Patents

Literature

42results about How to "Smooth and stable rotation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

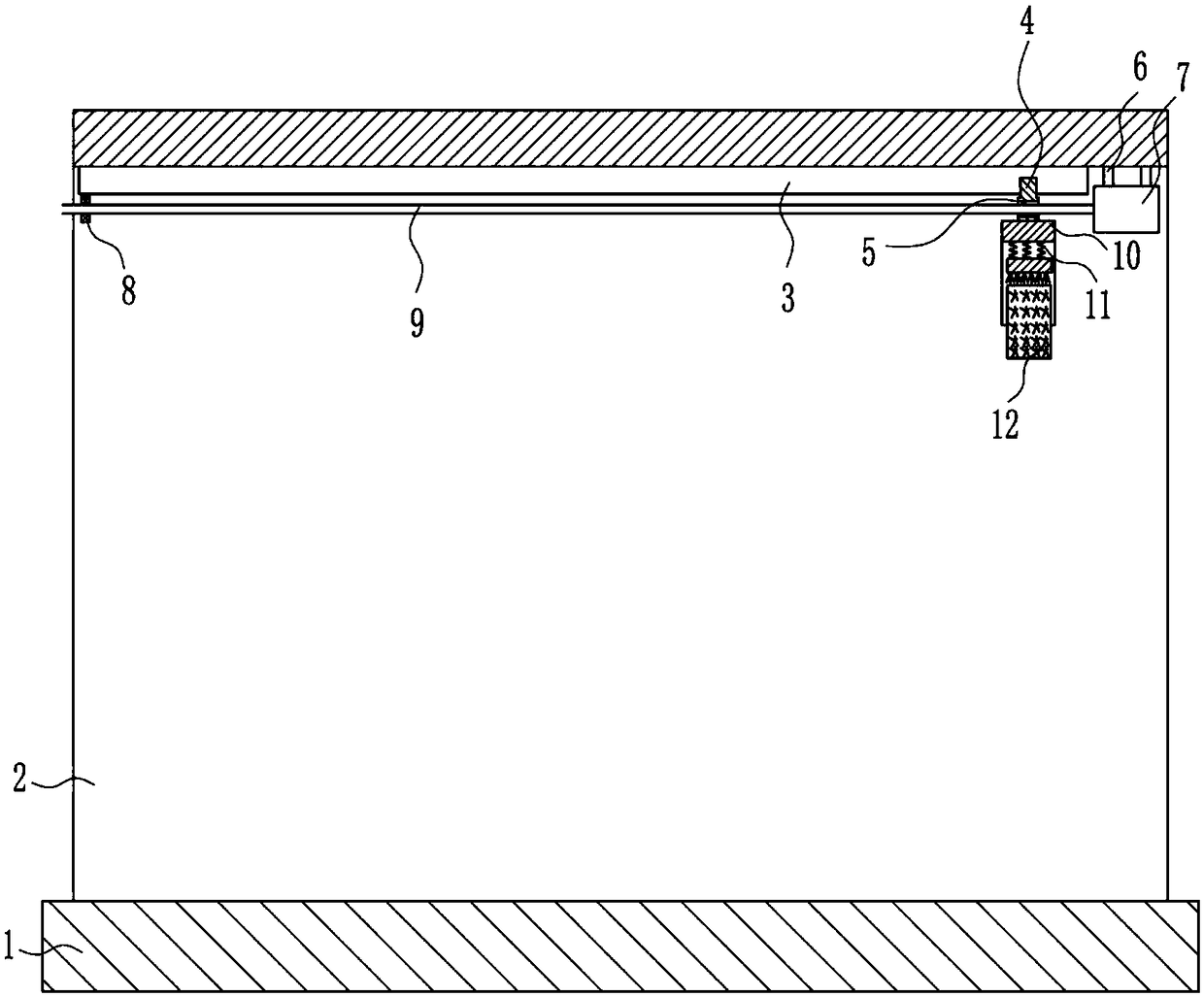

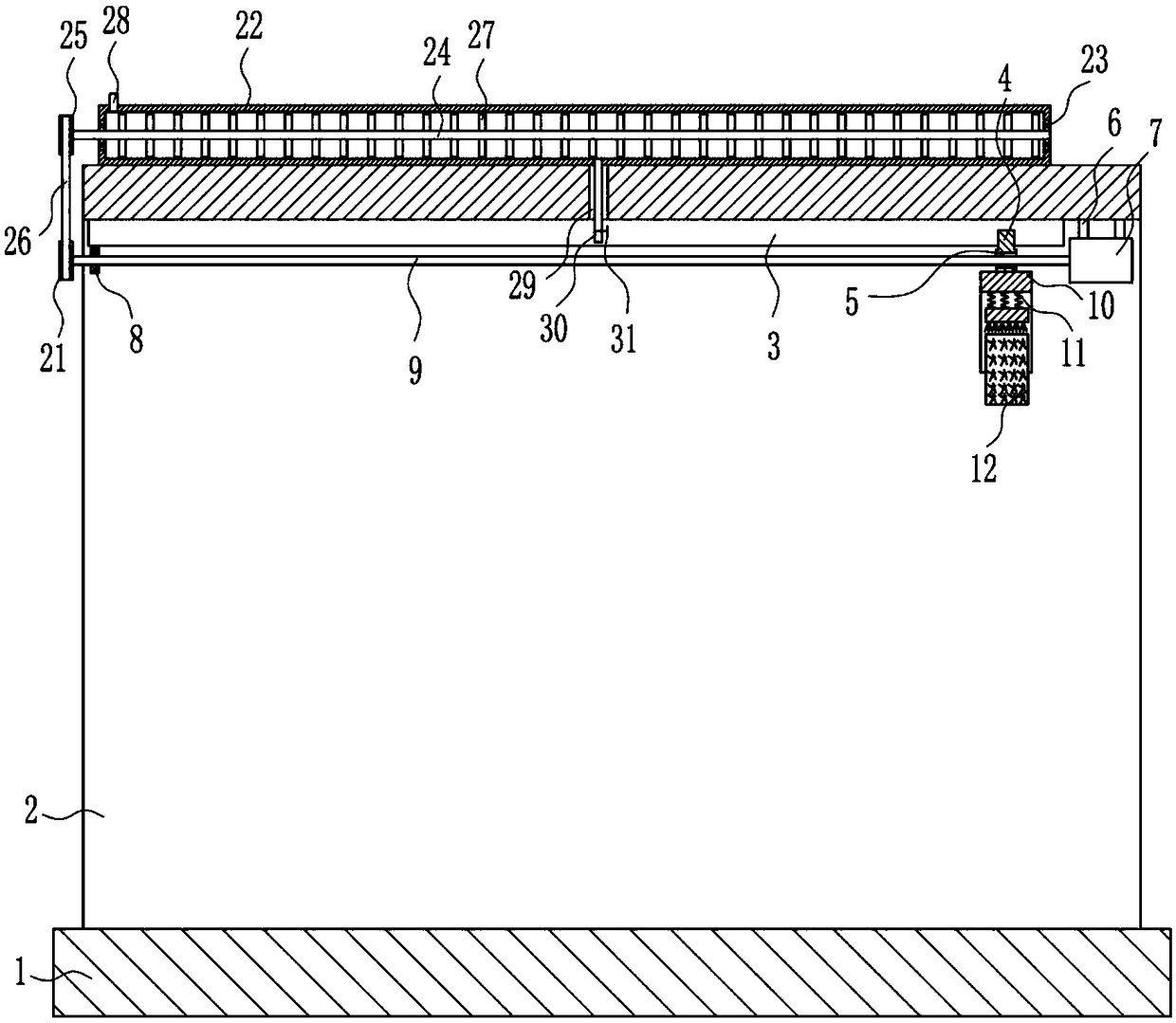

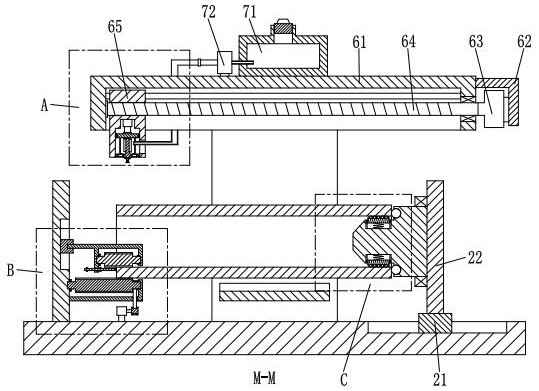

Near-remote distance comprehensive transfer placing system for building

ActiveCN105569374AReduce internal stressImprove protectionBuilding repairsInternal stressMechanical engineering

