Damper and circular air-conditioning air outlet

A damper, circular technology, applied in the field of circular air-conditioning outlets, can solve the problems of insufficient smooth and stable joint rotation, affecting joint retention, weakening material elasticity, etc., saving raw materials, enhancing shell strength, and reducing fineness. desired effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

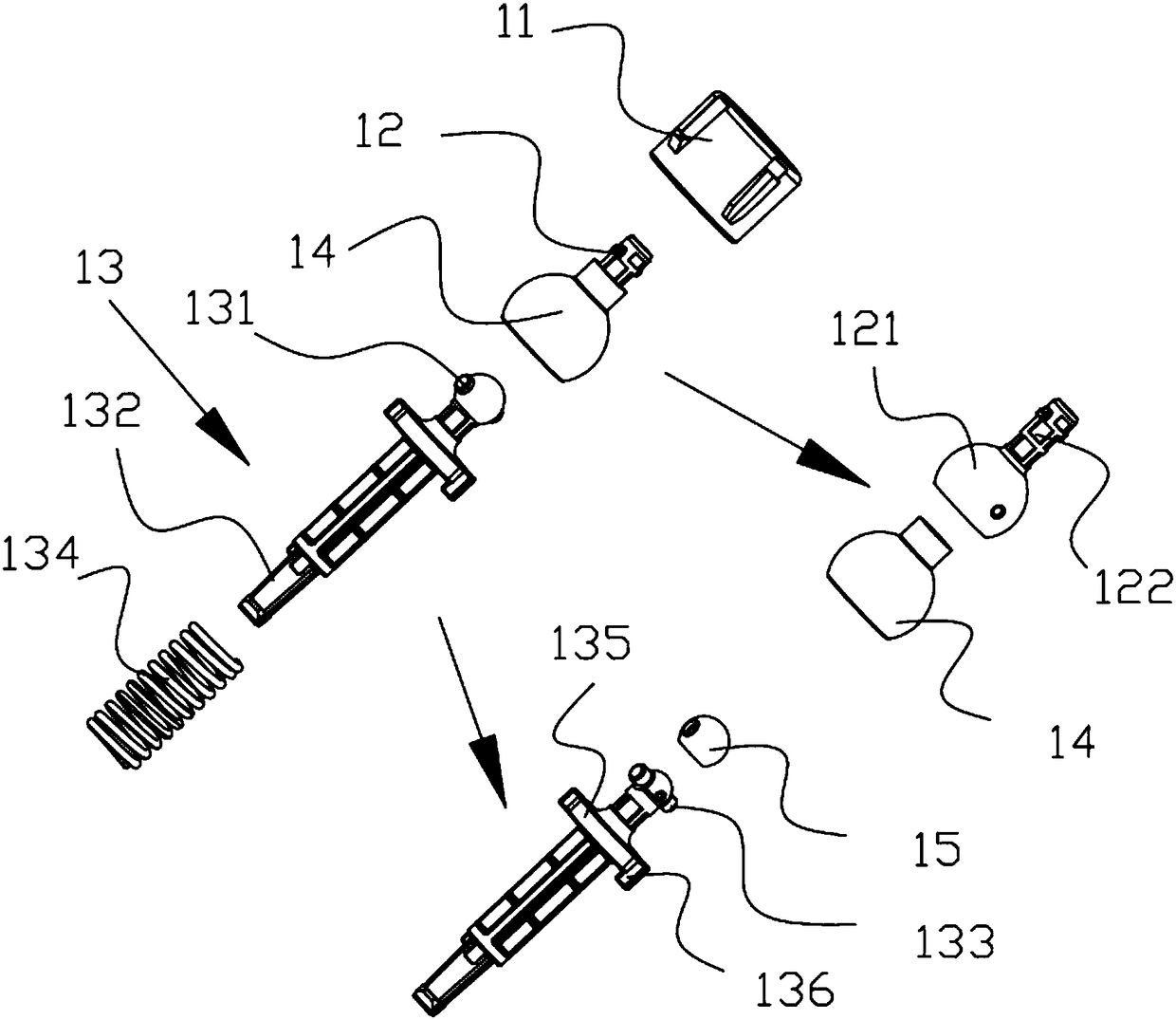

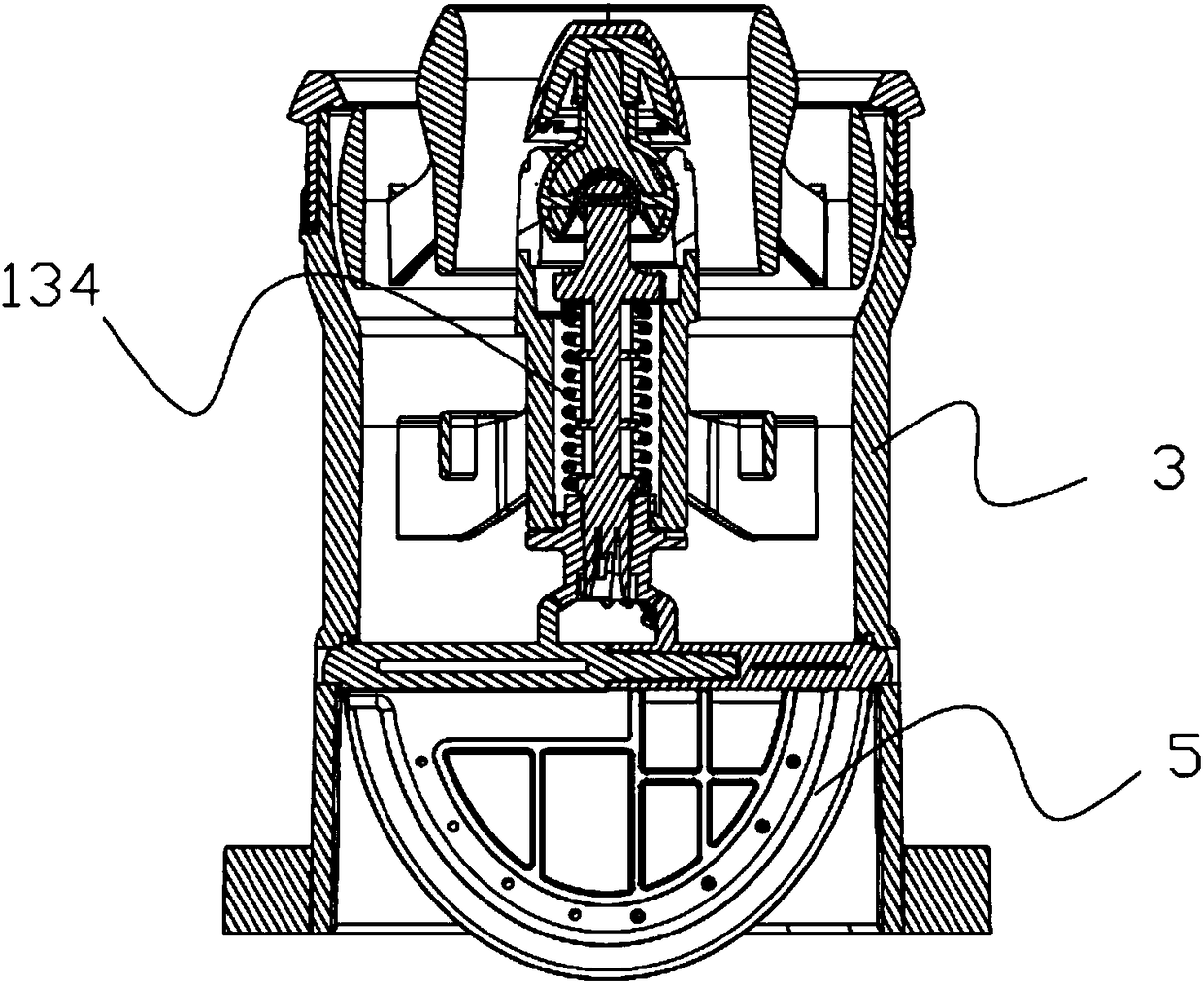

[0023] The embodiment of the present invention provides a damper 1, combined with Figure 1 to Figure 4 As shown, it includes a base 11, a rotating part 12 and a transmission part 13. The base 11 has a spherical inner cavity and is provided with openings at both ends. Correspondingly, the other end passes through the opening of one end of the base 11, the end of the rotating part 12 accommodated in the base 11 is provided with an opening and has an inner cavity, and one end of the transmission part 13 is rotatably accommodated in the inner cavity of the rotating part 12 and is connected to the inner cavity of the rotating part 12. The shape of the inner cavity is suitable, and the other end passes through the opening of the base 11 away from the end of the rotating part 12, and the transmission part can rotate around the axis under the drive of the rotating part.

[0024] The base 11 of this embodiment is an integral structure with a spherical inner cavity and openings at both...

