Patents

Literature

34results about How to "High shell strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

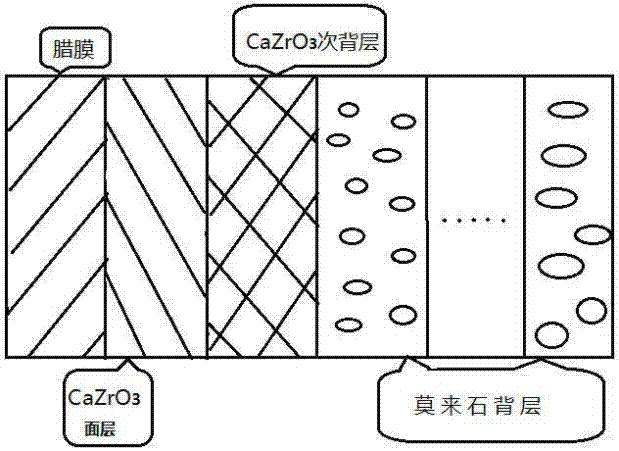

CaZrO3 mold shell used for titanium and titanium alloy precision casting and preparation method

ActiveCN103071764AHighlight substantiveSignificant progressFoundry mouldsFoundry coresZirconateTitanium

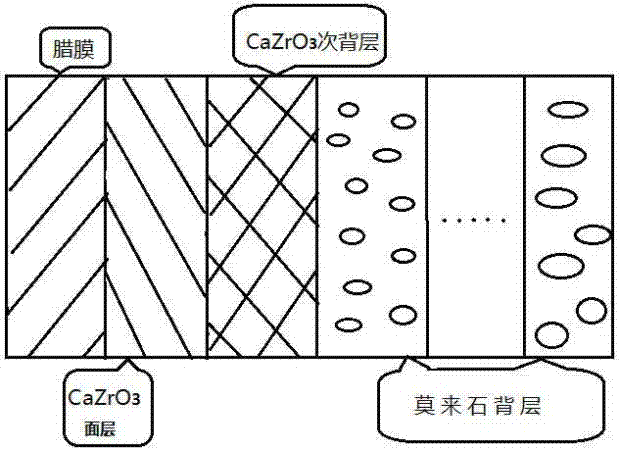

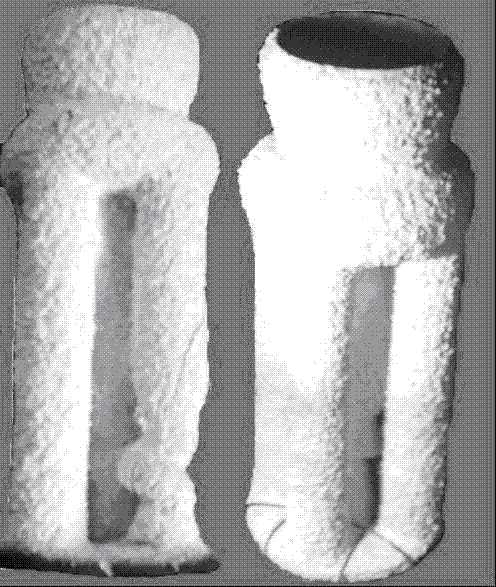

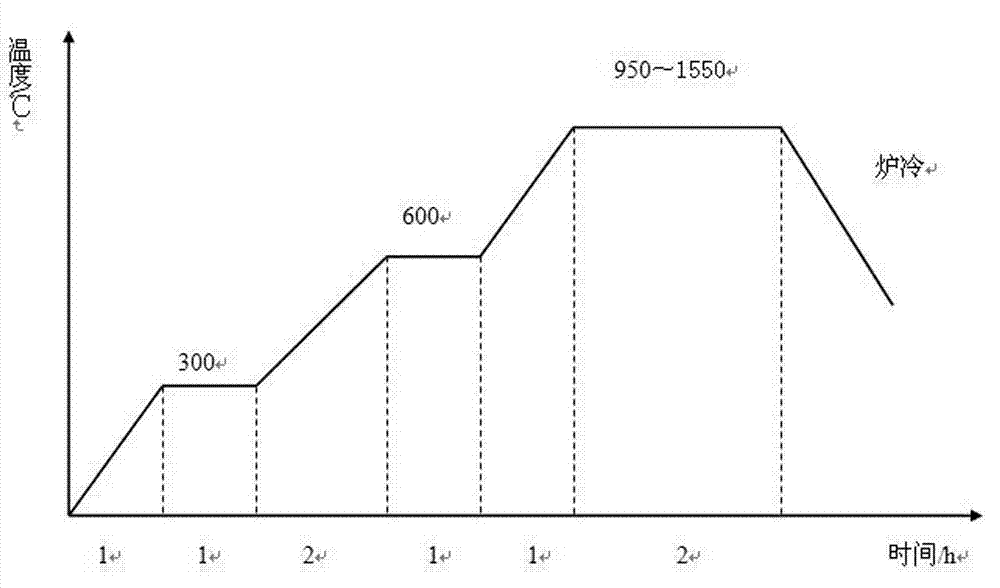

The invention discloses a CaZrO3 mold shell used for titanium and titanium alloy precision casting and a preparation method, which is characterized in that calcium zirconate is taken as a filling material, binders which are not reacted with a titanium alloy such as zirconium acetate or yttrium sol are pretreated, molded, hardened, roasted and the like to prepare the mold shell. The mold shell has small reaction degree with titanium and the titanium alloy, the thickness of contamination formed on the casting surface is small; the calcium zirconate ceramic mold shell has high strength, the casting surface has high fineness; a paint containing calcium zirconate is stable and is not easy to be gelled, the suspensibility is good, and the preservation time is long.

Owner:SHANGHAI UNIV +1

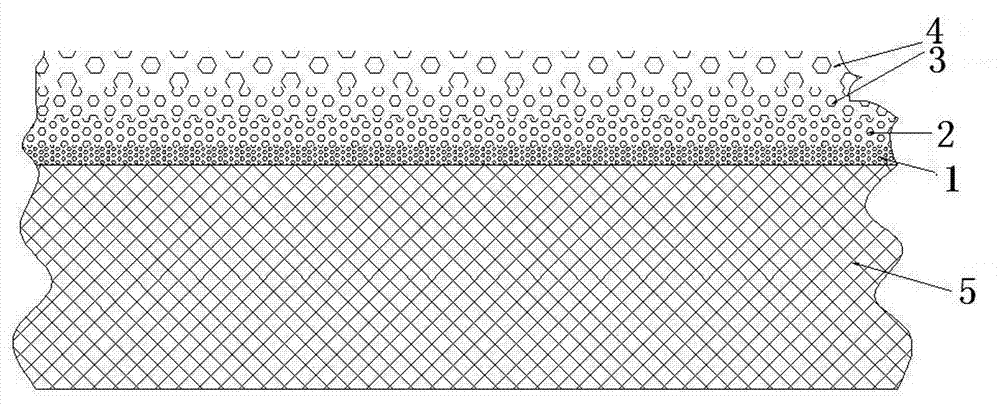

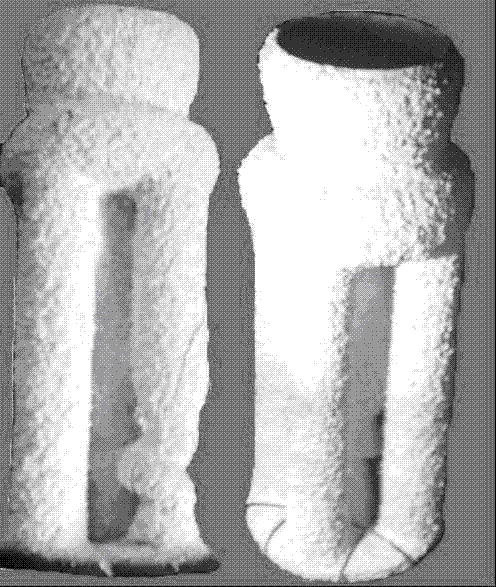

Anti-interface reaction composite ceramic shell

The invention relates to an anti-interface reaction composite ceramic shell. The shell consists of a surface layer and a reinforcing layer, the surface layer is made of yttria powder as refractory powder, yttria sand as refractory aggregate and silica sol as binder by adopting a multi-coating method, the reinforcing layer is made of electro-fused mullite powder as refractory powder, electro-fused corundum sand as refractory aggregate and silica sol as binder by adopting the multi-coating method, the reinforcing layer is fixed on the top surface of the surface layer, and the reinforcing layer and the surface layer are of an integrated structure; the total thickness of the shell is 5mm to 13mm, wherein the thickness of the surface layer is 0.15mm to 1.4mm. After the shell produced by the method is roasted, the surface of the cavity of the shell is smooth and does not have cracks, the surface does not have floating sand and floating powder, and the shape of a blade wax pattern is completely and clearly copied.

