Synthesis method of 2, 4-dichloroacetophenone

A kind of technology of dichloroacetophenone and synthetic method, applied in 2 fields, can solve the problems such as insufficient effect, waste of resources, high catalyst usage, etc., to achieve improved yield and purity, improved utilization rate, and improved utilization of raw materials rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

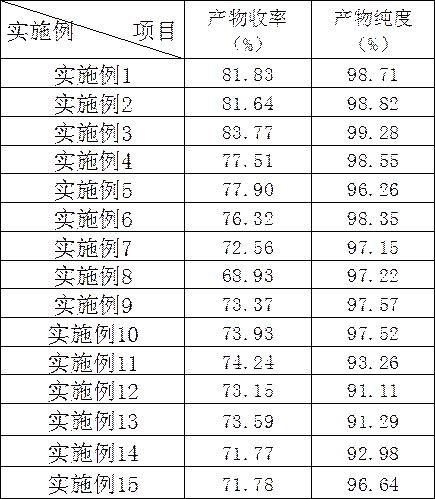

Examples

Embodiment 1

[0024] A kind of synthetic method of 2,4-dichloroacetophenone, comprises the following content:

[0025] The raw materials include 62 parts by weight of m-dichlorobenzene, 33 parts of acetyl chloride, 30 parts of catalyst, and 25 parts of water; the specific method is:

[0026] (1) Add m-dichlorobenzene into the reaction tank, raise the temperature to 45°C at 2°C / min, add 40% of the catalyst by weight at 180rpm, keep the temperature constant for 30min, keep the speed constant, and then add 30% The above parts by weight of the catalyst, then add the above parts by weight of acetyl chloride dropwise within 1 hour, raise the temperature to 65°C, keep the temperature for 15 minutes, add the remaining catalyst by weight above, raise the temperature to 95°C at 3°C / min, and stir the reaction at this temperature 7h, stirring speed is 420rpm;

[0027] (2) Keep the stirring rate constant, cool down to 60°C naturally, add 5 parts of modified molecular sieve catalyst, react at constant t...

Embodiment 2

[0037] A kind of synthetic method of 2,4-dichloroacetophenone, comprises the following content:

[0038] The raw materials include 95 parts of m-dichlorobenzene, 62 parts of acetyl chloride, 50 parts of catalyst and 45 parts of water in parts by weight; the specific method is:

[0039] (1) Add m-dichlorobenzene into the reaction tank, raise the temperature to 55°C at 5°C / min, add 40% of the catalyst by weight at a speed of 300rpm, keep the temperature constant for 60min, keep the speed constant, and then add 30% The above weight parts of catalyst, then dropwise add the above weight parts of acetyl chloride within 2 hours, raise the temperature to 75 ° C, keep the temperature for 30 min, add the remaining above weight parts of catalyst, raise the temperature to 115 ° C at 7 ° C / min, and stir the reaction at this temperature 10h, stirring speed is 650rpm;

[0040] (2) Keep the stirring rate constant, cool down to 70°C naturally, add 15 parts of modified molecular sieve cataly...

Embodiment 3

[0050] A kind of synthetic method of 2,4-dichloroacetophenone, comprises the following content:

[0051] The raw materials include 78 parts of m-dichlorobenzene, 48 parts of acetyl chloride, 40 parts of catalyst and 35 parts of water in parts by weight; the specific method is:

[0052] (1) Add m-dichlorobenzene into the reaction tank, raise the temperature to 50°C at 3°C / min, add 40% of the catalyst by weight at 240rpm, keep the temperature constant for 45min, and then add 30% The above parts by weight of the catalyst, then add the above parts by weight of acetyl chloride dropwise within 1.5 hours, raise the temperature to 70°C, keep the temperature constant for 22min, add the remaining catalyst by weight above, raise the temperature to 105°C at 5°C / min, and stir at this temperature Reaction 8h, stirring speed is 550rpm;

[0053] (2) Keep the stirring rate constant, lower the temperature to 65°C naturally, add 10 parts of modified molecular sieve catalyst, react at constant t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com