Embodiment 2

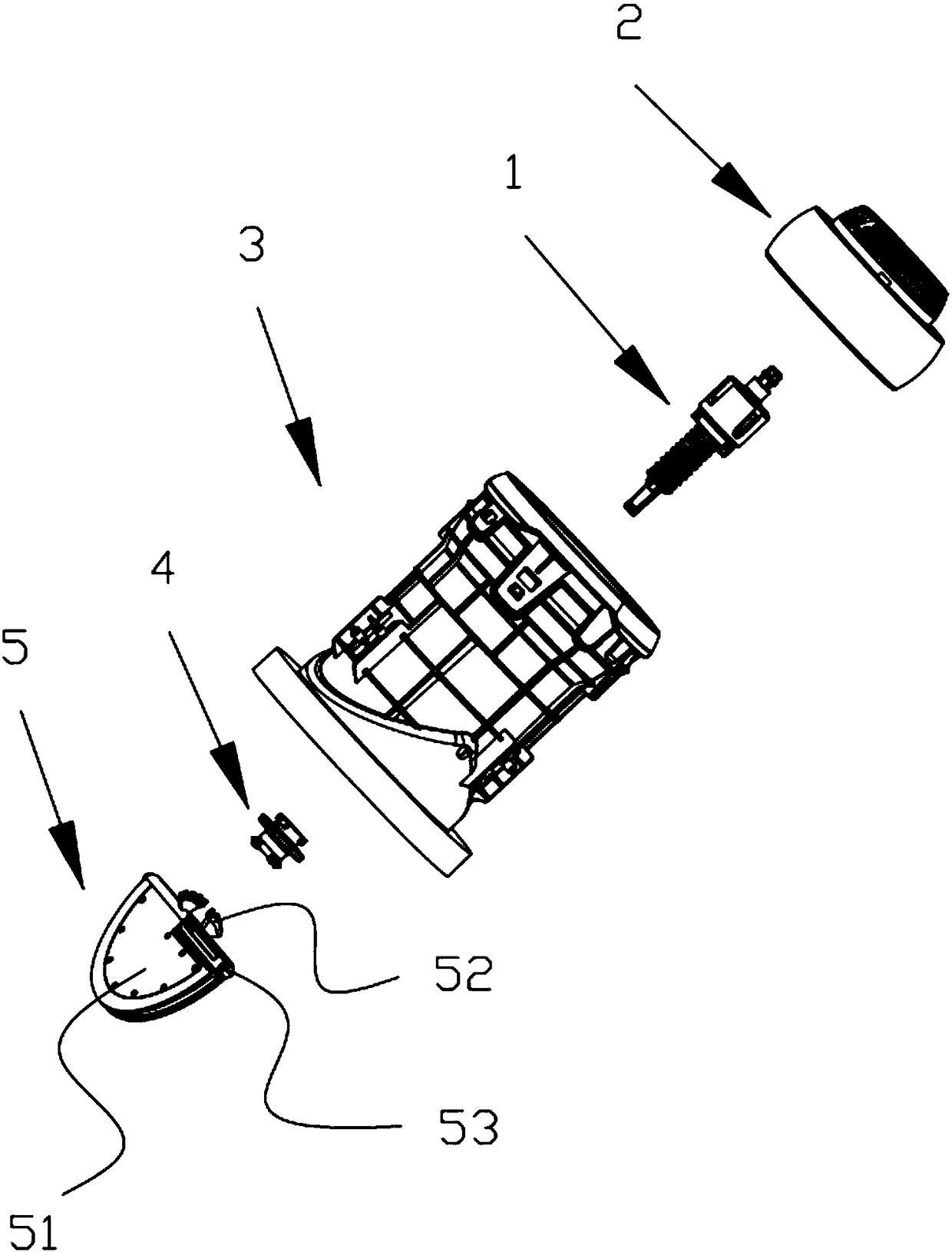

[0036] This embodiment provides a circular air-conditioning air outlet, including a housing 3, a blade 2 placed in the housing 3, a gear 4, a damper 5, and the damper 1 as described in the above-mentioned embodiment 1. The damper 1 The base 11 is fixedly connected to the inner surface of the housing 3. The blade 2 is circular and rigidly connected to the first operating shaft 122 of the rotating part 12 of the damper 1. By controlling the direction of the blade 2, the first operating shaft can be driven 122 movement, so as to control the rotating part 12 to rotate around the axis or to make multi-directional rotation around the center of the ball.

[0037] The damper 5 is rotatably connected to the housing 3 and driven by the damper 1 to rotate. The damper 5 includes a rotating shaft 53 connected to the housing 3 and a damper body 51 rotatably connected to the rotating shaft 53 , and the half bevel gear 52 located on the damper body 51. The damper body 51 can rotate around th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com