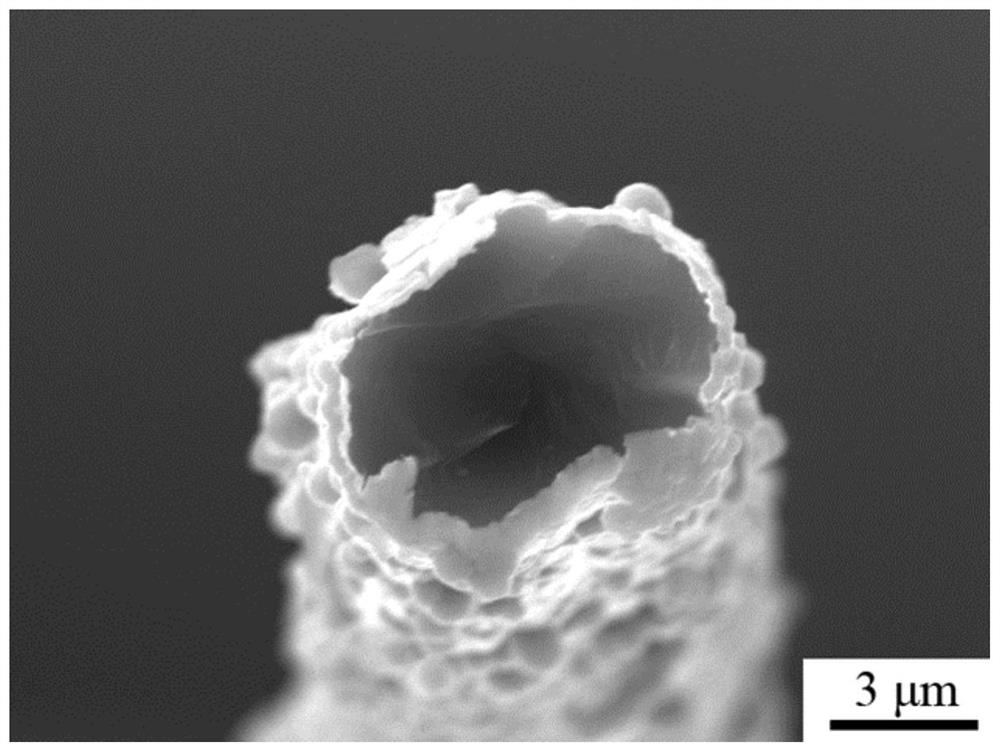

Preparation method of modified carbon fiber and zirconium carbide reinforced aluminum-based composite material

PendingCN112501523AImprove uniformityImprove mechanical propertiesLiquid/solution decomposition chemical coatingFiberCarbon fibers

The invention discloses a preparation method of a modified carbon fiber and zirconium carbide reinforced aluminum-based composite material. The preparation method comprises the following steps: carrying out degumming, roughening, sensitization, activation and reduction pretreatment on carbon fibers with the diameter of 6-7 [mu]m and the length of 0.5-2 mm; 2, a layer of metal nickel is plated on the surface of the carbon fiber by adopting a chemical plating method to obtain a nickel-plated carbon fiber; 3, ball-milling and mixing are performed on zirconium carbide and aluminum alloy powder, and nickel-plated carbon fibers are mechanically stirred to obtain mixed powder; and 4, spark plasma sintering is performed on the mixed powder, cooled and demolded to obtain the modified carbon fiber and zirconium carbide reinforced aluminum matrix composite material. The prepared modified carbon fiber and zirconium carbide reinforced aluminum matrix composite is good in mechanical property, high in hardness and good in wear resistance.

Owner:XI AN JIAOTONG UNIV +1

Quaternary nickel cobalt magnesium titanium cathode material of lithium ion battery, and preparation method thereof

InactiveCN106058172AIncrease capacityEasy to passCell electrodesSecondary cellsNickel saltMagnesium salt

