Preparation method of modified carbon fiber and zirconium carbide reinforced aluminum-based composite material

A technology for strengthening aluminum-based and composite materials, applied in metal material coating process, liquid chemical plating, coating, etc., can solve problems such as increasing the reaction degree of Al and C, large difference in carbon fiber density, and difficulty in uniform distribution of carbon fibers , to achieve the effects of improving wear resistance and mechanical properties, increasing sintering rate and shortening sintering time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

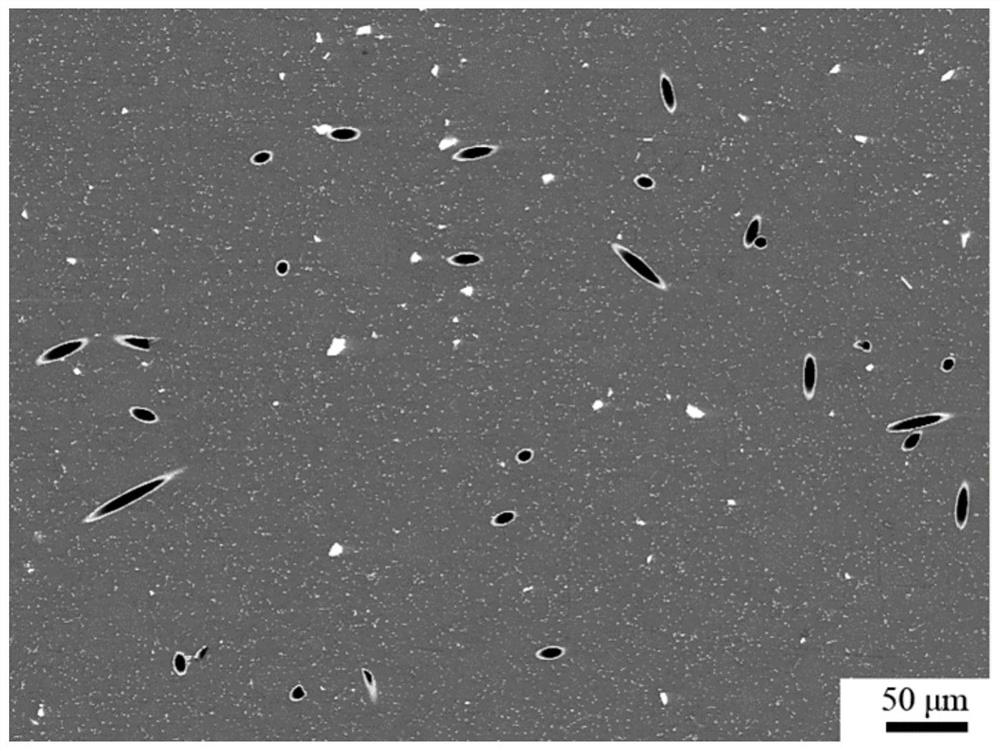

[0038] A preparation method of modified carbon fiber and zirconium carbide reinforced aluminum matrix composite material of the present invention comprises the following steps:

[0039] S1. Use acetone to degumming the carbon fiber. The degumming time is 24-48 hours. After the degumming is completed, wash the carbon fiber with deionized water until neutral;