Owner:SHENYANG RES INST OF FOUNDRY

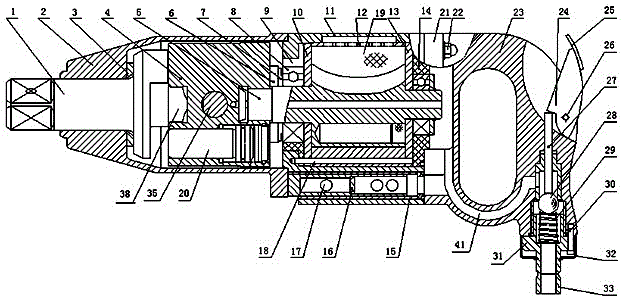

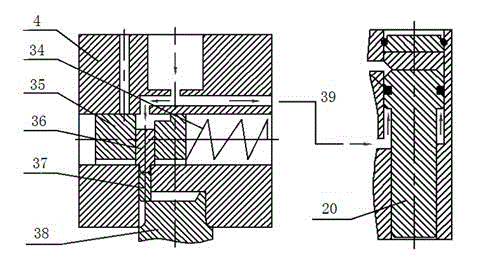

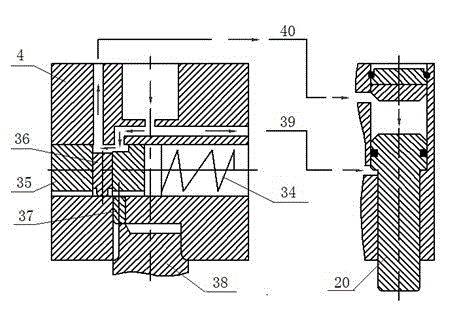

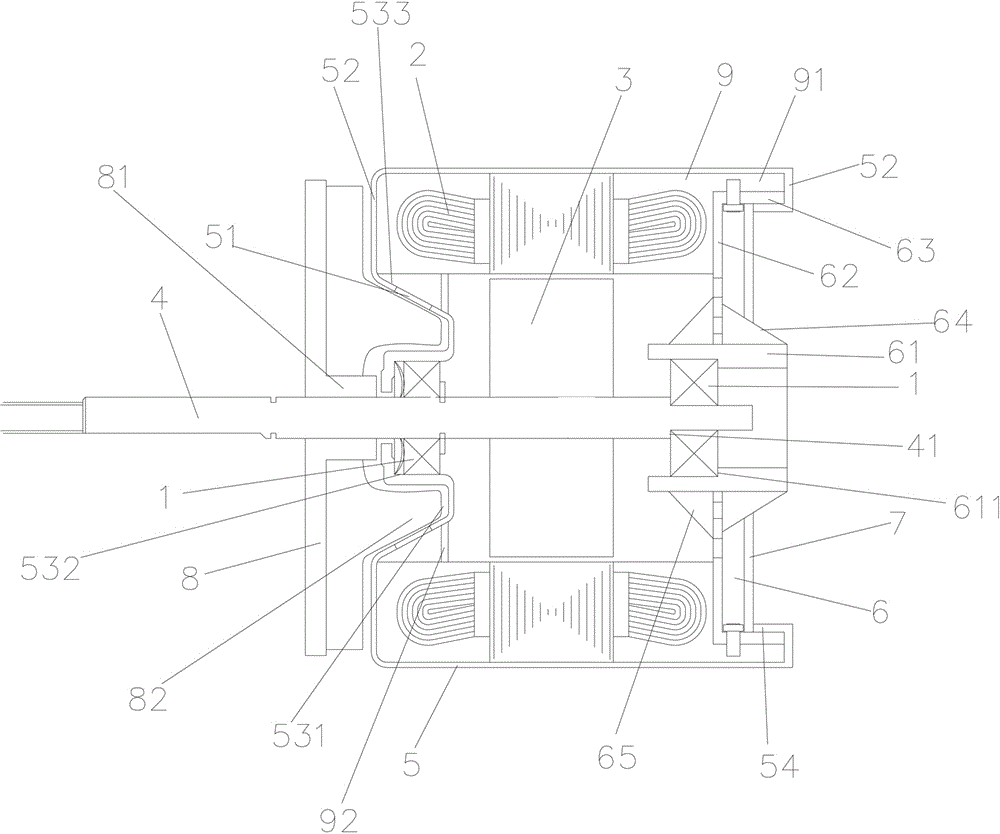

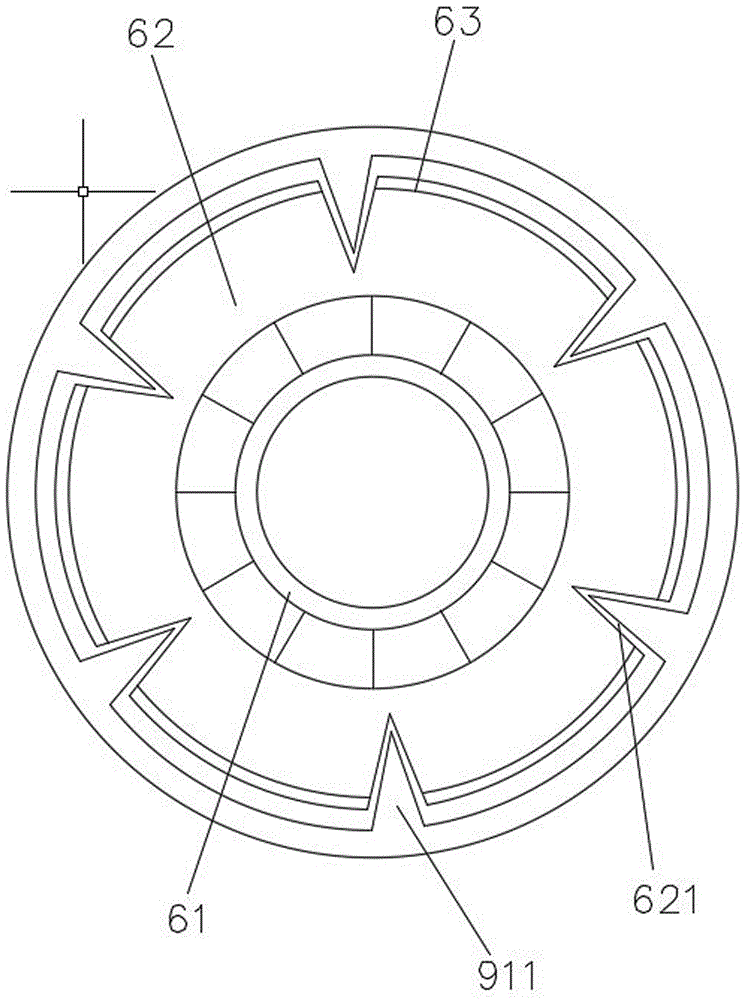

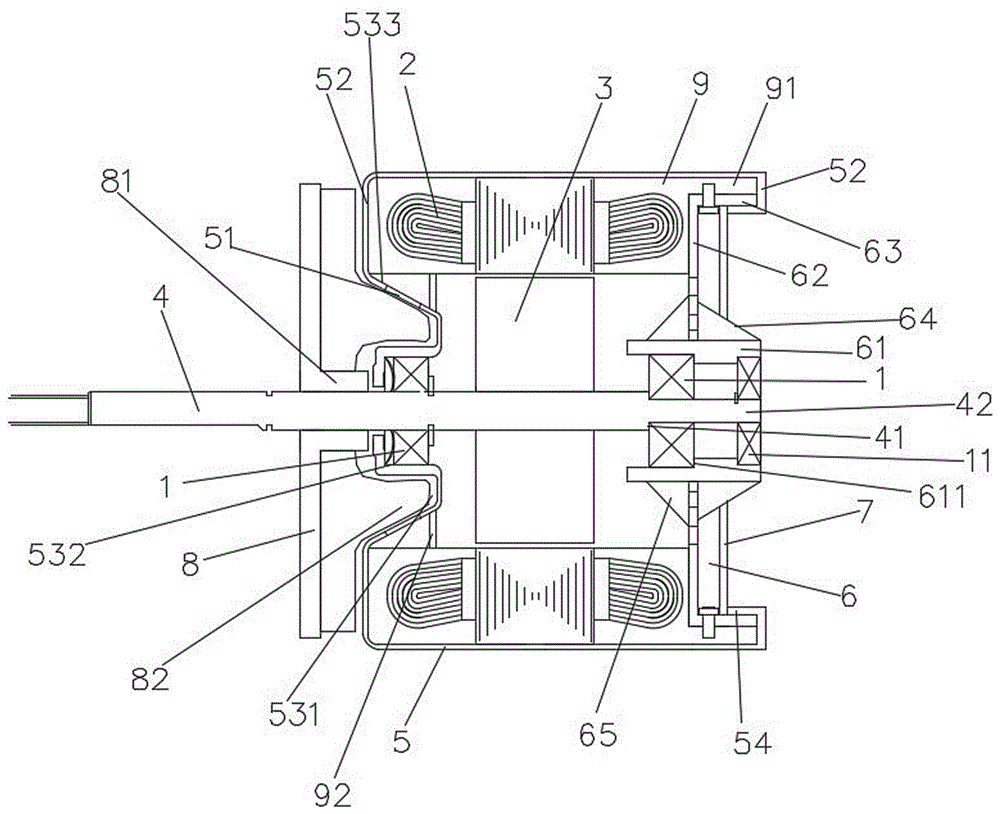

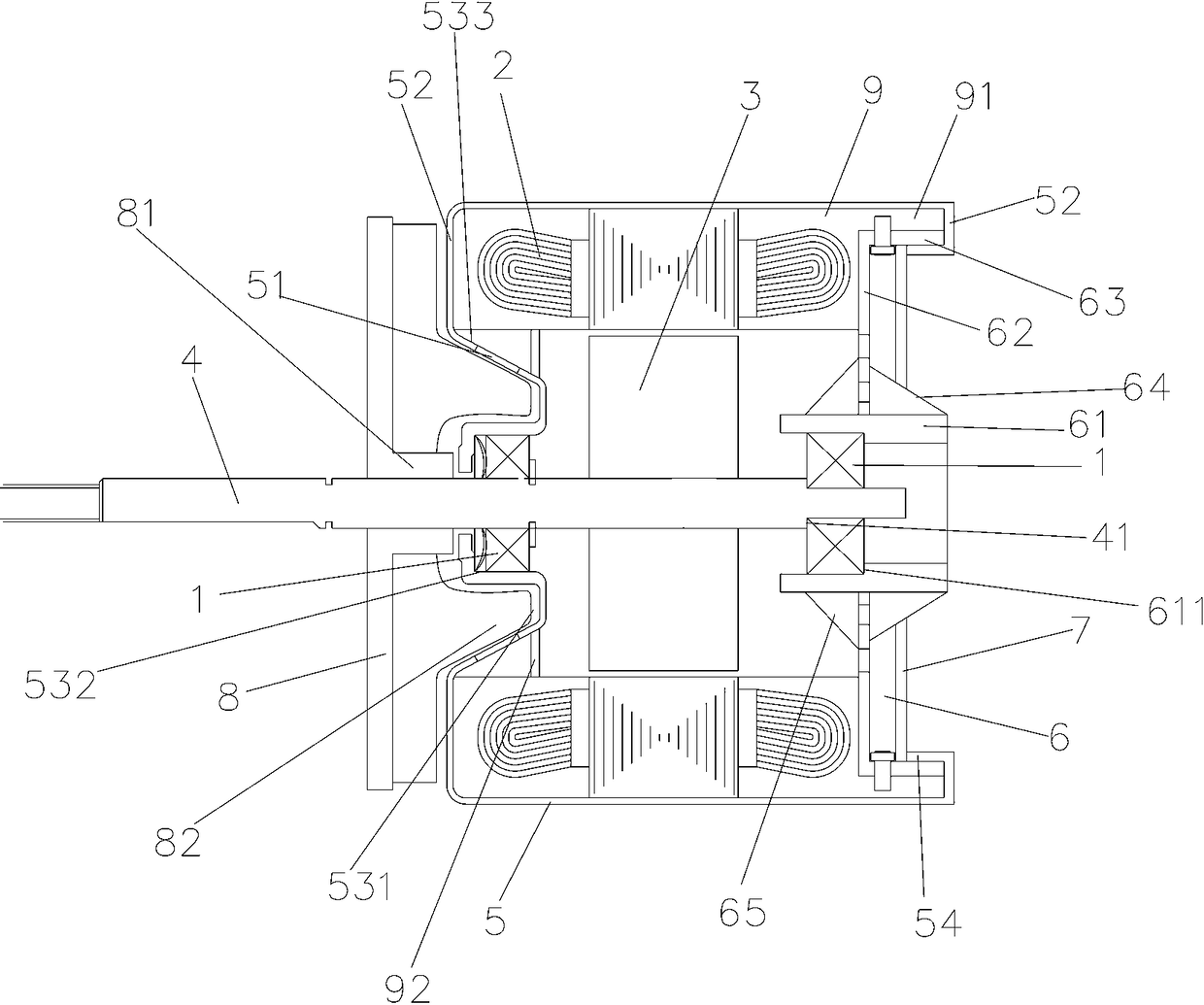

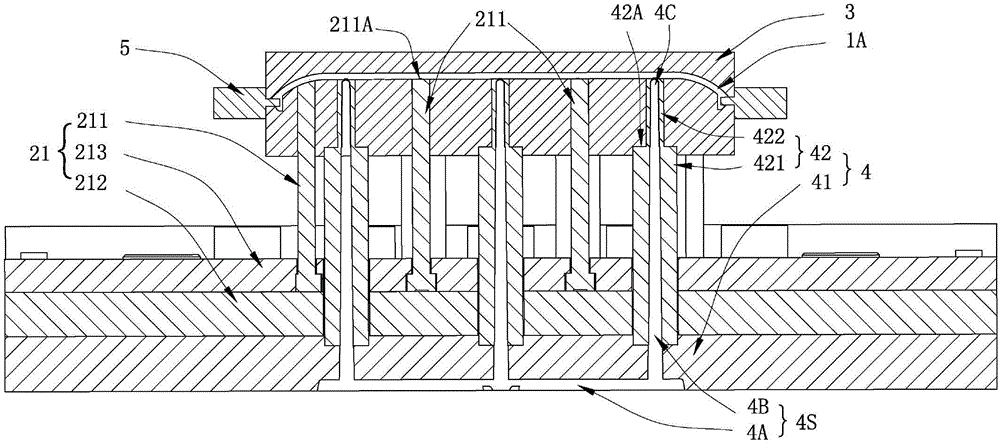

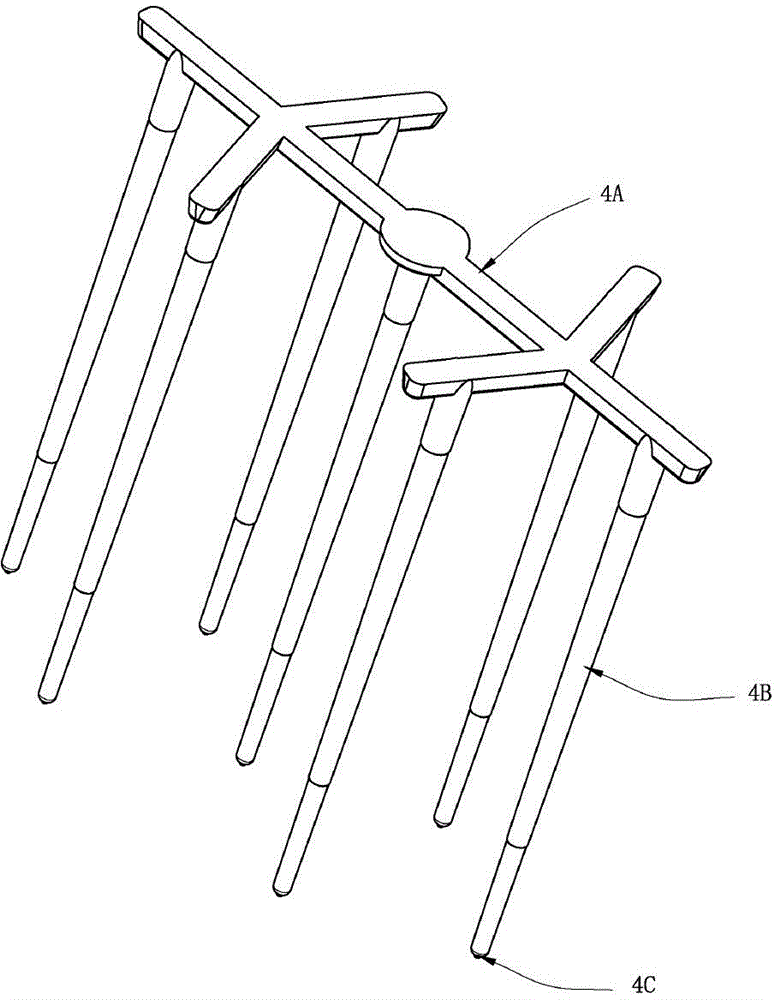

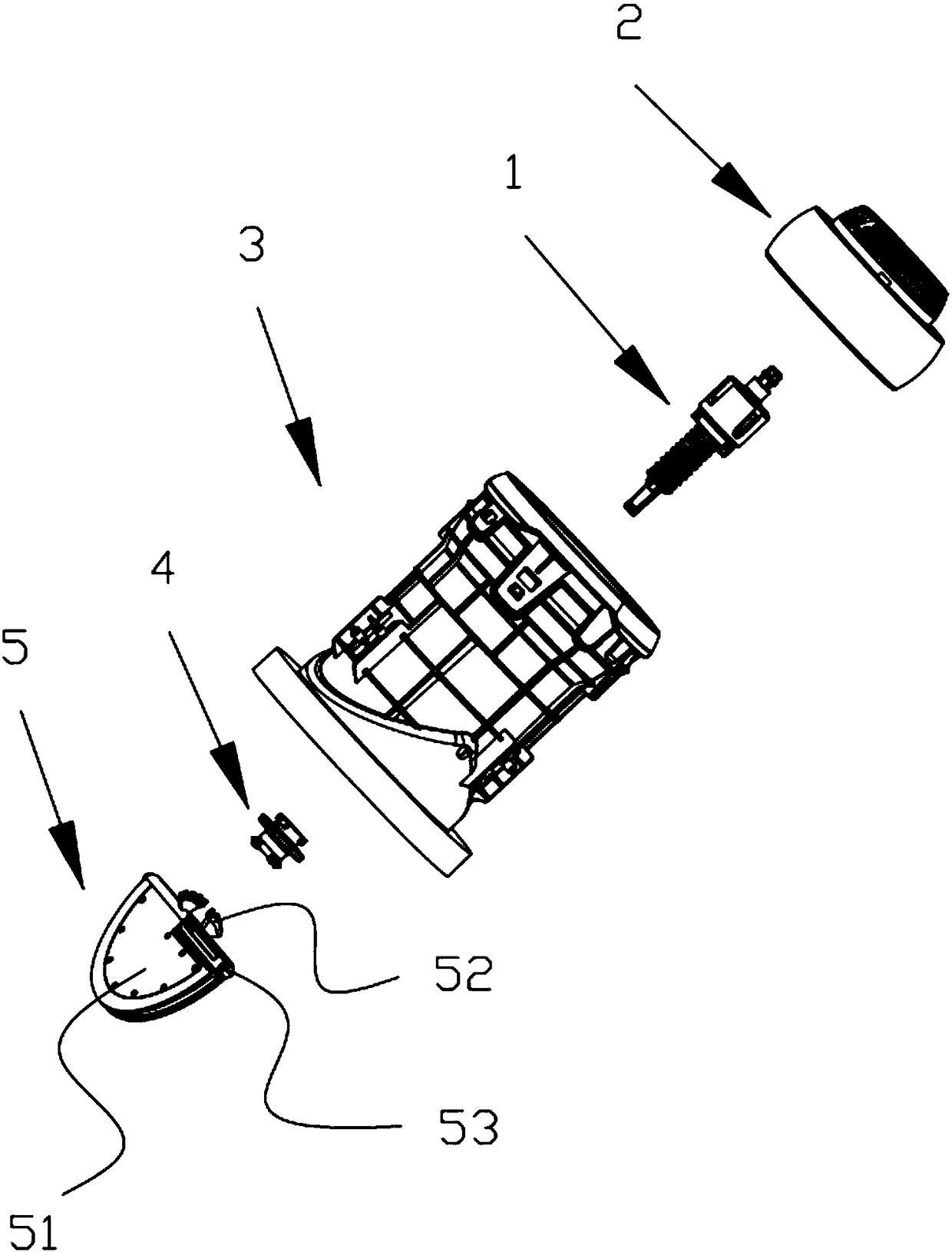

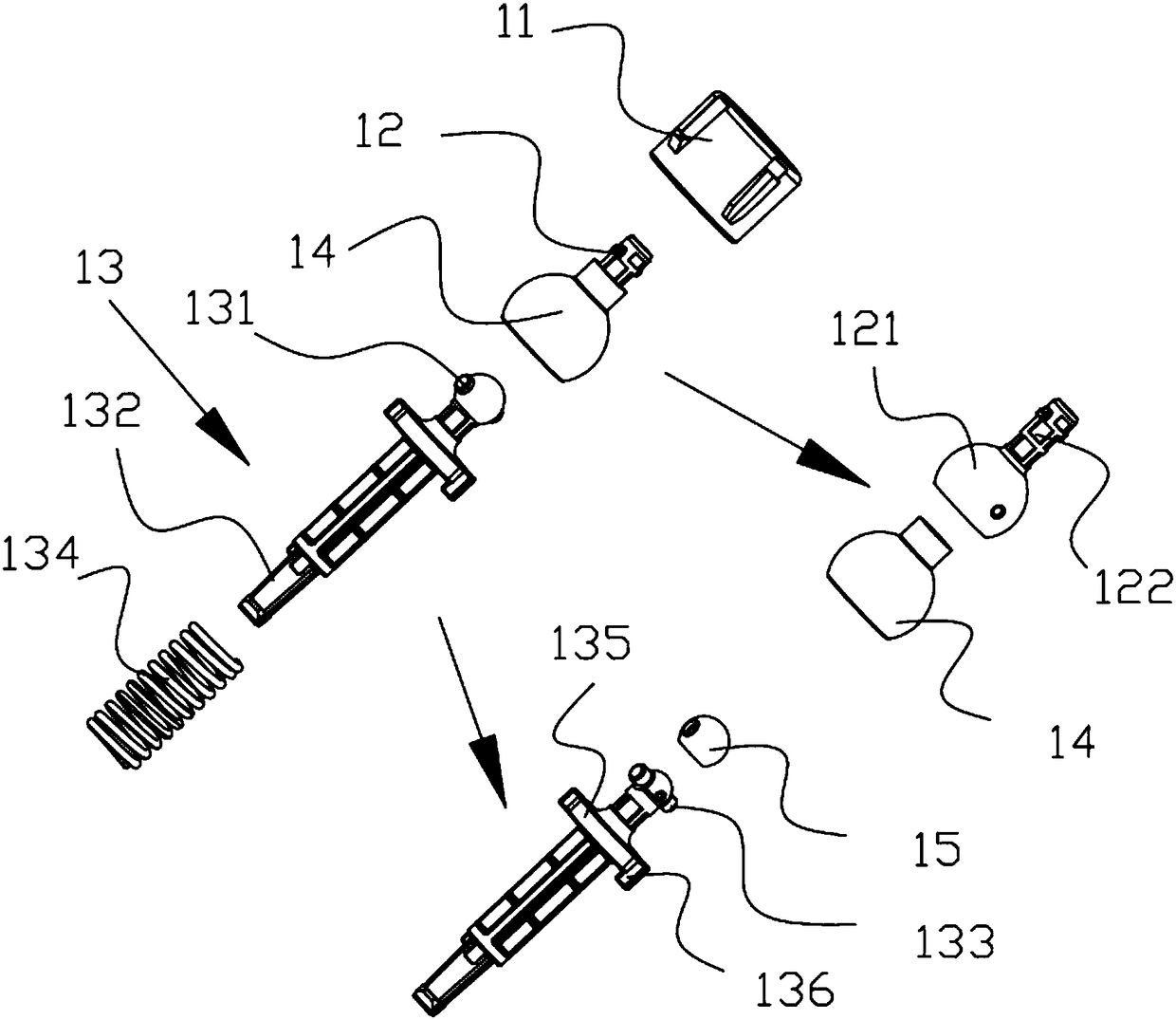

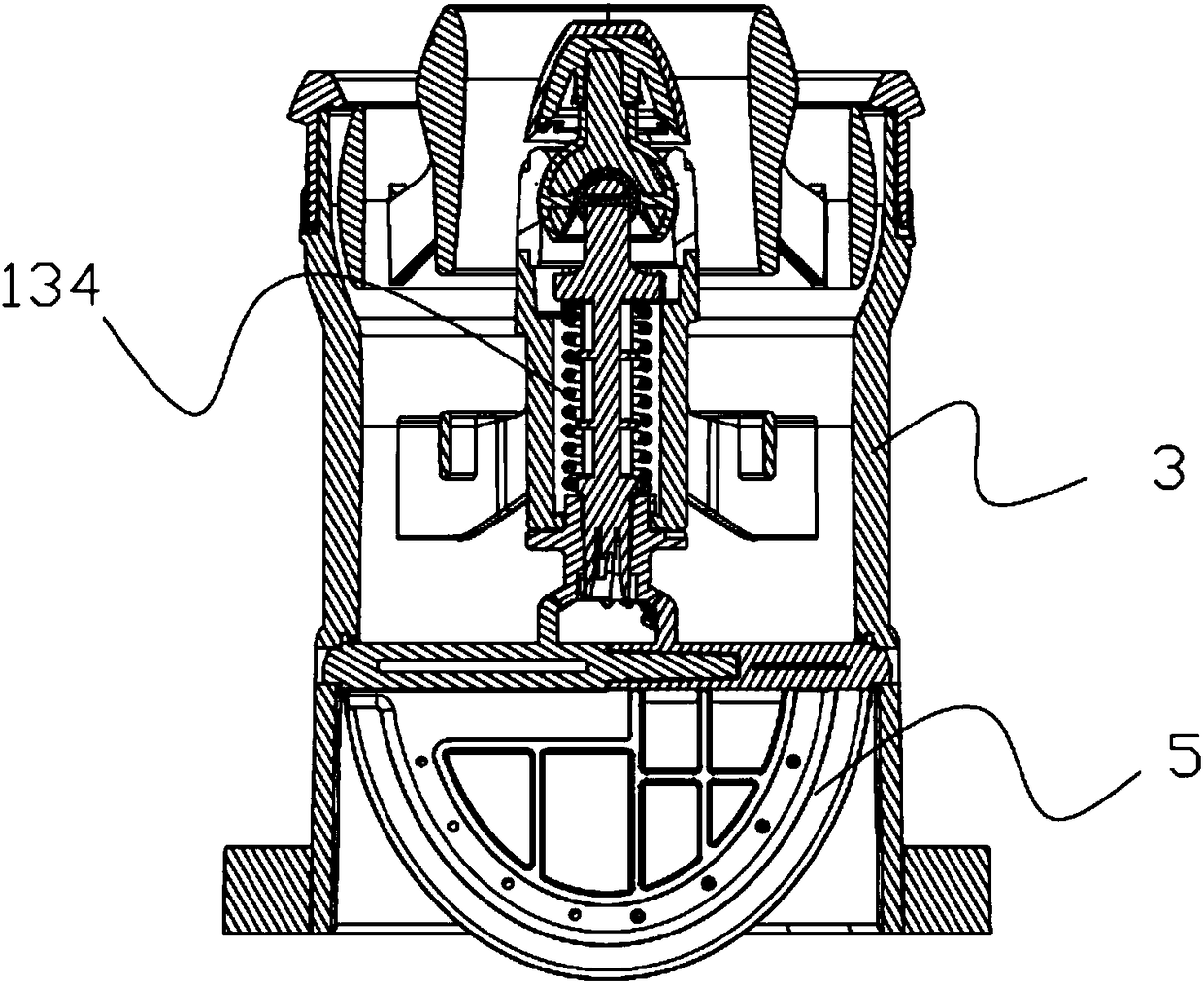

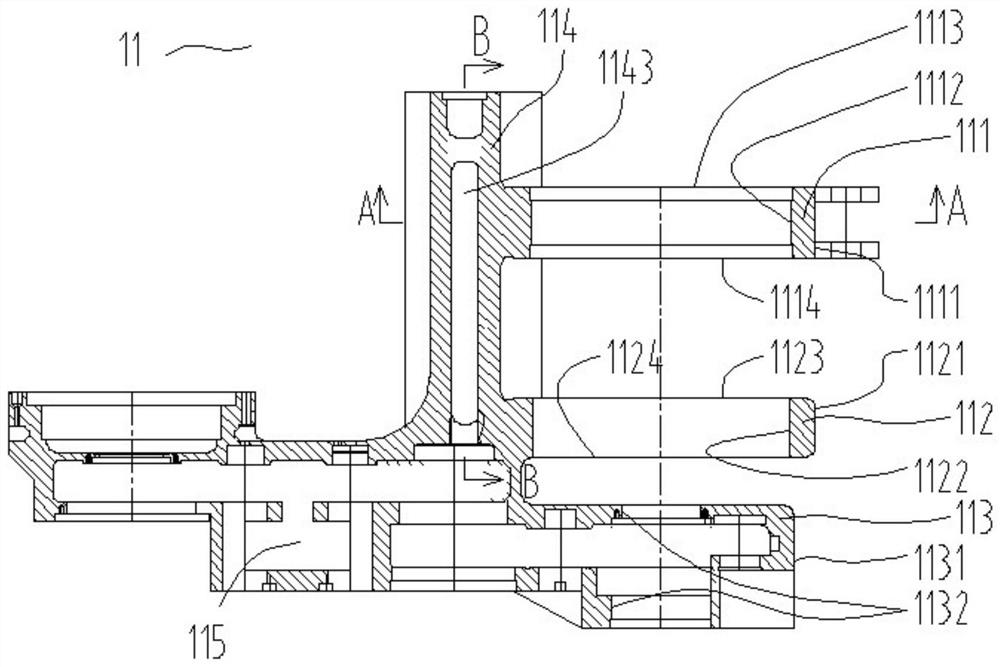

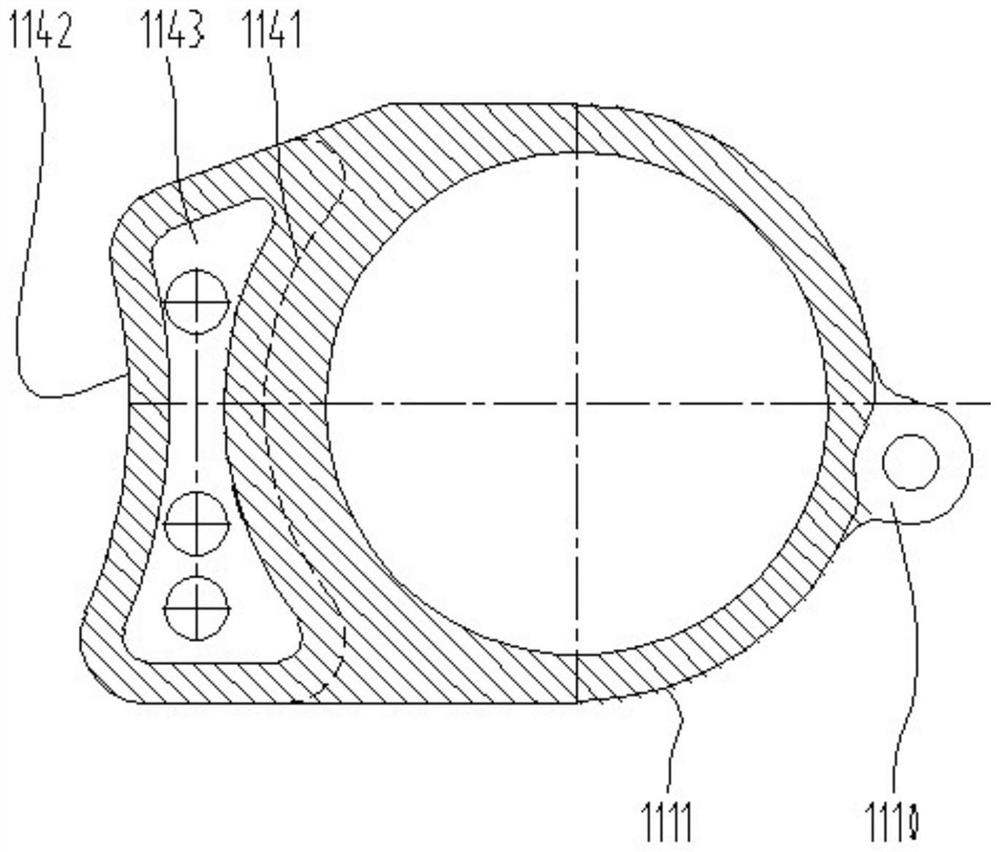

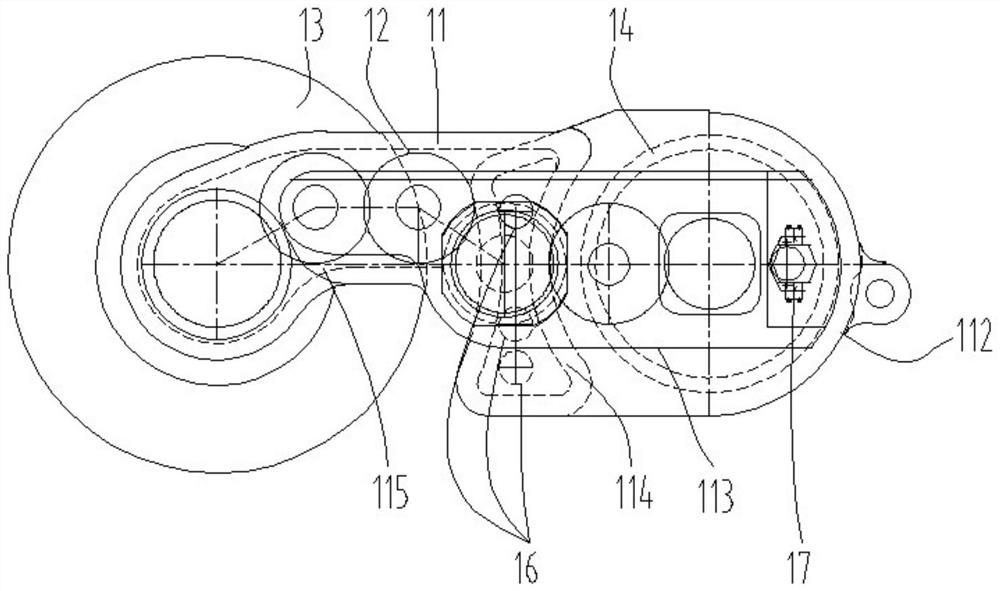

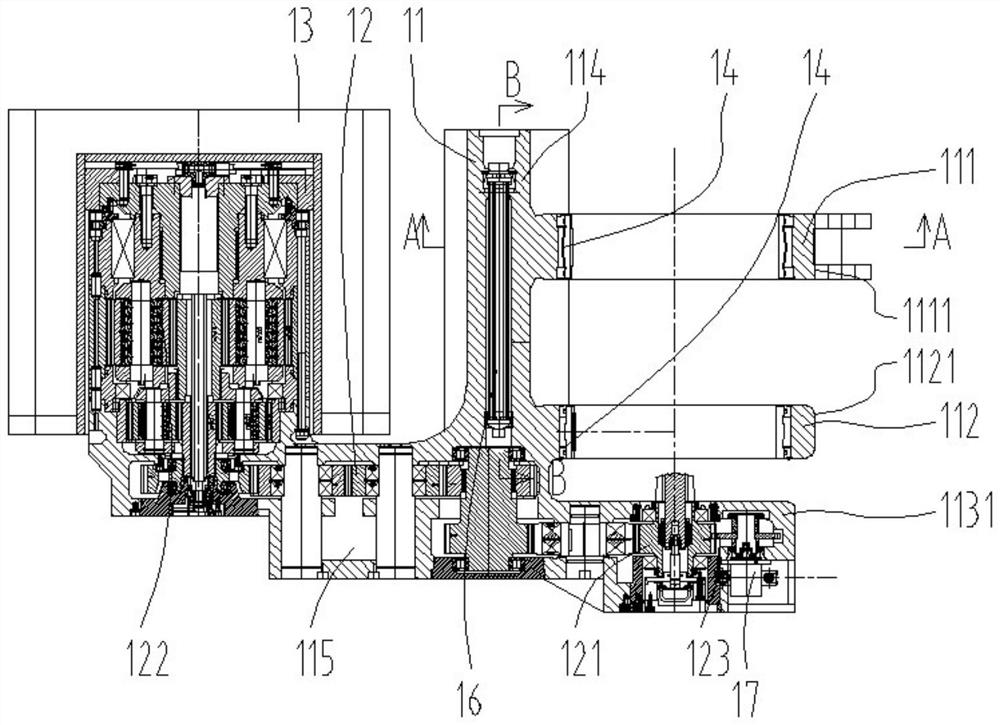

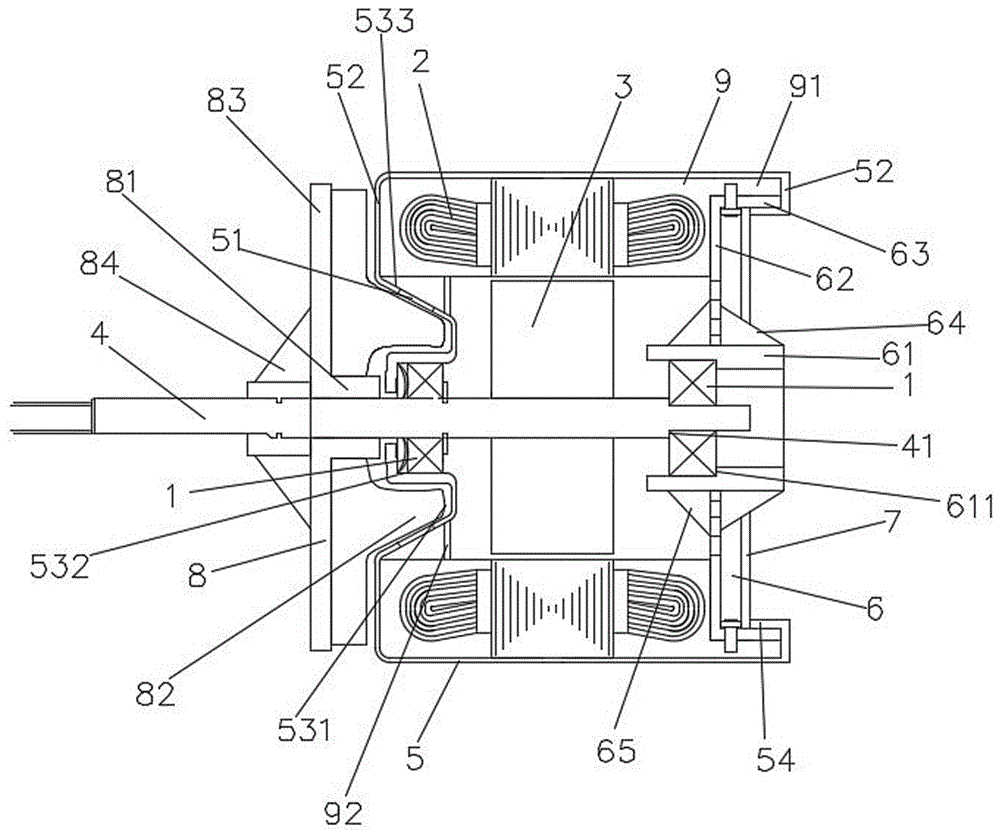

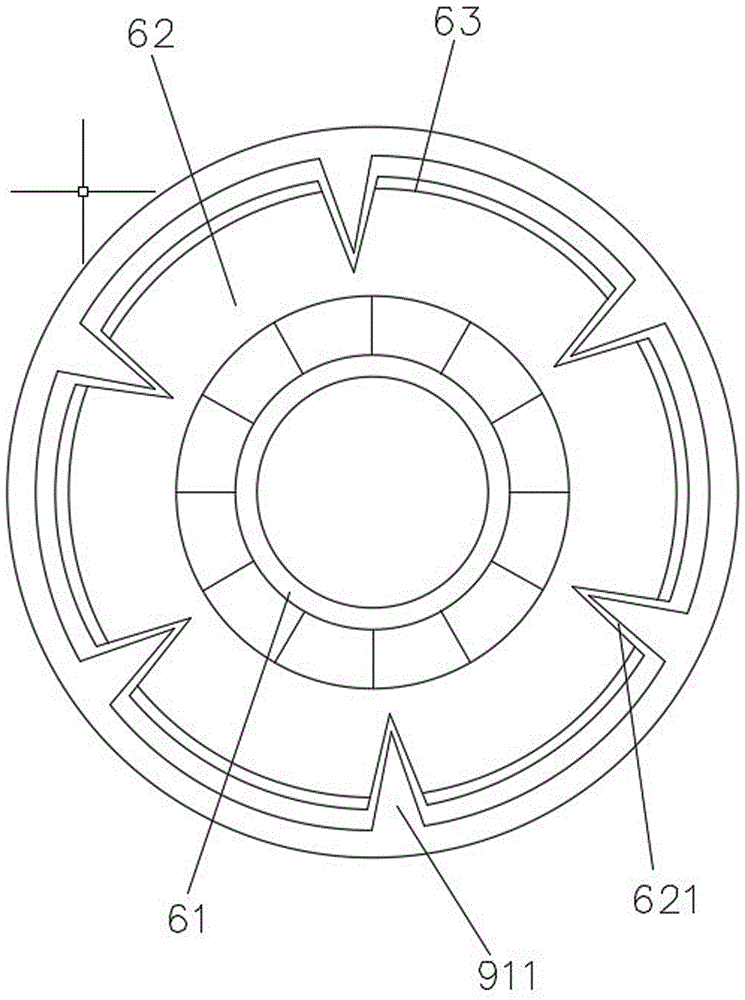

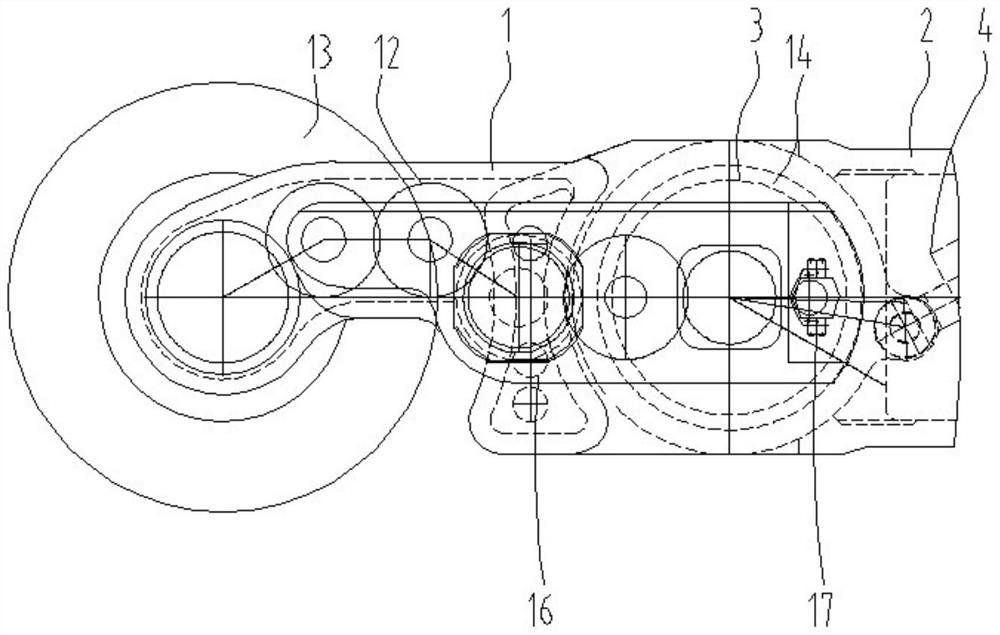

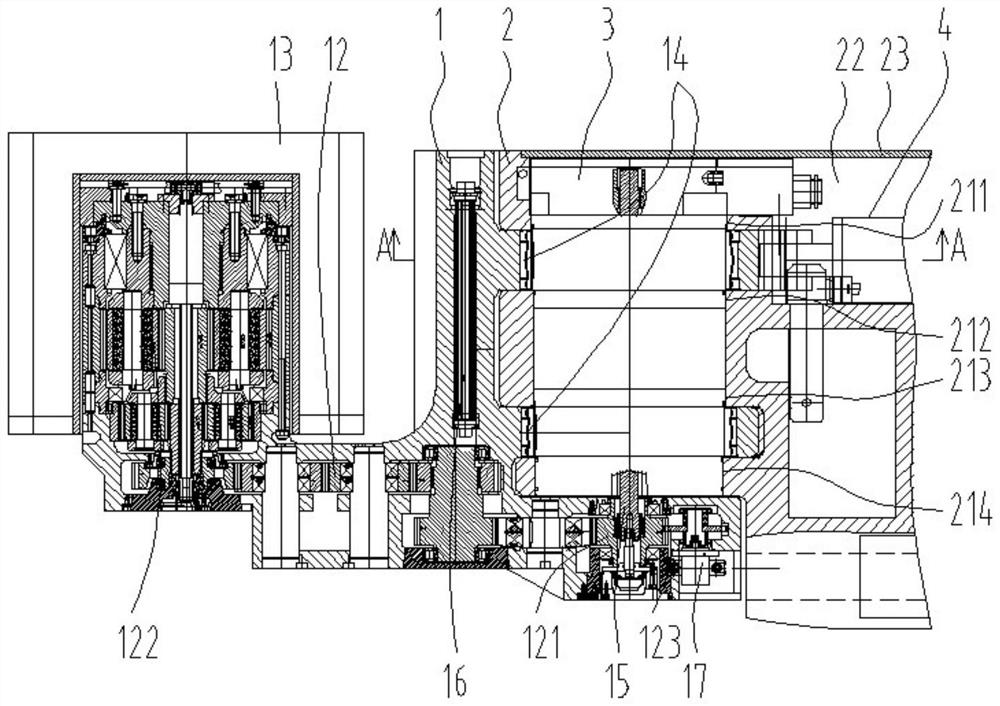

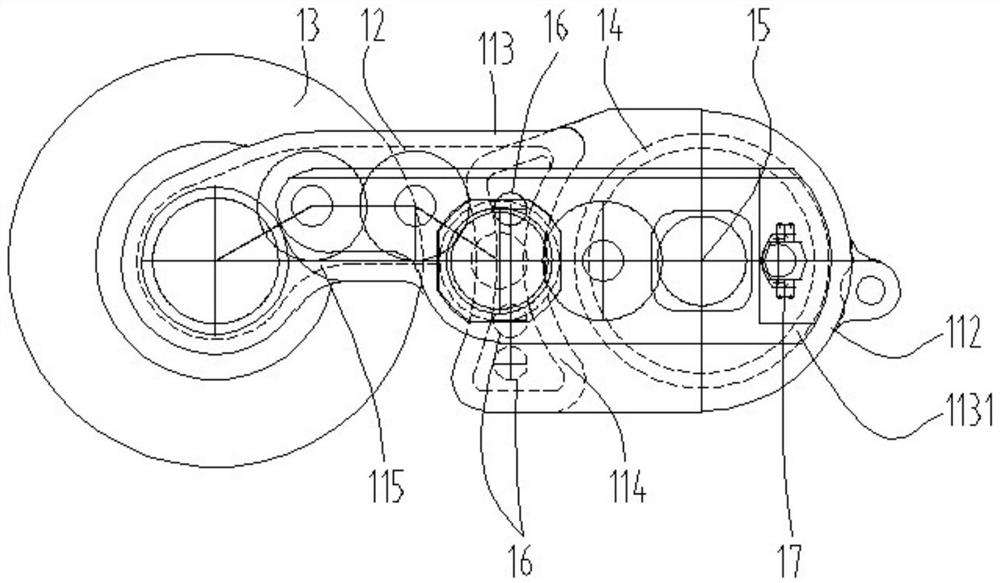

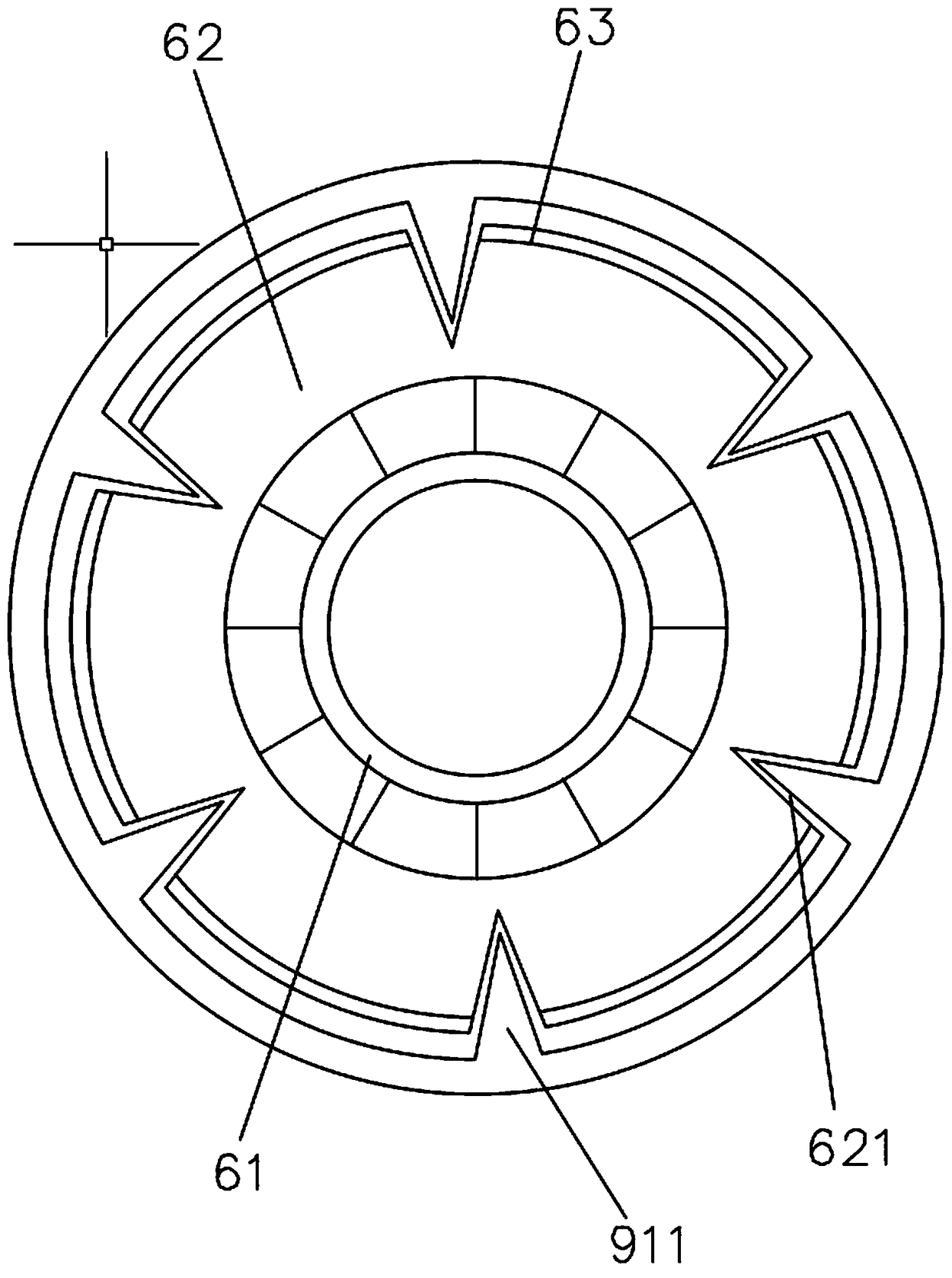

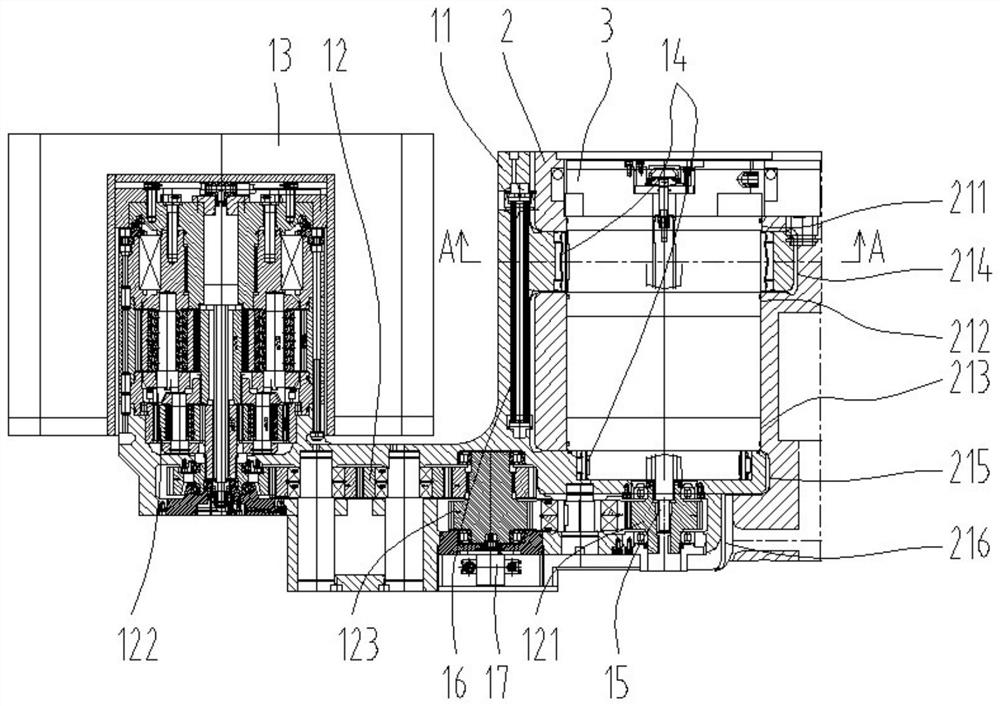

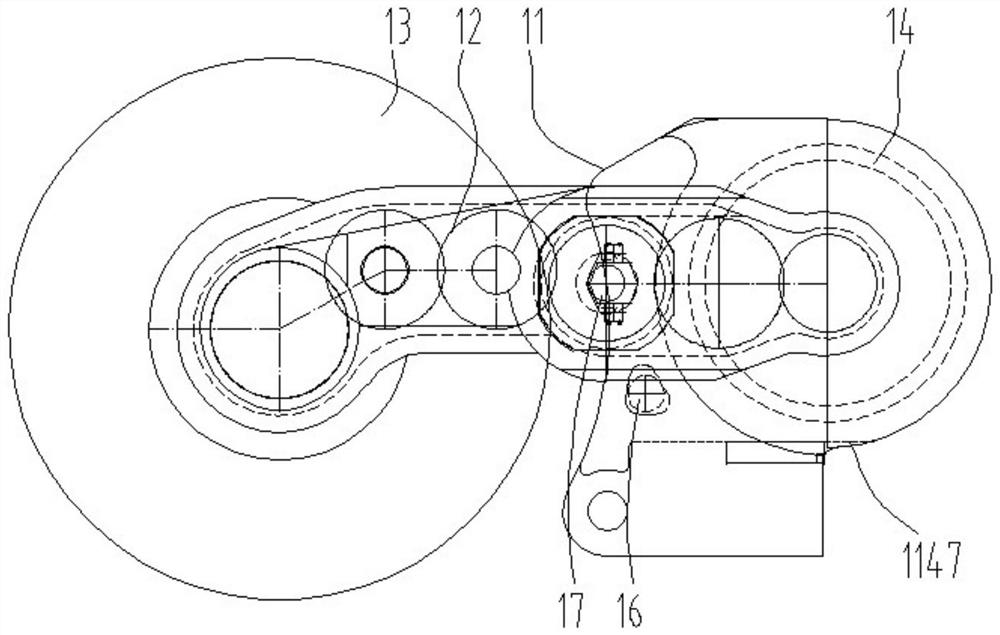

Improved energy-storage impact-type pneumatic wrench

InactiveCN103552021AHigh shell strengthIncreased impact energy and output torquePower driven toolsChemical industryWrench

The invention relates to an improved energy-storage impact-type pneumatic wrench. An air distribution mechanism is additionally arranged in an impact mechanism, the structural design of a hammer device is optimized, the impact energy and the output torque are effectively improved and the dead weight is obviously reduced. The energy-storage impact-type pneumatic wrench has the outstanding advantages that the structure is unique and novel, the weight is light, the torque is large, the pneumatic wrench is flexible and convenient and is suitable for mobile operation, the safety, the reliability and the efficiency are high, the labor productivity can be greatly improved and the labor intensity of operators is reduced. The improved energy-storage impact-type pneumatic wrench is suitable for use in an assembling line and in dangerous environments such as flammable and explosive environments, upper air and the like, and is especially suitable for rushed deadlines and rushed repair operation in industries such as petroleum, chemical industry and the like. The improved energy-storage impact-type pneumatic wrench is a high-efficiency manual tool for disassembling and assembling nuts, and can be widely used for bolt disassembling and assembling operation in industries such as machinery manufacture, petroleum, chemical industry, power plants, bridges, ships, locomotives and the like.