This invention provides a quaternary nickel cobalt magnesium titanium cathode material of lithium ion battery, and a preparation method thereof. The chemical formula of the cathode material is Li (NixCoyMgzTiz) O2; the cathode material is formed by calcining a precursor and a lithium source; the precursor is prepared by a chemical coprecipitation reaction of soluble nickel salt, soluble cobalt salt, soluble magnesium salt and soluble titanium salt according to the following mole ratio of metal materials: Ni:Co:Mg:Ti=x:y:z; x+y+2z=1; x is not less than 0.7 and is less than 1; y is not less than 0.05 and is not greater than 0.1; and z is not less than 0.05 and is not greater than 0.1. In this invention, four metal elements are used as the cathode material; the incorporation of Co, Ti and Mg is helpful to increase and improve the capacity of the cathode material, can reduce the reaction degree of Co4+ and HF (Hydrogen Fluoride) generated by LiPF6 in the electrolyte, and can improve the fast charging and discharging capacity and the cycling performance of the quaternary nickel cobalt magnesium titanium cathode material.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Process for improving plating thickness of zinc-nickel-plated low area

ActiveCN109402685AImprove complexation abilityImprove uniformityVacuum evaporation coatingSputtering coatingAlloyBiological activation

The invention belongs to the technical field of metal surface treatment, and particularly relates to a process for improving the plating thickness of a zinc-nickel-plated low area. The process comprises the following steps: pre-treatment, specifically, an alloy workpiece is subjected to de-oiling, hot washing, derusting and cold washing treatment in sequence, and then is subjected to physical activation and chemical activation in sequence; film formation, specifically, magnesium metal is evaporated on the activated alloy workpiece, sealing treatment is carried out, and then the workpiece is immersed in electrolyte for electroplating treatment to obtain a film-coated workpiece; and post-treatment, specifically, the film-coated workpiece is rinsed with clean water, leached with cold water, and dried to obtain the finished alloy workpiece. By using the magnesium metal as a pre-plating, the weight of the plating is greatly reduced, and through simple boiling water sealing and sodium silicate heat sealing treatment, the inertness of the magnesium plating and the corrosion resistance of the plating are improved.

Owner:NINGBO YADA METAL SURFACE TREATMENT

Application of serpentine magnesium extraction tailings in field of concrete and the concrete

ActiveCN110482991AHigh strengthAvoid crackingCement productionCrack resistanceUltimate tensile strength

The invention provides application of serpentine magnesium extraction tailings in the field of concrete and the concrete, and belongs to the field of concrete. According to the method, the serpentinemagnesium extraction tailings are used for preparing the concrete, so that the serpentine magnesium extraction tailings are completely utilized, and reutilization of resources is acehived. The invention further provides the concrete, in which the serpentine magnesium extraction tailings are used, and the effect of the concrete is equivalent to the performance of cement clinker-based concrete, so that the strength of the concrete can be improved, the concrete can completely replace cement for use; and meanwhile, the serpentine magnesium extraction tailings enable the concrete not to easily generate cracks; due to the water reducing agent, the concrete has good construction fluidity and is convenient to construct; the desulfurized gypsum can effectively reduce the setting time of the concrete, accelerate the construction speed and improve the durability of the concrete, and the components are matched with each other and have a synergistic effect, so that the concrete provided by the invention has very excellent strength, durability, fluidity and crack resistance, and is suitable for wide popularization and application.

Owner:BEIJING OUFEI JINTAI TECH CO LTD

Synthesis method of 2, 4-dichloroacetophenone

InactiveCN112500277AIncrease profitThorough responseMolecular sieve catalystsCarbonyl compound preparation by condensationAluminium chloridePtru catalyst

The invention provides a synthesis method of 2, 4-dichloroacetophenone, which breaks through a conventional temperature curve, effectively enhances the utilization ratio of the catalyst by using temperature change and adding the catalyst in different time periods according to the proportion, and promotes the reaction degree to be more thorough. Meanwhile, a modified mixture of aluminum chloride and ferric chloride is adopted as the catalyst, and the catalyst is supported on the porous support by utilizing the porous support, so that the activity of the catalyst is improved, the yield and the purity are improved, and the reaction rate and the reaction degree are prevented from being reduced due to catalyst deposition in the reaction process; and besides, in the reaction process, the modified molecular sieve catalyst is used for carrying out directional isomerization treatment on the by-product, the treated modified molecular sieve catalyst has high stability and high selectivity, the p-dichlorobenzene by-product and the o-dichlorobenzene by-product in the reaction process are converted into the reaction raw material m-dichlorobenzene, the utilization rate of the raw material is increased, and the generation of the by-product is reduced.

Owner:JIANGXI YONGTONG TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com