Aluminum/steel special metal low-power laser coupling DP-MIG welding-brazing method

A DP-MIG, dissimilar metal technology, applied in the field of low-power laser coupling DP-MIG welding and brazing of aluminum/steel dissimilar metals, can solve the problem of high heat input of high-power laser-arc hybrid welding, and it is difficult to effectively control the intermetallic The thickness of the compound layer, the poor wettability and spreadability of the joint, etc., can reduce the welding heat input, improve the applicability and reliability, and achieve the effect of grain refinement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The low-power laser coupling DP-MIG arc is used to weld aluminum alloy and steel. The base metal is 5052 aluminum alloy and ultra-high-strength thermoforming steel 22MnB5. The thickness of the aluminum alloy is 1.5mm, and the thickness of the thermoforming steel 22MnB5 is 1.3mm. The joint form is a butt joint.

[0038] Before welding, use sandpaper to grind the surface of aluminum alloy and thermoformed steel to remove surface impurities, oil stains and oxide layers, clean them with alcohol, and then fix them with clamps.

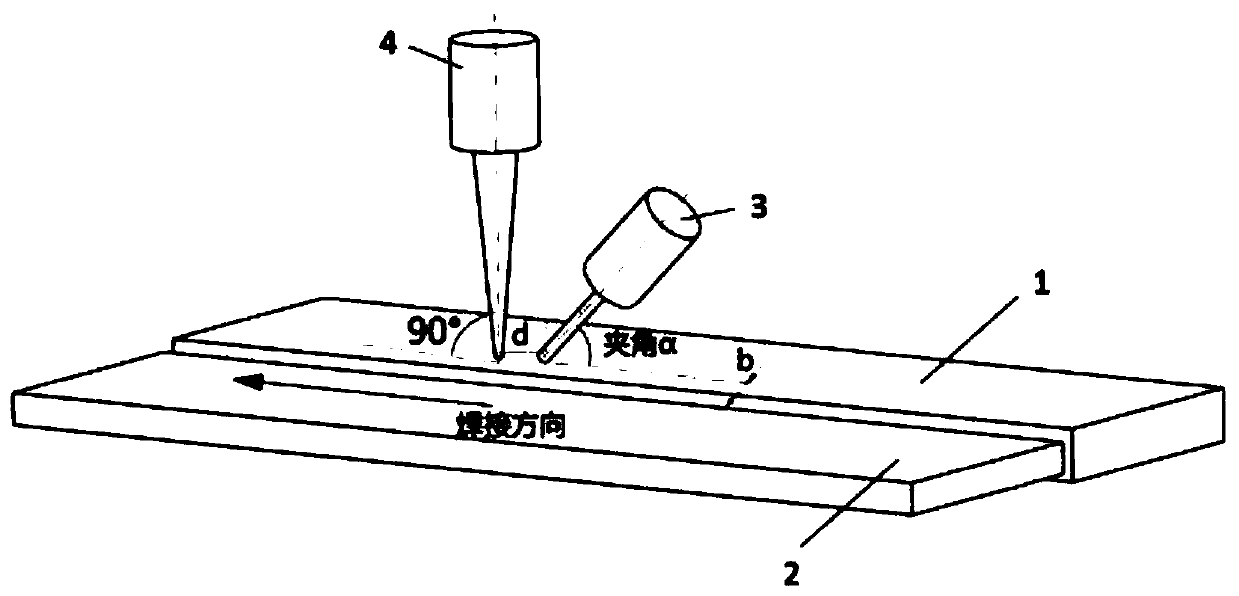

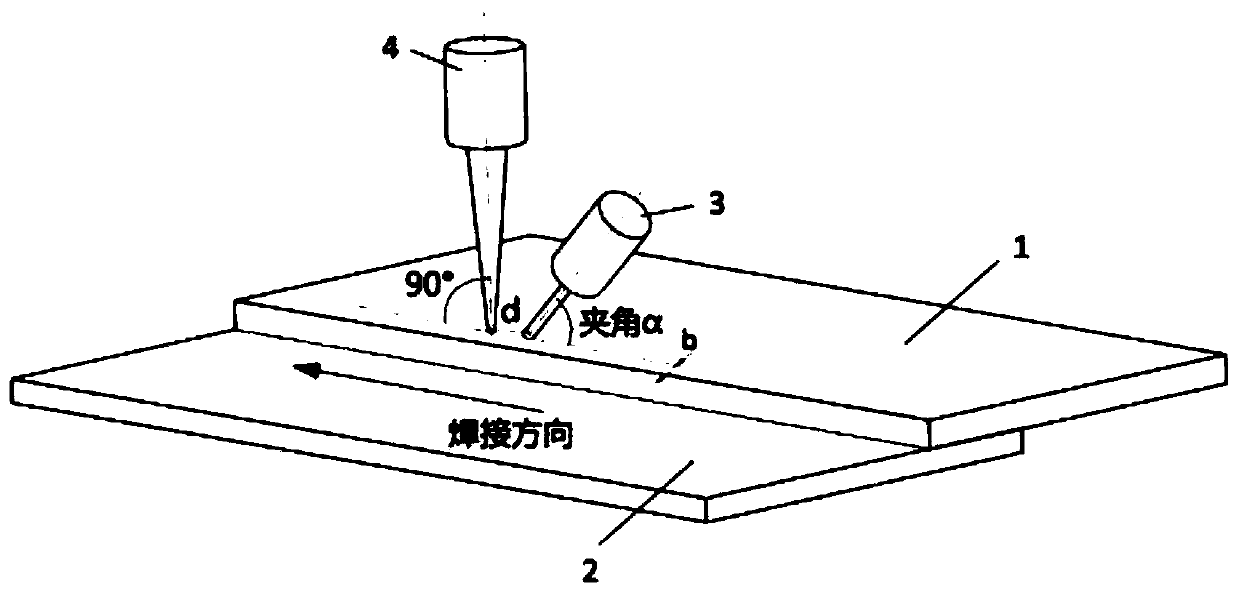

[0039]The laser and the DP-MIG arc adopt paraxial coupling. During the welding process, the laser is in front and the arc is in the back. The distance between the base metal intersection point and the laser action point on the base metal) is 0.5mm, the offset b is 0.6mm, the angle α between the arc welding torch and the welding base metal is 45°, and the average current of the high-energy pulse group is 120A. The average current of the low-energy pu...

Embodiment 2

[0041] The low-power laser coupling DP-MIG arc is used to weld aluminum alloy and steel. The base metal is 5052 aluminum alloy and ultra-high-strength thermoforming steel 22MnB5. The thickness of the aluminum alloy is 2.2mm, and the thickness of the thermoforming steel 22MnB5 is 1.8mm. The joint form is a butt joint.