Owner:SHANGHAI MINSHENG ELECTRIC APPLIANCE

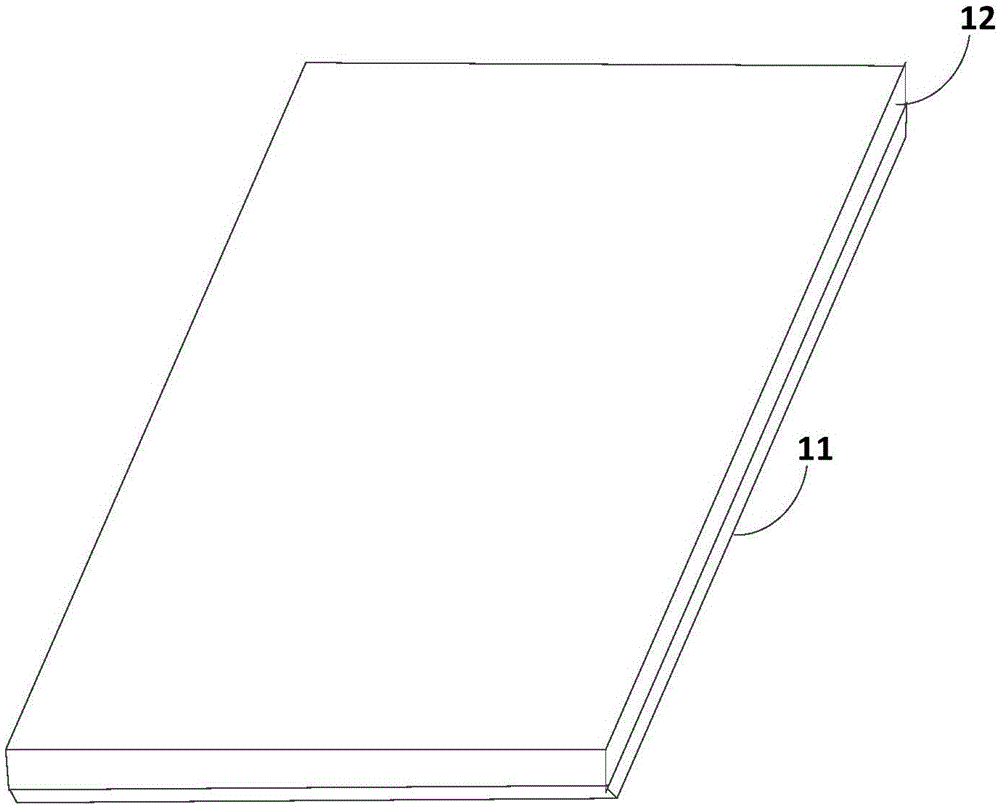

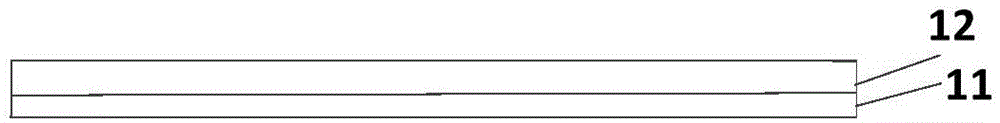

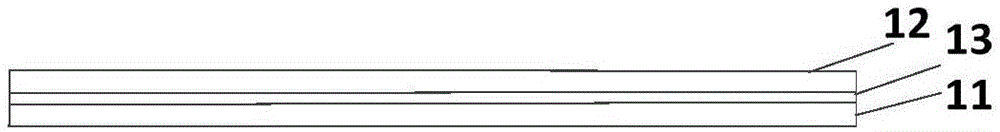

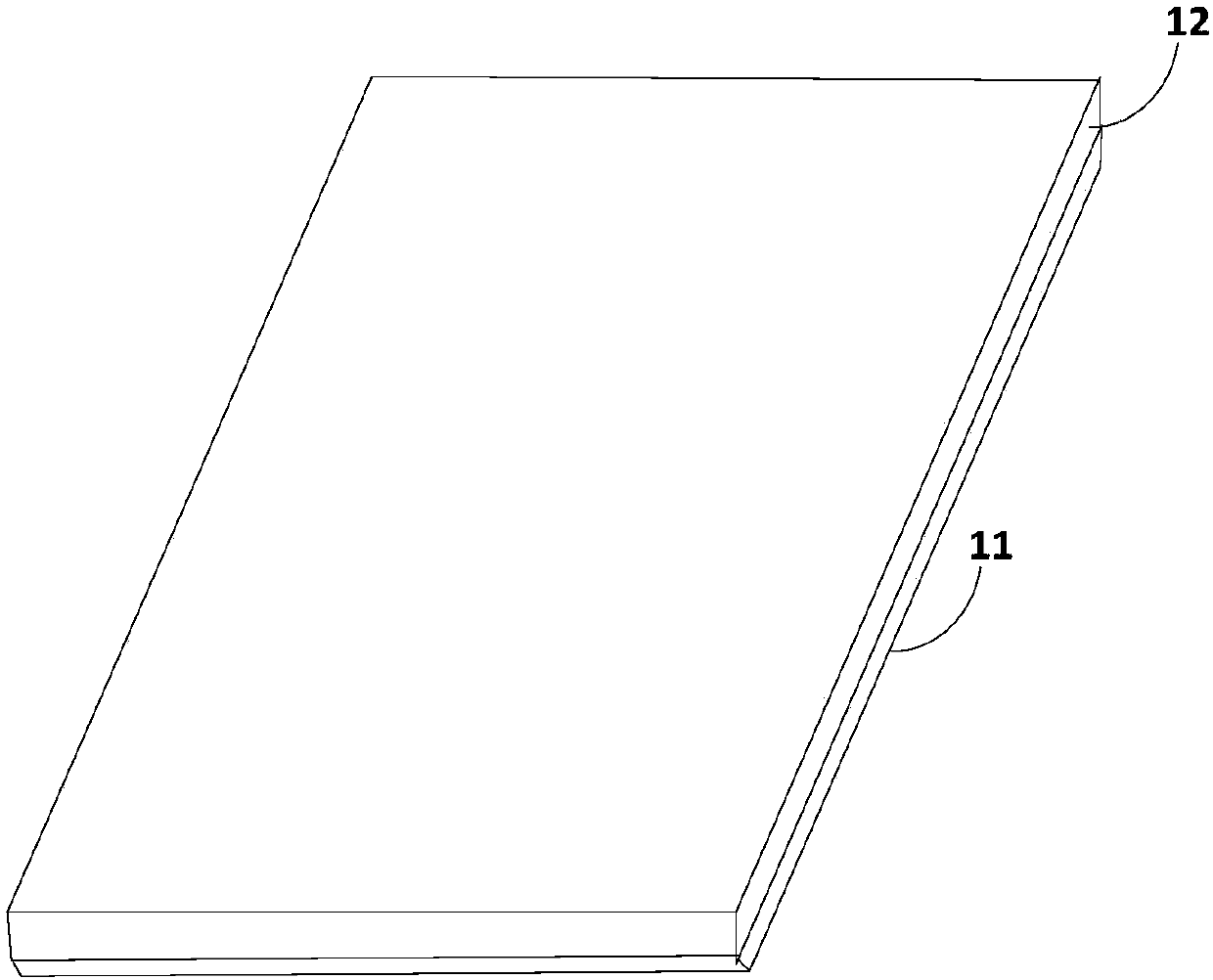

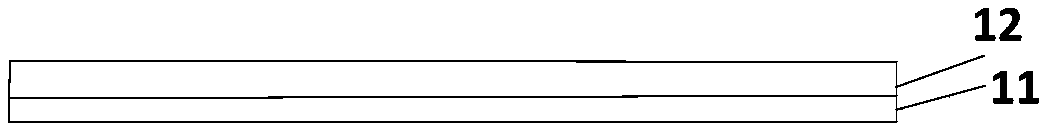

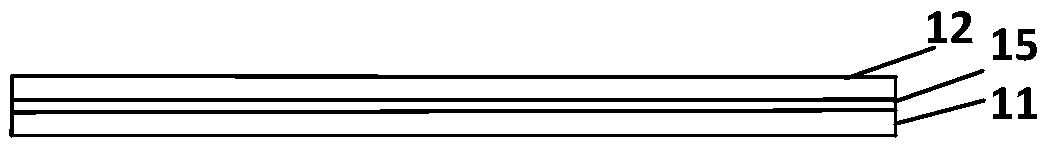

Ceramic component, shell device of mobile terminal and mobile terminal

The invention discloses a ceramic component, a shell device of a mobile terminal and the mobile terminal. The ceramic component comprises a ceramic shell and a fastener; the thickness of the ceramic shell is smaller than that of a conventional ceramic rear cover in the mobile terminal; the ceramic shell is connected with the fastener; the fastener is any one of a metal plate, a magnesium alloy, a stainless steel and a plastic component. The embodiment of the invention can reduce the thickness of the ceramic shell, so as to reduce the whole weight of the ceramic component.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Method for preparing shell primary layer coating for titanium alloy precision investment casting

InactiveCN104923721AReduced hydrationHigh shell strengthFoundry mouldsFoundry coresOrganic acidOrganic solvent

The invention discloses a method for preparing a shell primary layer coating for titanium alloy precision investment casting. The method includes the steps that electric melting yttrium oxide powder with a certain coarse and fine powder ratio is obtained through preprocessing of primary layer fireproof materials, a compound binding agent is prepared from organic acid, an inert organic solvent and acetic acid zirconium, and finally the primary layer coating is prepared. According to the method for preparing the shell primary layer coating for titanium alloy precision investment casting, the specific surface area of the yttrium oxide powder is reduced, organic acid and yttrium oxide can generate hydroxide of yttrium salt, the hydration of yttrium oxide is weakened, and the function of the high-temperature binding agent is achieved; viscosity is adjusted regularly, volatilization is reduced regularly, and stability of the coating is kept. The performance of the primary layer coating prepared through the method is stable and can be prolonged for 20 days, the temperature of the coating is 20+ / -5 DEG C, and therefore preparing and preserving can be conducted in a common constant-temperature and constant-humidity environment, and the coating preparing and preserving technology control is simplified.

Owner:HEBEI GANGYAN DEKAI TECH CO LTD

Mineral substance premix of white jade snails

InactiveCN101703161APromote growthEmission reductionAnimal feeding stuffAccessory food factorsManganese sulphateSulfate

The invention discloses a mineral substance additive premix of white jade snails. The standard is to prepare 25kg of premix, and the components thereof and the use amount thereof are: 240-360g of copper sulfate, 1, 664-2, 496g of ferrous sulphate, 1, 664-2, 496g of manganese sulphate, 1, 720-2, 580g of zinc sulfate, 832-1, 248g of 1% cobalt chloride, 133.36-200.4g of 1% sodium selenite, 384-576g of 1% potassium iodide and the balance of bran cake. The premix has excellent compatibility, supplements the requirement of white jade snails on mineral substances and promotes growth. The mineral substance has no residue and no pollution in snail meat. The premix can be added to feed according to the addition ratio of 0.25 percent in the total weight of the feed.

Owner:ZHEJIANG UNIV

Processing method of air inlet end cone

The invention provides a processing method of an air inlet end cone. The processing method comprises the steps of (1) preparing a wax mould; (2) preparing a mould shell; (3) dewaxing; (4) roasting the mould shell; (5) pouring; (6) after pouring, carrying out shell shaking, shot blasting, cutting, acid pickling and finishing; and (7) processing end openings of the air inlet end cone through adopting rolling. According to the processing method, through adopting a reasonable shell making technology, the obtained shell is high in strength and is easily unshelled, the production technology is simplified, the production cost is reduced, and the production efficiency is improved.