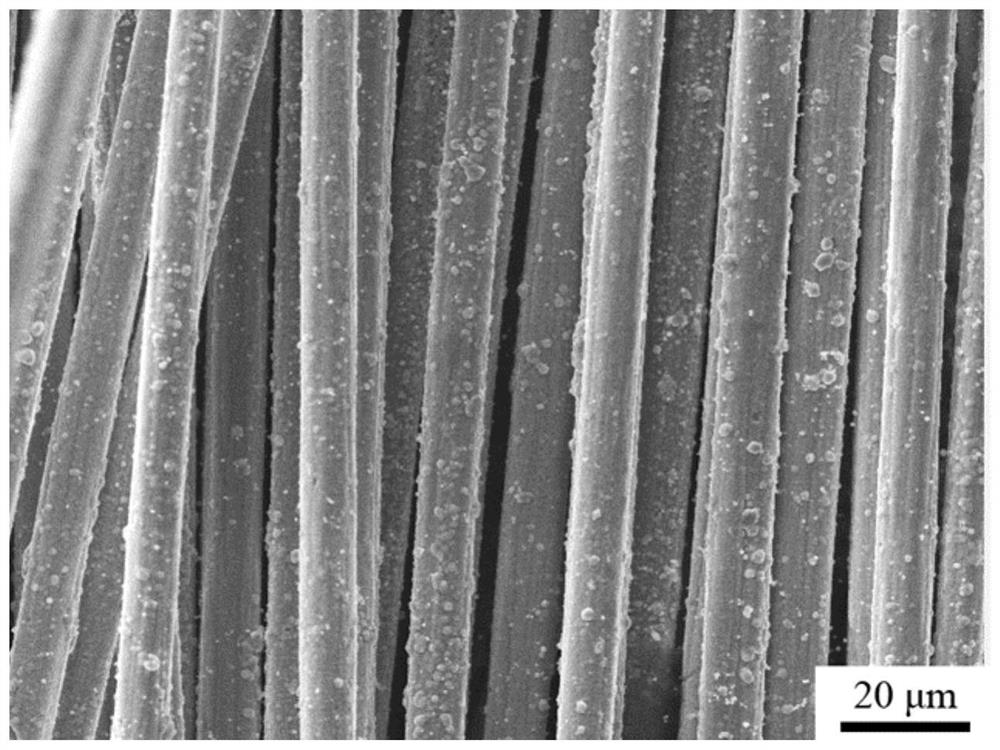

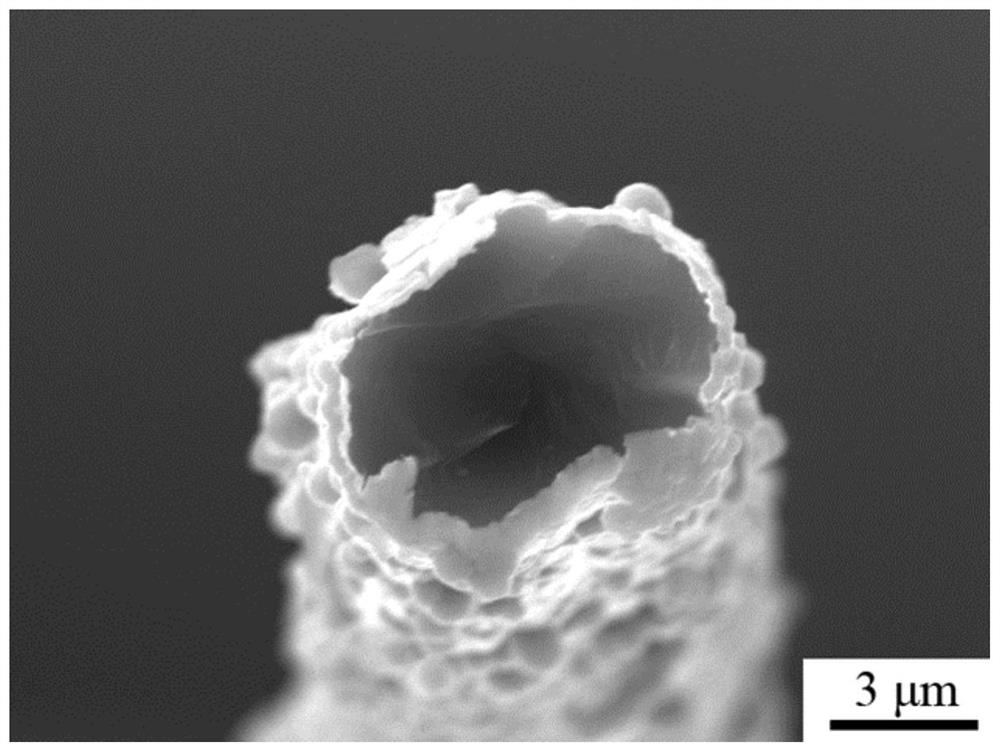

[0040] The carbon fiber model is T300-12k, with a diameter of 6-7 μm and a length of 0.5-2 mm.

[0041] S2. Put the carbon fiber into the roughening solution, roughen it for 2-4 hours, and then wash it with deionized water until neutral;

[0042] Rough solution is 100~140ml / L H 2 SO 4 and 140~200g / L (NH 4 ) 2 SO 4 .

[0043] S3. Put the carbon fibers into the sensitization solution, stir with a magnetic stirrer for 15-30 minutes, and then wash the carbon fibers with deionized water until neutral;

[0044] The sensitization solution is SnCl with a concentration of 20-40g / L 2 And 40~50ml / L concentrated HCl.

[0045...

Embodiment 1

[0057] S1. Use acetone to degumming the carbon fiber. The degumming time is 24 hours. After the degumming is completed, the carbon fiber is washed with deionized water until neutral; the carbon fiber model is T300-12k, the diameter is 6-7 μm, and the length is 0.5mm.

[0058] S2, add 100ml / L of H 2 SO 4 and 140g / L (NH 4 ) 2 SO 4 Make a roughening solution, put the carbon fibers treated in step S1 into the roughening solution, roughen for 4 hours, and then wash with deionized water until neutral;

[0059] S3, SnCl with a concentration of 20g / L 2 Make a sensitization solution with concentrated HCl of 40ml / L, put the carbon fiber treated in step S2 into the sensitization solution, stir with a magnetic stirrer for 30min, and then wash the carbon fiber to neutrality with deionized water;

[0060] S4, the PdCl of 0.2g / L 2 Make an activation solution with 15ml / L concentrated HCl, put the carbon fiber treated in step S3 into the activation solution, stir it magnetically for 30mi...

Embodiment 2

[0068] S1. Use acetone to degumming the carbon fiber. The degumming time is 36 hours. After the degumming is completed, the carbon fiber is washed with deionized water until neutral; the carbon fiber model is T300-12k, the diameter is 6-7 μm, and the length is 1mm.

[0069] S2, add 110ml / L of H 2 SO 4 and 155g / L (NH 4 ) 2 SO 4 Prepare a roughening solution, put the carbon fibers treated in step S1 into the roughening solution, roughen for 3.5 hours, and then wash with deionized water until neutral;

[0070] S3, SnCl with a concentration of 25g / L 2 Make a sensitization solution with 42ml / L of concentrated HCl, put the carbon fibers treated in step S2 into the sensitization solution, stir with a magnetic stirrer for 25min, and then wash the carbon fibers with deionized water until neutral;

[0071] S4, the concentration is the PdCl of 0.24g / L 2 Make an activation solution with 16ml / L concentrated HCl, put the carbon fiber treated in step S3 into the activation solution, st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com