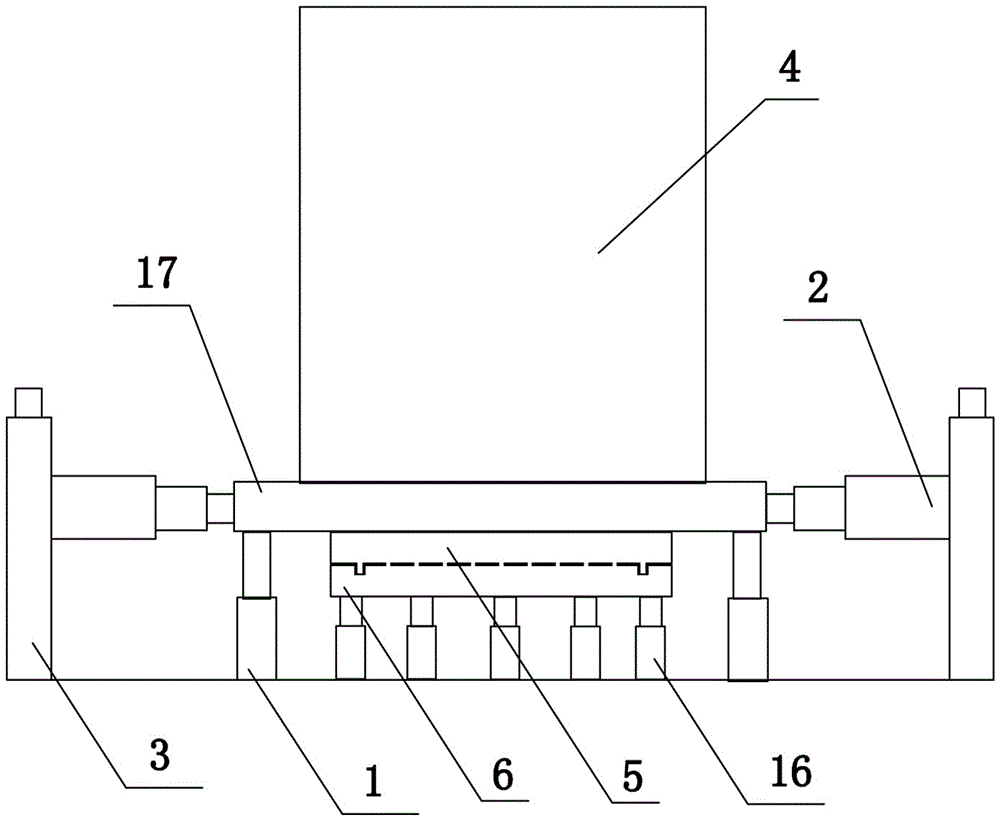

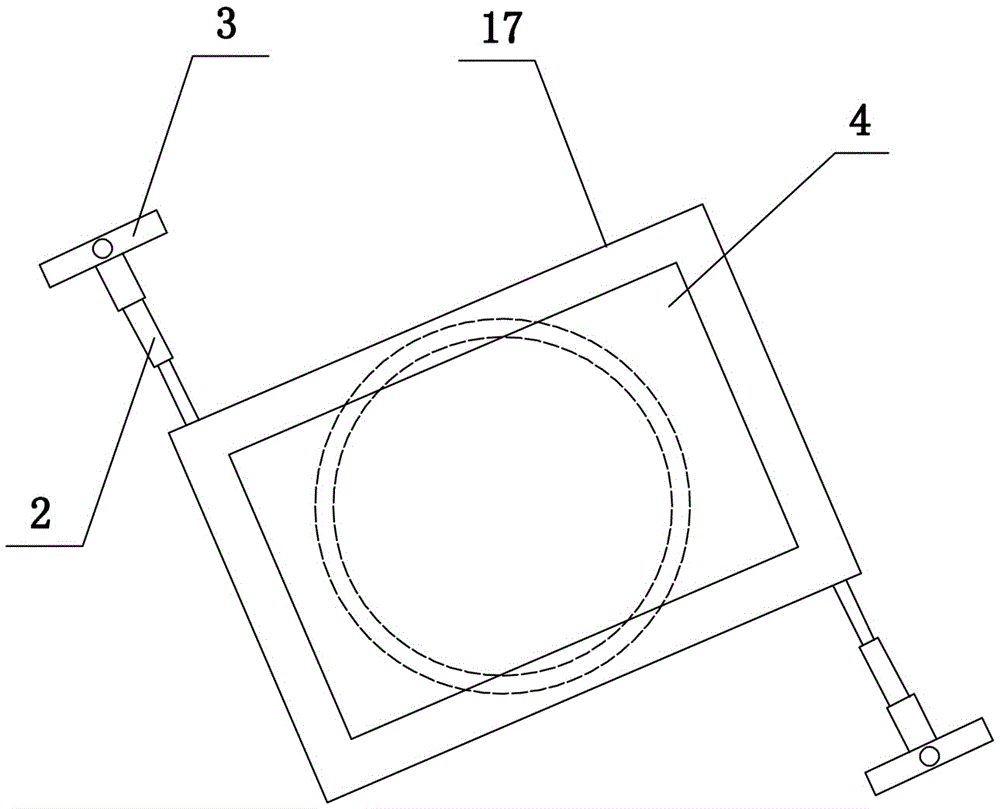

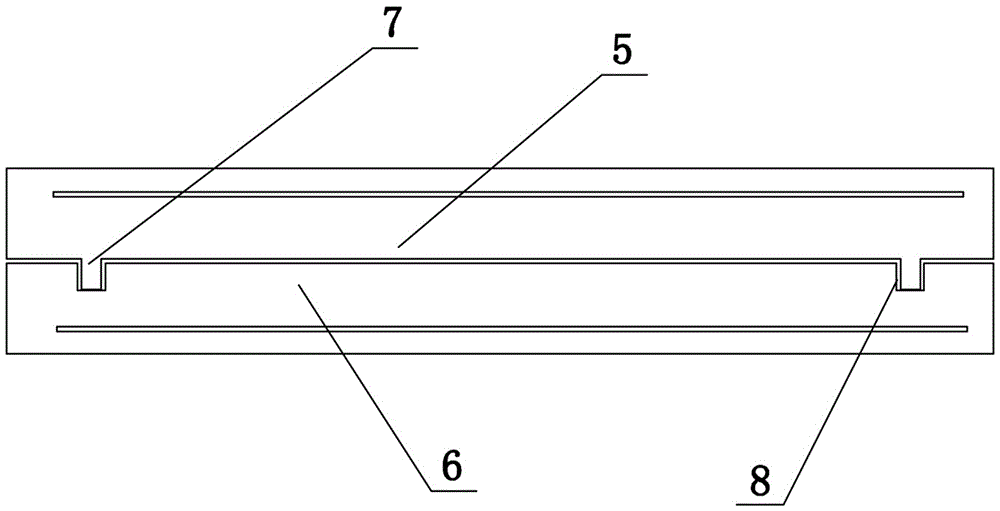

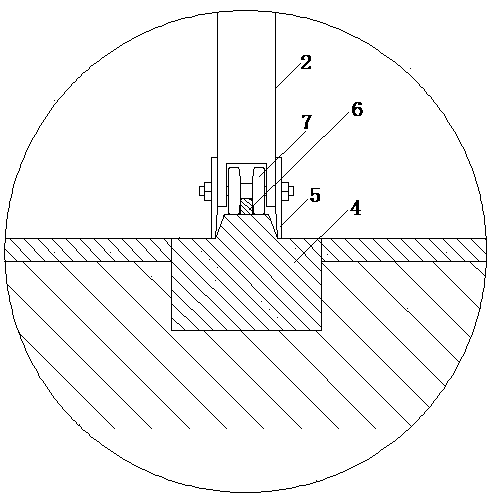

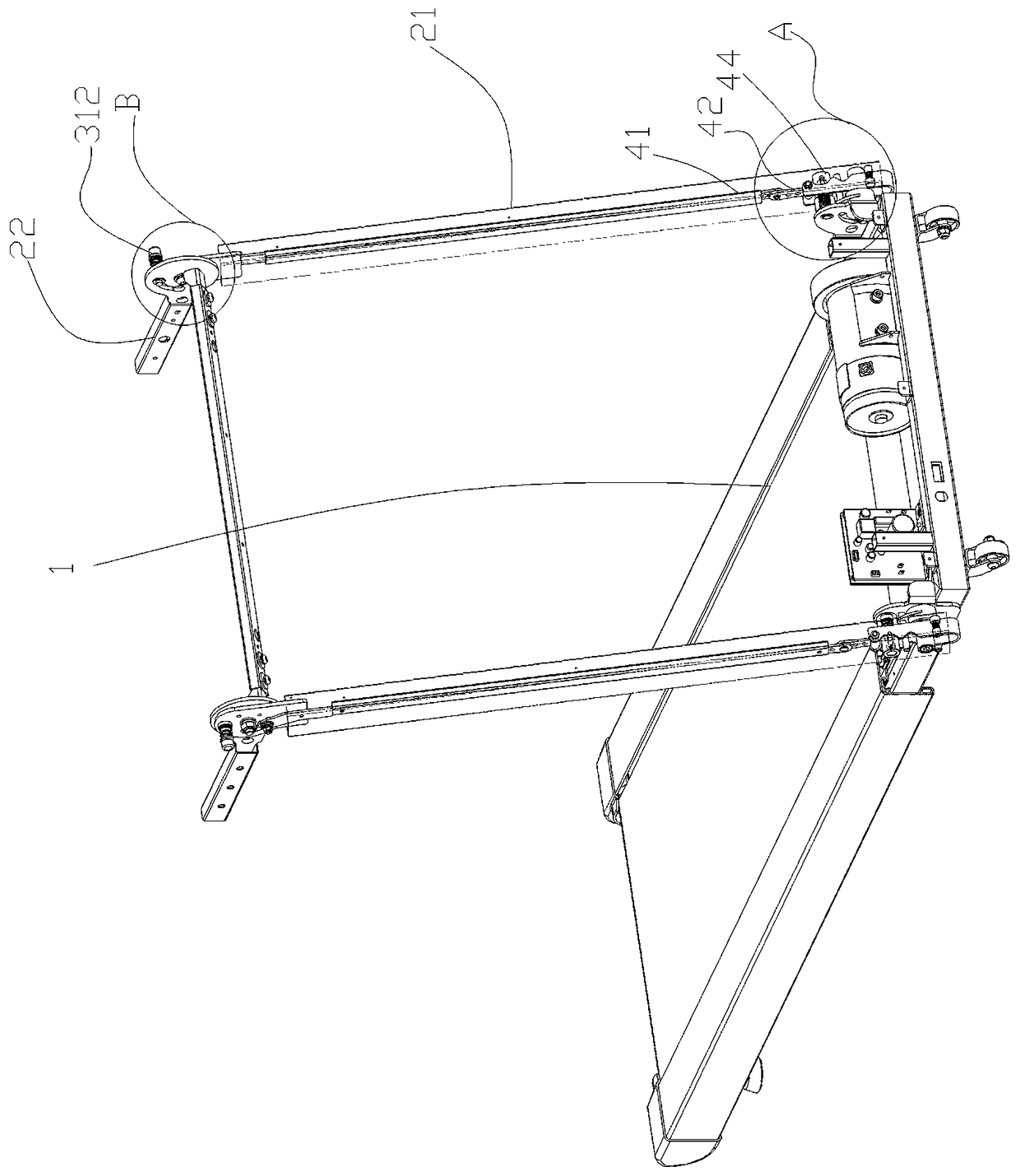

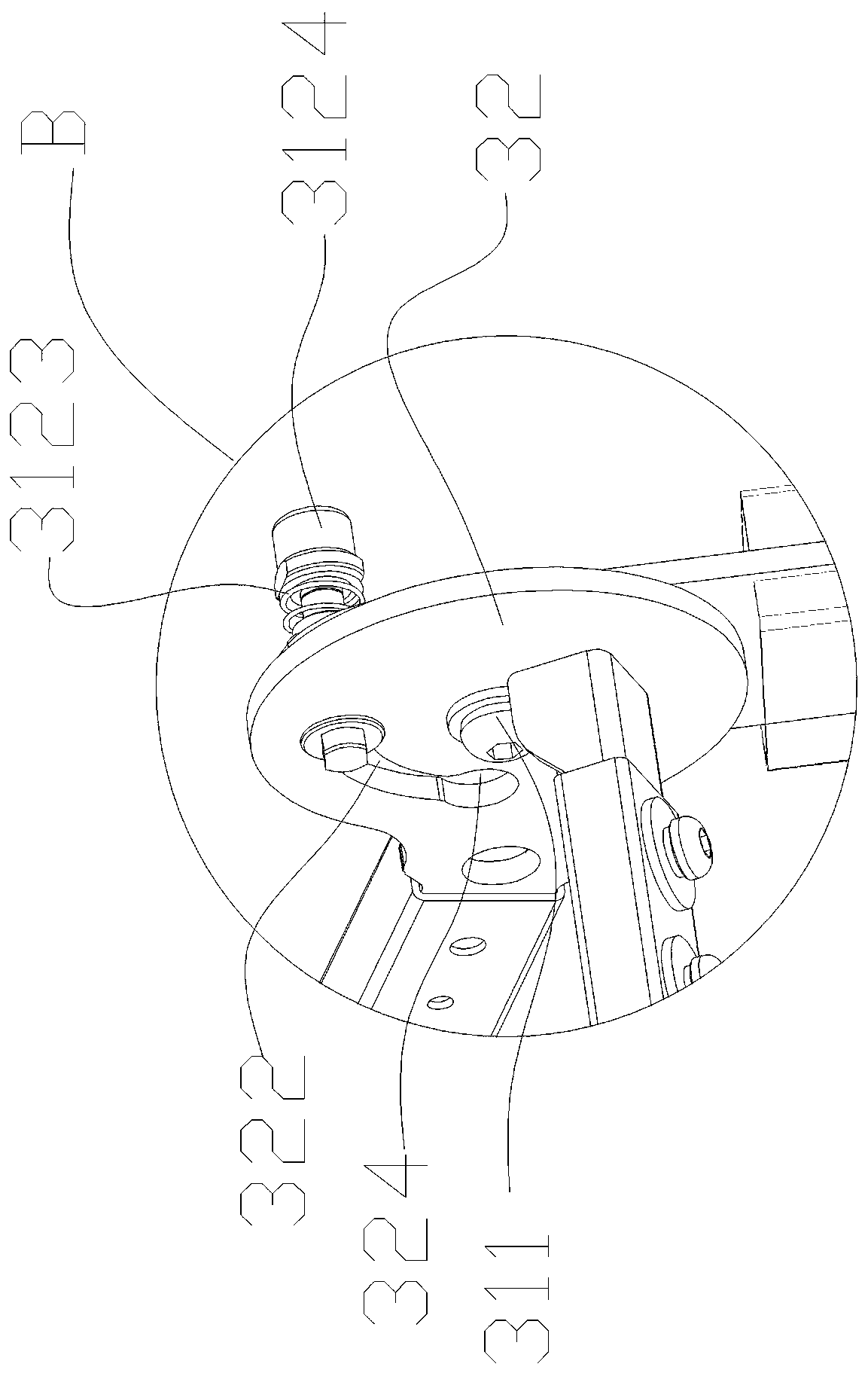

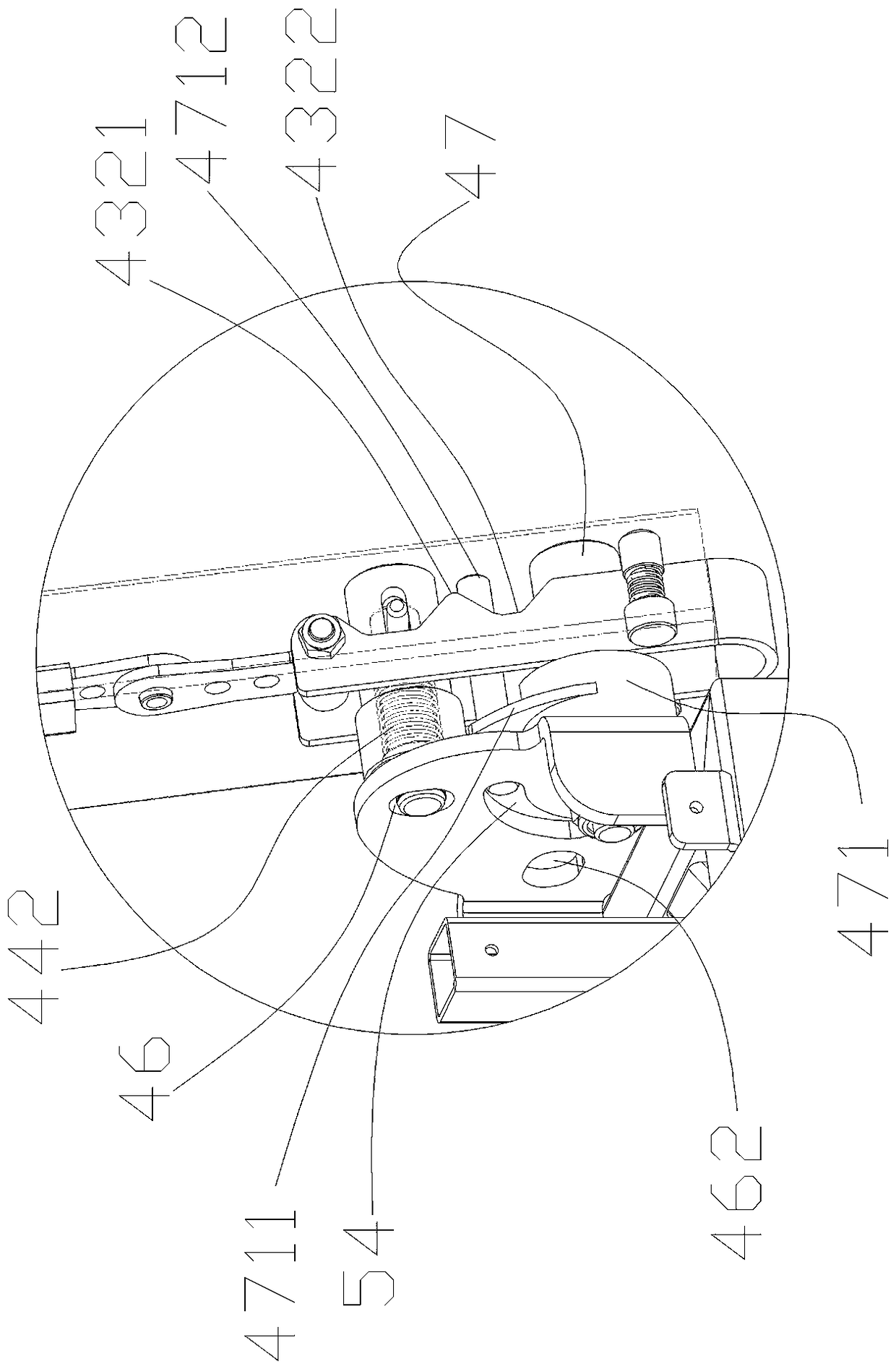

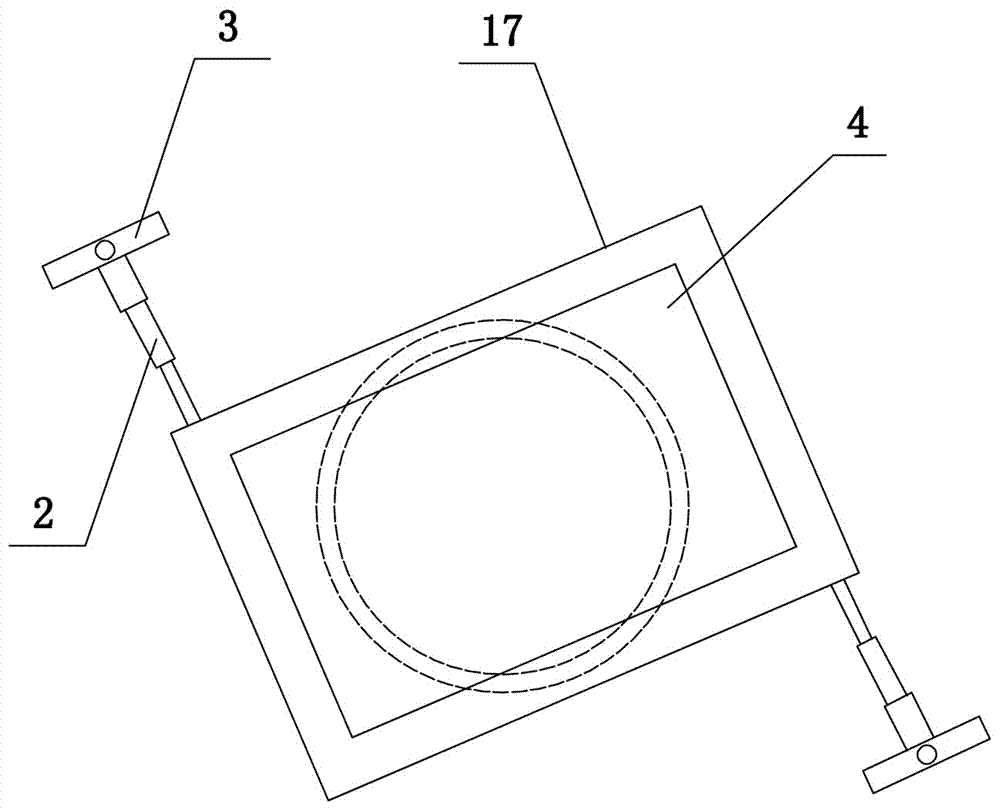

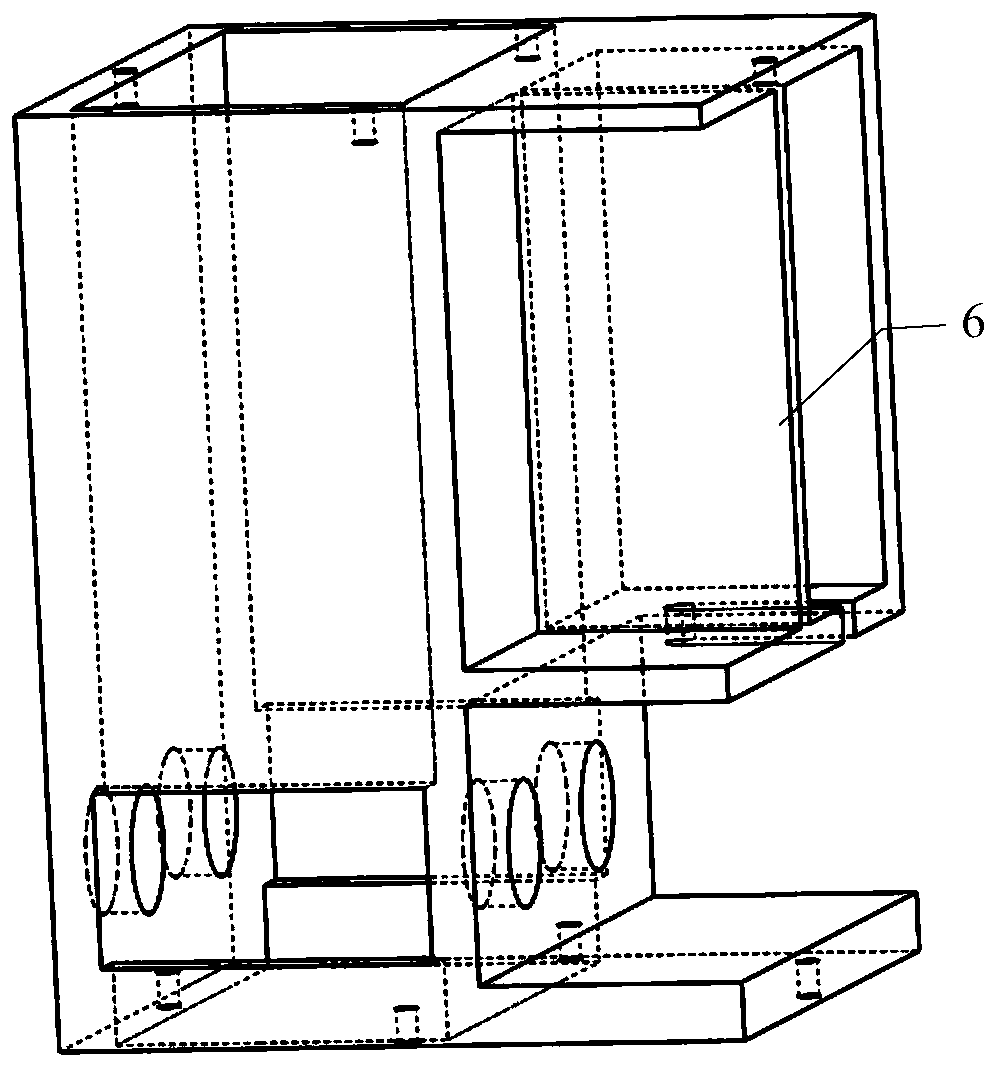

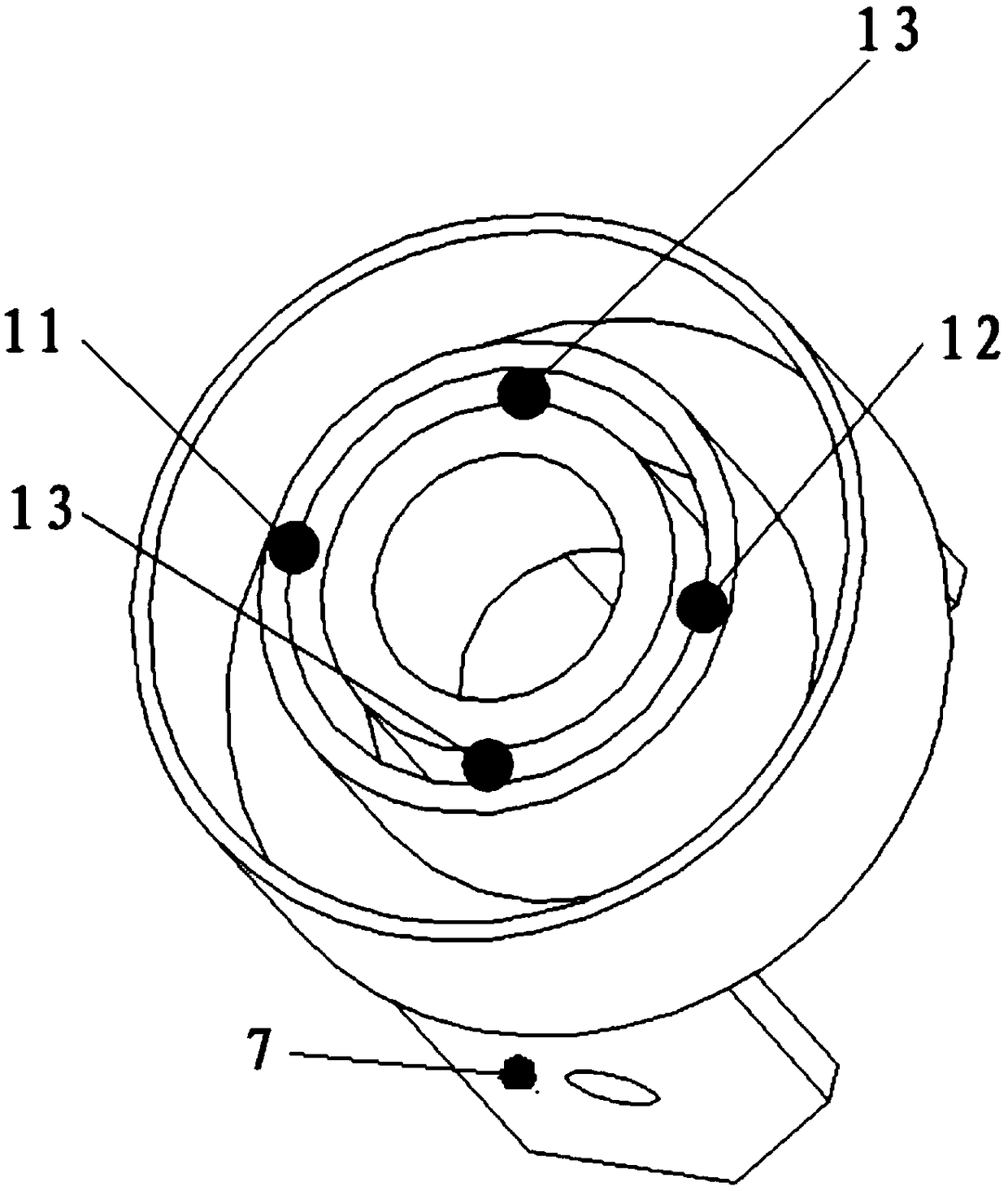

The invention discloses a near-remote distance comprehensive transfer placing system for a building. The near-remote distance comprehensive transfer placing system comprises a translation track mechanism, a positioning mechanism, a jacking mechanism, an underpinning beam, a monitoring mechanism as well as a rotating mechanism, wherein the rotating mechanism is arranged on the lower end surface of the underpinning beam; the rotating mechanism comprises an upper rotating base and a lower rotating base; the upper rotating base and the lower rotating base are rotationally connected; an annular bulge is formed in the lower end surface of the upper rotating base; an annular groove matched with the annular bulge is formed in the upper end surface of the lower rotating base. The annular bulge and the annular groove are matched with each other, so that mutual matching of the upper rotating base and the lower rotating base can be achieved, the whole building is on a stable platform and in a rotating environment in the rotating process, internal stress generated to the building in the rotating process is effectively reduced, the building can be prevented from structural damage, and the phenomenon of crack or collapse can be effectively avoided.

Owner:重庆博视知识产权服务有限公司

Vehicle cleaning shed with automatic vehicle cleaning function

InactiveCN108773352ASmooth and stable rotationIncrease the areaCleaning apparatus for vehicle exteriorsTime efficientAutomotive engineering

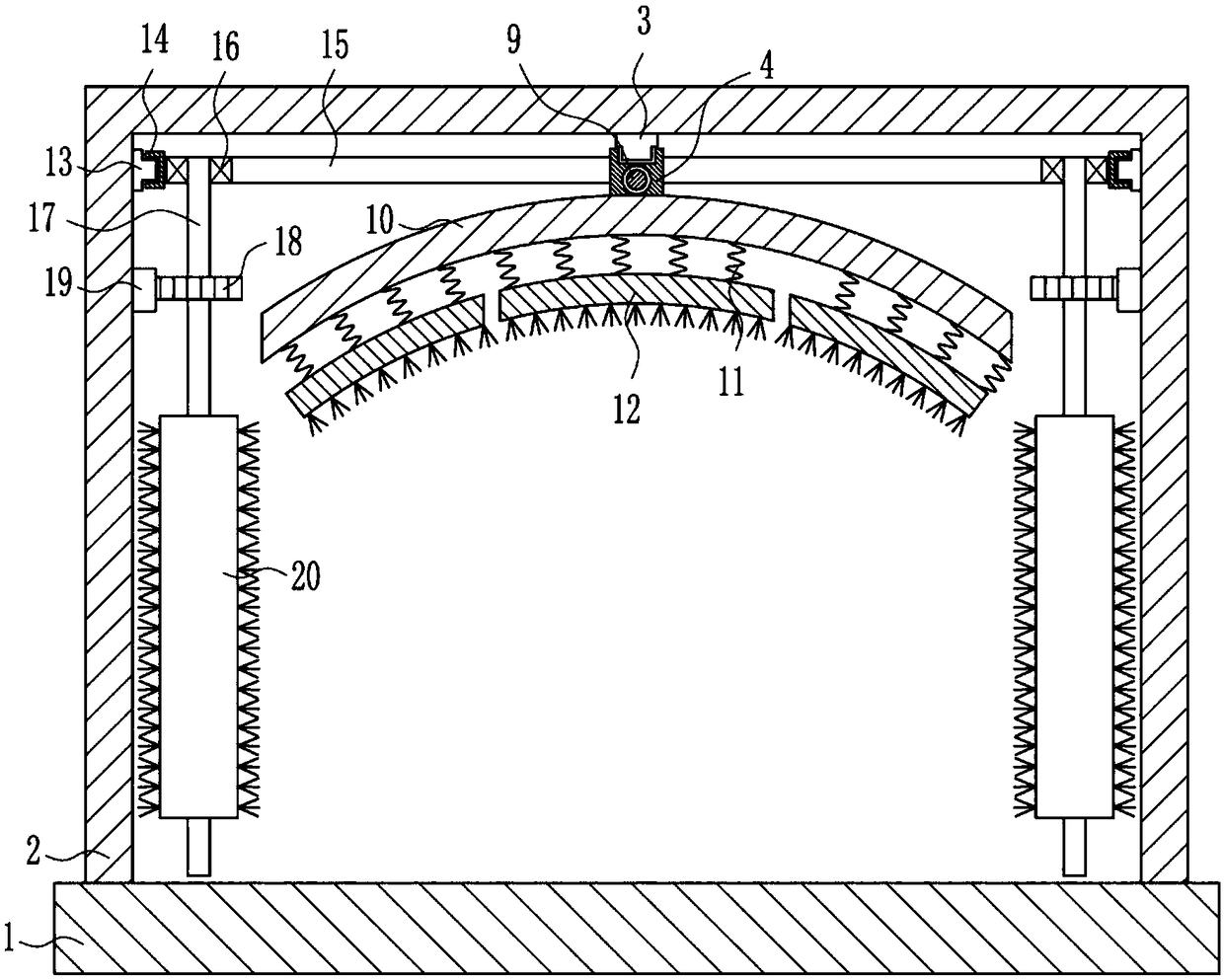

The invention relates to a vehicle cleaning shed, and especially relates to a vehicle cleaning shed with an automatic vehicle cleaning function. A technical problem is that the invention provides thevehicle cleaning shed with the automatic vehicle cleaning function, and the vehicle cleaning shed is time-saving and clean enough. The technical scheme is that the vehicle cleaning shed with the automatic vehicle cleaning function includes an n-shaped rack, a first sliding rail, a first sliding block, vertical rods, a first motor, a first bearing base, a screw rod, an arc-shaped plate, first springs, arc-shaped hairbrushes, a second sliding rail, and the like; and the n-shaped rack is installed on the ground, the first sliding rail is installed in the central section of the inner top of the n-shaped rack, the first sliding rail is slidingly provided with the first sliding block, the first sliding block is provided with a threaded hole, and the vertical rods are installed on the rear side of the central section of the inner top of the n-shaped rack. Through the first motor as a drive of the vehicle cleaning shed, so that the arc-shaped hairbrushes can be driven to clean a vehicle roof;and a brush roller is driven by gears and racks to move back and forth and to rotate, thereby cleaning both sides of an automobile, and the effects of time conservation and enough thorough cleaning are achieved.

Owner:钟世杰

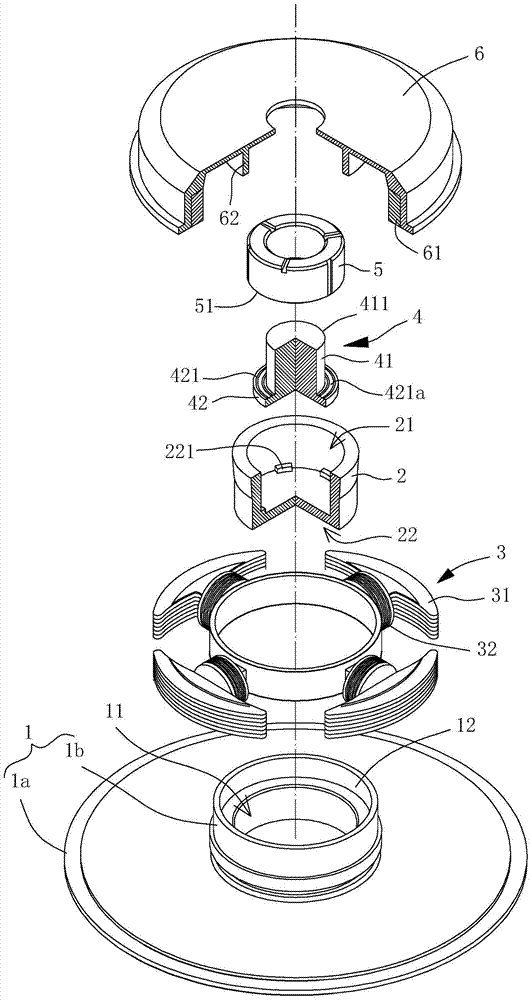

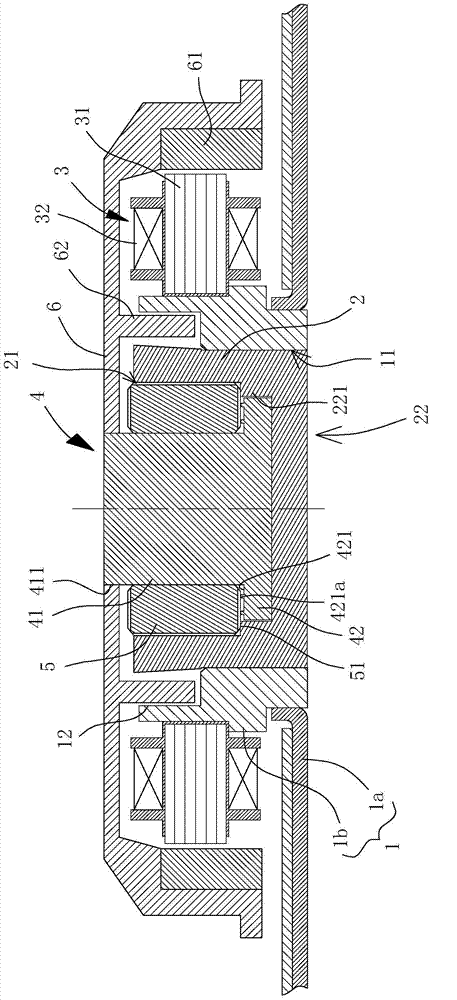

Motor with thrust bearing

ActiveCN104753235AImprove running qualitySmooth and stable rotationBearing assemblyShaftsCouplingThrust bearing

A motor includes: a bearing sleeve arranged with a base and having opposite opening and sealing ends; a stator coupled with the base or bearing sleeve; a rotating member disposed in the bearing sleeve and comprising a shaft and a limiting portion adjacent to the sealing end, wherein a first end of the shaft connects with the limiting portion, a second end of the shaft has a coupling portion, and the limiting portion has a first contact surface; a thrust bearing arranged between the shaft and the bearing sleeve and having a second contact surface facing the first contact surface, wherein at least one of the first and second contact surfaces is an uneven surface; a hub coupled with the coupling portion of the shaft and having a permanent magnet corresponding to the stator.