Owner:QINGDAO LIBO AUTO PARTS PRECISION CASTING

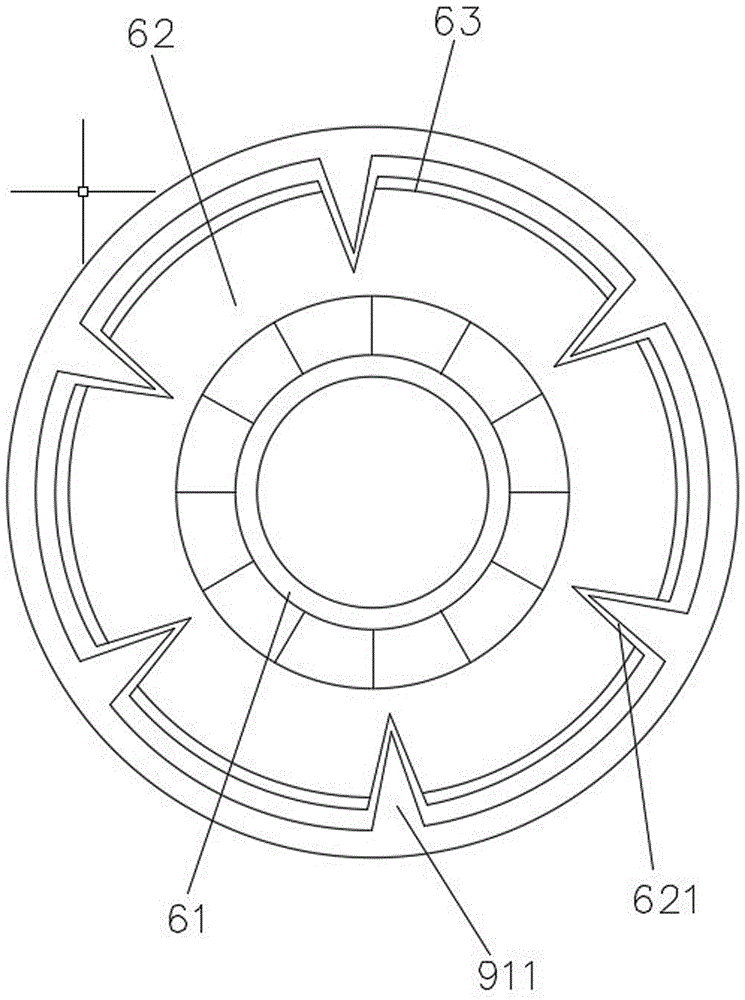

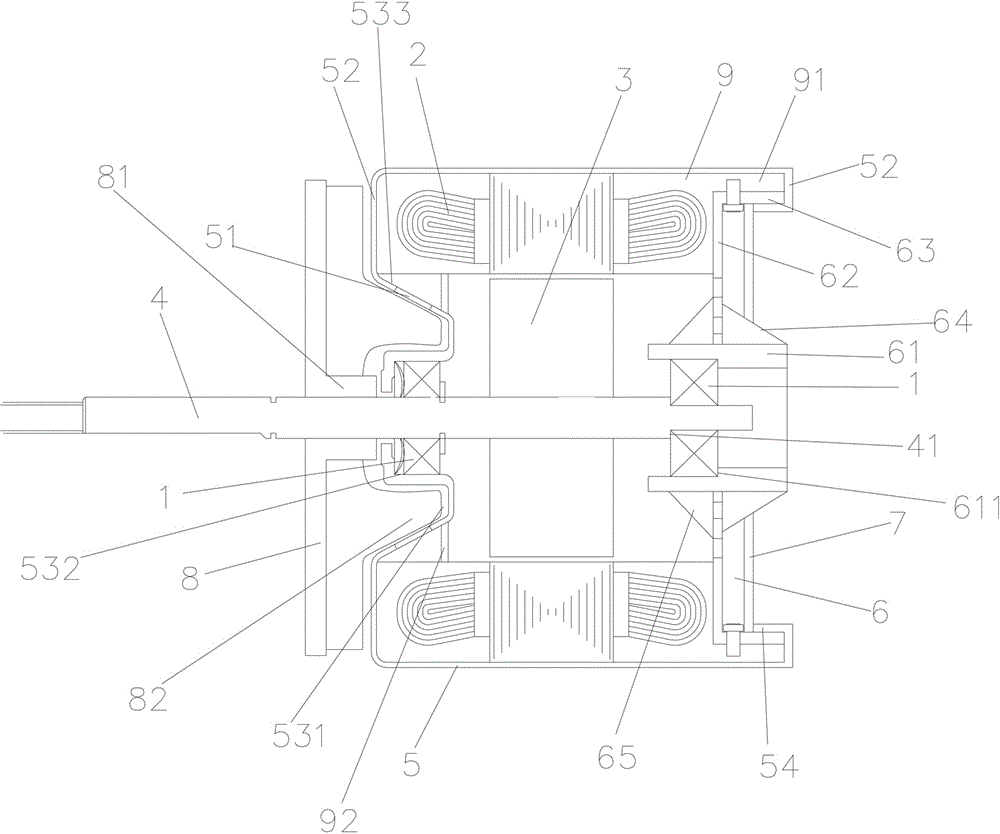

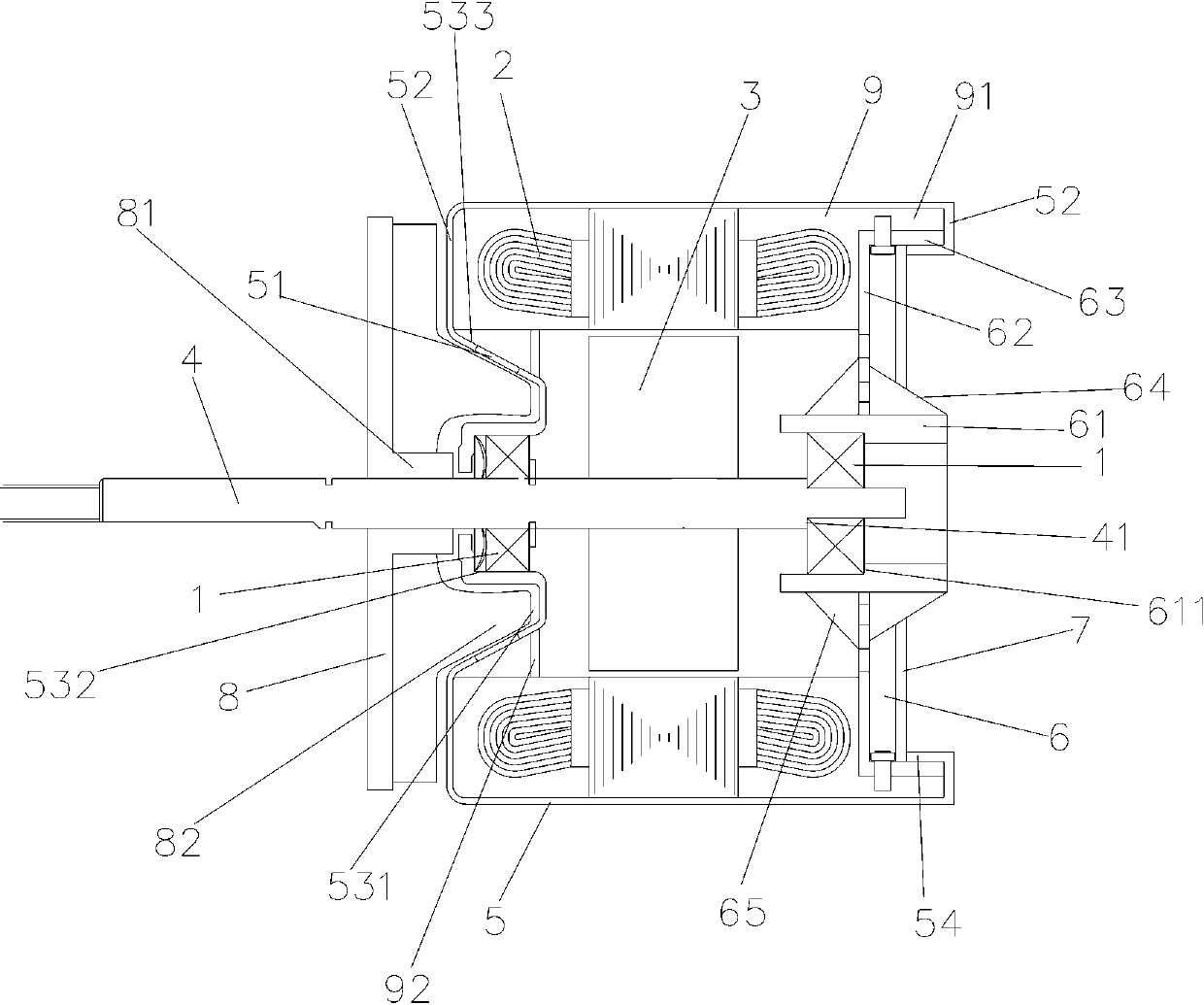

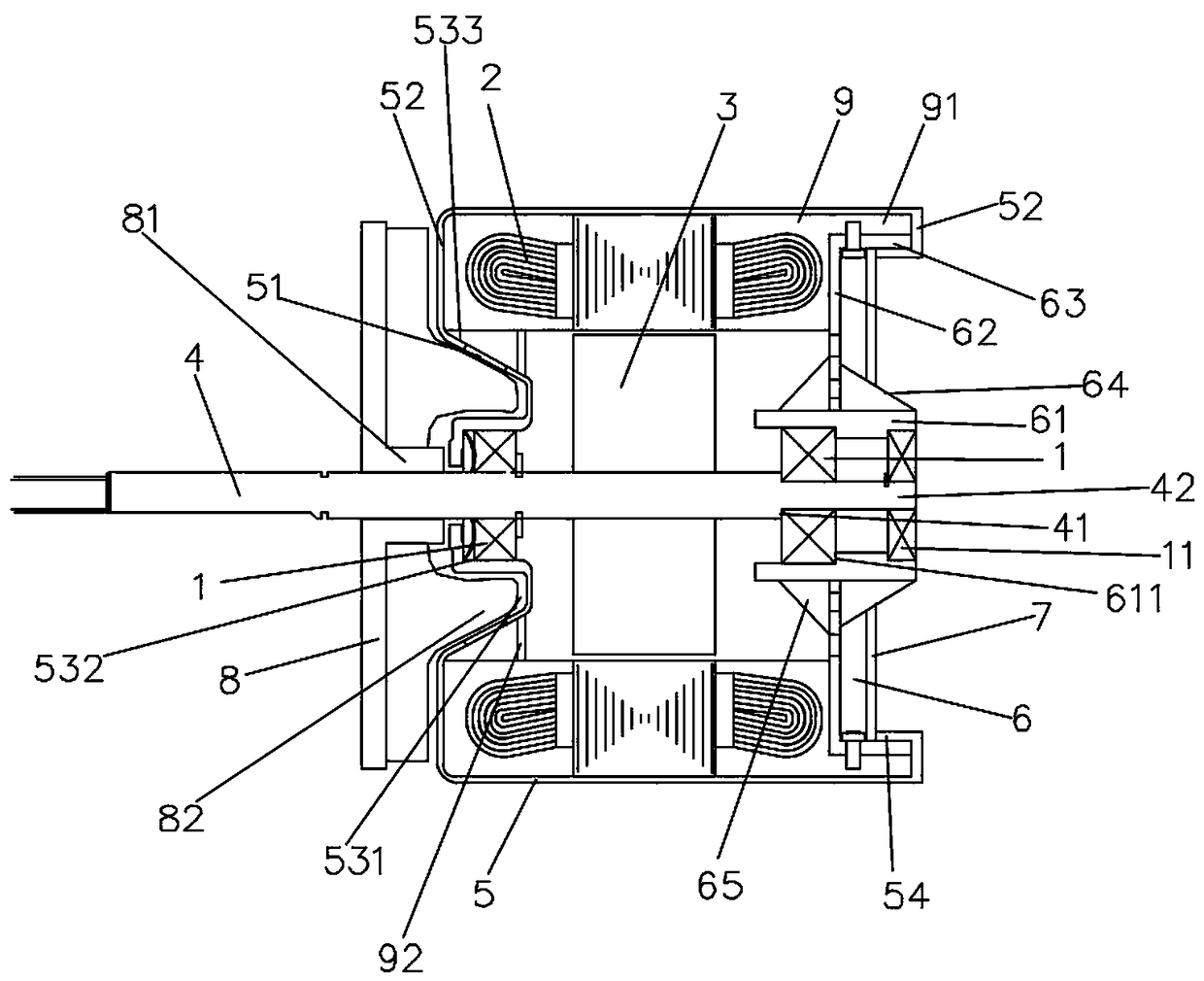

High-rotation speed and rapid heat-conduction motor

ActiveCN105914948AShort stayDrainage is highly targetedMagnetic circuit stationary partsStructural associationLow noiseHigh integrity

The invention relates to the field of a motor, and specifically relates to a high-rotation speed and rapid heat-conduction motor. The motor comprises a stator, a rotor sleeved in the stator and a rotation shaft penetrating the rotor. The motor also comprises a shell and a base which fit with each other. The shell sleevesthe stator. Vent holes are arranged on a shell end face. A positioning and installing hole post is arranged at the center of the base. A circuit board is arranged on an outer side frame of the base. A drainage fan is fixedly arranged on the rotation shaft and is located at the outer side of the shell end face. A plastic package body is packaged out of the stator. A plastic package reinforcing connection ring is integrally connected with the end face of one side of the plastic package body facing towards the base. The plastic package reinforcing connection ring is arranged against the side wall face of the shell. Airflow at the rear end of the circuit board is sent in the motor through the circuit board and the vent holes on a base plate. Equally, the airflow between the circuit board and the base plate is sent in the motor through the vent holes on the base plate, then the heat in the motor is absorbed by the airflow, and then the airflow is rapidly exported out of the motor through vent holes on an incline reinforced hole slot wall. The whole motor has the advantages of high integrity, compact structure, convenient disassembly, low cost, high strength, high stability and low noise.

Owner:YIWU YUMA MECHANICAL & ELECTRICAL EQUIP CO LTD

Stable motor

ActiveCN105932829AShort stayDrainage is highly targetedCooling/ventillation arrangementSupports/enclosures/casingsEngineeringAirflow

The invention relates to the field of motors, and in particular relates to a stable motor. The stable motor comprises a stator, a rotor sleeved in the stator and a rotating shaft arranged on the rotor in a penetrating manner, and also comprises a shell and a base which are fit with each other, wherein the shell is sleeved on the stator and provided with vent holes in the shell end face, the base is provided with a locating mounting hole column at the center, a circuit board is erected on the outer side of the base, a draught fan is fixedly arranged on rotating shaft on the outer side of the shell end face, the stator is packaged with a plastic package body, and a circle of plastic package reinforced connecting ring arranged close to the side wall of the shell is integrally connected on the end face of the plastic package body facing the base side. Air flows at the rear end of the circuit board are sent into the motor via vent holes in the circuit board and base plate, in the same way, the air flows between the circuit board and base plate are sent into the motor via the vent holes in the base plate, then absorb heat in the motor, and then are rapidly exported from the motor via vent holes in the inclined reinforced pored groove wall. The whole motor is strong in integrality, compact in structure, convenient to dismount, low in cost, high in strength, good in stability and low in noise.

Owner:佛山市顺德区乐普达电机有限公司

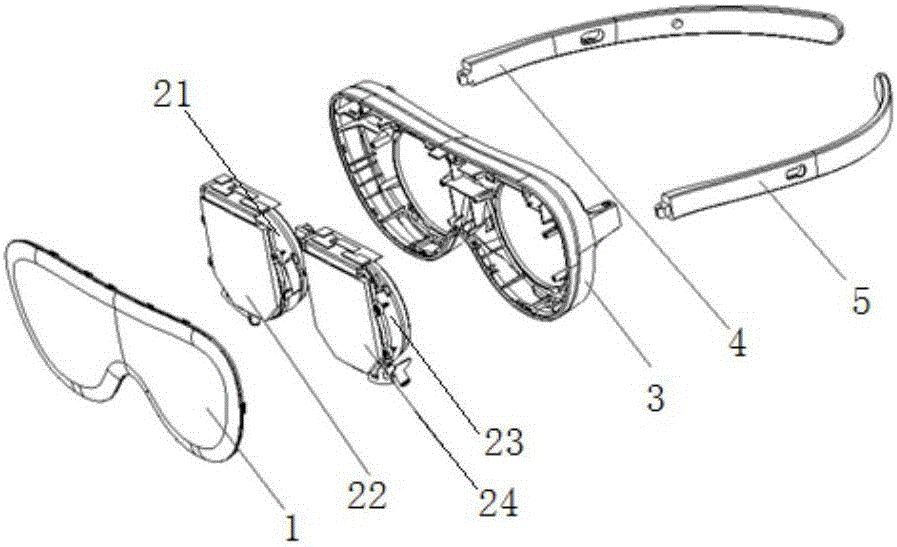

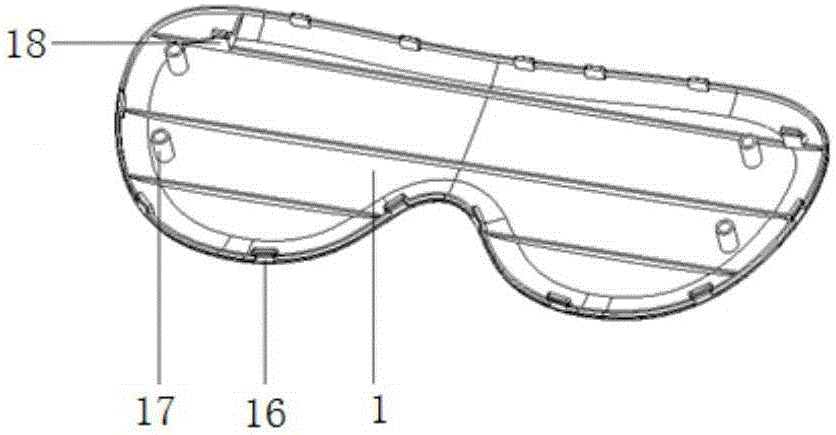

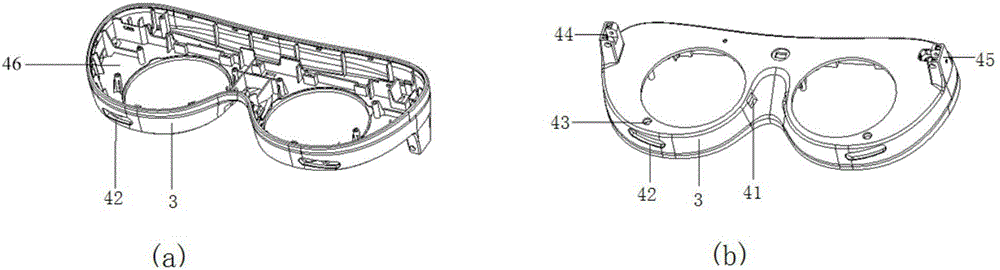

Virtual reality equipment

ActiveCN107526169AStable 3D stereo imaging effectHas a thin shapeMountingsEngineeringLarge deformation

The invention provides virtual reality equipment. A frame comprises a rear frame surface and a front frame surface along a direction which is vertical to a rear shell bottom surface. A connection position of the front frame surface and the rear frame surface forms a ridge-shaped structure. Through the ridge-shaped structure, the frame of the virtual reality equipment forms a stable structure possessing a triangular form. When the virtual reality equipment is under an external force effect, because of the ridge-shaped structure, a force direction and the rear frame surface of the ridge-shaped structure and the force direction and the front frame surface form included angles which are less than 90 degree so that the force can be dispersed and conducted towards two sides of the virtual reality equipment along the rear frame surface and the front frame surface. A condition that the force borne by the frame can not be dispersed so that a local stress is too large and the frame is damaged can be avoided. Because of the ridge-shaped structure, the frame of the virtual reality equipment forms a stable structure possessing the triangular form. A breakage condition caused by large deformation is not generated and stability of 3D imaging is increased. By using the virtual reality equipment, the virtual reality equipment possesses a light and thin form and simultaneously high shell intensity is possessed.

Owner:SHENZHEN DLODLO NEW TECHNOLOGY CO LTD

A high-speed, fast thermal conduction motor

ActiveCN105914948BShort stayDrainage is highly targetedMagnetic circuit stationary partsStructural associationLow noiseHigh integrity

The invention relates to the field of a motor, and specifically relates to a high-rotation speed and rapid heat-conduction motor. The motor comprises a stator, a rotor sleeved in the stator and a rotation shaft penetrating the rotor. The motor also comprises a shell and a base which fit with each other. The shell sleevesthe stator. Vent holes are arranged on a shell end face. A positioning and installing hole post is arranged at the center of the base. A circuit board is arranged on an outer side frame of the base. A drainage fan is fixedly arranged on the rotation shaft and is located at the outer side of the shell end face. A plastic package body is packaged out of the stator. A plastic package reinforcing connection ring is integrally connected with the end face of one side of the plastic package body facing towards the base. The plastic package reinforcing connection ring is arranged against the side wall face of the shell. Airflow at the rear end of the circuit board is sent in the motor through the circuit board and the vent holes on a base plate. Equally, the airflow between the circuit board and the base plate is sent in the motor through the vent holes on the base plate, then the heat in the motor is absorbed by the airflow, and then the airflow is rapidly exported out of the motor through vent holes on an incline reinforced hole slot wall. The whole motor has the advantages of high integrity, compact structure, convenient disassembly, low cost, high strength, high stability and low noise.

Owner:YIWU YUMA MECHANICAL & ELECTRICAL EQUIP CO LTD

Quick heat radiation motor

ActiveCN106059196AShort stayDrainage is highly targetedCooling/ventillation arrangementSupports/enclosures/casingsLow noiseEngineering

The invention relates to the field of motors, and particularly to a quick heat radiation motor. The motor comprises a stator, a rotor which is sleeved in the stator, a rotating shaft which penetrates through the rotor, a housing which sleeves the stator and is provided with ventilating holes on a housing end surface, and a base which is provided with a positioning mounting hole column at the center, wherein the housing and the base are adapted with each other. The outside rack of the base is provided with a circuit board. A drainage fan is fixedly arranged on the rotating shaft at outside of the housing end surface. A plastic sealed member is sealed outside the stator. The end surface, which faces the base, of the plastic sealed member is integrally connected with a plastic sealed reinforcing connecting ring which is arranged in a manner of abutting against the sidewall surface of the housing. Air flow at the back end of the circuit board is sent into the motoring through the circuit board and the ventilating holes on a base board. Similarly, the air flow between the circuit board and the base board is sent into the motor through the ventilating holes on the base board. Heat in the motor is absorbed, and then the heat is quickly leaded out of the motor through ventilating holes of inclined reinforcing hole slot walls. The quick heat radiation motor has advantages of high integrity, compact structure, convenient detachment, low cost, high strength, high stability and low noise.

Owner:佛山市顺德区乐普达电机有限公司

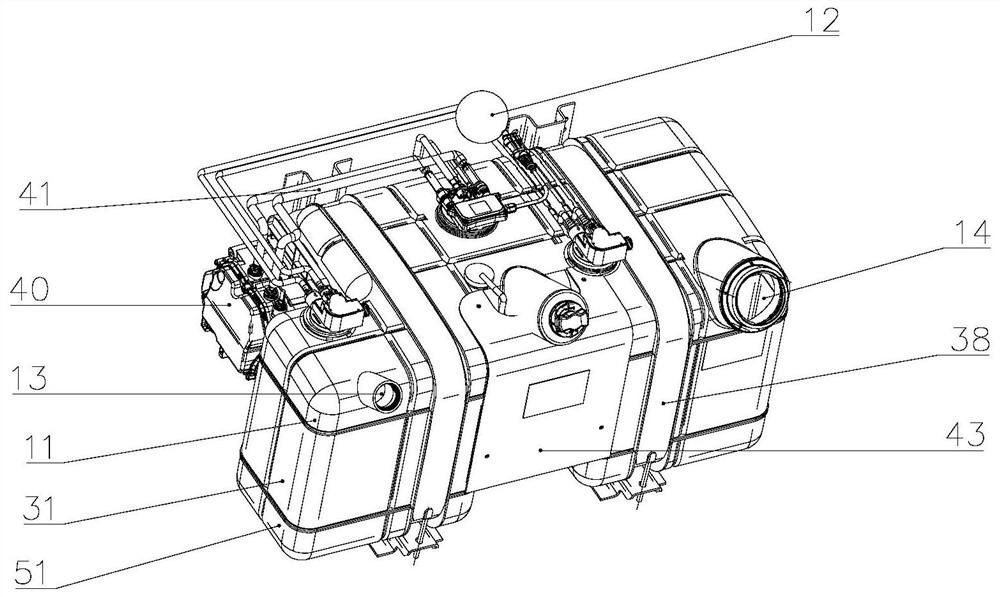

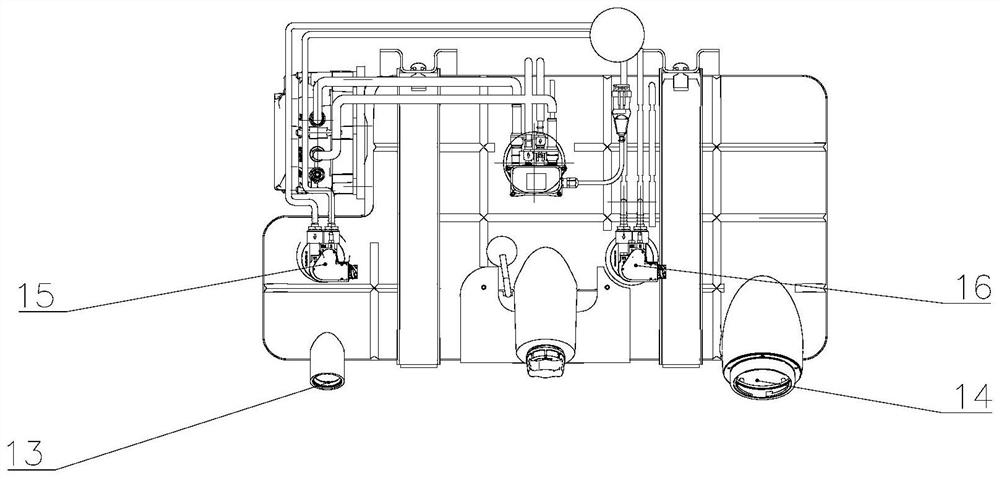

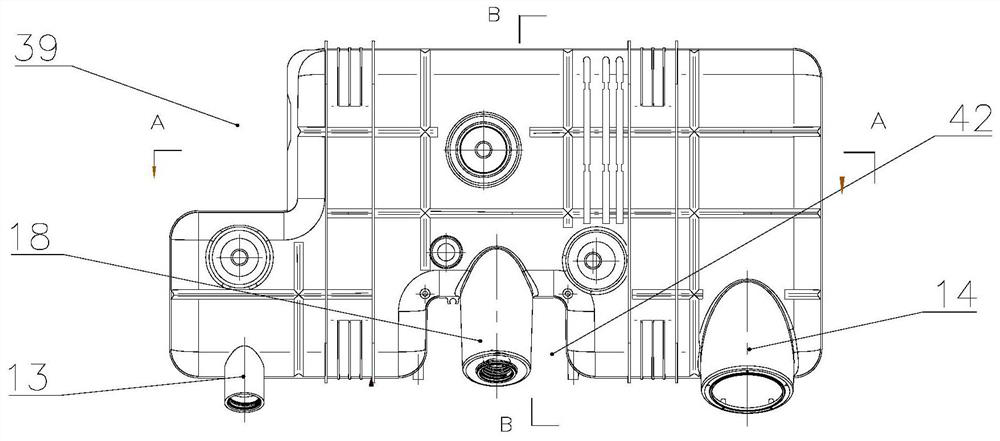

Double oil tanks and integrated double oil tank and urea tank assembly

ActiveCN113427999AImprove rigidityReduce surge phenomenonExhaust apparatusSilencing apparatusFuel tankFuel oil

The invention discloses double oil tanks and an integrated double oil tank and urea tank assembly, and belongs to the field of automobile parts. The double-oil-tank assembly comprises an oil tank shell, the oil tank shell defines a cavity, and the oil tank shell comprises an upper shell area on the upper portion, a middle shell area in the middle and a lower shell area on the lower portion; a middle grid rib structure is arranged in an area, corresponding to the height of the middle shell, in the cavity, the middle part of the cavity is divided into a plurality of middle grid cavities by the middle grid rib structure, the middle grid cavities are not communicated in the radial direction, the middle grid rib structure comprises a first middle grid cavity group and a second middle grid cavity group which are not communicated with each other, the bottom end of the first middle grid cavity group is provided with a first oil passing opening so as to be communicated with each other to form a first fuel oil cavity, the bottom end of the second middle grid cavity group is provided with a second oil passing opening so as to be communicated with each other to form a second fuel oil cavity, and the first fuel oil cavity and the second fuel oil cavity are connected through a conversion valve.

