Method for growing cz si crystal in total nitrogen environment

A technology of Czochralski silicon and single crystal, applied in the direction of crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of not effectively improving product quality, affecting product quality, crystalline silicon breaking, etc., to reduce The fragmentation rate of silicon wafers, the improvement of crystallization, and the effect of reducing the fragmentation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

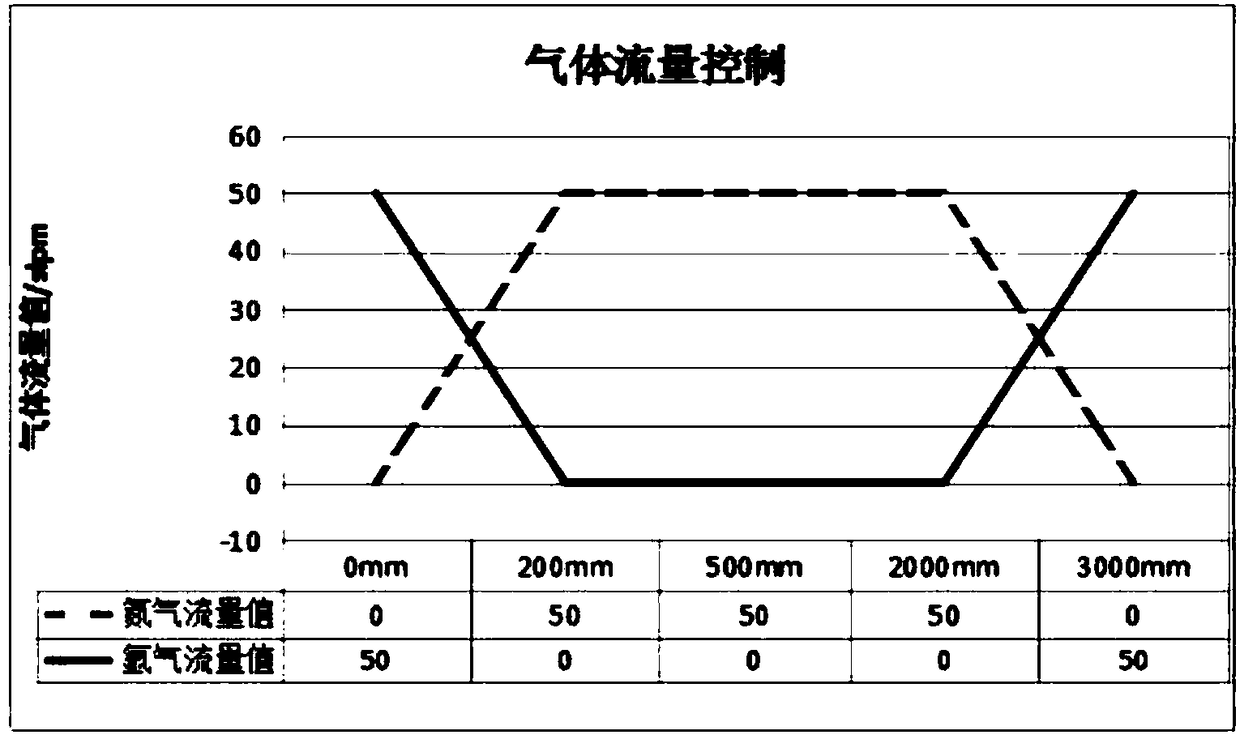

[0021] This example is a method for growing a Czochralski silicon single crystal with all nitrogen, which sequentially includes the steps of melting, temperature stabilization, seeding, shouldering, shoulder turning, equal diameter, and finishing.

[0022] The melting steps are as follows: crush the high-purity polysilicon material to an appropriate size, and put it into a high-purity quartz crucible. After charging, put the quartz crucible into the graphite crucible in the single crystal furnace, and then pump the single crystal furnace into A certain vacuum keeps it within a certain pressure range, and then fills in 99.999% high-purity argon with a flow rate of 50 slpm and a pressure of 11 Torr as a protective gas, and then heats up to a temperature exceeding 1420°C to ensure that the heating temperature reaches Above the melting point of silicon, the raw material is melted, the temperature should not be too high, a large amount of silicon vapor will accumulate, the bottom of...

Embodiment 2

[0030] The difference from Example 1 is that in the steps of melting, temperature stabilization, seeding, shoulder setting, shoulder turning, equal diameter, and finishing, the pressure in the furnace is 9 Torr, and the flow rate of the protective gas is 60 slpm.

Embodiment 3

[0032] The difference from Example 1 is that the pressure in the furnace is 10 Torr and the flow rate of the protective gas is 80 slpm in the steps of melting, temperature stabilization, seeding, shoulder setting, shoulder turning, equal diameter, and finishing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com