Owner:SUNONWEALTH ELECTRIC MACHINE IND

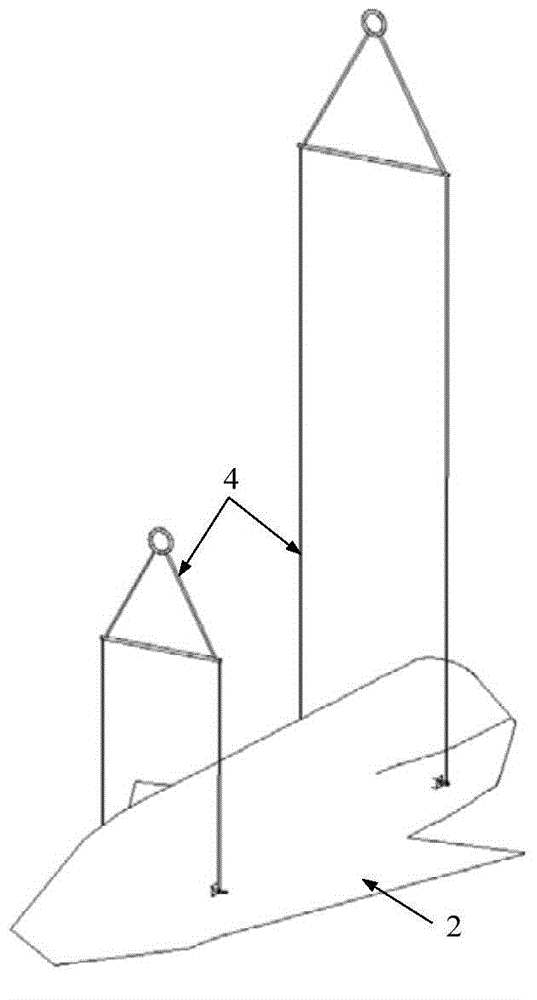

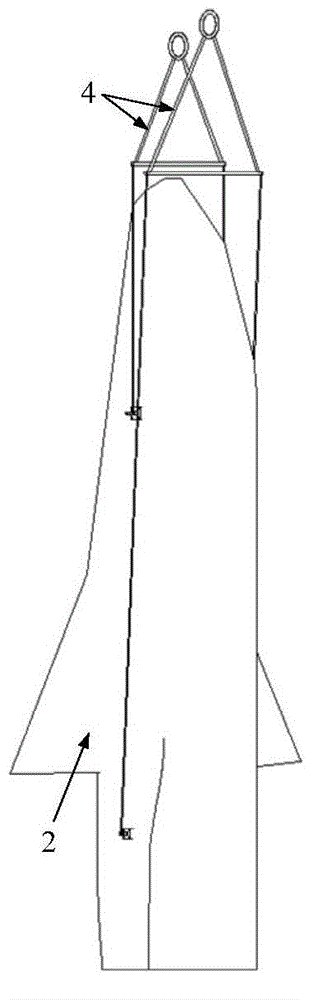

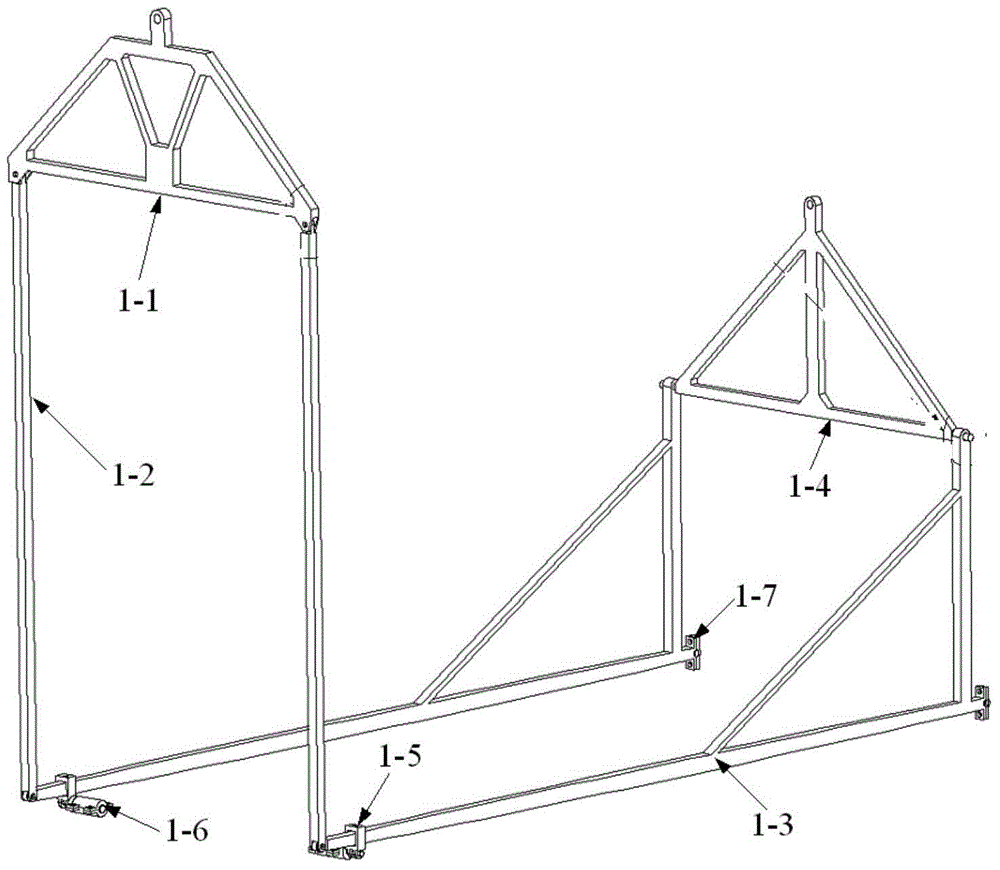

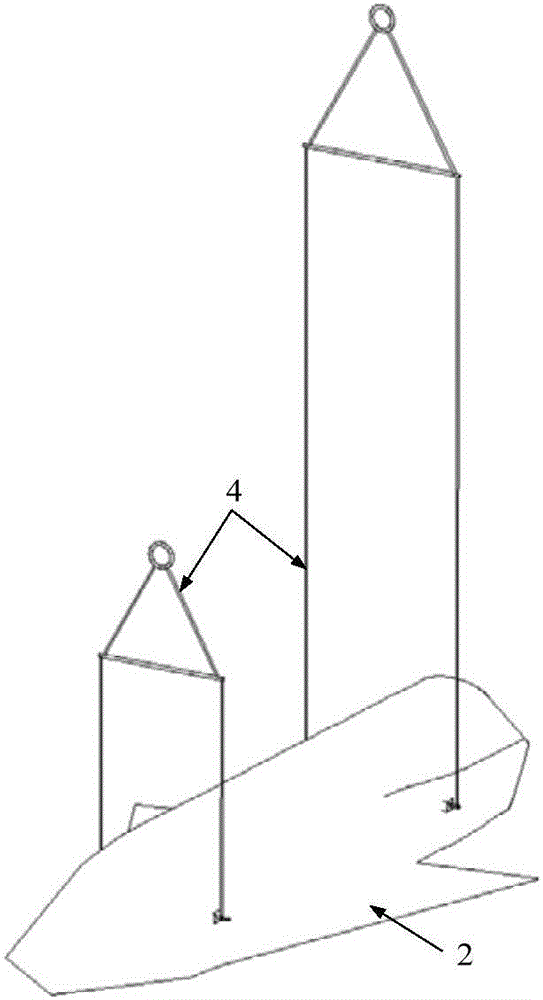

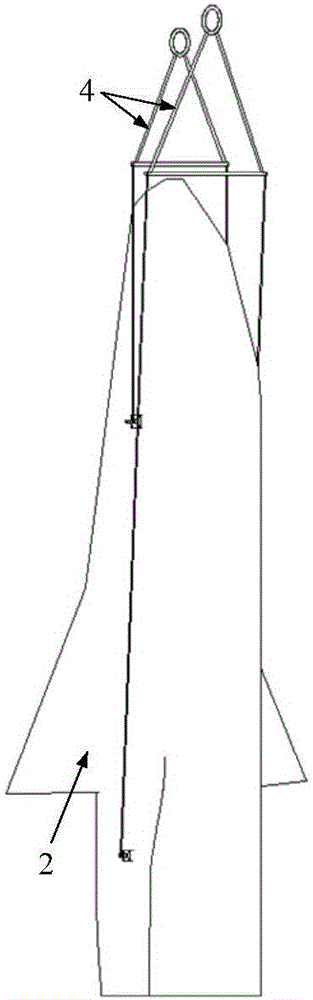

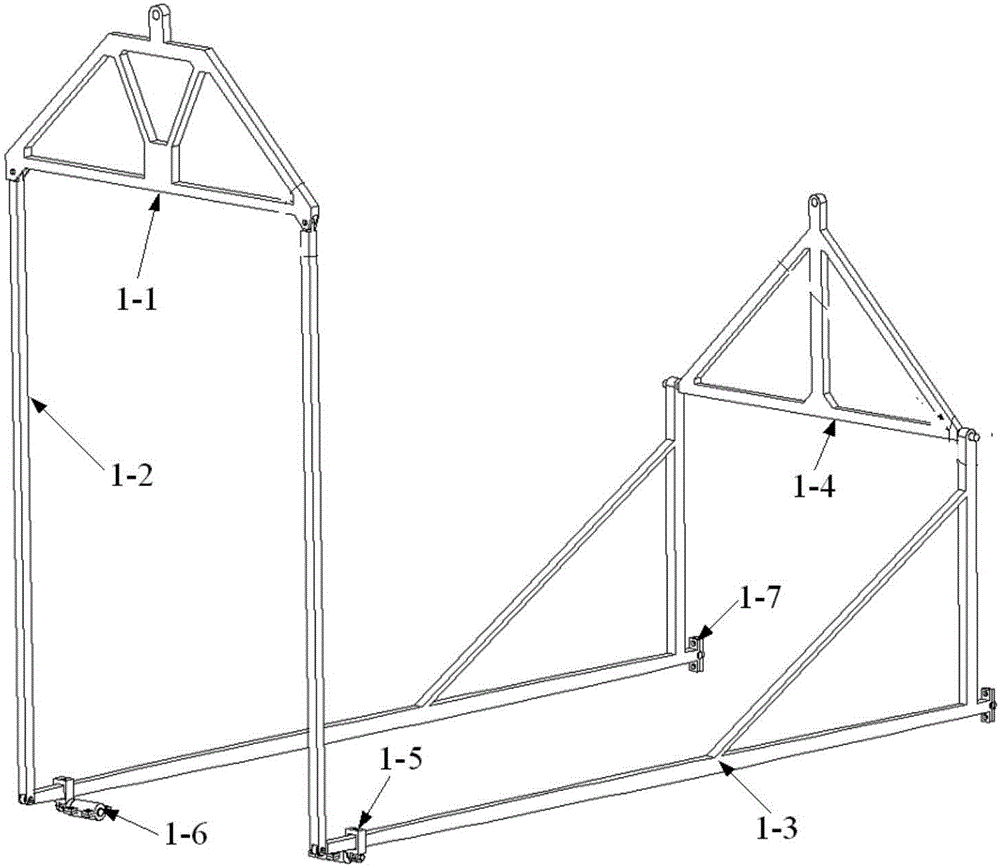

Lifting appliance structure used for lifting and overturning aircraft

A lifting appliance structure used for lifting and overturning an aircraft comprises a front lifting fame, a front lifting arm, an L-shaped lifting beam, a rear lifting frame, a locking sliding block, a front lifting clasp and a rear lifting clasp. The front lifting frame is connected with the front lifting arm through a hinge. The vertical rod end of the L-shaped lifting beam is connected with the rear lifting frame through a hinge, and the transverse rod end of the L-shaped lifting beam is connected with the front lifting arm. The locking sliding block is located on the transverse rod of the L-shaped lifting beam, and a double-lifting lug is arranged at the bottom of the locking sliding block and connected with the front lifting clasp. The front lifting clasp and the rear lifting clasp are each divided into two parts, and through holes are formed between the two parts of the front lifting clasp and the two parts of the rear lifting clasp respectively, after assembly with a front end journal and a rear end journal of the aircraft is finished, the two parts of the front lifting clasp and the two parts of the rear lifting clasp are buckled and connected through bolts. According to the scheme of the lifting appliance, the overall truss-type structure with the hinged front part and the fixedly connected rear part is adopted, and the lifting appliance structure used for lifting and overturning the aircraft is convenient to operate, simple, reliable, high in universality and suitable for rapid lifting and overturning of various wing-fuselage combination aircrafts, launch vehicles and the like, and has broad application prospects in the field of aerospace.

Owner:CHINA ACAD OF LAUNCH VEHICLE TECH

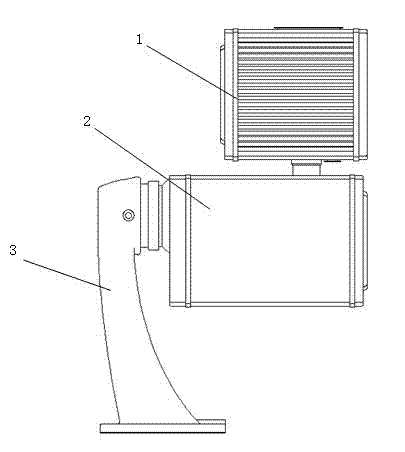

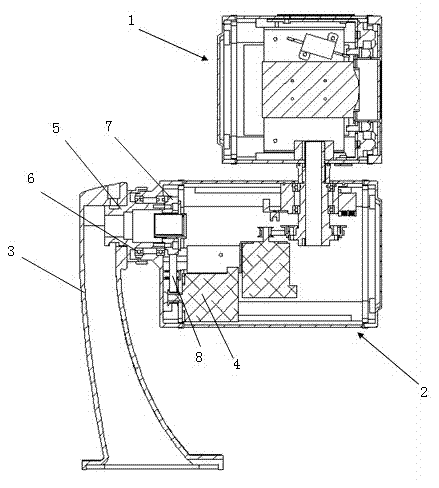

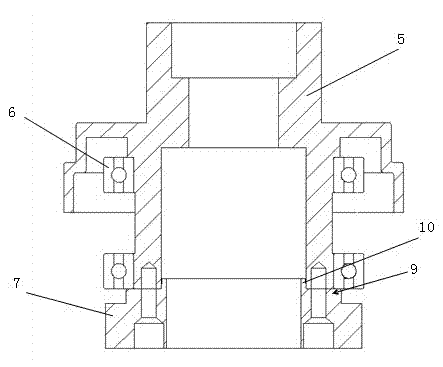

Transmission structure of PTZ (Pan/Tilt/Zoom) camera

InactiveCN102359703ASmooth and stable rotationTurn easilyTelevision system detailsColor television detailsPosition effectEngineering

The invention relates to a transmission structure of a PTZ (Pan / Tilt / Zoom) camera, wherein the PTZ camera comprises a camera, a cloud platform and a supporting base; a motor and a rotating shaft are arranged in the cloud platform; a synchronous belt pulley is fixedly arranged at one end of the rotating shaft, which is positioned inside the cloud platform; the motor is in drive connection with the synchronous belt pulley through a belt; when the motor operates, the rotating shaft is driven to rotate in a bearing by the synchronous belt pulley; the synchronous belt pulley and the rotating shaft are coaxial mutually; one side of the synchronous belt pulley, which corresponds to the rotating shaft, is provided with a boss structure; a frustum is arranged on the plane of the boss; and when the synchronous belt pulley is matched with the rotating shaft, the frustum is totally inserted into a hollow structure of the rotating shaft and the plane of the boss is tightly attached to the rotating shaft. The frustum takes an assembly positioning effect in the assembling process, so that the rotating shaft and the synchronous belt pulley can be in close fit more accurately, the problem that the rotating shaft and the synchronous belt pulley are eccentrical mutually in the operating process is avoided and the rotating process of the PTZ camera in use is more smooth and stable.