Owner:山东统亚模塑科技实业有限公司

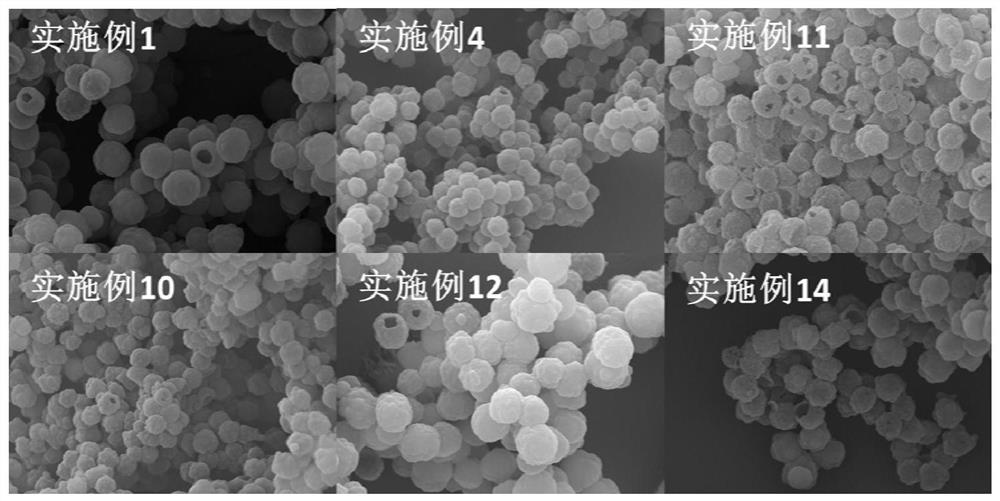

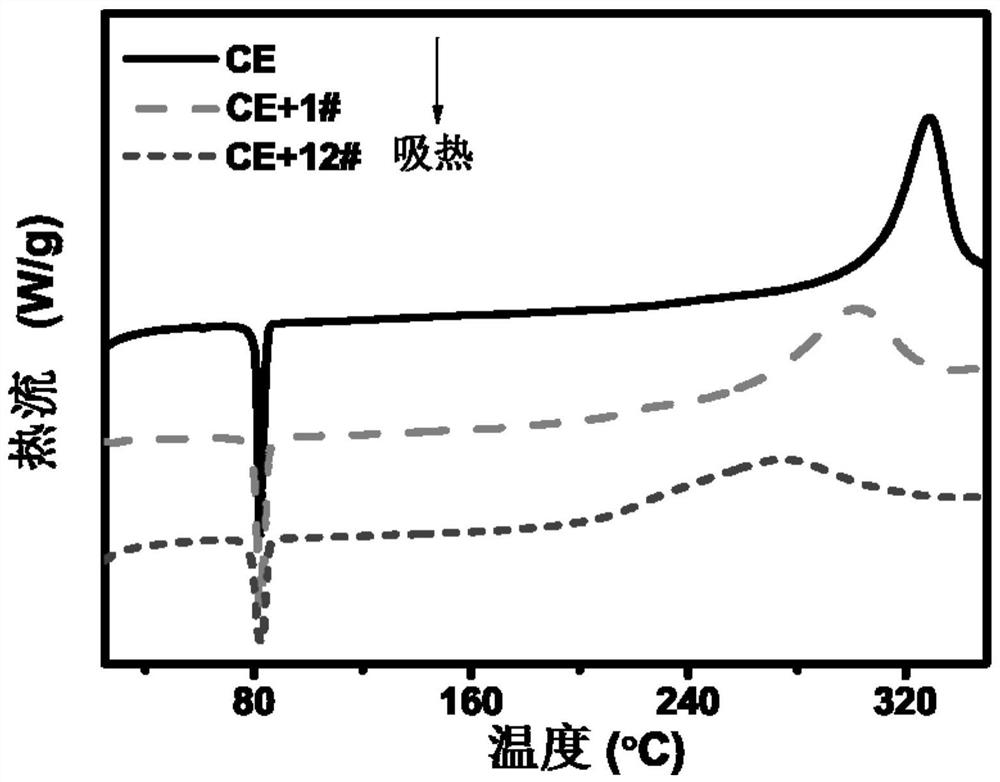

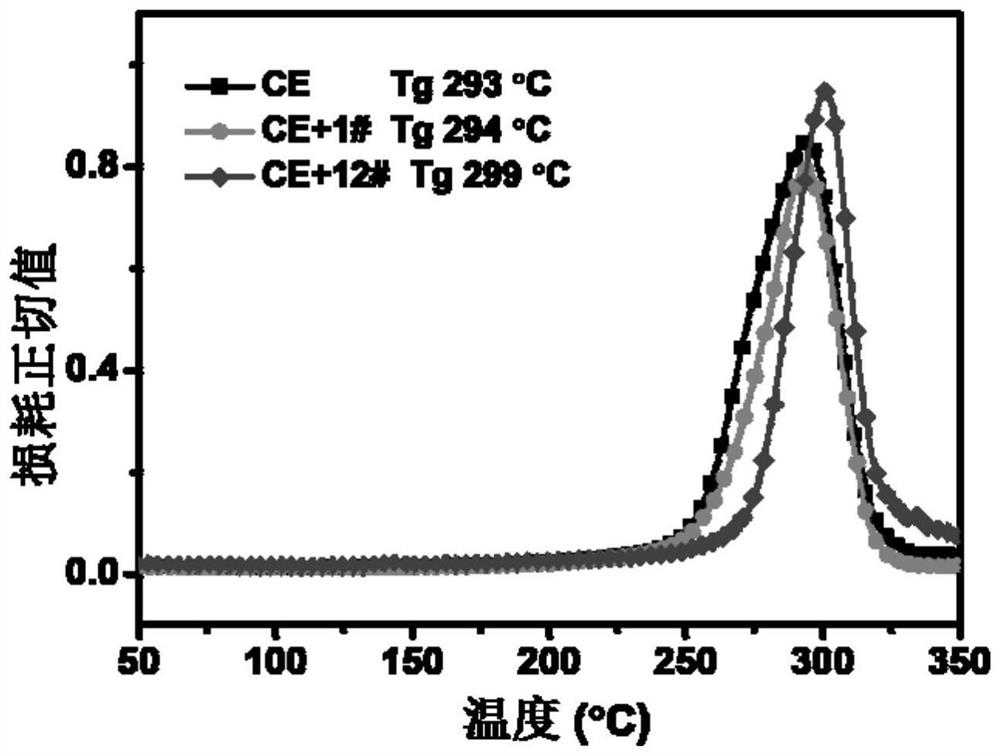

Bismaleimide resin hollow polymer microsphere, preparation method thereof and method for modifying cyanate ester resin

PendingCN114797697ASimple methodHigh yieldMicroballoon preparationMicrocapsule preparationPolymer scienceMicrosphere

The invention relates to a bismaleimide resin hollow polymer microsphere, a preparation method thereof and a method for modifying cyanate ester resin. The bismaleimide resin hollow polymer microsphere with a shell layer containing a high-activity dangling double bond group and a maleimide group is prepared by adopting a template method and a precipitation polymerization mode, and the active group can chemically react with cyanate ester resin at a relatively low curing temperature; as a heat-resistant modifier, the microspheres can effectively enhance the mechanical properties of modified resin, and meanwhile, by utilizing the unique hollow structure and excellent dielectric properties of the microspheres, the dielectric loss and dielectric constant of a cyanate resin matrix can be effectively reduced, so that the requirements in the application fields of large-scale integrated circuits, radar antennas, 5G communication and the like are expected to be met.

Owner:BEIJING UNIV OF CHEM TECH

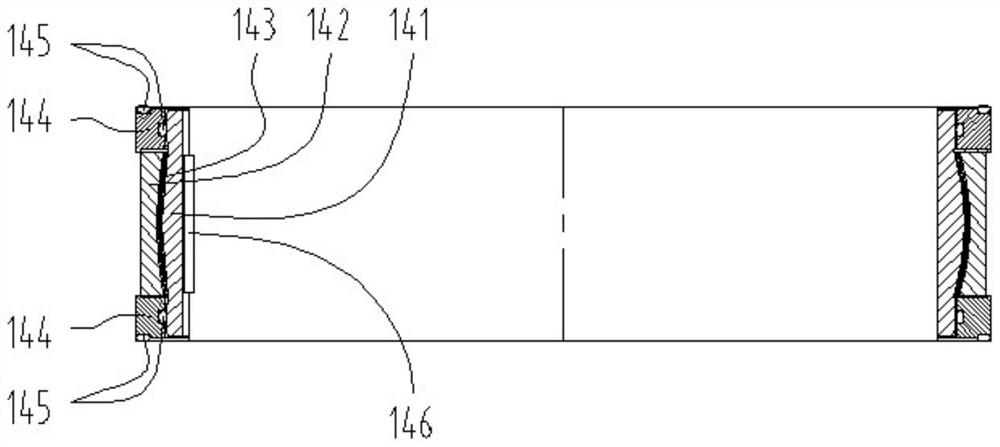

Injection mold and molding method

InactiveCN104890186ALow liquidity requirementsHigh carbon fiber contentCoatingsFiberInjection molding machine

The invention provides an injection mold for molding of a carbon fiber composite material outer shell; the injection mold comprises a fixed mold, a movable mold and a runner system; the runner system forms runners having a plurality of pouring gates communicated with a molding cavity of the injection mold. The invention also provides a molding method using the injection mold, wherein the molding method comprises the steps: the fixed mold and the movable mold are assembled, so that the pouring gates are communicated with the molding cavity; a carbon fiber composite material successively passes through a main runner and sub-runners and then is injected into the molding cavity by the plurality of pouring gates, and thus the outer shell is obtained; and the fixed mold and the movable mold are opened, the outer shell is pushed out from one side of the fixed mold through a thimble and is separated from the injection mold. The injection mold and the molding method are simple and practical, are suitable for injection molding of the carbon fiber composite material, and have low requirement on liquidity of the carbon fiber composite material which can be molded; and the carbon fiber content of the carbon fiber composite material which can be subjected to injection molding is higher, and the molded carbon fiber composite material outer shell has higher strength.

Owner:QUNDA PLASTIC ELECTRONICS SHENZHEN

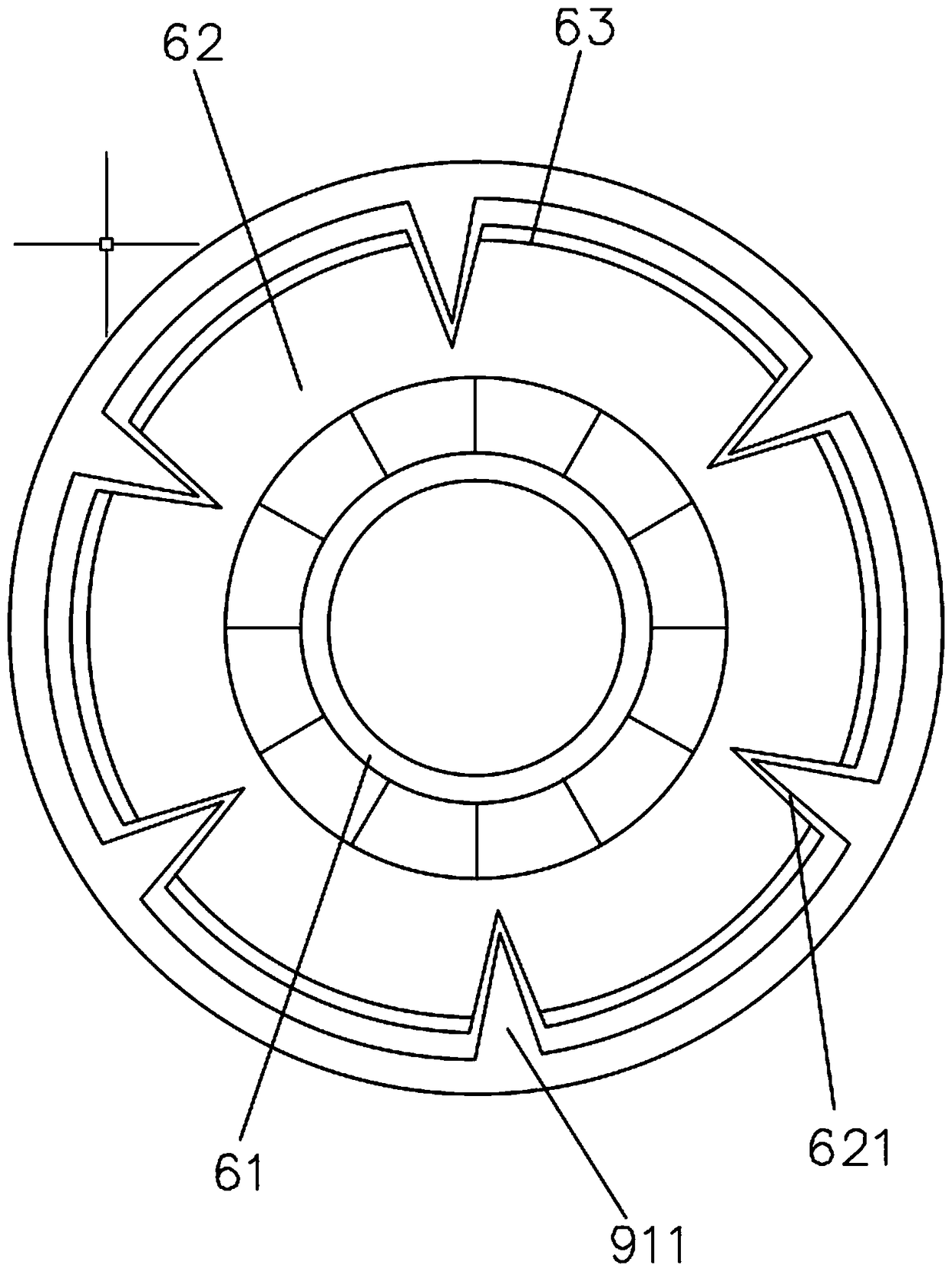

Damper and circular air-conditioning air outlet

InactiveCN108501662ASmooth and stable rotationConstant damping forceAir-treating devicesVehicle heating/cooling devicesAir conditioningControl theory

The invention discloses a damper. A base is provided with an inner cavity; openings are arranged at two ends of the base; one end a rotation part is rotationally held in the inner cavity of the base and matched with the shape of the inner cavity; one end of a transmission part is rotationally held in the inner cavity of the rotation part; a first friction part is arranged between the rotation partand the base; and a second friction part is arranged between the transmission part and the rotation part. The invention also provides a circular air-conditioning air outlet comprising a casing, blades arranged in the casing, a gear, an air damper and the damper. The damper used in the invention further simplifies the structure and allows the rotating operation of the damper to be smooth and stable. The damper can maintain a more constant damping force. In addition, the casing strength of parts is enhanced in the production of the parts so as to prolong the service life, reduce the fine requirements of dimensional specifications and facilitate the production.

Owner:YINGHUALI AUTO MOLD SYST SHENZHEN

A motor with fast heat dissipation

ActiveCN106059196BShort stayDrainage is highly targetedCooling/ventillation arrangementSupports/enclosures/casingsLow noiseHigh integrity

