Passivating treatment method for stainless steel rare earth conversion coatings

A passivation treatment and rare earth conversion technology, applied in the direction of metal material coating process, etc., can solve the problems of waste water pollution to the environment, health hazards of workers, and high toxicity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

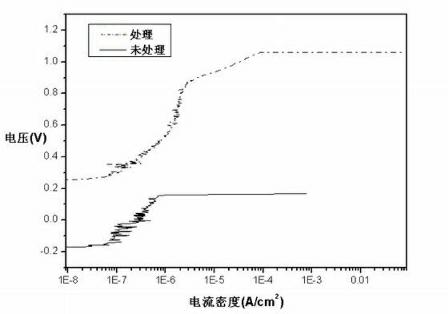

[0016] Surface treatment and polarization curve test of 316L stainless steel at 55°C

[0017] The 316L stainless steel is treated according to the steps described in the content of the invention: mechanically polish a 20mm×10mm×5mm 316L stainless steel sample to clean the surface and remove oil stains; the passivation temperature is controlled at 55°C, and 0.023mol / L cerium nitrate is added to the passivation solution and citric acid with a mass fraction of 0.4%, and distilled water and hydrogen peroxide (with a mass fraction of 30% hydrogen peroxide) at a volume ratio of 1:1, and treat for a certain period of time until the surface color of the sample turns golden yellow to obtain a uniform rare earth conversion coating; then Take out the sample, wash it with deionized water, put it into a desiccator at room temperature and wait for it to dry completely, and get a dense rare earth oxide film on the stainless steel surface. Seal the non-working surface with epoxy resin, leavin...

Embodiment 2

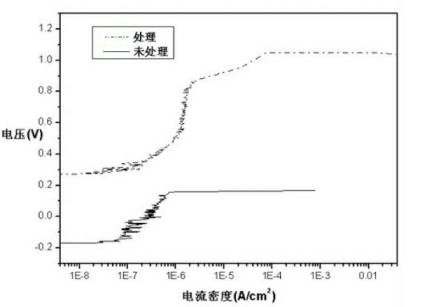

[0019] Surface treatment and polarization curve test of 316L stainless steel at 70°C

[0020] The 316L stainless steel is treated according to the steps described in the content of the invention: mechanically polish a 20mm×10mm×5mm 316L stainless steel sample to clean the surface and remove oil stains; the passivation temperature is controlled at 70°C, and 0.023mol / L cerium nitrate is added to the passivation solution and citric acid with a mass fraction of 0.5%, and distilled water and hydrogen peroxide (30% hydrogen peroxide) in a volume ratio of 1:1, and treat for a certain period of time until the surface color of the sample turns golden yellow to obtain a uniform rare earth conversion coating; then Take out the sample, wash it with deionized water, put it into a desiccator at room temperature and wait for it to dry completely, and get a dense rare earth oxide film on the stainless steel surface. Seal the non-working surface with epoxy resin, leaving only the surface of 15...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com