Owner:TIANJIN TIANDY DIGITAL TECH

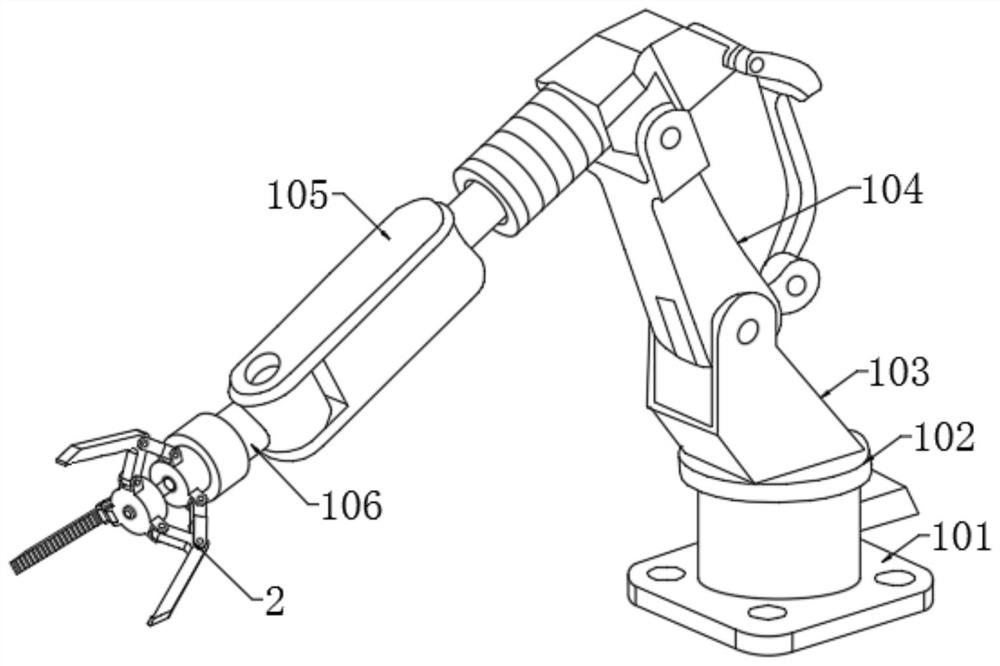

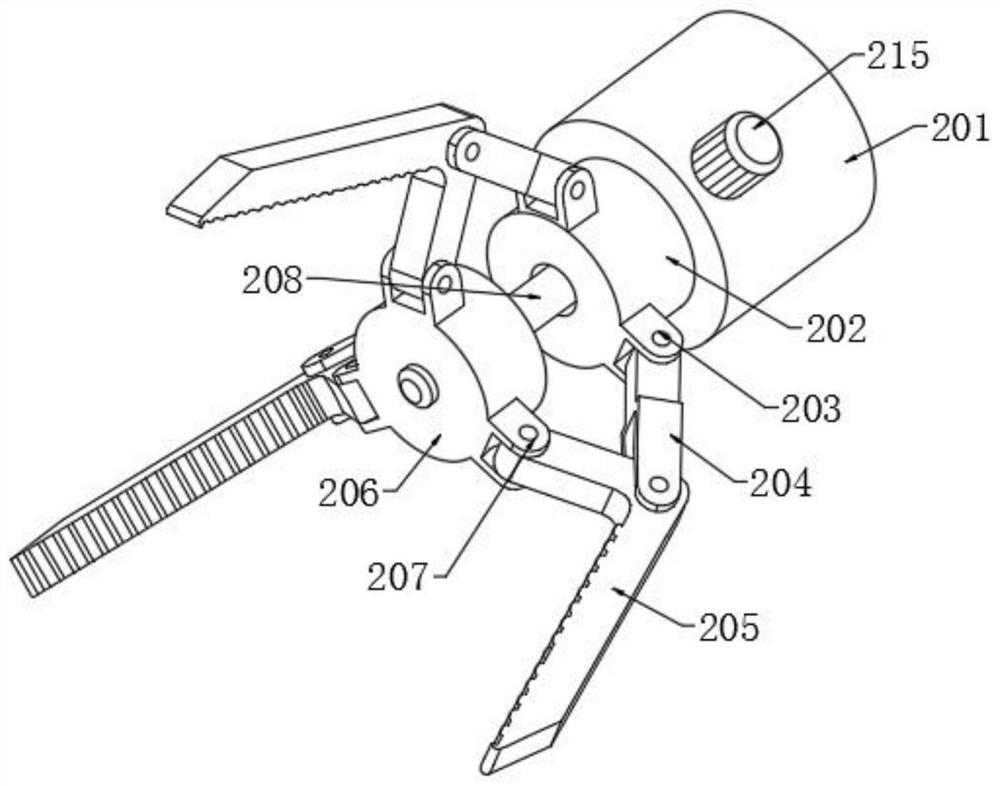

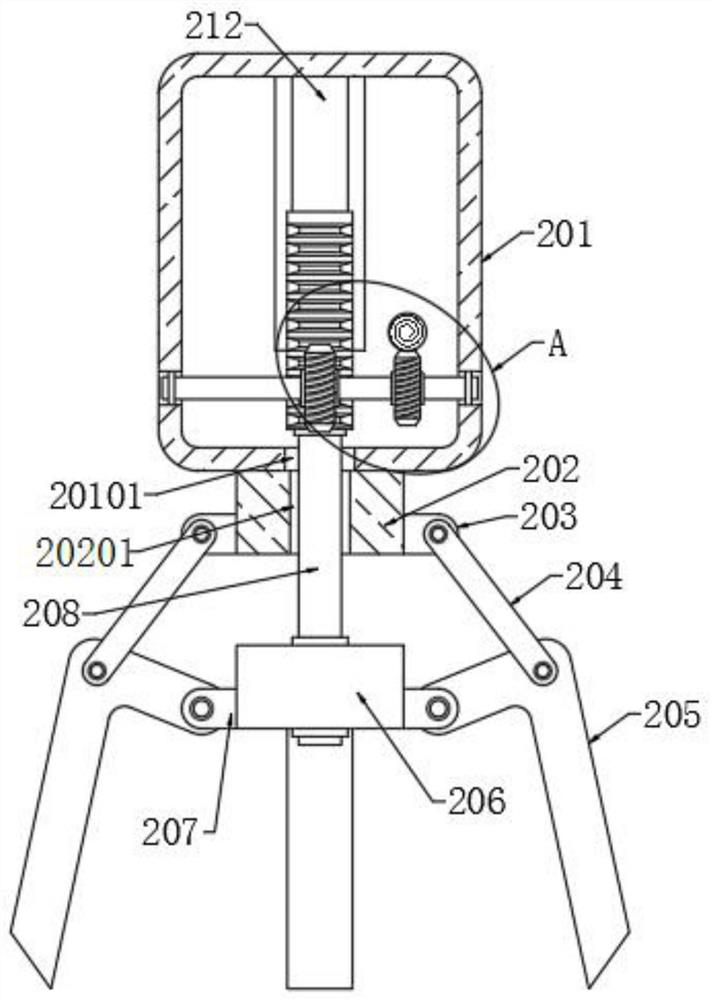

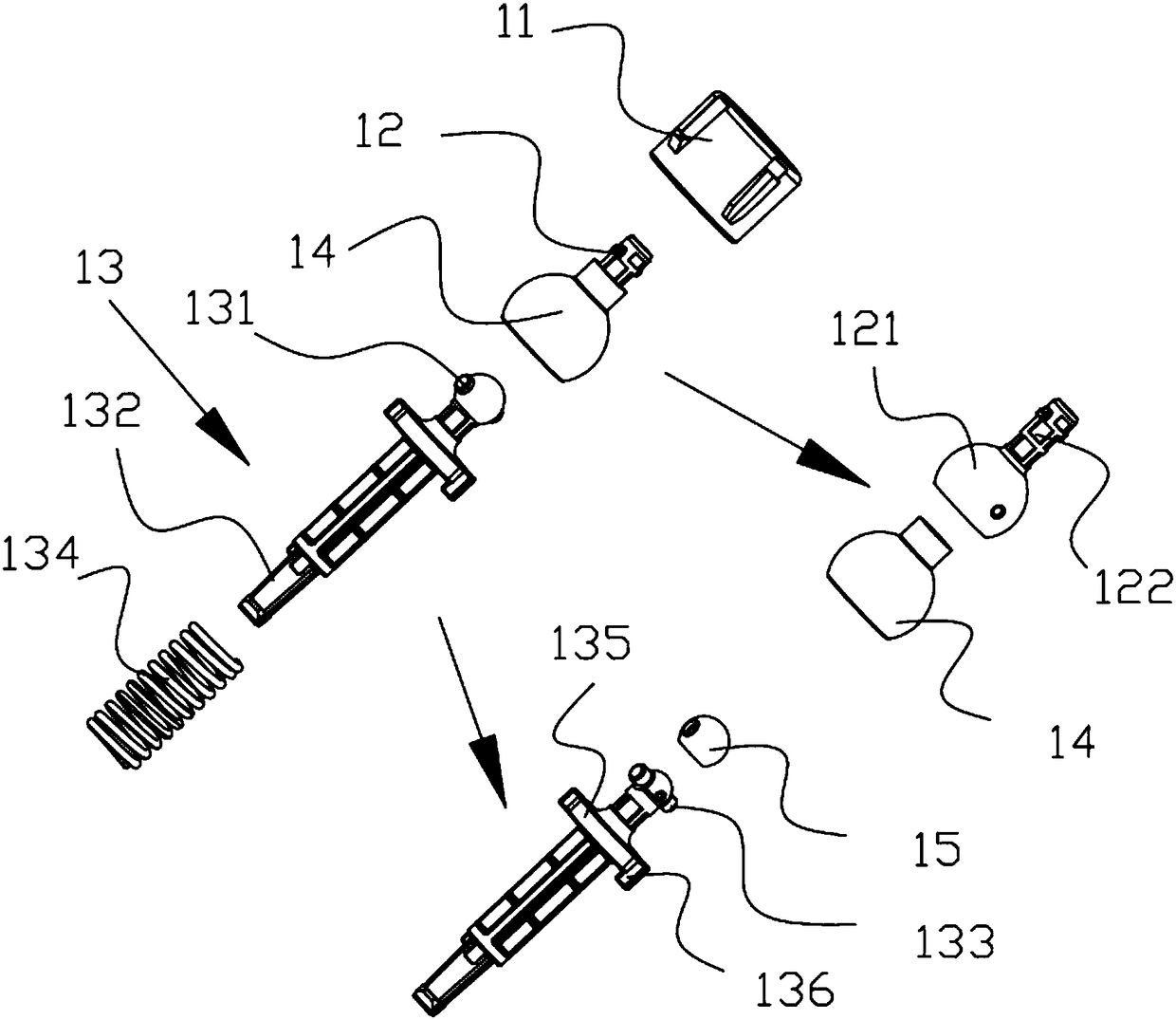

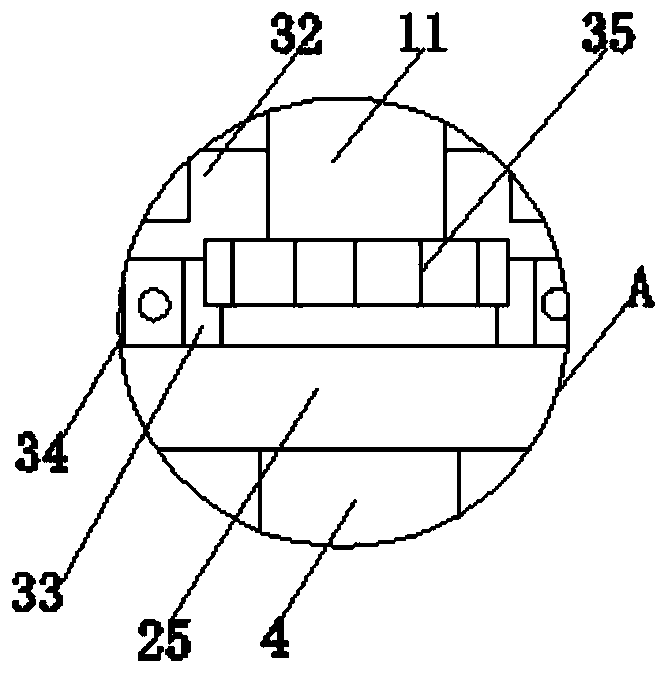

Automatic multi-finger linkage type manipulator

PendingCN113211490AImprove securityPrevent slippingProgramme-controlled manipulatorGripping headsControl engineeringLinkage (mechanical)

The invention belongs to the technical field of manipulators, and particularly relates to an automatic multi-finger linkage type manipulator. The automatic multi-finger linkage type manipulator comprises a mechanical arm and a mechanical claw, wherein the mechanical arm comprises a base, a rotating seat is fixedly installed on the base, a fixed seat is fixedly installed on the top of the rotating seat, a driving arm is rotatably installed on the fixed seat, a driven arm is rotationally mounted on the driving arm, a rotary fixing piece is rotationally mounted on the driven arm, the rotary fixing piece and the mechanical claw are fixedly connected together, the mechanical claw comprises a round box, the top end of the round box and the rotary fixing piece are fixedly connected together, a fixing block is fixedly mounted at the bottom of the round box, three first fixing frames arranged in a circular shape are fixedly mounted on the outer wall of the fixing block, and connecting frames are rotationally mounted on the three first fixing frames. The automatic multi-finger linkage type manipulator is high in practicability, clamped articles can be tightly clamped, meanwhile, the clamped articles cannot be loosened when the mechanical claw loses power, and thus the safety is high.

Owner:赵丽丽

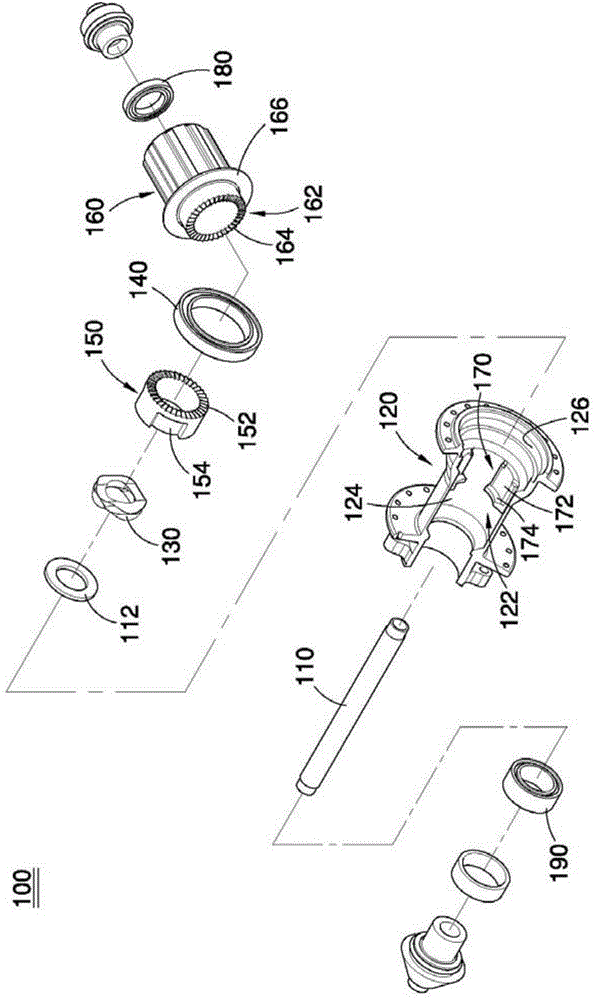

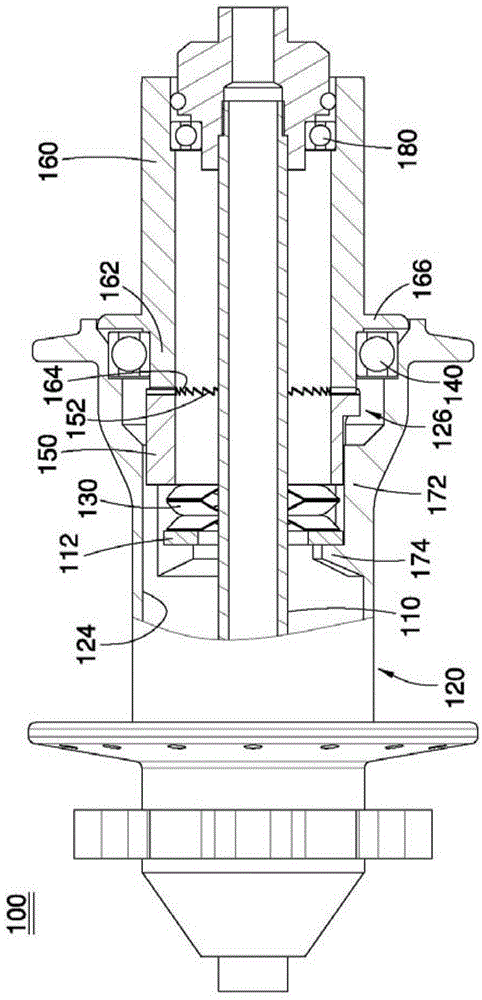

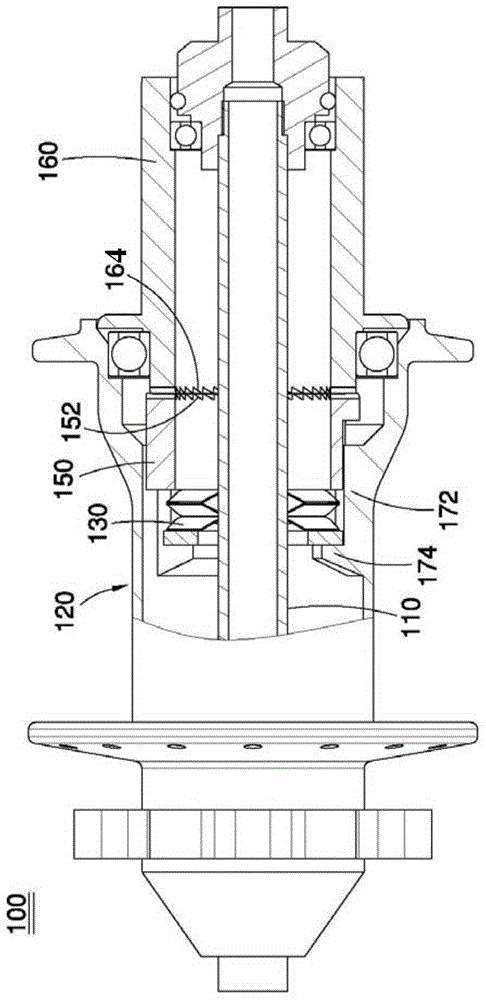

Hub structure

The invention provides a hub structure. The hub structure is mainly characterized in that a shell is connected with a transmission device, and the transmission devices drives the shell to rotate; the transmission device is composed of a driving ratchet wheel and a driven ratchet wheel; one end face of the driving ratchet wheel is provided with a first ratchet ring, and on end face of the driven ratchet wheel is provided with a second ratchet ring; the first ratchet ring of the driving ratchet wheel is meshed with the second ratchet ring of the driven ratchet wheel; and the driven ratchet wheel is fixed to the shell in a radial manner and can axially displace in the shell.

Owner:VOG IMAGE POLICE

Armrest horizontal limiting device, seat and automobile

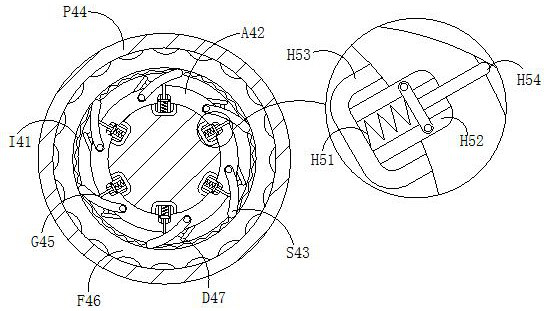

ActiveCN113352972AImplement the rotation functionRealize the locking functionArm restsPhysicsRatchet

The invention relates to an armrest horizontal limiting device, a seat and an automobile. The limiting device comprises a gravity assembly and a ratchet wheel assembly, the gravity assembly is used for controlling unlocking and locking of the ratchet wheel assembly, and the ratchet wheel assembly comprises a ratchet wheel lock disc, ratchet wheel swing teeth, a ratchet wheel swing tooth unlocking rotating shaft and a main shaft; the ratchet wheel assembly comprises ratchet wheel swing teeth and a ratchet wheel lock disc, the ratchet wheel swing teeth are meshed with the ratchet wheel lock disc, the ratchet wheel lock disc is used for controlling a handrail to rotate, the ratchet wheel swing teeth are rotationally connected with the main shaft, the gravity assembly comprises a gravity lock and a gravity lock disc, the gravity lock is fixedly installed on the ratchet wheel lock disc, and the gravity lock is meshed with the gravity lock disc when located at the first position; the gravity lock disc is fixedly connected with the main shaft, and the ratchet swing teeth are rotationally connected around the ratchet swing tooth unlocking rotating shaft. Through cooperation of the gravity assembly and the ratchet wheel assembly, the one-way locking function of the handrail is achieved; and the problem that in the prior art, after a seat backrest rotates, armrests cannot be kept horizontal, and the comfort of passengers is affected is solved.

Owner:SCI SEATING (NINGBO) CO LTD

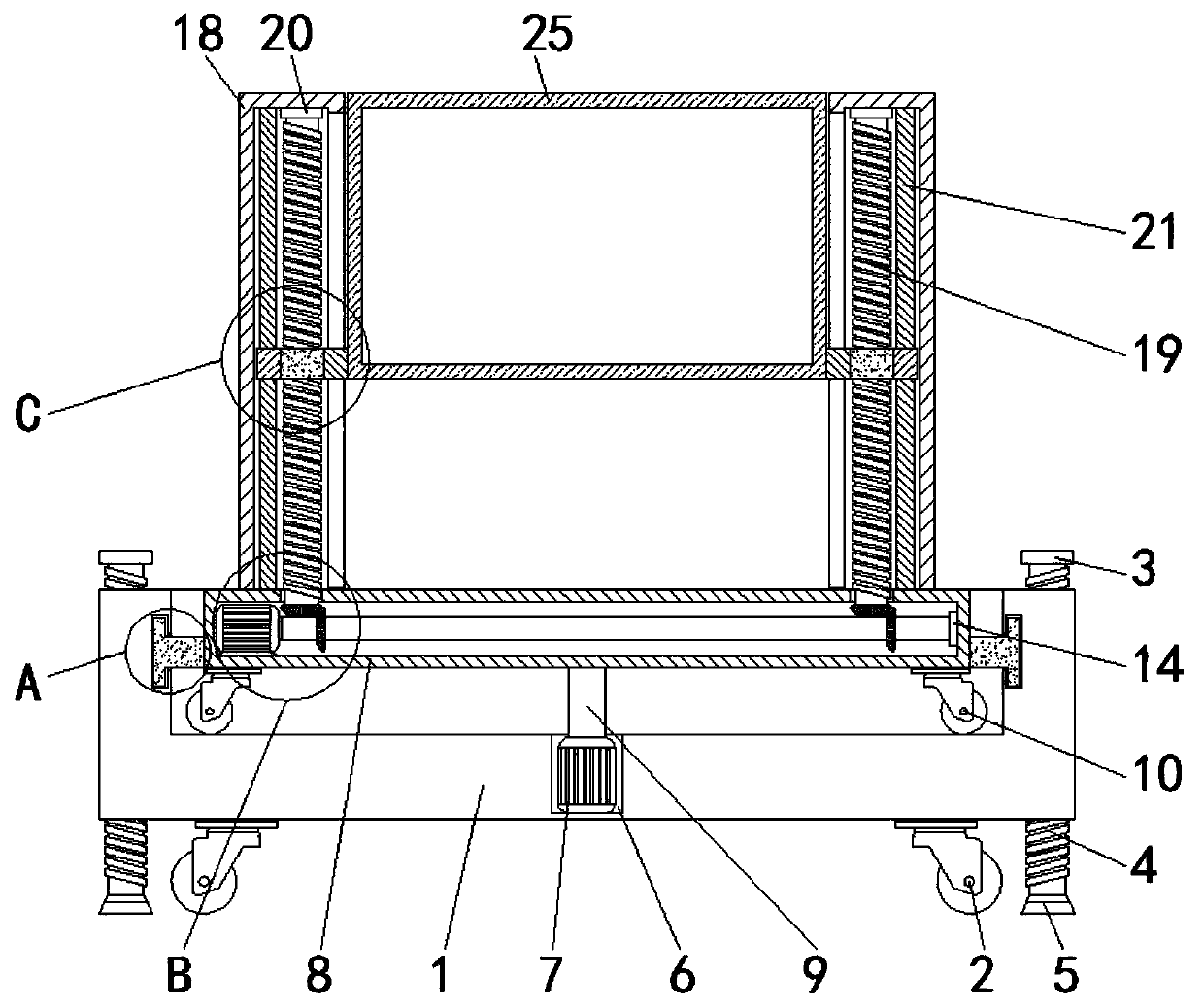

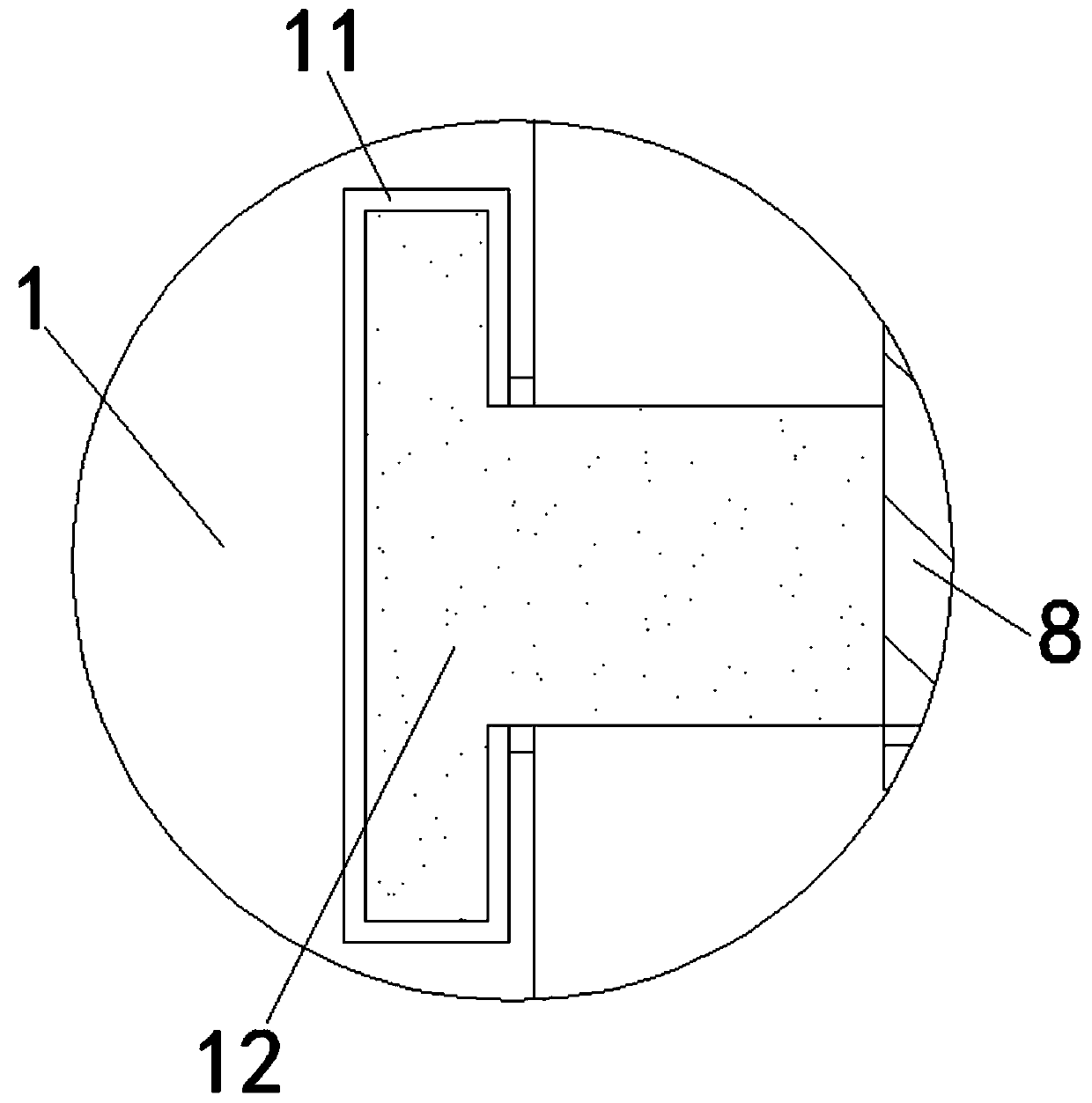

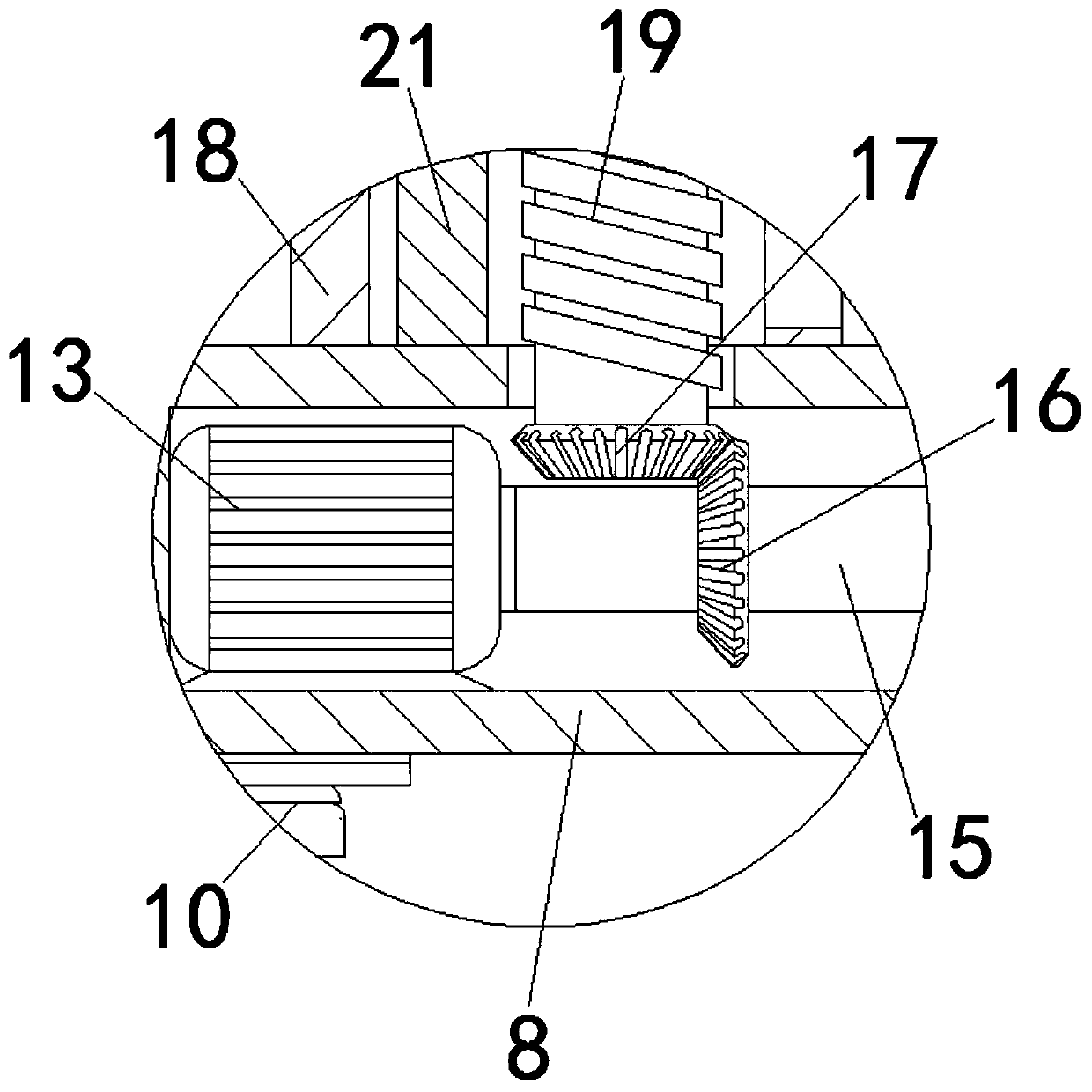

Demonstration device for informatization teaching of building construction process

ActiveCN112242089ARealize storageEasy transferEducational modelsPhotovoltaic energy generationAutomatic controlConstruction engineering

The invention discloses a demonstration device for informatization teaching of building construction technology, which belongs to the technical field of building teaching, and comprises a placement box, two driving assemblies are arranged on the lower surface of the inner wall of the placement box, the same transverse plate is arranged on the outer surfaces of the two driving assemblies, and a rotating assembly plate is clamped on the upper surface of the transverse plate. According to the demonstration device for informatization teaching of the building construction technology, through arrangement of the driving assembly, the rotating box, the piston frame, the suction cups, the supporting wheels, the sliding rails, the display assembly, the pressing plate and the contact switch, after the rotating box moves to a proper position, the transverse plate extrudes the contact switch to control the driving assembly to stop working, and the device can store a model; meanwhile, the model canbe automatically controlled to stably rotate in the demonstration process, the situations of uneven rotating speed and deformation possibly caused by manually controlling the model to rotate are avoided, the storage and transfer process of the model is more convenient and labor-saving, and it is guaranteed that the demonstration effect of the device is more ideal to a certain extent.