Owner:佛山市顺德区乐普达电机有限公司

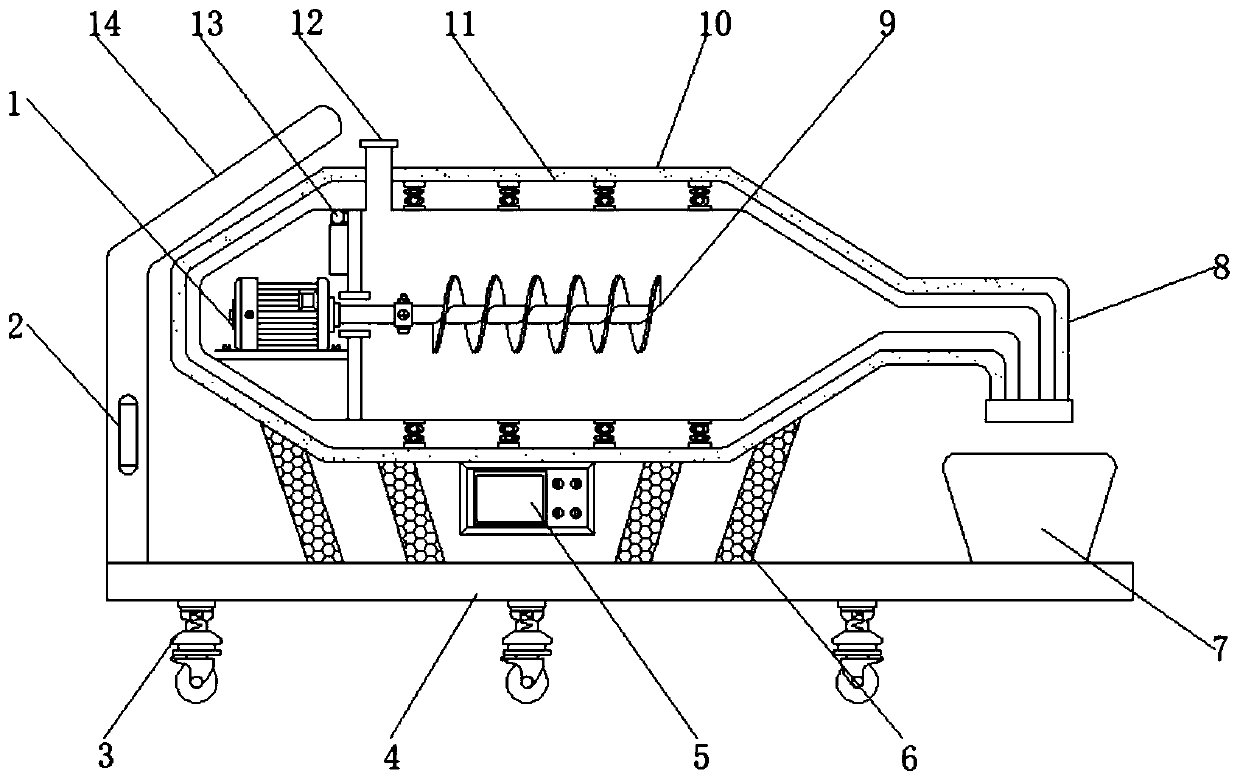

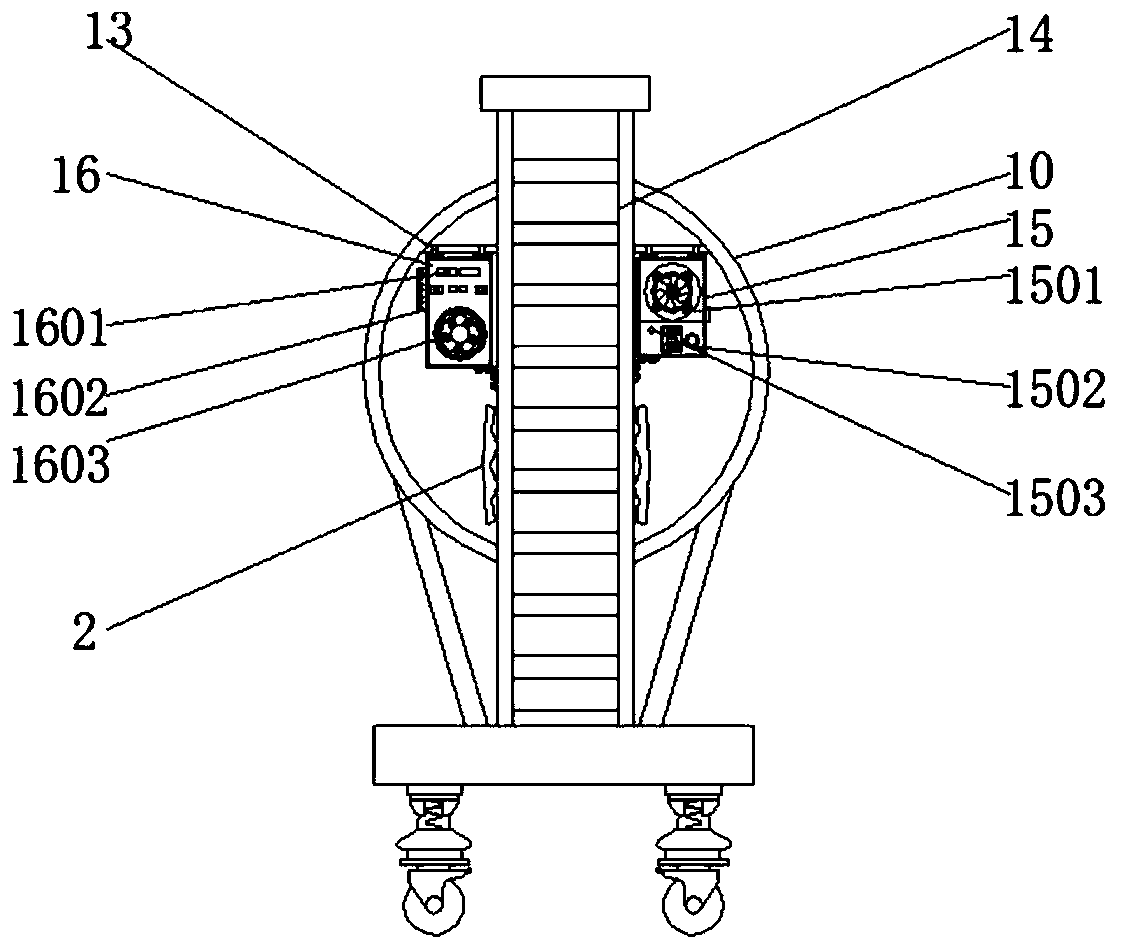

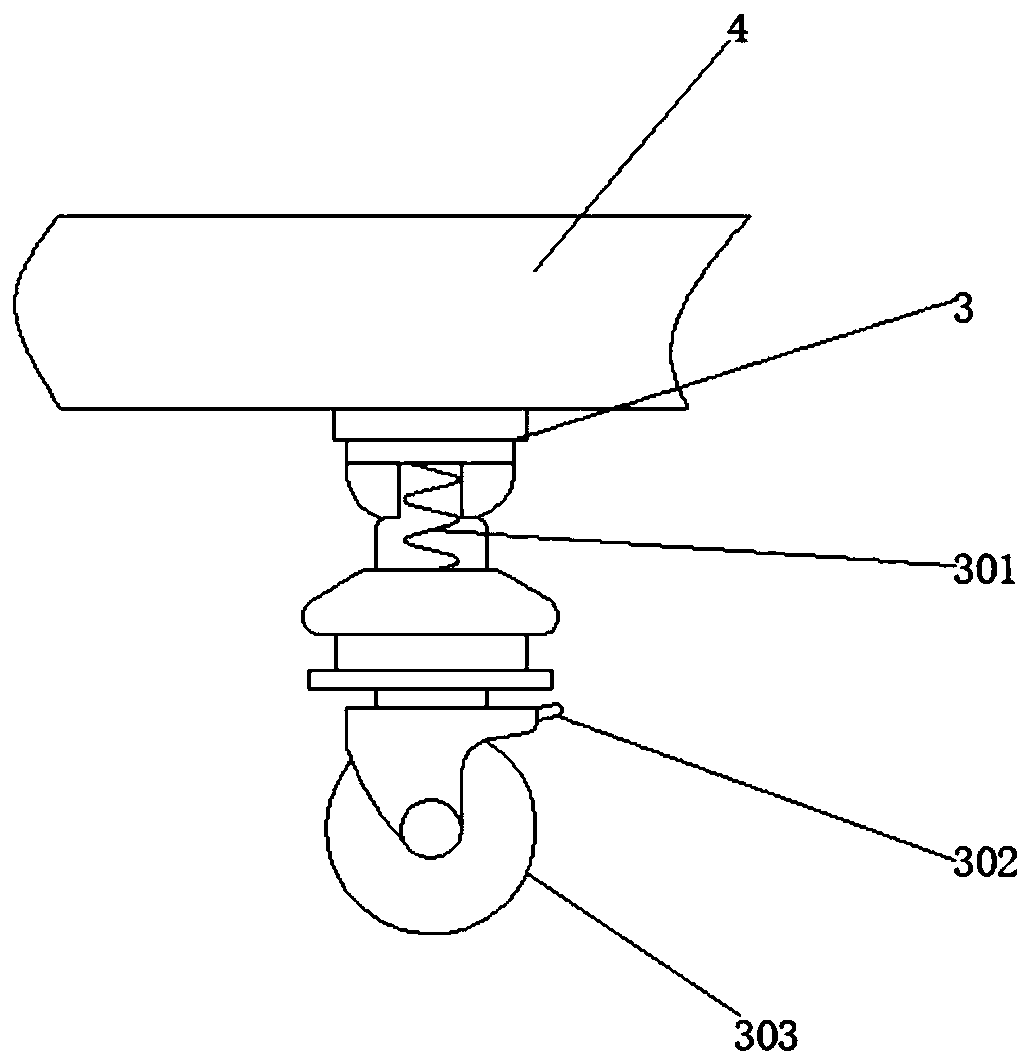

Device for uniformly mixing medicines under the condition of low rotating speed

InactiveCN110917980AReasonable structureHigh shell strengthTransportation and packagingMixer accessoriesExplosive AgentsEngineering

The invention discloses a device for uniformly mixing medicines under the condition of low rotating speed. The device comprises a stirring bin, explosion-proof structures, an electrostatic neutralization structure and a dehumidification structure. A crusher is arranged in the middle of the interior of the stirring bin, and one side of the crusher is connected with a servo motor. A feeding ladder is arranged on one side of the servo motor, and handrails are installed at the two ends of the feeding ladder. The explosion-proof structures are arranged at the top end and the bottom end of the stirring bin. A fixing rod is arranged at the top end of one side of the stirring bin, the dehumidification structure is installed on one side of the bottom end of the fixing rod, and the electrostatic neutralization structure is installed on the other side of the bottom end of the fixing rod. Supporting frames are installed on the two sides of the bottom end of the stirring bin, and a base is installed at the bottom ends of the supporting frames. By means of an exhaust fan in the dehumidification mechanism, moisture in air is pumped out, the problem that explosives cannot be used due to the fact that the explosives are exposed in the air and affected with damp is solved, and the production cost is saved through the structure.

Owner:郴州七三二零化工有限公司

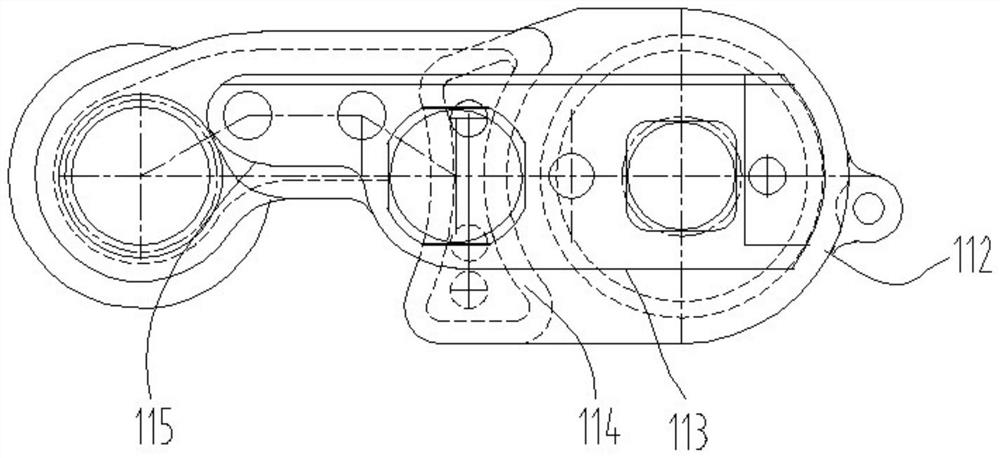

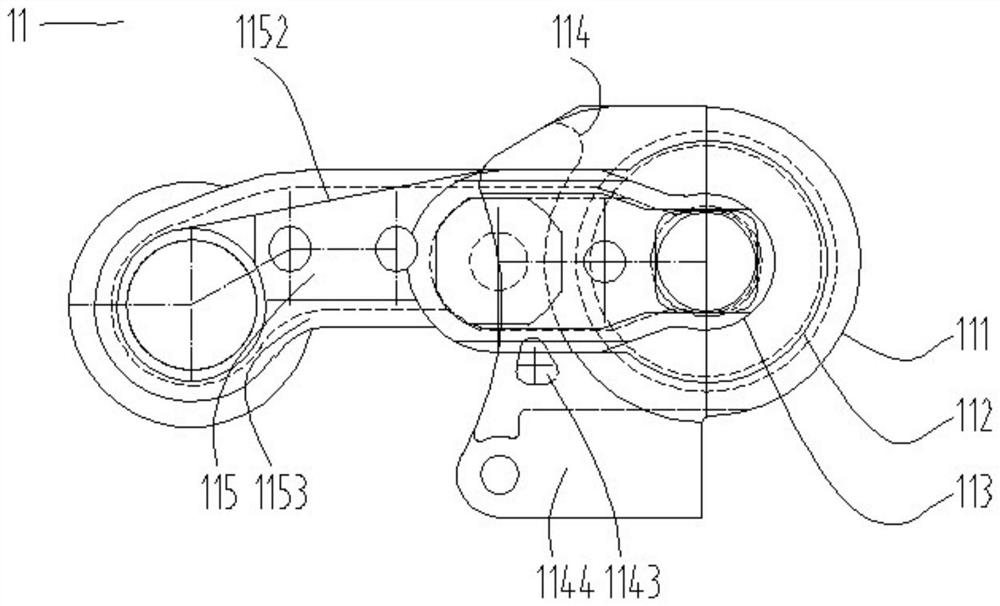

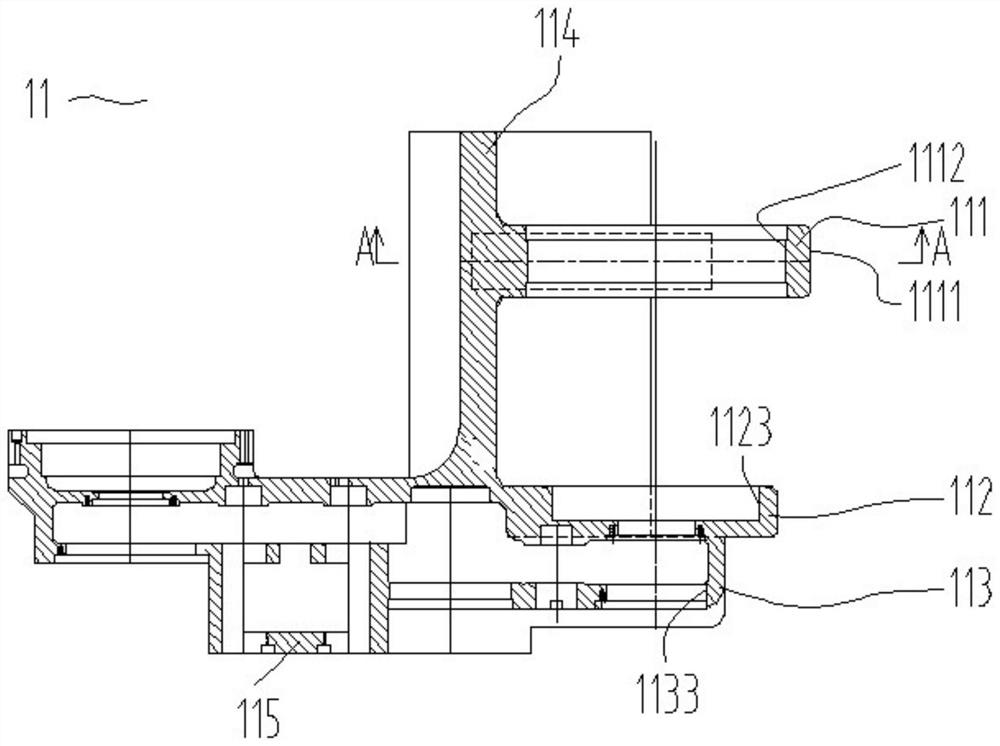

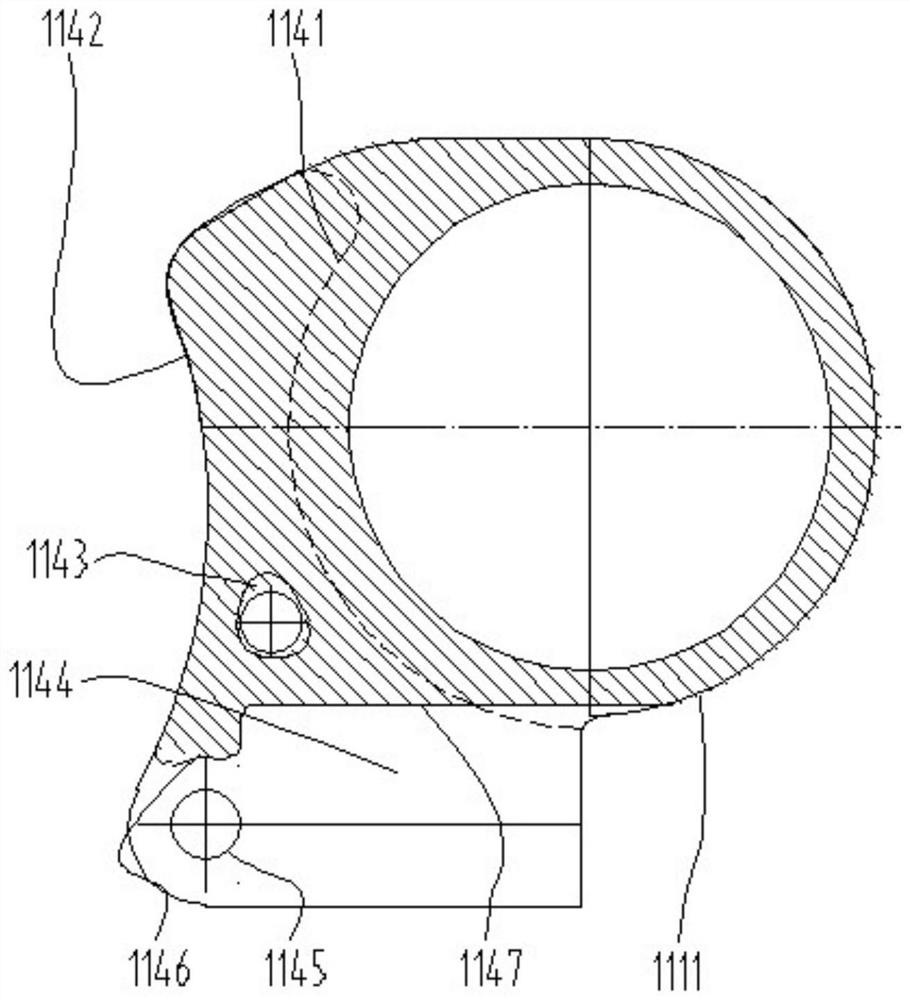

Swing arm shell of thin seam mining machine

PendingCN114396278AShorten the left and right lengthSimple structureSlitting machinesCutting machinesGear wheelElectric machinery

A main body of the swing arm shell is an arm support extending leftwards and rightwards, a transmission cavity used for installing a cutting transmission mechanism is formed in the arm support, and an input end gear installation hole and an output end gear installation hole are formed in the two ends of the transmission cavity respectively. The ends where the input end gear mounting hole and the output end gear mounting hole are located are the high-speed end and the low-speed end of the arm support respectively, a connecting arm overhanging forwards from the arm support is arranged in the middle of the arm support, a front arm and a rear arm overhanging leftwards or rightwards from the connecting arm are arranged on the connecting arm, and the front arm, the rear arm and the high-speed end of the arm support are sequentially arranged at intervals from front to back. The front arm and the rear arm are respectively provided with a front pin shaft mounting hole and a rear pin shaft mounting hole which are used for mounting the cutting motor as a pin shaft; and the front pin shaft mounting hole and the rear pin shaft mounting hole are coaxial with the input end gear mounting hole. According to the invention, a larger mining range can be provided, the machine body can be shortened, and the gravity center of the coal mining machine can be improved.

Owner:SHANGHAI TIANDI MINING EQUIP TECH CO LTD +2

Swing arm of thin seam mining machine

PendingCN114382479AShorten the left and right lengthSimple structureSlitting machinesCutting machinesGear wheelElectric machinery

The invention relates to a swing arm of a thin seam mining machine, which comprises a swing arm shell, the main body of the swing arm shell is an arm frame extending left and right, a cutting transmission mechanism is arranged in the arm frame, and the ends of an input end gear and an output end gear of the cutting transmission mechanism are respectively used as the high-speed end and the low-speed end of the arm frame. A connecting arm overhanging forwards from the arm frame is arranged in the middle of the arm frame, a front arm and a rear arm overhanging leftwards or rightwards from the connecting arm are arranged on the connecting arm, and the high-speed end of the front arm, the high-speed end of the rear arm and the high-speed end of the arm frame are parallel to one another and are sequentially arranged at intervals from front to back. The front arm and the rear arm are respectively provided with a front pin shaft mounting hole and a rear pin shaft mounting hole which are used for mounting the cutting motor as a pin shaft; and the front pin shaft mounting hole and the rear pin shaft mounting hole are coaxial with an input end gear of the cutting transmission mechanism. According to the invention, a larger mining range can be provided, the machine body can be shortened, and the gravity center of the coal mining machine can be improved.

Owner:SHANGHAI TIANDI MINING EQUIP TECH CO LTD +2

Ceramic exterior member, housing device for mobile terminal, and mobile terminal

ActiveCN105141721BReduce weightHigh shell strengthTelephone set constructionsTerminal equipmentComputer terminal

The invention discloses a ceramic appearance component, a mobile terminal shell device and a mobile terminal, wherein the ceramic appearance component includes: a ceramic shell and a buckle; the thickness of the ceramic shell is smaller than that of a conventional ceramic back cover in a mobile terminal; The ceramic shell is connected with the fastener; the fastener is any one of metal plate, magnesium alloy, stainless steel and plastic. The embodiment of the present invention can reduce the thickness of the ceramic shell, thereby reducing the overall weight of the ceramic appearance component.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

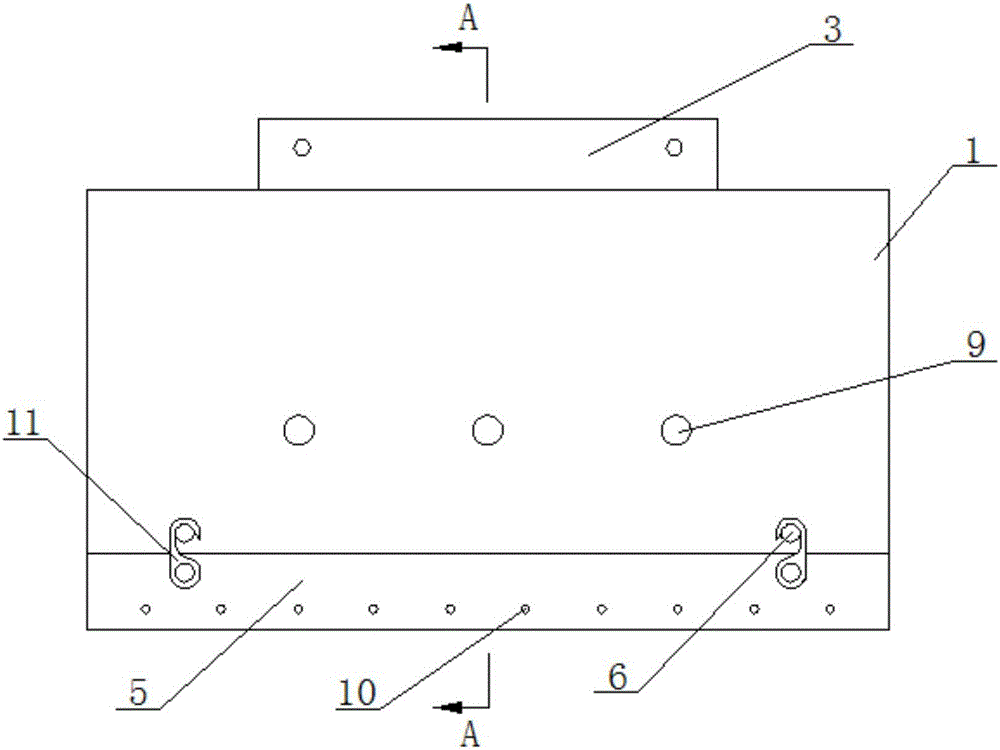

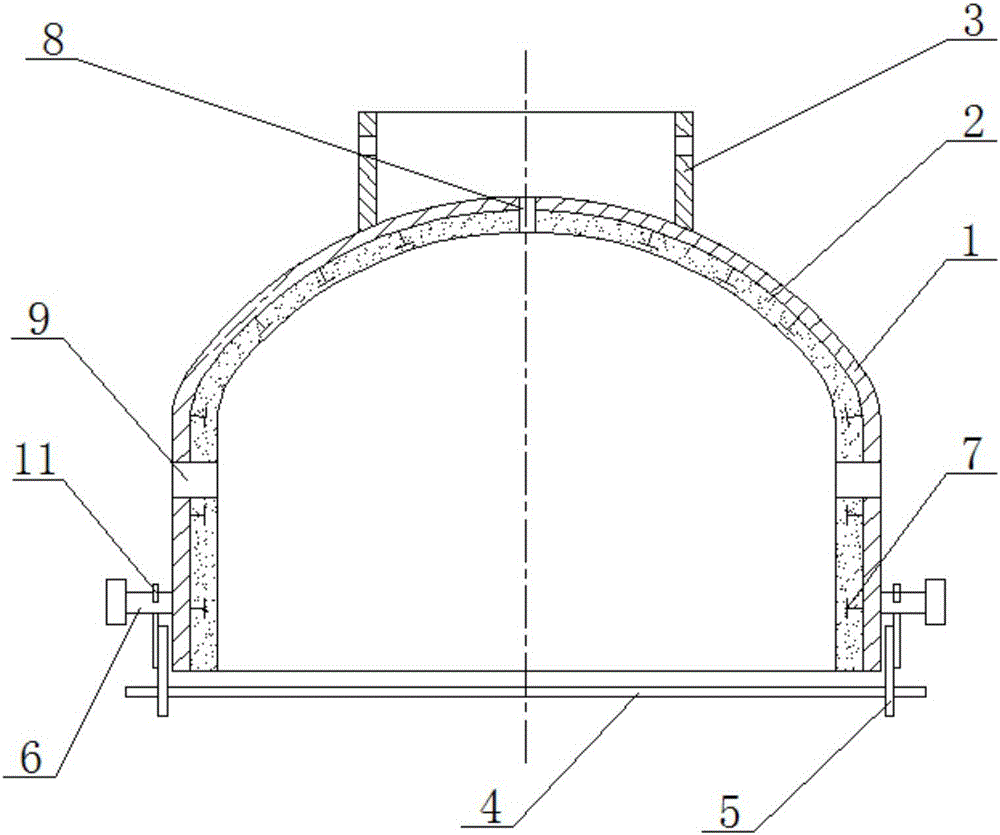

Heat preservation device used for firing of earthenware and use method of heat preservation device

PendingCN106766941AImprove connection strengthIncrease in sizeMaintainance of heating chambersHandling discharged materialEngineeringSlow cooling

The invention relates to a heat preservation device used for firing of earthenware and a use method of the heat preservation device, and belongs to the technical field of heat preservation devices used for firing of the earthenware. The heat preservation device and the use method mainly solve the technical problems that an existing heat preservation device is likely to crack, low in production efficiency and high in labor intensity. According to the technical scheme, the heat preservation device used for firing of the earthenware comprises a heat preservation cover composed of a shell, a heat preservation layer and a hoisting component, wherein the heat preservation device further comprises multiple fork tools, fork tool connection plates, hooks and lifting lugs; and multiple mud fixing jaws are evenly arranged on the inner wall of the shell, the heat preservation layer is arranged on the inner wall of the shell and is fixed through the mud fixing jaws, the lifting lugs are symmetrically arranged on the lower portions of the outer walls on the two sides of the shell, the hoisting component is arranged on the top of the shell, the fork tools are arranged below the heat preservation cover, and multiple through holes are formed in the fork tool connection plates. The method for using the heat preservation device used for firing of the earthenware includes the first step of earthenware firing, the second step of fork tool placement and the third step of slow cooling.