[0042] Before welding, use sandpaper to grind the surface of aluminum alloy and thermoformed steel to remove surface impurities, oil stains and oxide layers, clean them with alcohol, and then fix them with clamps.

[0043] The laser and the DP-MIG arc adopt paraxial coupling. During the welding process, the laser is in front and the arc is in the back. The distance between the base metal intersection point and the laser action point on the base metal) is 2mm, the offset b is 1mm, the angle α between the arc welding torch and the welding base metal is 60°, the average current of the high-energy pulse group is 250A, and the low-energy The pulse group average curr...

Embodiment 3

[0045] The low-power laser coupling DP-MIG arc is used to weld aluminum alloy and steel. The base metal is 5052 aluminum alloy and TWIP980 high-strength steel. The thickness of aluminum alloy is 2mm, and the thickness of TWIP 980 is 1.5mm. The welding joint is lap joint. connector.

[0046] Before welding, use sandpaper to grind the surface of aluminum alloy and thermoformed steel to remove surface impurities, oil stains and oxide layers, clean them with alcohol, and then fix them with clamps.

[0047] The laser and DP-MIG arc adopt paraxial coupling. During the welding process, the laser is in front and the arc is in the back. The distance between the base metal intersection point and the laser action point on the base metal) is 0.3mm, the offset b is 1mm, the angle α between the arc welding torch and the welding base metal is 45°, the average current of the high-energy pulse group is 140A, and the low The average current of energy pulse group is 50A, the frequency of low en...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com