Owner:长春建工集团有限公司

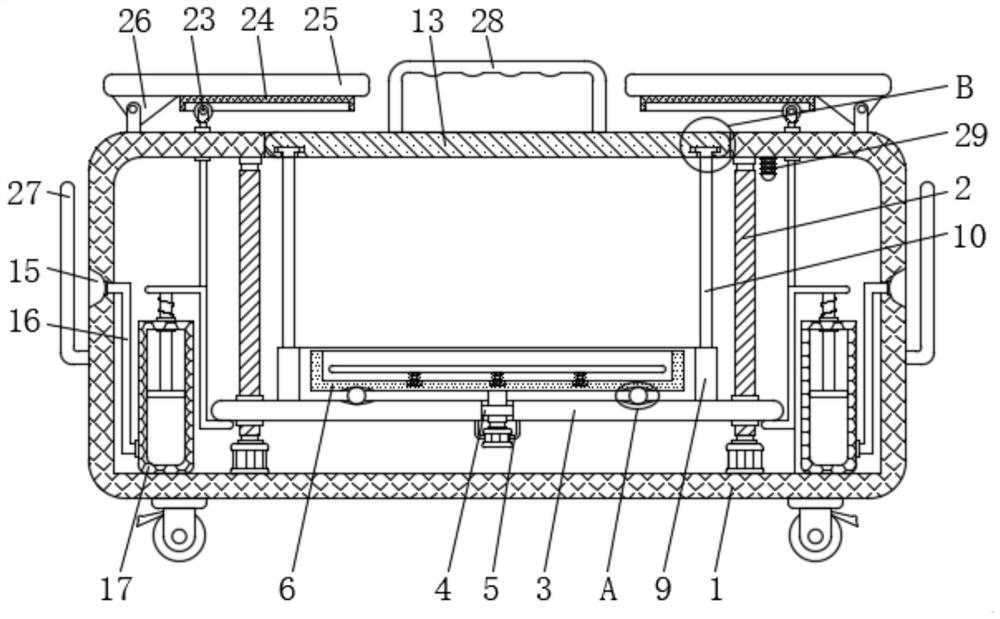

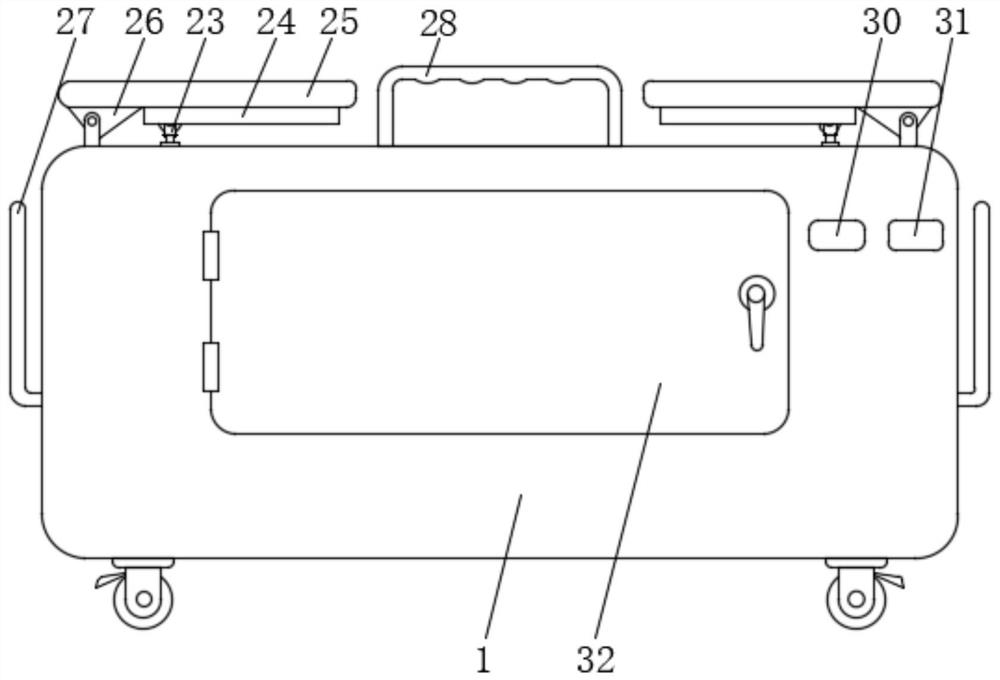

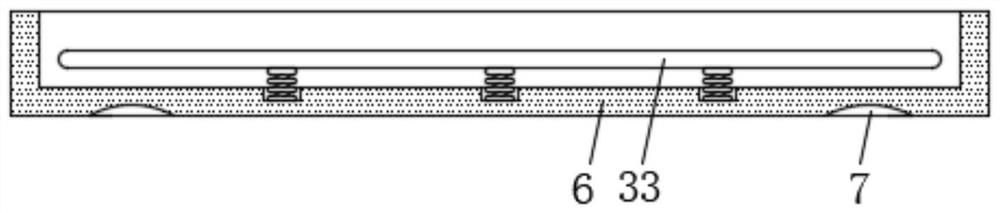

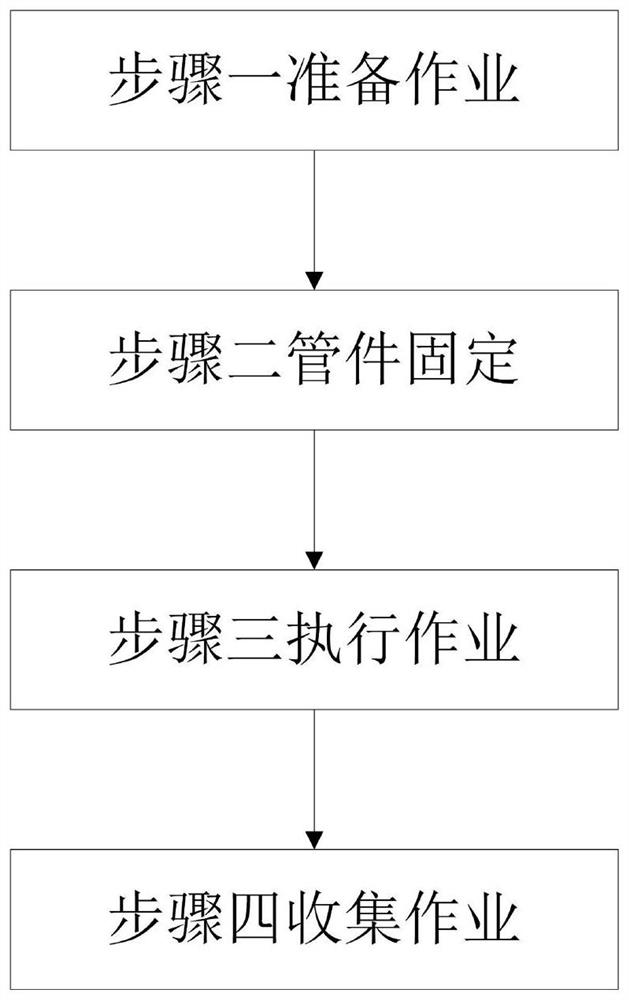

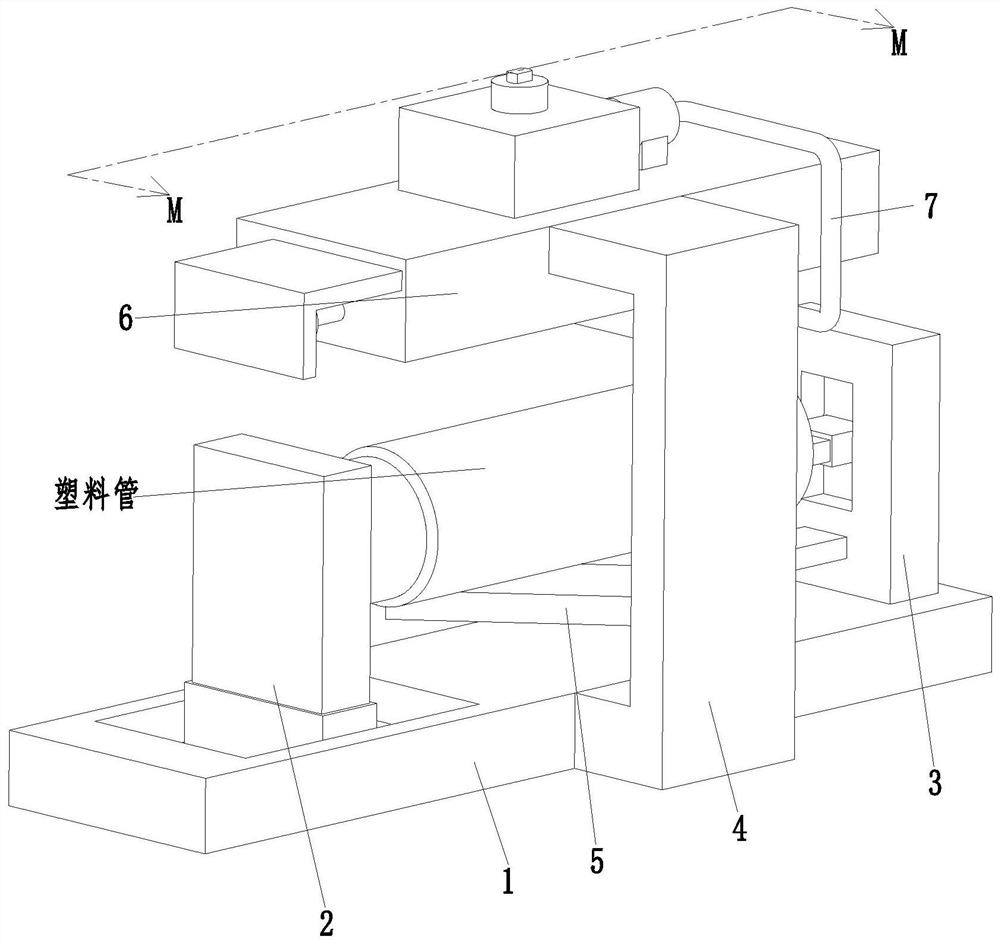

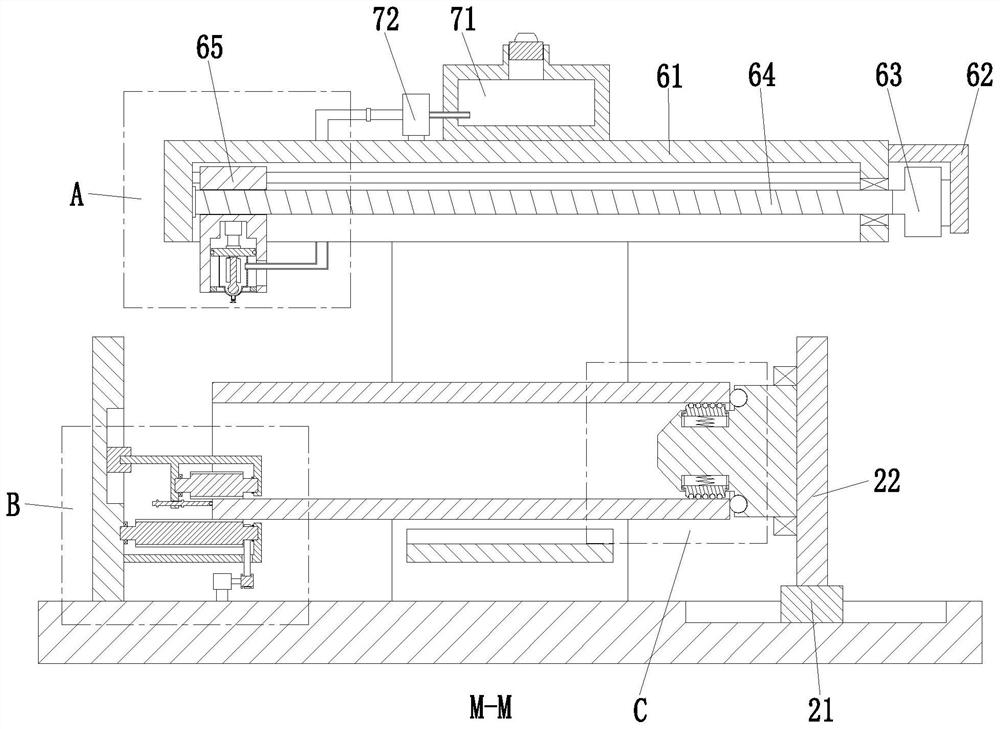

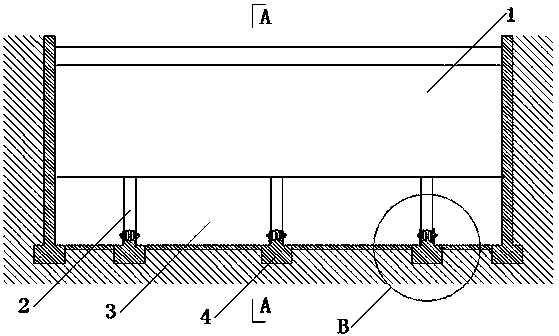

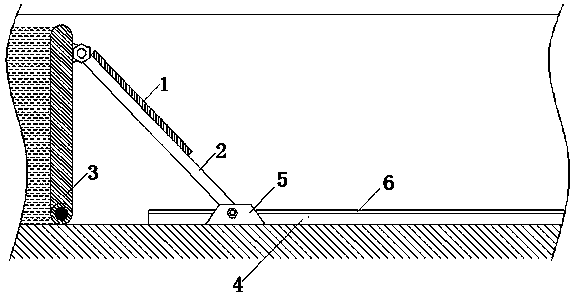

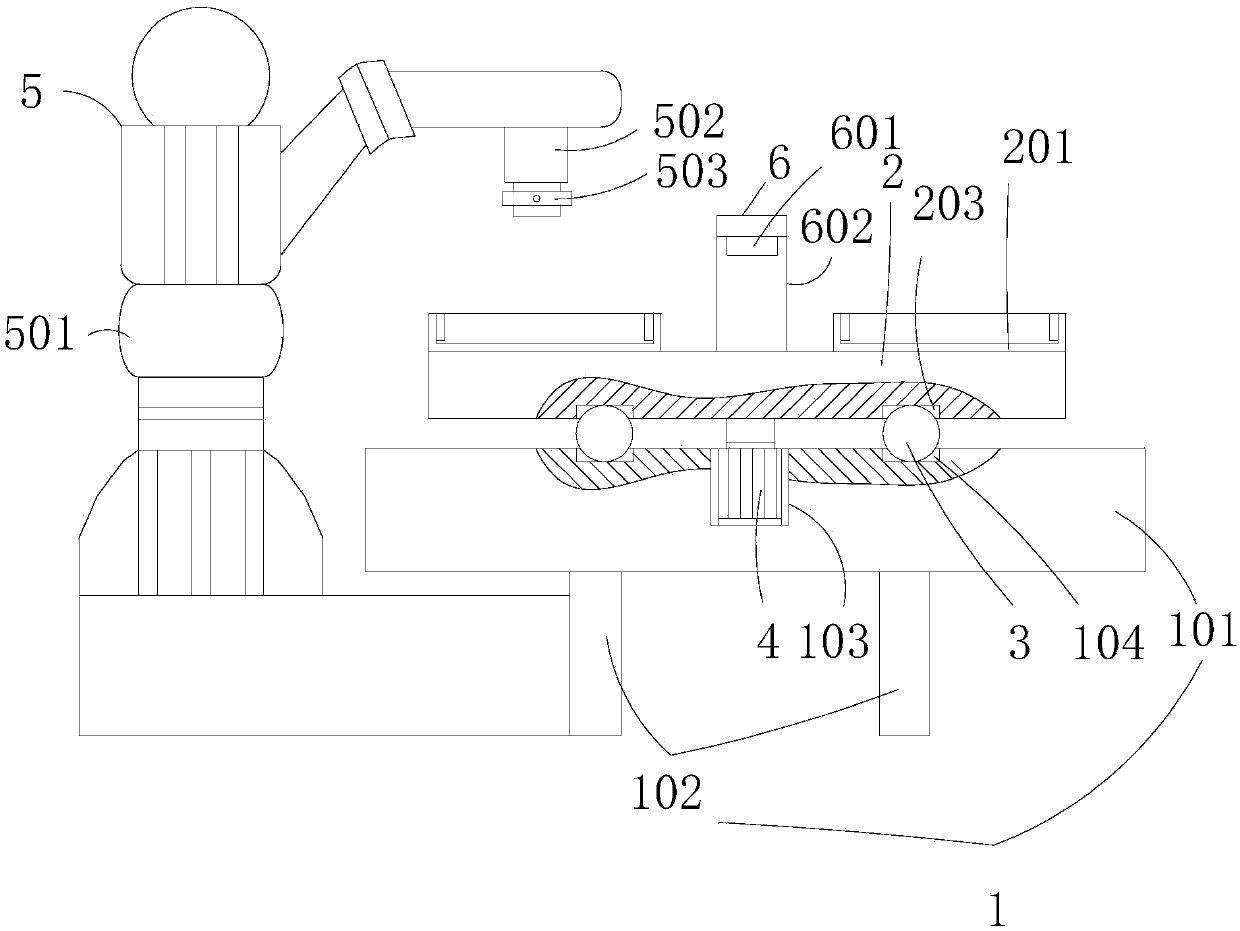

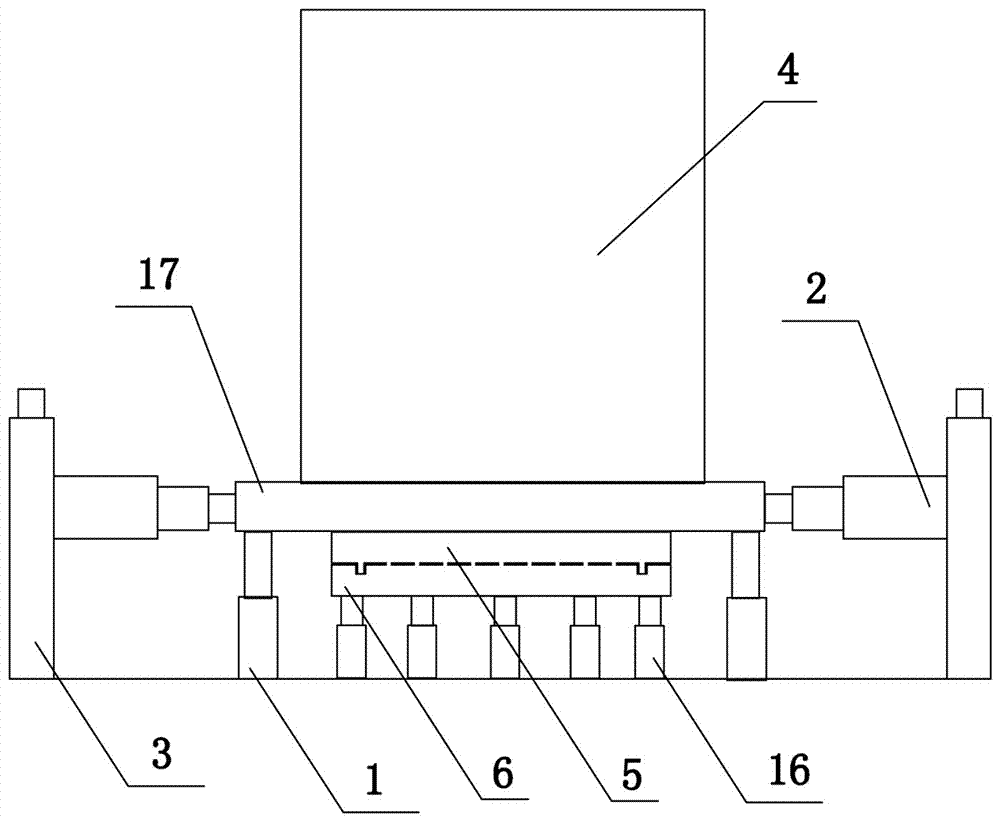

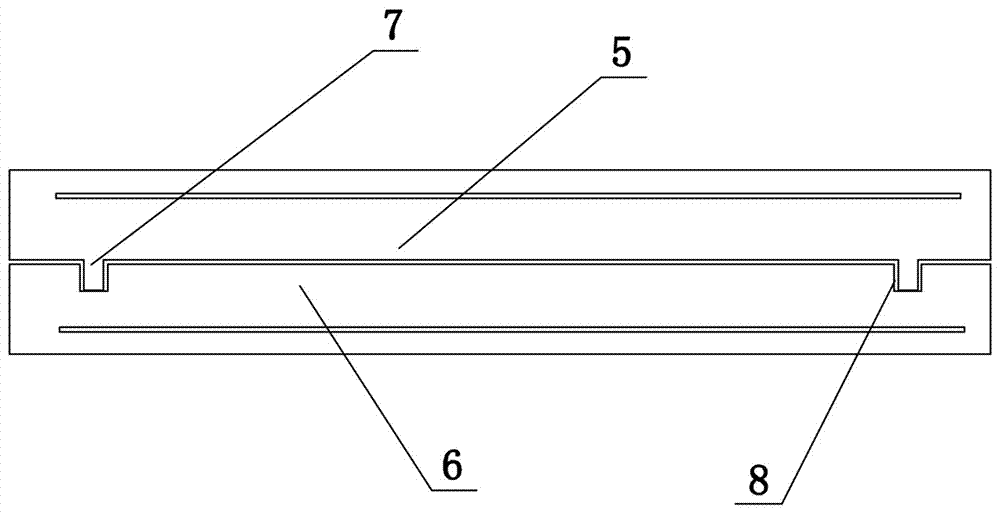

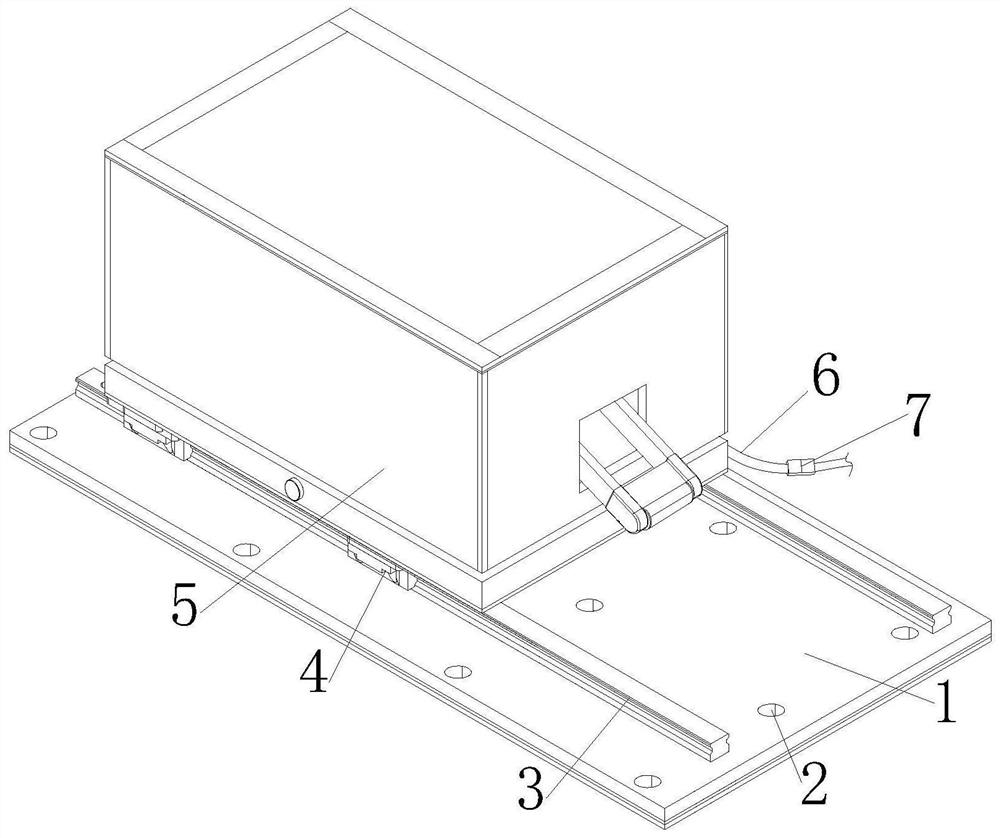

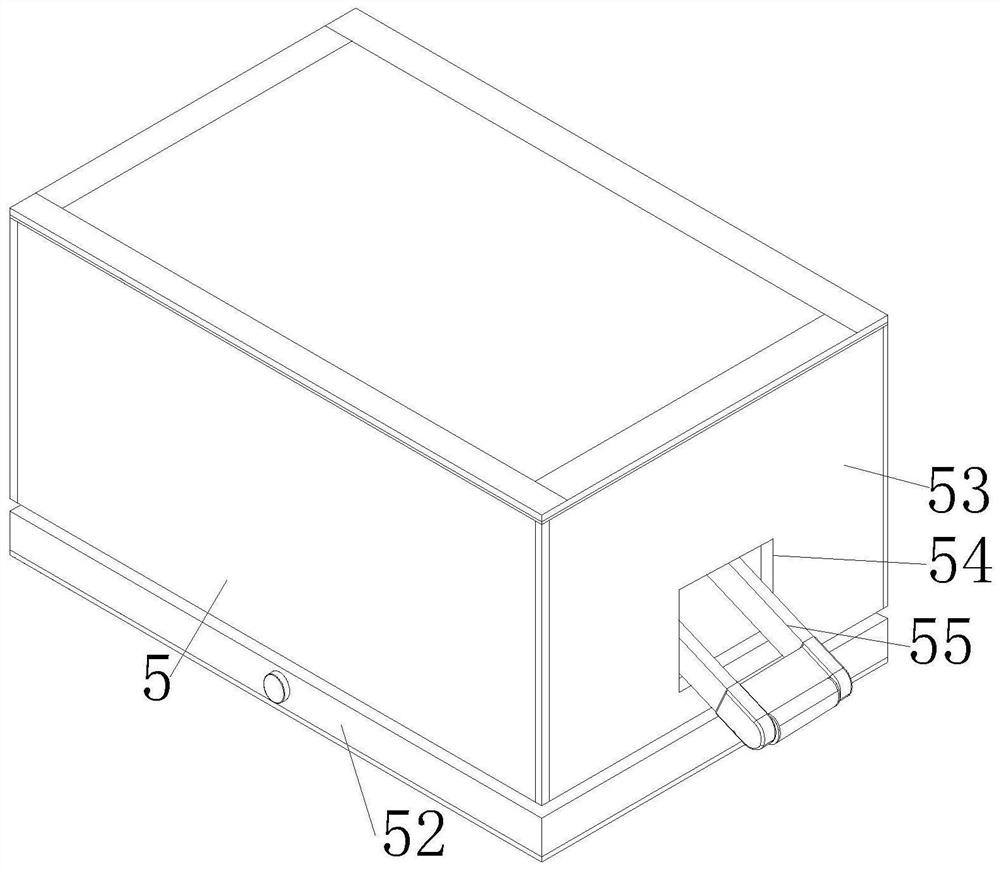

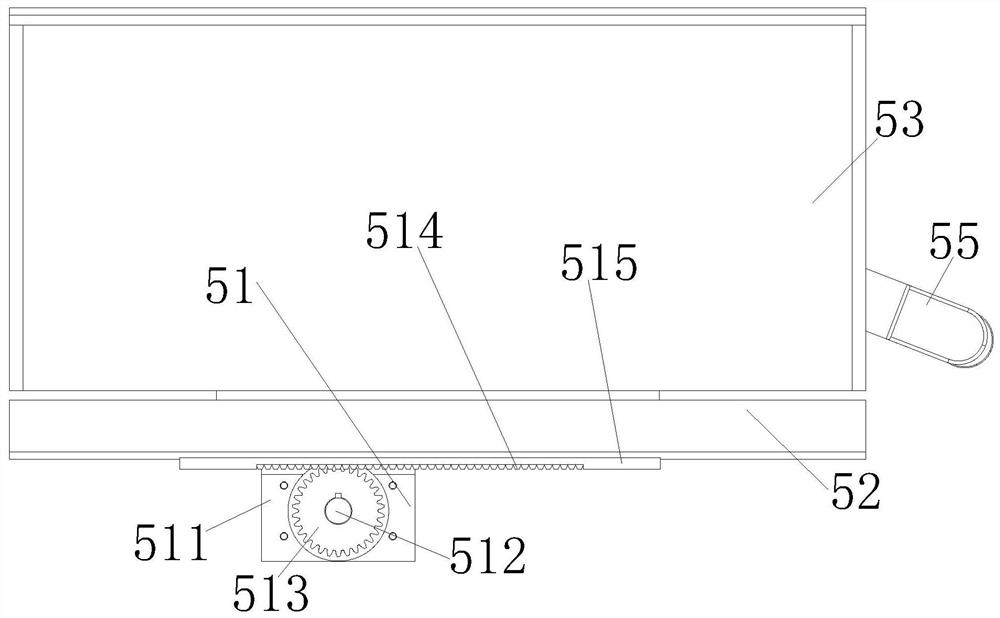

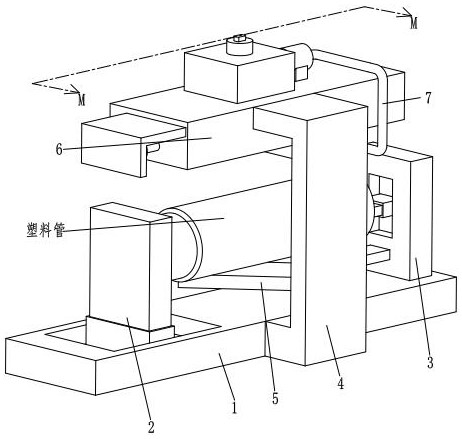

Surface processing process for plastic tube

ActiveCN112337670AGuaranteed spraying effectUniform thicknessLiquid surface applicatorsLiquid spraying apparatusSurface processingCeramic materials

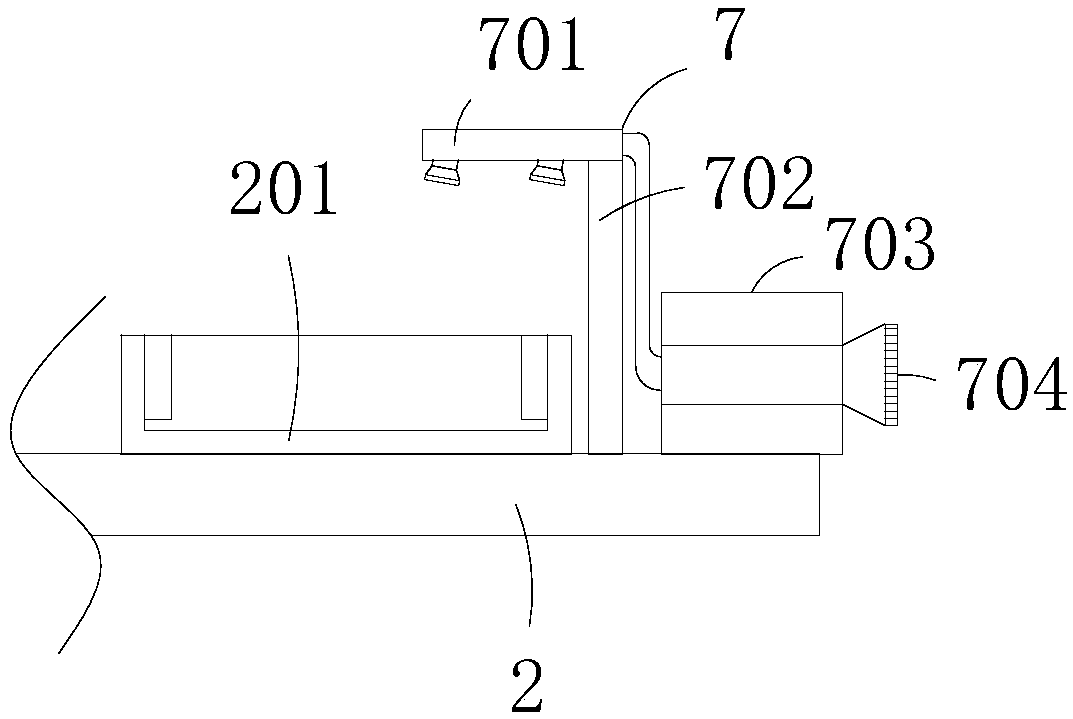

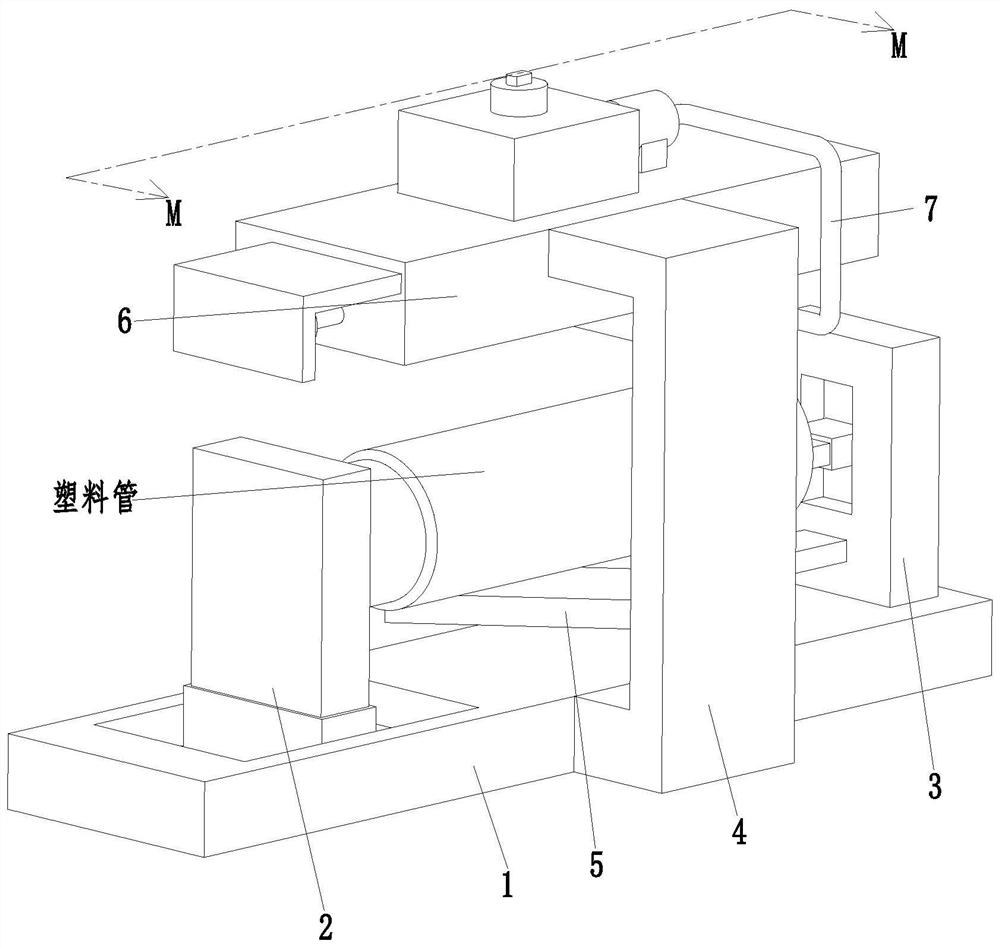

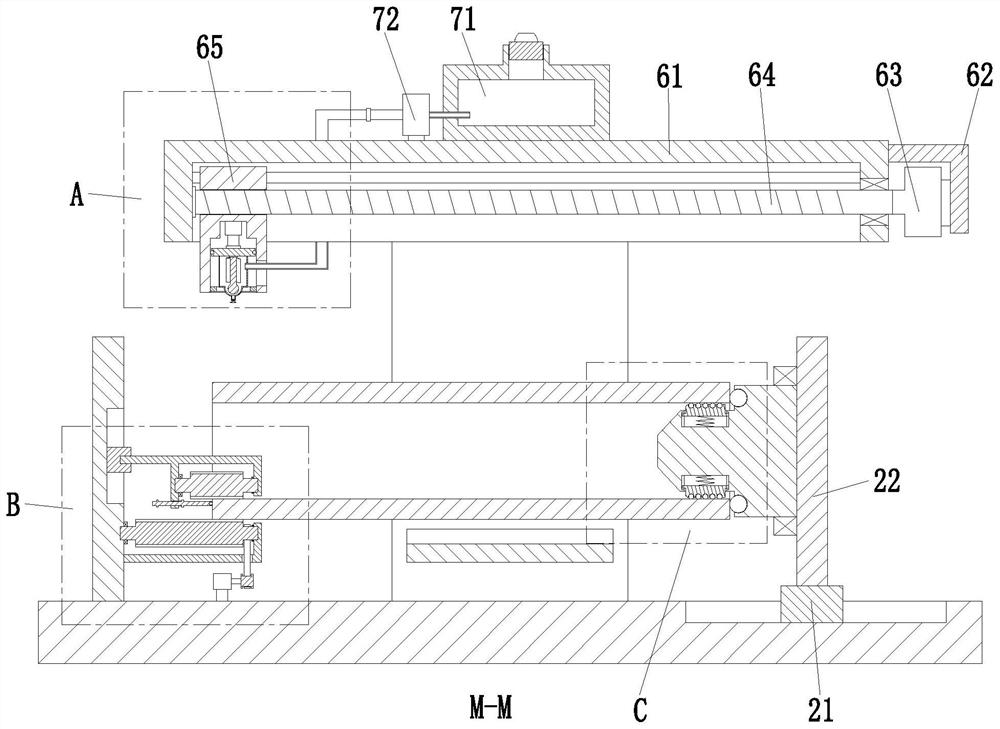

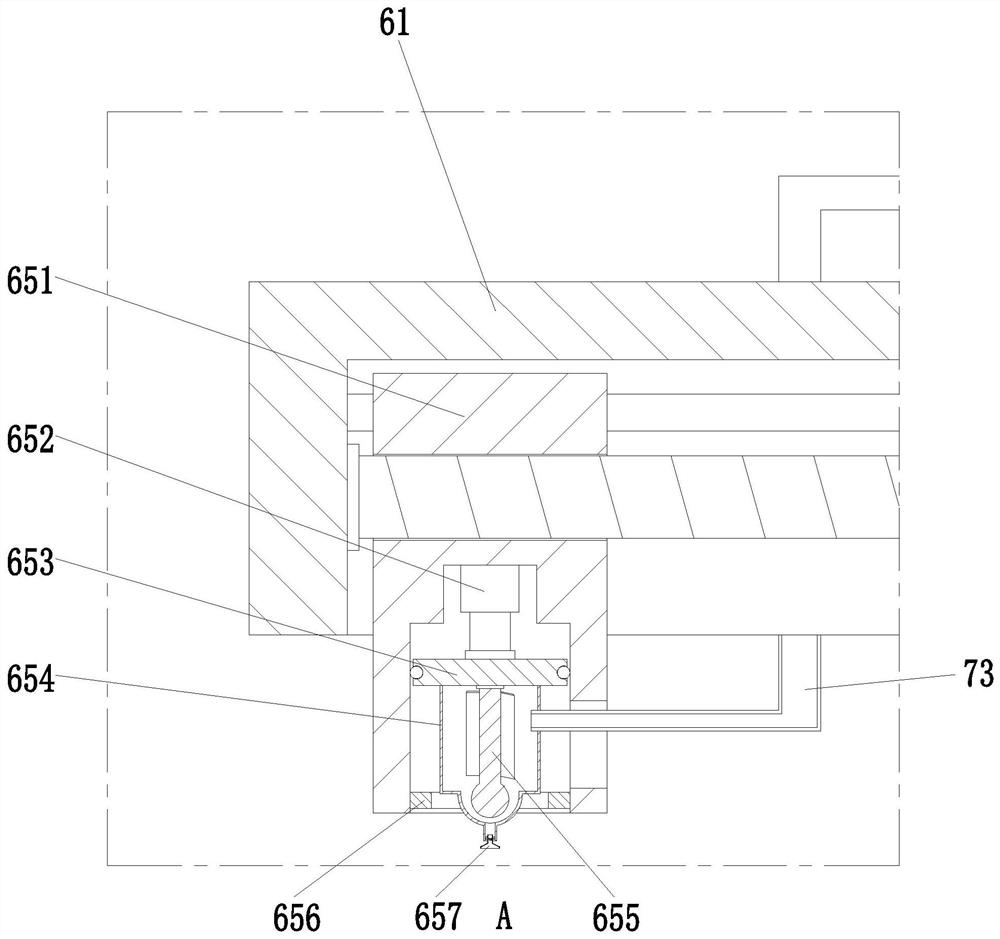

The invention provides a surface processing process for a plastic tube. The surface processing process uses surface processing equipment which comprises a bottom plate, a fixed device I, a fixed device II, a U-shaped frame, an auxiliary slide plate, a spraying regulating device and a material collecting device. The surface processing process solves the problems that outer wall quality of the sprayed plastic tube is affected as the uniform spraying material thickness on the outer tube of the plastic tube is difficult to guarantee in a spraying process of the spraying material, the spraying effect of the spraying material is affected as the spraying material is liable to condensate in the spraying process, and the spraying effect is further affected as the plastic tube is uneven in rotationand is liable to shake in the spraying process.

Owner:YANCHENG JIACHENG PLASTIC

Water blocking gate for river dike

The invention discloses a water blocking gate for a river dike. The water blocking gate for the river dike comprises a gate body, and further comprises a water flow noise control device; the water flow noise control device comprises supporting rods, a flow guiding plate and walking wheels; the first ends of the supporting rods are connected with the top of the gate body in a hinge manner, and thetail ends of the supporting rods are connected with the walking wheels; the flow guiding plate is arranged on the supporting rods and is fixedly connected with the supporting rods, and is used for performing flow guiding on running water flowing out of a water overflow port of the gate body; and the walking wheels are arranged on a riverbed.