Owner:闫银来

Long-life safety motor

ActiveCN105978229AShort stayDrainage is highly targetedCooling/ventillation arrangementSupports/enclosures/casingsLow noisePlastic packaging

The invention relates to the field of motors, and specifically relates to a long-life safety motor. The motor comprises a stator, a rotor sleeved in the stator and a rotating shaft penetrating through the rotor, and further comprises a shell adaptively sleeved on a shell end face of the stator and provided with a vent hole and a base in the center of which a positioning installation hole post is arranged, wherein a circuit board is arranged on the outer side of the base, a draught fan is fixedly arranged on the rotating shaft and on the outer side of the shell end face, a plastic packaging body is packaged outside the stator, and a plastic packaging reinforcing connecting ring attached to the side wall of the shell is arranged on the end face of one side of the plastic packaging body facing the base in an integrated connection mode. Airflow at the rear end of the circuit board is fed into the motor via the circuit board and the vent hole in the bottom plate, the airflow between the circuit board and the bottom plate is also fed into the motor via the vent hole in the bottom plate, then the heat in the motor is absorbed, and the heat is quickly guided out of the motor via the vent hole in the inclined reinforcing hole slot wall. The whole motor has the advantages of strong integrality, compact structure, convenience in disassembly and assembly, low cost, high strength, good stability and low noise.

Owner:徐州亚泰电机有限公司

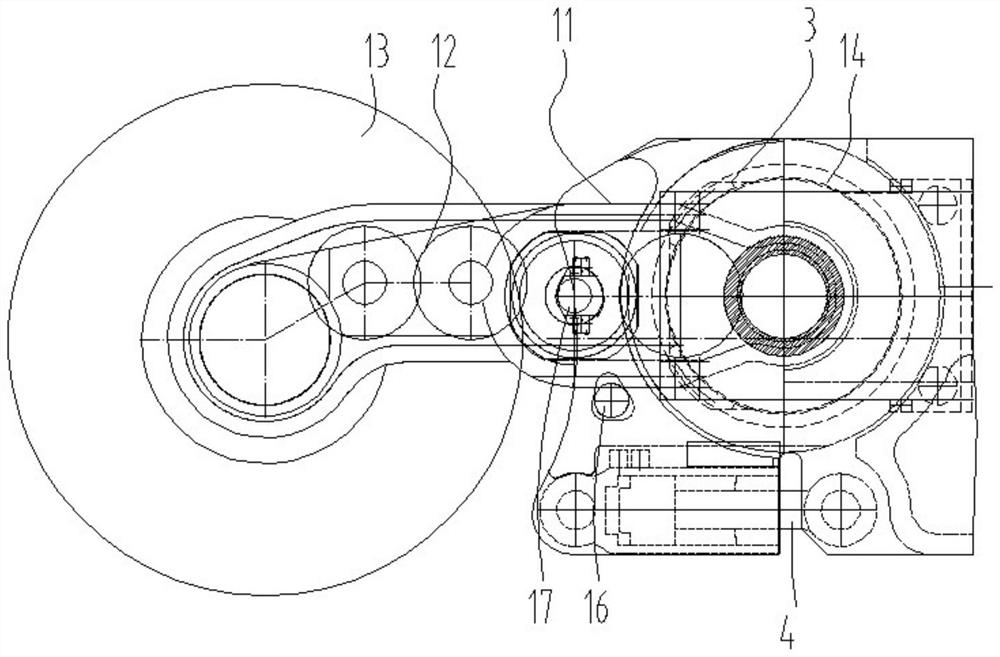

Cutting mechanism of thin seam mining machine

PendingCN114396276AShorten the left and right lengthSimple structureSlitting machinesCutting machinesGear wheelElectric machinery

The invention relates to a cutting mechanism of a thin seam mining machine, which is characterized in that a swing arm shell is hinged with a main body shell by taking a cutting motor as a pin shaft, the cutting motor is fixed relative to the main body shell, the main body of the swing arm shell is an arm frame extending left and right, and a connecting arm overhanging forwards from the arm frame is arranged in the middle of the arm frame; a front arm and a rear arm which overhang leftwards or rightwards are arranged on the connecting arm, the front arm, the rear arm and the high-speed end of the arm frame are sequentially arranged at intervals from front to back, the front arm and the rear arm are hinged to a first lug base, a second lug base and a third lug base on the front portion of the main body shell, and loads from the roller are transmitted to the main body shell. An input end gear of a cutting transmission mechanism installed in the high-speed end of the arm frame is in coaxial transmission connection with an output shaft of the cutting motor, a height adjusting oil cylinder is arranged in an inner cavity in the front portion of the main body shell, and the two ends of the height adjusting oil cylinder are hinged to the front arm and the main body shell respectively. A large mining range can be provided, the machine body can be shortened, and the gravity center of the coal mining machine is improved.

Owner:SHANGHAI TIANDI MINING EQUIP TECH CO LTD +2

a stable motor

ActiveCN105932829BShort stayDrainage is highly targetedCooling/ventillation arrangementSupports/enclosures/casingsEngineeringUltimate tensile strength

The invention relates to the field of motors, and in particular relates to a stable motor. The stable motor comprises a stator, a rotor sleeved in the stator and a rotating shaft arranged on the rotor in a penetrating manner, and also comprises a shell and a base which are fit with each other, wherein the shell is sleeved on the stator and provided with vent holes in the shell end face, the base is provided with a locating mounting hole column at the center, a circuit board is erected on the outer side of the base, a draught fan is fixedly arranged on rotating shaft on the outer side of the shell end face, the stator is packaged with a plastic package body, and a circle of plastic package reinforced connecting ring arranged close to the side wall of the shell is integrally connected on the end face of the plastic package body facing the base side. Air flows at the rear end of the circuit board are sent into the motor via vent holes in the circuit board and base plate, in the same way, the air flows between the circuit board and base plate are sent into the motor via the vent holes in the base plate, then absorb heat in the motor, and then are rapidly exported from the motor via vent holes in the inclined reinforced pored groove wall. The whole motor is strong in integrality, compact in structure, convenient to dismount, low in cost, high in strength, good in stability and low in noise.

Owner:佛山市顺德区乐普达电机有限公司

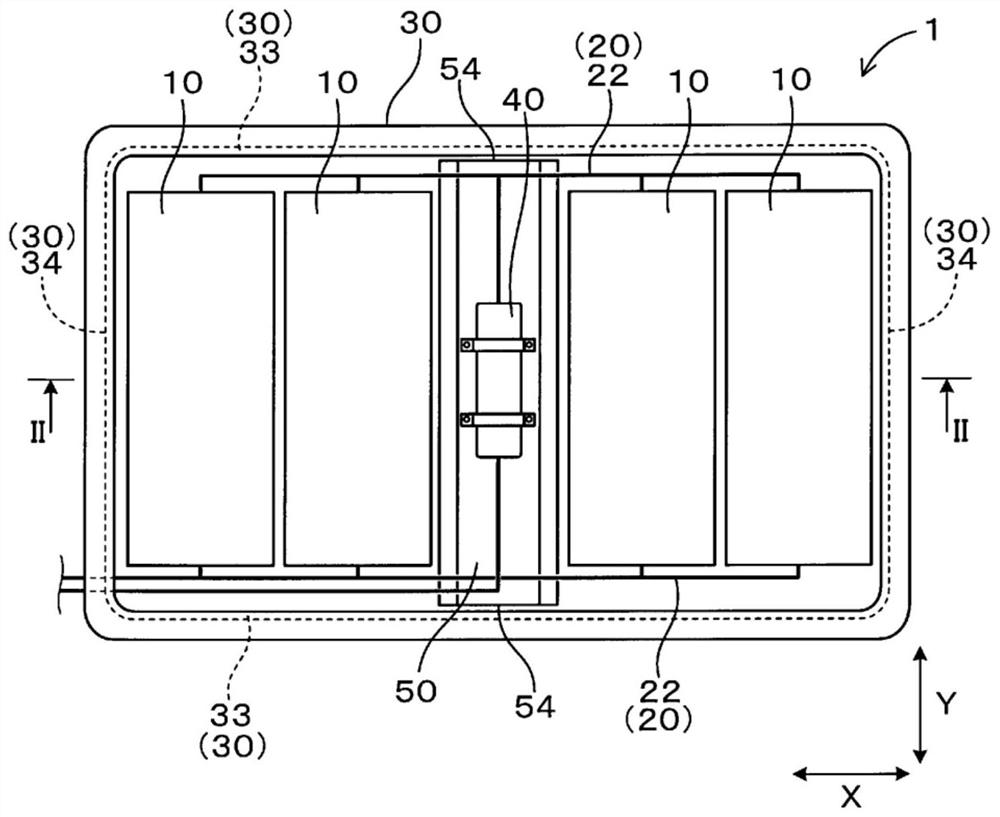

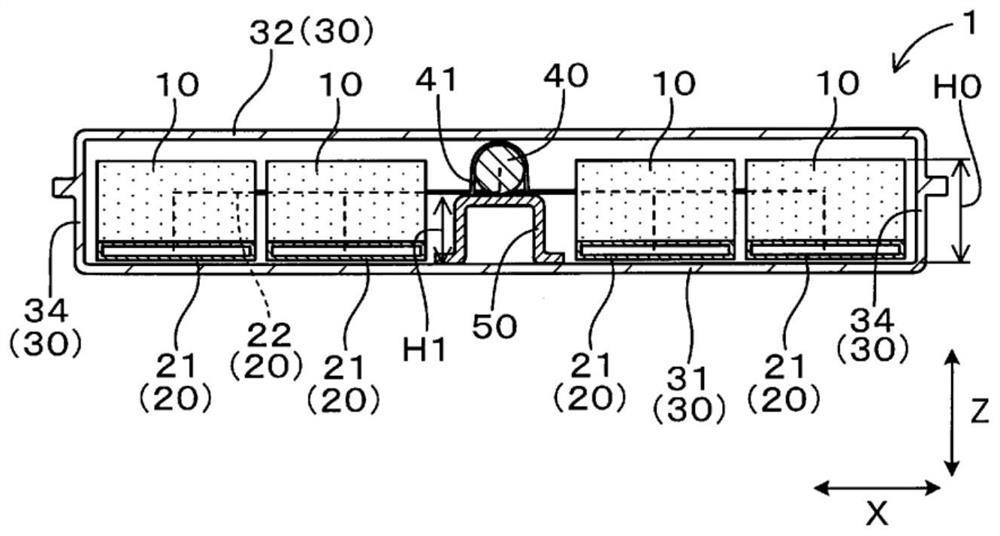

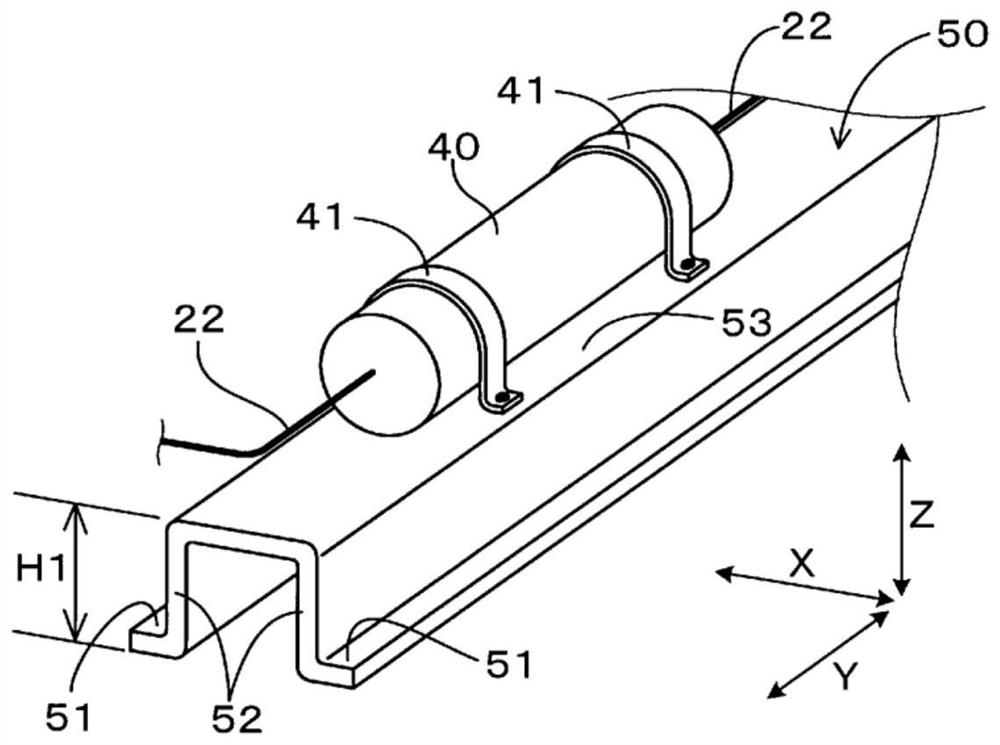

Power supply system

PendingCN113809447AExpanded loading spaceHigh shell strengthCell temperature controlCell component detailsElectrical batteryRefrigerant

The invention provides a power supply system in which while enlargement of a space for placement of the power supply system is suppressed, strength of a housing is improved. The power supply system (1) includes a plurality of batteries (10), a cooling portion (20) through which a refrigerant for cooling the plurality of the batteries flows, a housing (30) that has a bottom plate (31), a top plate (32), and side walls (33, 34) that extend upright from a peripheral edge of the bottom plate to a peripheral edge of the top plate, the housing accommodating the plurality of the batteries and the cooling portion, and a compressor configured to pump the refrigerant to the cooling portion. In the housing, a strength member that extends in a direction in which the side walls face each other and reinforces the housing is mounted on the bottom plate or the top plate. The compressor is disposed in a position in which the compressor and the strength member are overlapped in the upright direction of the side walls.

Owner:TOYOTA IND CORP

Swing arm shell of short-span coal mining machine for thin coal seam

PendingCN114396275AShorten the left and right lengthSimple structureSlitting machinesCutting machinesGear wheelElectric machinery

The invention relates to a thin seam short-span coal mining machine swing arm shell, a main body of the shell is an arm frame extending left and right, a transmission cavity used for installing a cutting transmission mechanism is arranged in the arm frame, and the left end and the right end of the arm frame are respectively a high-speed end and a low-speed end. An input end gear mounting hole and an output end gear mounting hole are formed in the rear portion of the high-speed end of the arm frame and the low-speed end of the arm frame respectively, a connecting arm overhanging forwards from the arm frame is arranged in the middle of the arm frame, and a front arm overhanging leftwards or rightwards from the connecting arm is arranged on the connecting arm. The front parts of the high-speed ends of the front arm and the arm frame are respectively provided with a front pin shaft mounting hole and a rear pin shaft mounting hole which are used for mounting the cutting motor as a pin shaft; and the front pin shaft mounting hole, the rear pin shaft mounting hole and the input end gear mounting hole are coaxial. According to the invention, a larger mining range and larger cutting power can be provided, the machine body can be shortened, and the gravity center of the coal mining machine can be improved.

Owner:SHANGHAI TIANDI MINING EQUIP TECH CO LTD +2

A coating for lost foam casting and its application method

InactiveCN103394636BImprove surface qualityIncrease productivityFoundry mouldsFoundry coresSlagGranularity

The invention provides a coating for lost foam casting. The coating is prepared from the following raw materials by weight percent: 40%-47% of water glass with the modulus of 2.0-2.5, 52-59% of bauxite with the granularity of 62-74 microns or silica sand with the granularity of 62-74 microns, not more than 0.2% of emulsifier op-10, and 0.95% of phenolic resin liquid. The application method of the coating for lost foam casting comprises the following steps of: firstly, mixing the water glass, the emulsifier op-10 and the phenolic resin liquid together, and then adding the bauxite or the silica sand, and stirring all the materials evenly; then painting a lost foam module with the mixture pass by pass while drying; drying after the last pass of painting, and then cooling to room temperature; roasting the lost foam module; preserving heat at a temperature not lower than 400 DEG C; after burying the lost foam module in a box, carrying out slight vibration and then performing casting molding. The coating for lost foam casting can be used for solving the problems of recarburization, pore formation and slag inclusion in the lost foam casting process; the application time from coating painting to completion of roasting is reduced to not more than 32 hours from previously at least 48 hours; besides, the coating is excellent in high temperature resistance, high in shell mould strength and excellent in moulded shell collapsibility; the cost can be reduced by **-**.

Owner:武汉钢实融鑫科技发展有限公司

Cutting mechanism of thin seam short-span coal mining machine

PendingCN114396264AShorten the left and right lengthSimple structureSlitting machinesCutting machinesGear wheelElectric machinery

The invention relates to a thin seam short-span coal mining machine cutting mechanism which comprises a cutting motor, a swing arm shell and a front main body shell, a main body of the swing arm shell is an arm frame extending left and right, a connecting arm overhanging forwards is arranged in the middle of the arm frame, and a front arm overhanging leftwards or rightwards is arranged on the connecting arm. A first lug seat, a second lug seat and a connecting base are sequentially arranged on the right edge or the left edge of the front main body part shell from front to back, and the high-speed end of the front arm and the high-speed end of the arm frame are mutually inserted and hinged with the first lug seat, the second lug seat and the connecting base of the front main body part shell; an output shaft of the cutting motor is in coaxial transmission connection with an input end gear of a cutting transmission mechanism in the arm frame, and the cutting motor is fixedly connected and rotationally connected relative to the front main body part shell and the swing arm shell respectively. According to the invention, a larger mining range and larger cutting power can be provided, the machine body can be shortened, and the gravity center of the coal mining machine can be improved.

Owner:SHANGHAI TIANDI MINING EQUIP TECH CO LTD +2

Preparation method of Cazro3 type shell for precision casting of titanium and titanium alloy

ActiveCN103071764BHighlight substantiveSignificant progressFoundry mouldsFoundry coresSurface finishZirconate

The invention discloses a method for preparing a CaZrO3 shell used for precision casting of titanium and titanium alloys. Calcium zirconate is used as a filler, and binders such as zirconium acetate or yttrium sol that do not react with titanium alloys are pretreated and formed. , hardening, sintering and other processes to make the shell. The mold shell has a small reaction degree with titanium and titanium alloys, and the thickness of the dirt layer formed on the surface of the casting is small; the strength of the calcium zirconate ceramic shell is high, and the surface finish of the casting is high; the coating containing calcium zirconate is stable, not easy to gel, and suspended Good performance, long storage time.

Owner:SHANGHAI UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com