Bottom cork pulling type vacuum induction melting and casting control device

A technology of vacuum induction melting and control device, which is applied in the direction of manufacturing tools, casting melt containers, metal processing equipment, etc., can solve the problems of increasing the contact time and contact area between the melt and the crucible, which is not conducive to vacuum melting, and the use of castings is difficult. , to achieve the effect of reducing contact time and contact area, reducing structural complexity and good interchangeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

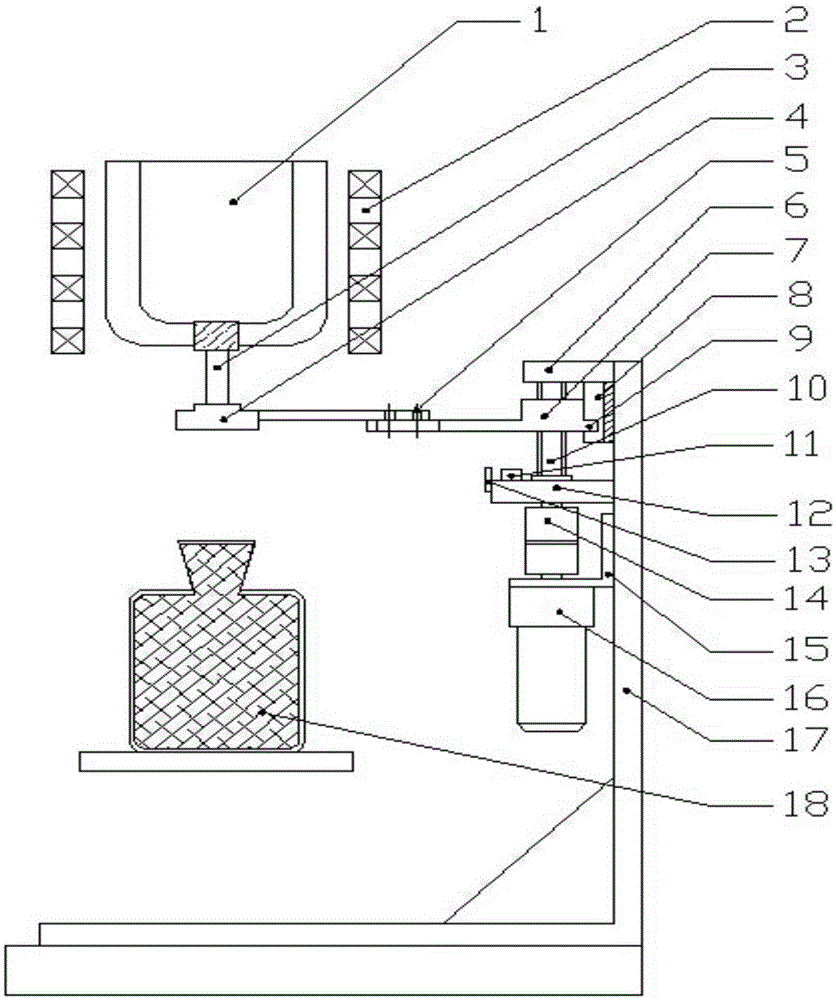

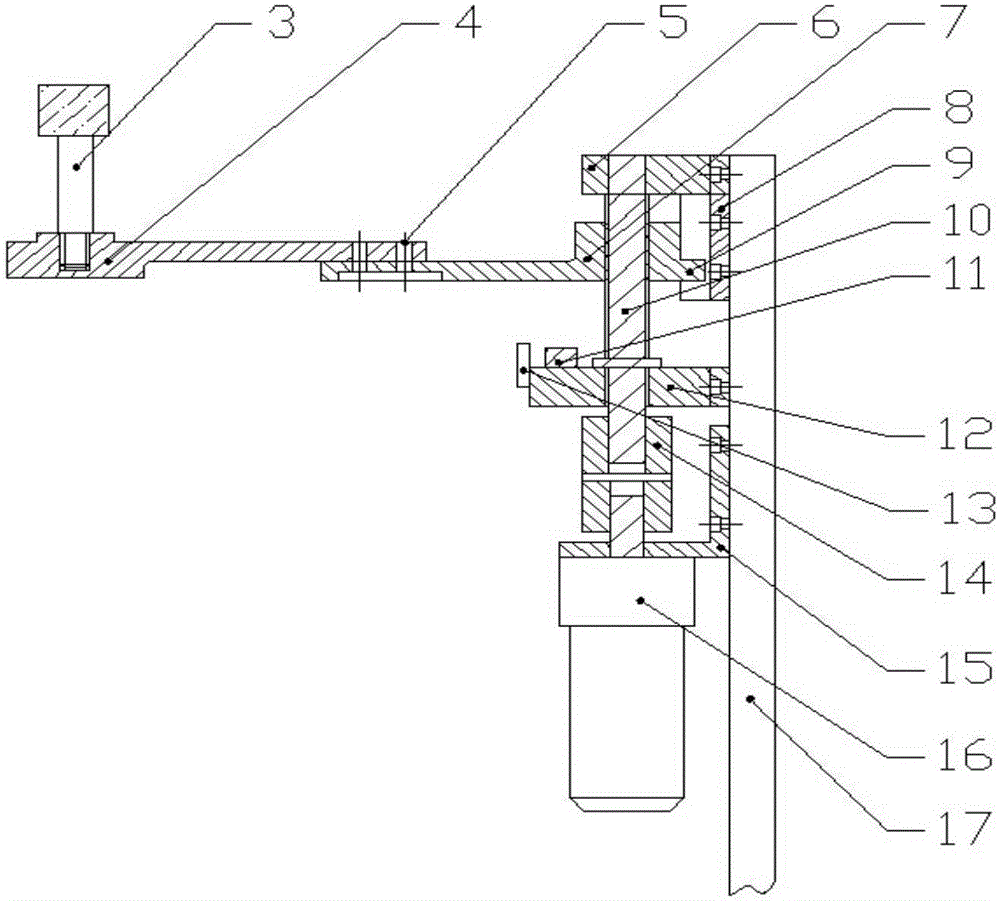

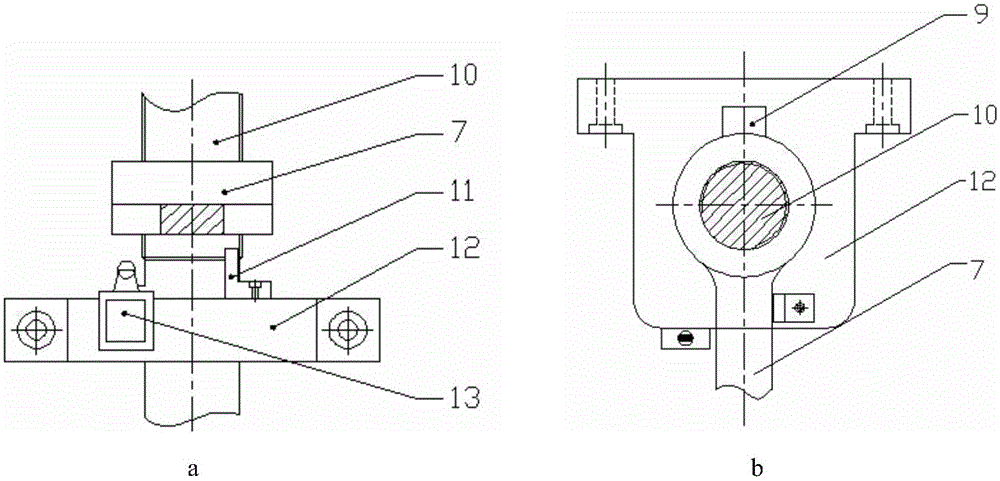

[0023] This embodiment is a bottom plugging type vacuum induction melting and pouring control device, which includes a melting and casting system, a plugging mechanism, a bracket 17 and a power control system. The melting and casting system includes a crucible 1 , an electromagnetic induction heating coil 2 and a casting mold 18 . The bottom of the crucible 1 has a pouring hole processed by a drilling machine; the electromagnetic induction heating coil 2 powered by a 30KHz high-frequency power supply adopts the existing technology and is set on the crucible 1 . Wherein: the plugging mechanism is installed on the supporting positioning mechanism, and the plug 3 in the plugging mechanism is installed in the pouring hole at the bottom of the crucible. The mold 18 is located below the plug.

[0024] The bracket 17 is the carrier of this embodiment, on which the top plate 6 , clamping plate 8 , support plate 12 and motor base 15 are fixed from top to bottom. The top plate 6 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com