Owner:CHENZHOU HENGDA SOPARATIAN MACHINERY FACTORY

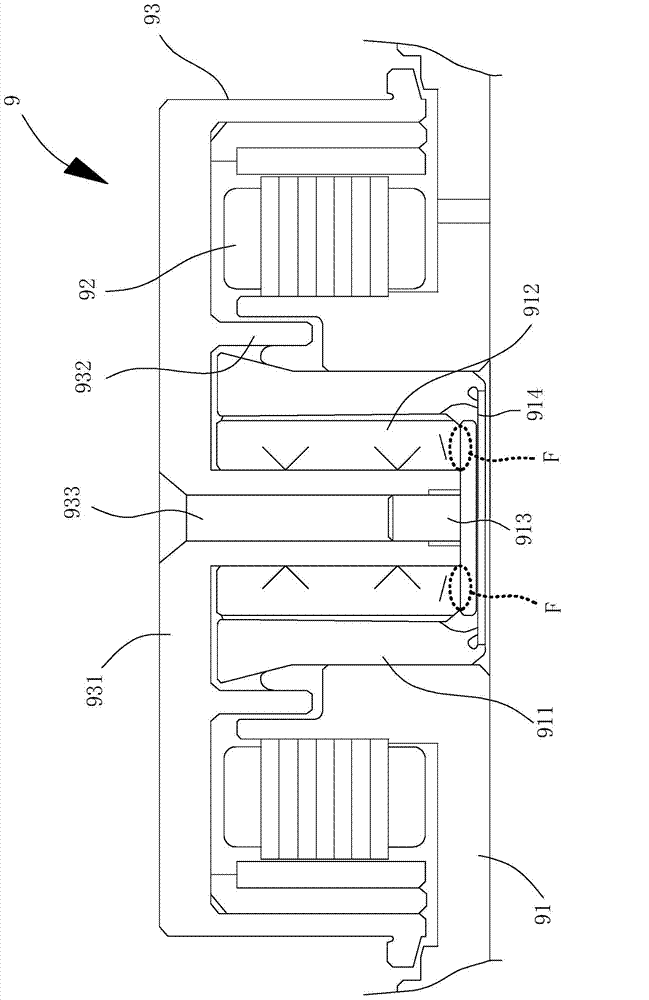

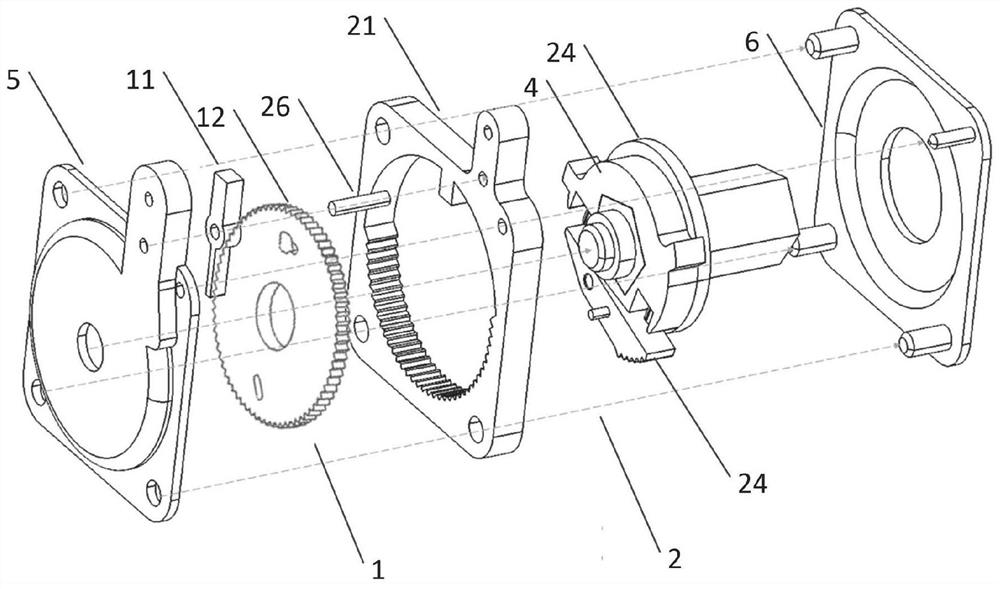

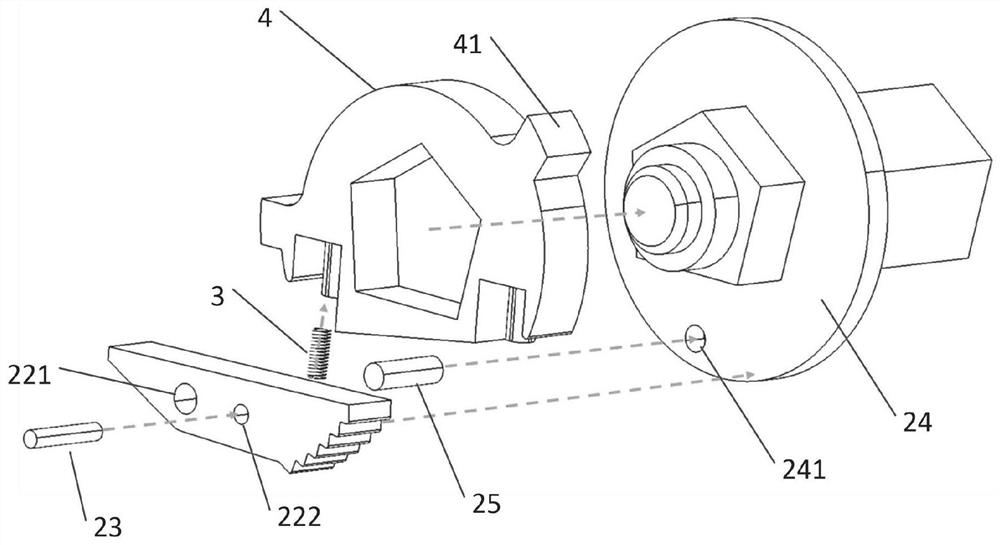

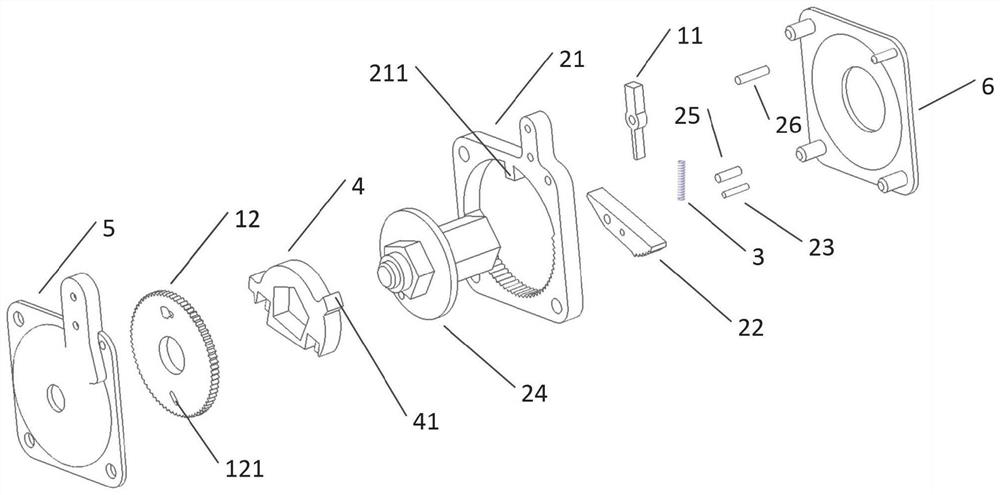

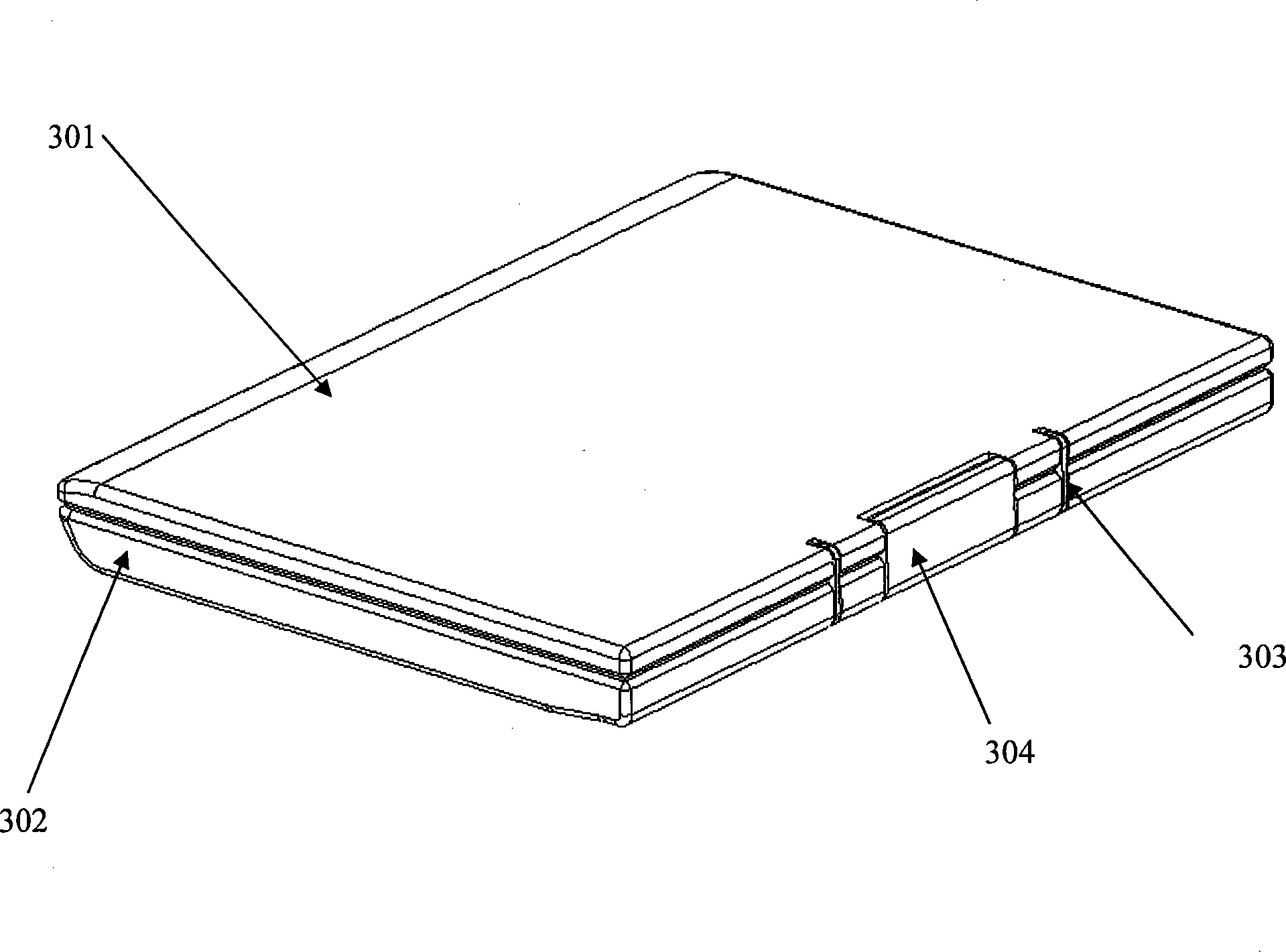

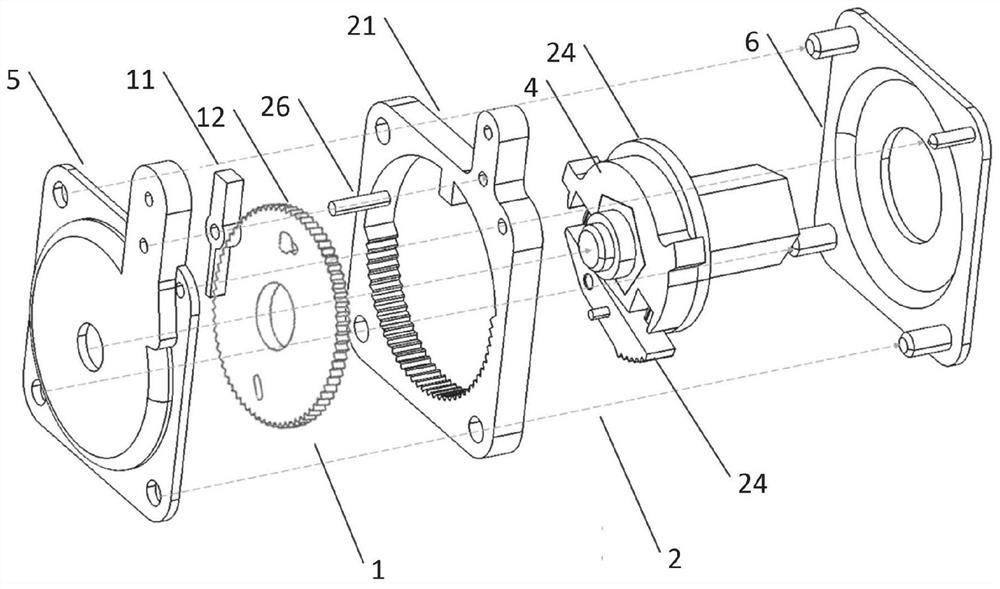

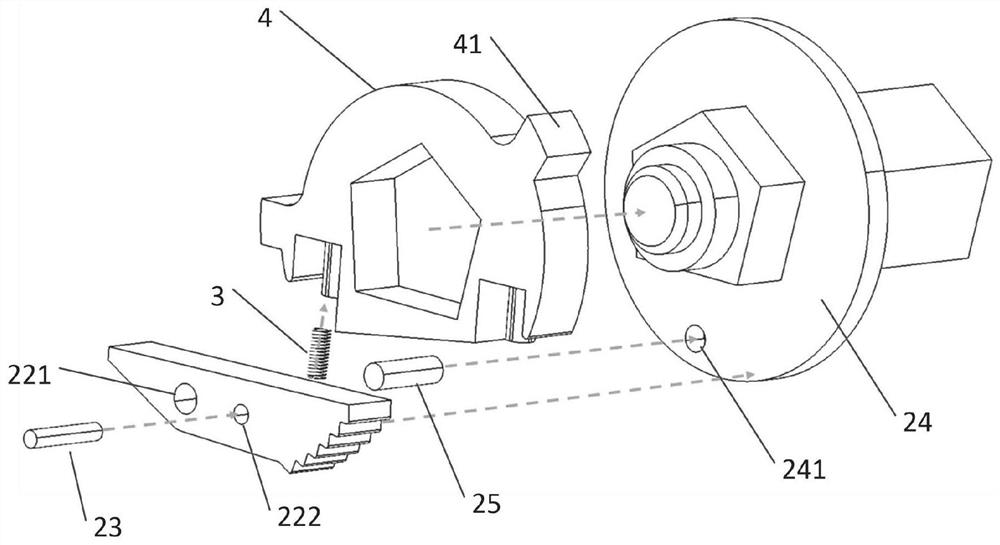

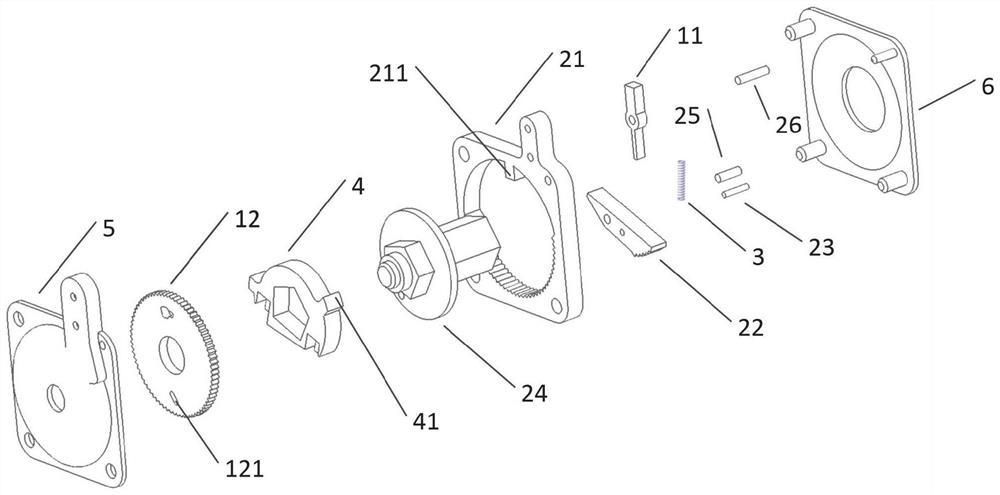

Folding mechanism and treadmill using same as column folding mechanism

PendingCN108939410ASmooth and stable rotationReduce noiseSpace saving gamesMovement coordination devicesEngineeringMechanical engineering

The invention relates to a folding mechanism. The folding mechanism comprises a bracket body, a folding assembly connected to the bracket body at an angle, a folding control assembly and a linkage locking assembly used for operating the folding assembly to be folded and mounted on the bracket body. The linkage locking assembly comprises a linkage assembly and a locking assembly, one end of the linkage assembly is in transmission connection with the folding control assembly, and the other end of the linkage assembly is in transmission connection with the locking assembly; the locking assembly comprises push bodies, spring bolts and groove holes, wherein the groove holes are used for cooperatively inserted by the spring bolts to fix locking assembly to the bracket body; the push bodies are provided with push-pull slideways, and the push-pull slideways are provided with protrusive push blocks and recessed pull grooves; the spring bolts include bolt bodies and return springs arranged for cooperating with the bolt bodies, wherein the bolt bodies slide up and down on the protrusive push blocks and the recessed pull grooves. The folding control assembly is operated to for transmission ofthe linkage assembly, and the linkage assembly pulls the push blocks to move, so that the bolt bodies are pulled out of the groove holes on the basis of a pull force of the protrusive push blocks or the bolt bodies or are inserted back into the groove holes on the basis of a return force of the recessed pull grooves and a resilience force of the return springs.

Owner:姚谷丰

Connecting structure for traffic warning

InactiveCN110984019AConvenient commandSmooth and stable rotationTraffic signalsRoad signsSimulationScrew thread

The invention relates to the technical field of traffic warning, and discloses a connecting structure for traffic warning. The connecting structure comprises a moving box, wherein movable wheels are fixedly mounted at the bottom of the moving box, rotating blocks are movably mounted on the left side and the right side of the top of the moving box respectively, first threaded rods with one ends penetrating through and extending out of the moving box are fixedly mounted at the bottom parts of the two rotating blocks respectively, fixing blocks are fixedly mounted at the bottom parts of the two first threaded rods respectively, and a fixing groove is formed in the moving box. According to the connecting structure for traffic warning, the rotating block is arranged, when the moving box needs to be fixed, the two rotating blocks are twisted, the two first threaded rods drive the fixing blocks to descend until the fixing blocks are in contact with the ground. Due to the fact that the bottomparts of the two fixing blocks are both made of rubber, the friction force between the fixing blocks and the ground is increased, and the moving box can be fixed to a set place, so that the position of a warning sign can be freely adjusted according to the actual use condition, and the traffic guidance is facilitated.

Owner:WENZHOU UNIV OUJIANG COLLEGE

Damper and circular air-conditioning air outlet

InactiveCN108501662ASmooth and stable rotationConstant damping forceAir-treating devicesVehicle heating/cooling devicesAir conditioningControl theory

The invention discloses a damper. A base is provided with an inner cavity; openings are arranged at two ends of the base; one end a rotation part is rotationally held in the inner cavity of the base and matched with the shape of the inner cavity; one end of a transmission part is rotationally held in the inner cavity of the rotation part; a first friction part is arranged between the rotation partand the base; and a second friction part is arranged between the transmission part and the rotation part. The invention also provides a circular air-conditioning air outlet comprising a casing, blades arranged in the casing, a gear, an air damper and the damper. The damper used in the invention further simplifies the structure and allows the rotating operation of the damper to be smooth and stable. The damper can maintain a more constant damping force. In addition, the casing strength of parts is enhanced in the production of the parts so as to prolong the service life, reduce the fine requirements of dimensional specifications and facilitate the production.

Owner:YINGHUALI AUTO MOLD SYST SHENZHEN

Automatic gluing device

InactiveCN110743742AUnified fixed positionGood for volatilizationPretreated surfacesCoatingsMechanical engineering

Owner:精诚工科汽车系统有限公司

Surface spraying equipment for plastic pipe

ActiveCN112337671AGuaranteed spraying effectUniform thicknessLiquid spraying apparatusSlide plateComposite material

The invention provides surface spraying equipment for a plastic pipe. The surface spraying equipment for the plastic pipe comprises a bottom plate, a first fixing device, a second fixing device, a U-shaped frame, an auxiliary sliding plate, a spraying adjusting device and a material collecting device. The main problems that in a process of spraying a spraying material on the outer wall of a plastic pipe at present, a uniform thickness of the spraying material on the outer wall of the plastic pipe is difficultly ensured in the process of spraying the spraying material, so that the quality of the outer wall of the sprayed plastic pipe is affected, the spraying material is prone to coagulation in the spraying process, and then the spraying effect of the spraying material is affected, and in the spraying process, the plastic pipe does not rotate uniformly and is prone to shaking, so that the spraying effect is further affected, are solved.

Owner:YANCHENG JIACHENG PLASTIC

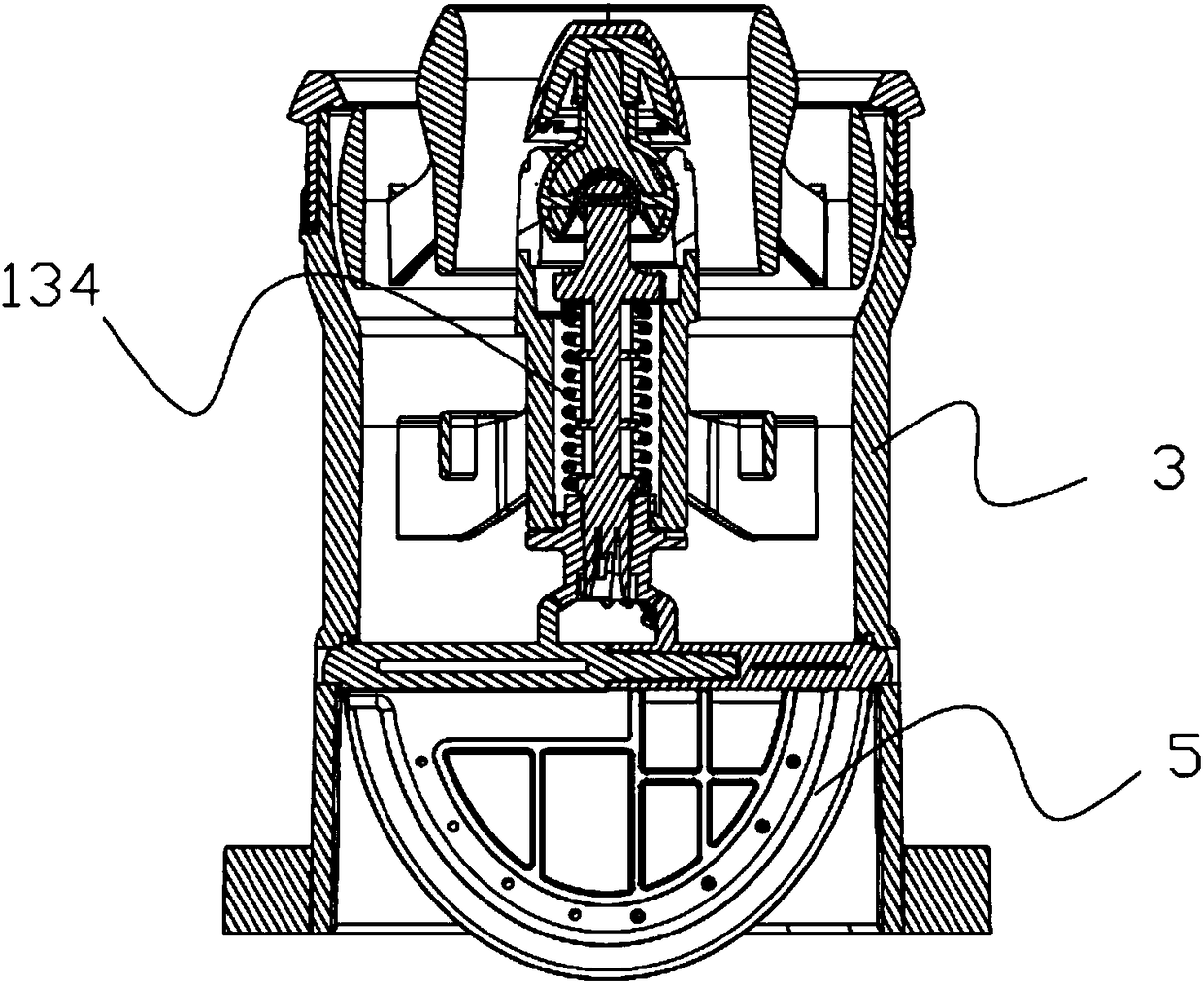

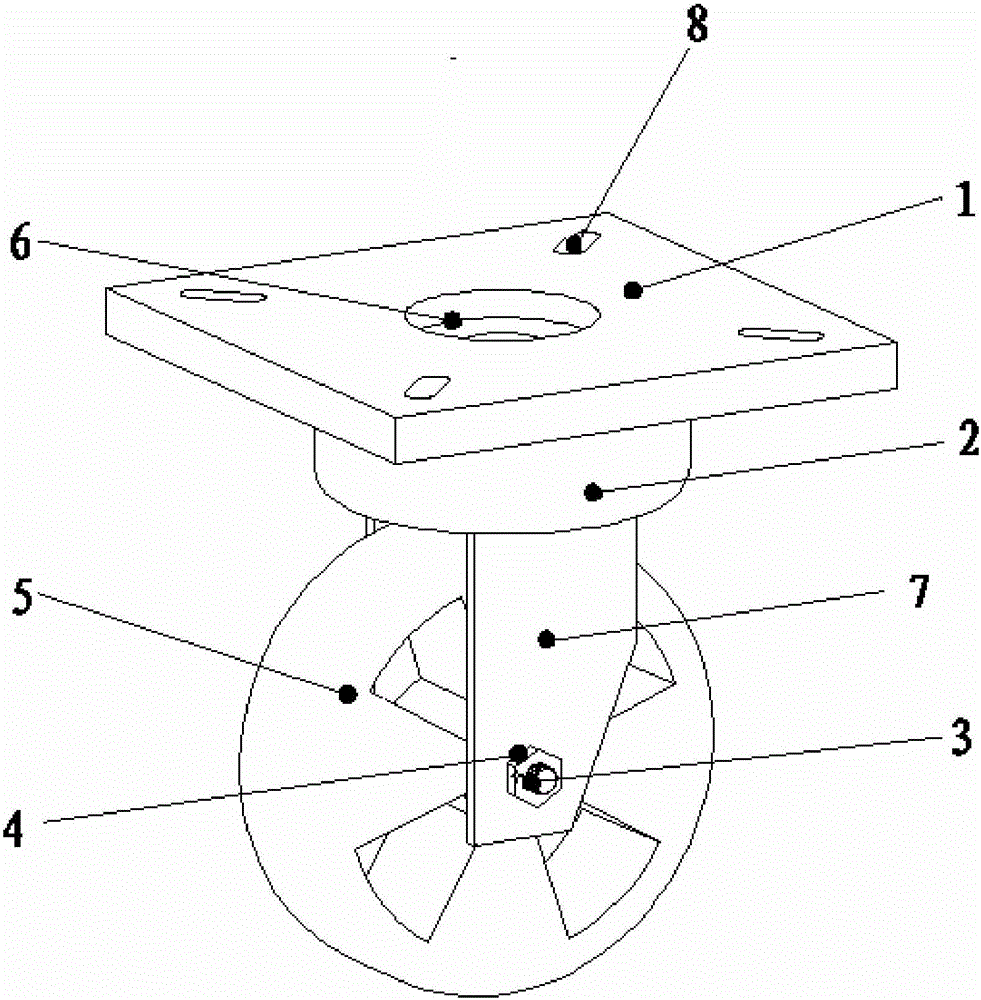

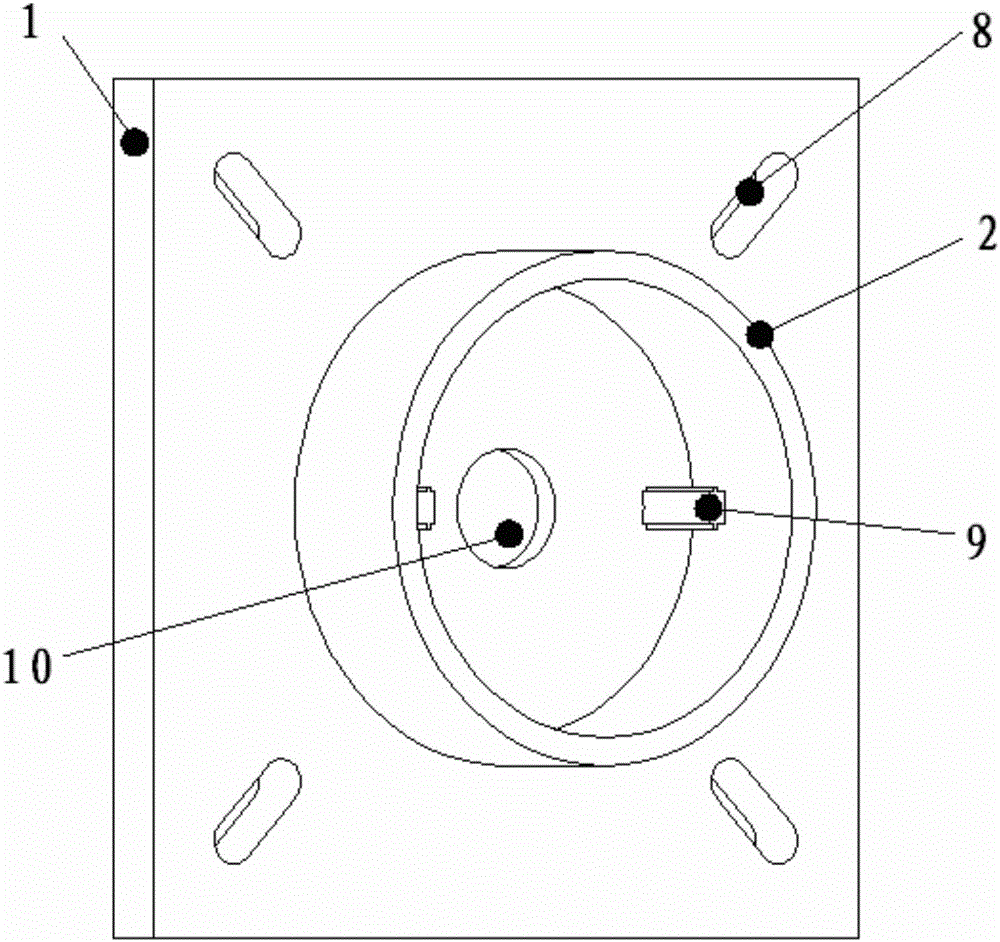

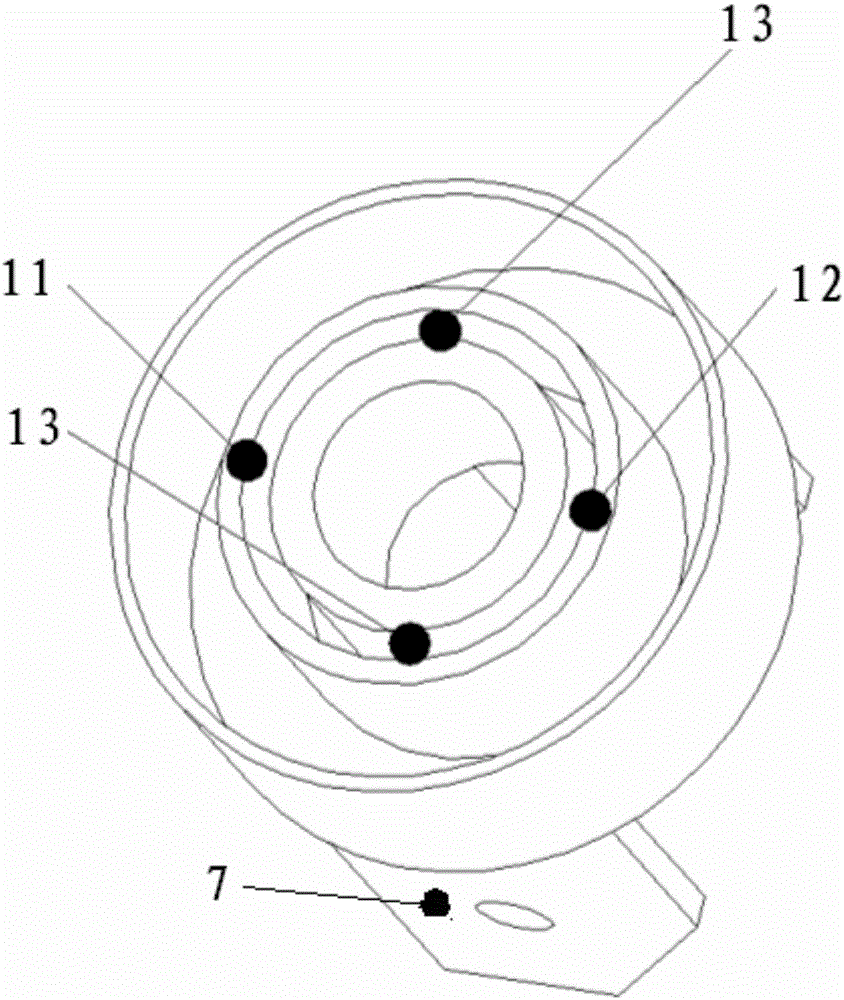

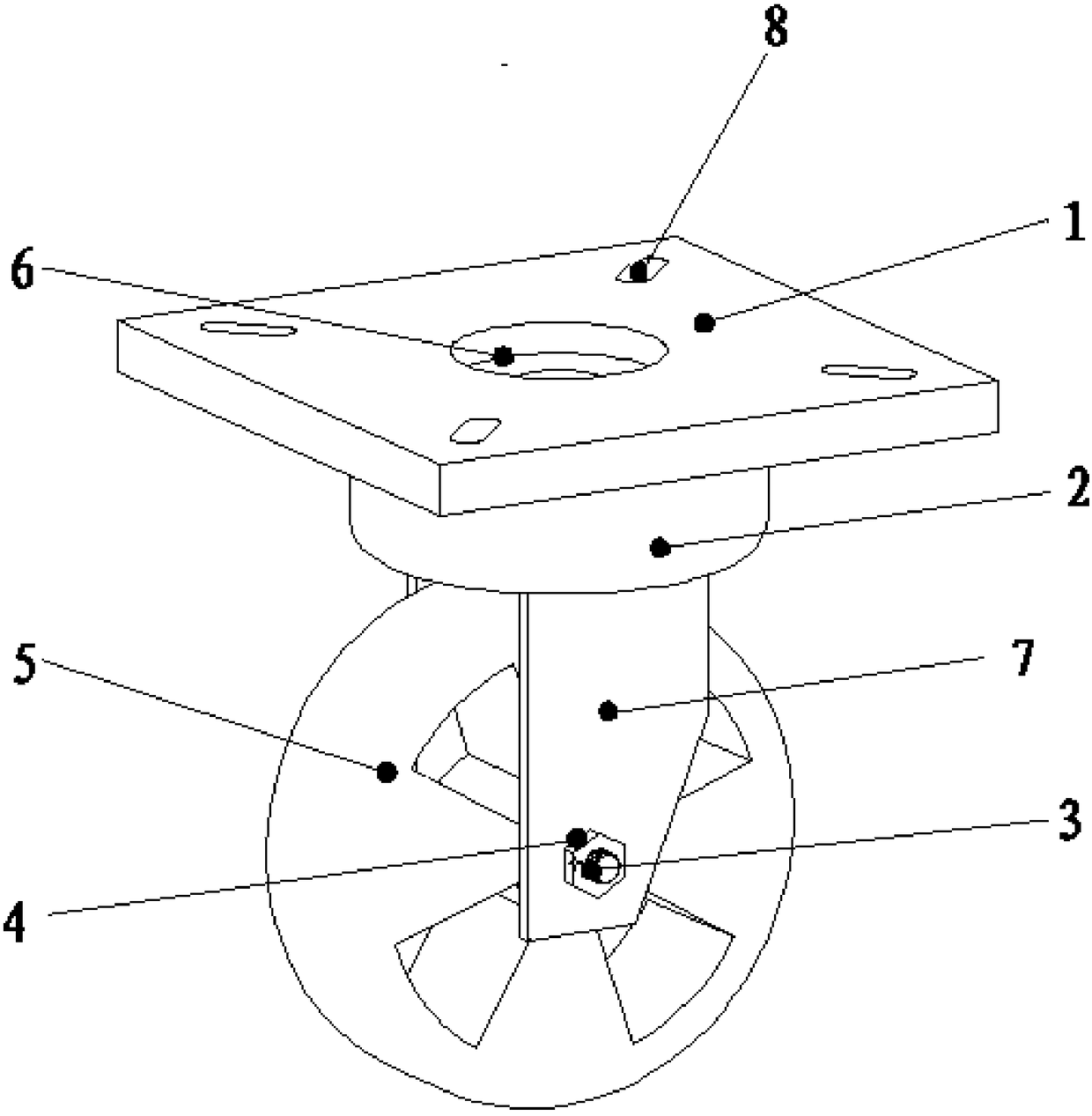

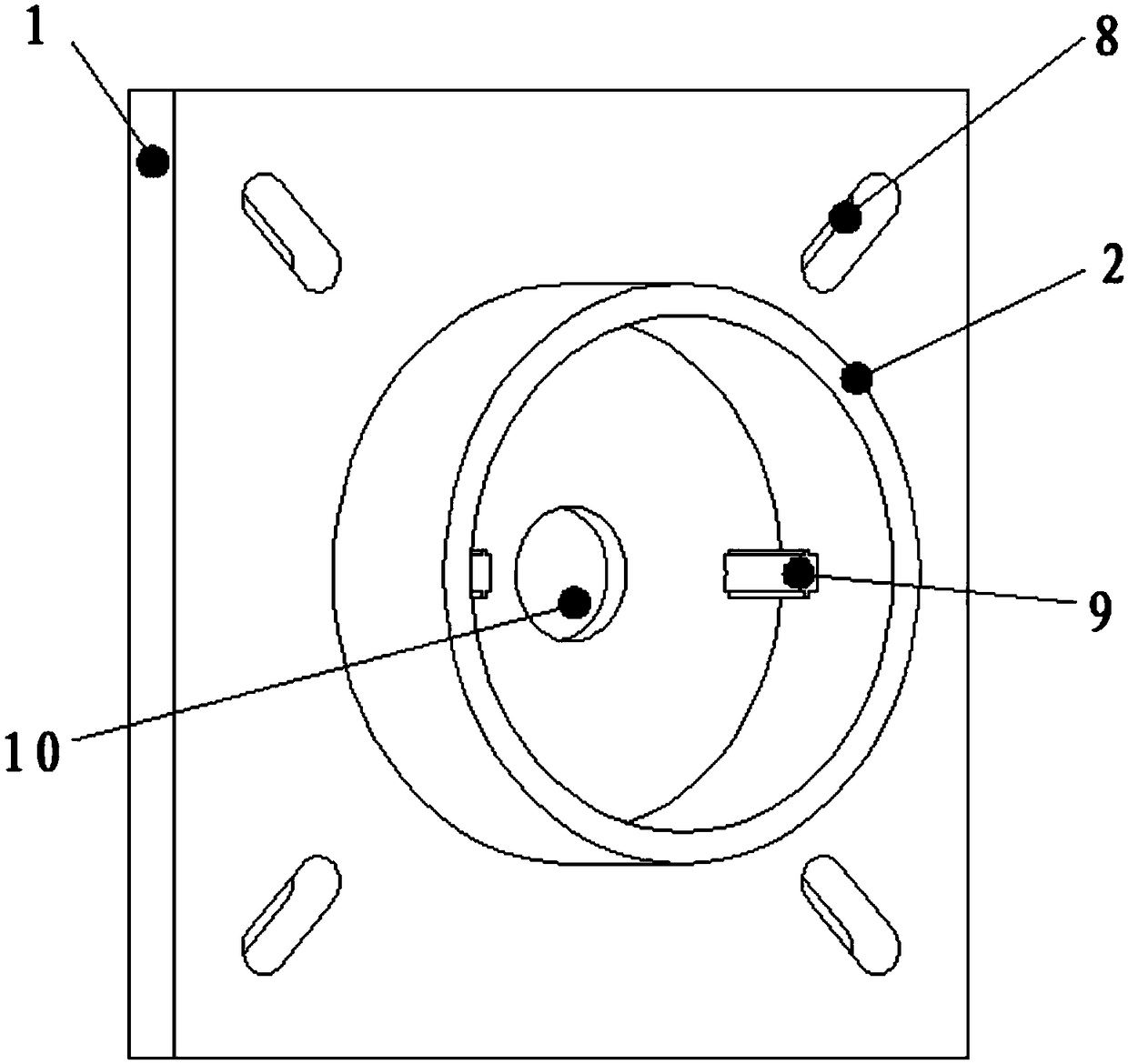

Intelligent follow-up universal wheel

ActiveCN105966174AReduce vibration and shakingSmooth and stable rotationCastorsEngineeringMechanical engineering

The invention provides an intelligent follow-up universal wheel. The intelligent follow-up universal wheel comprises a fixing base, a rotating ring, a wheel shaft, a wheel shaft assembly, a wheel body, a transfer bearing base, connecting lugs, positioning slot holes, stopping blocks, a bearing hole, a first spring installation groove, a second spring installation groove, stopping block installation grooves and springs. According to the intelligent follow-up universal wheel, rotating is more gentle and stable, the rotating direction sense is higher, and the problem that the universal wheel is frequently shaken and waggled during rotating is solved.

Owner:严格科创产业发展集团有限公司

A short-distance comprehensive transfer and placement system for buildings

ActiveCN105569374BReduce internal stressImprove protectionBuilding repairsEngineeringMechanical engineering

The invention discloses a near-remote distance comprehensive transfer placing system for a building. The near-remote distance comprehensive transfer placing system comprises a translation track mechanism, a positioning mechanism, a jacking mechanism, an underpinning beam, a monitoring mechanism as well as a rotating mechanism, wherein the rotating mechanism is arranged on the lower end surface of the underpinning beam; the rotating mechanism comprises an upper rotating base and a lower rotating base; the upper rotating base and the lower rotating base are rotationally connected; an annular bulge is formed in the lower end surface of the upper rotating base; an annular groove matched with the annular bulge is formed in the upper end surface of the lower rotating base. The annular bulge and the annular groove are matched with each other, so that mutual matching of the upper rotating base and the lower rotating base can be achieved, the whole building is on a stable platform and in a rotating environment in the rotating process, internal stress generated to the building in the rotating process is effectively reduced, the building can be prevented from structural damage, and the phenomenon of crack or collapse can be effectively avoided.

Owner:重庆博视知识产权服务有限公司

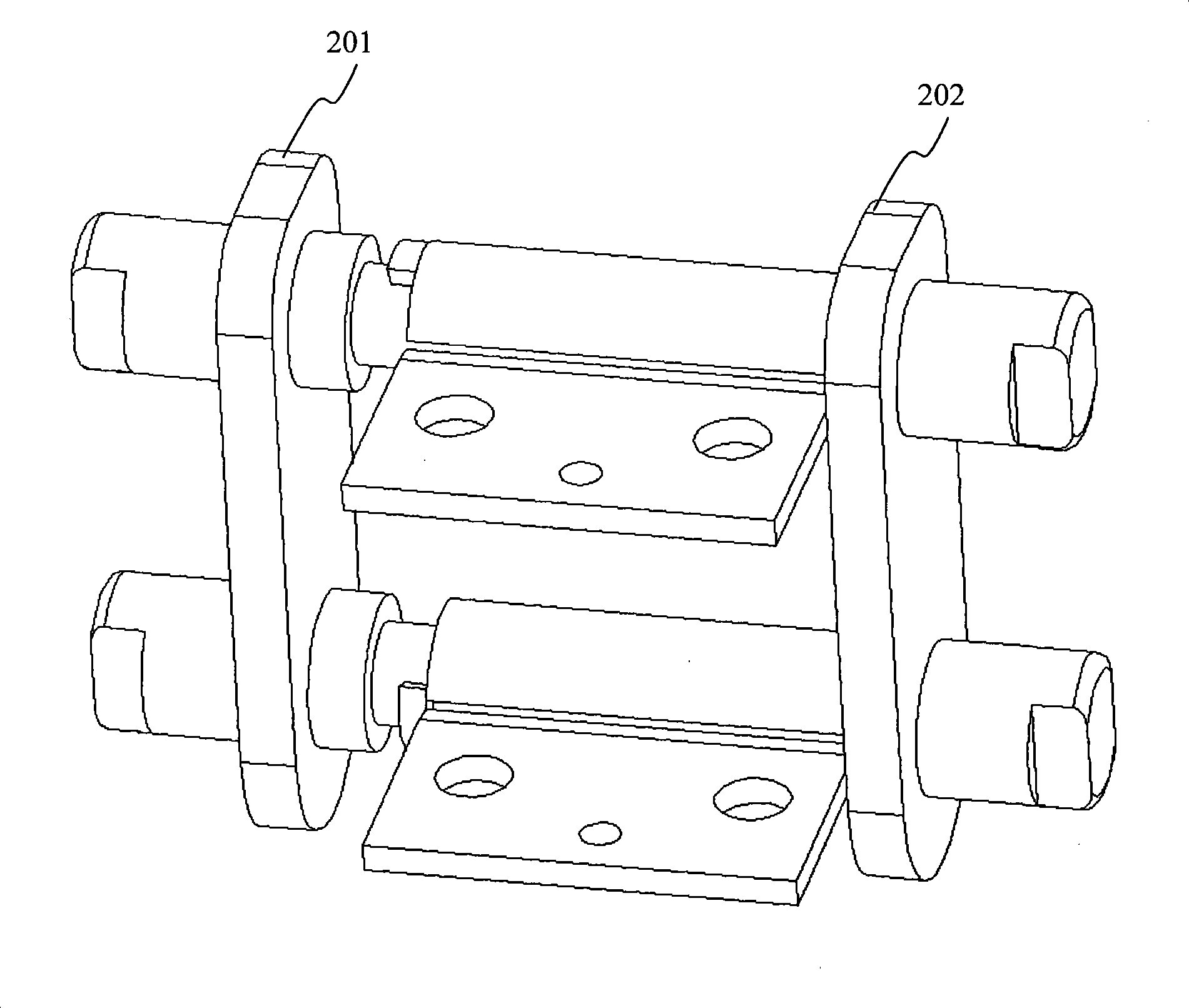

Notebook computer and rotating shaft device

ActiveCN101561697BSmooth and stable rotationSynchronous rotationDigital data processing detailsLiquid-crystal displayMechanical engineering

Owner:LENOVO (BEIJING) LTD

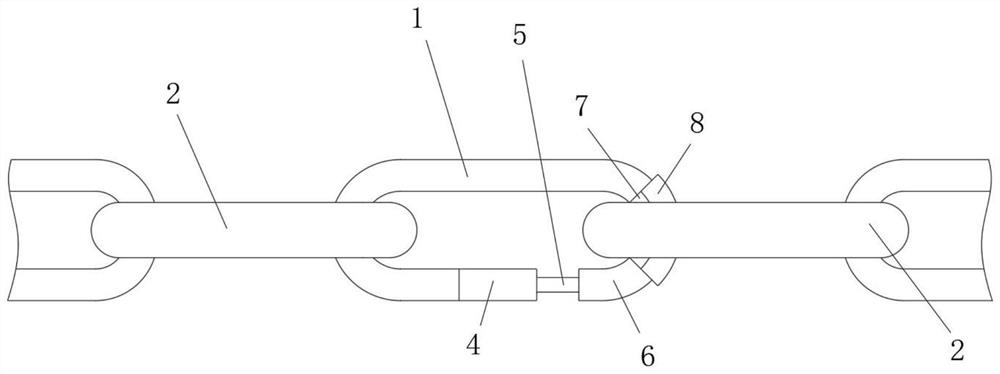

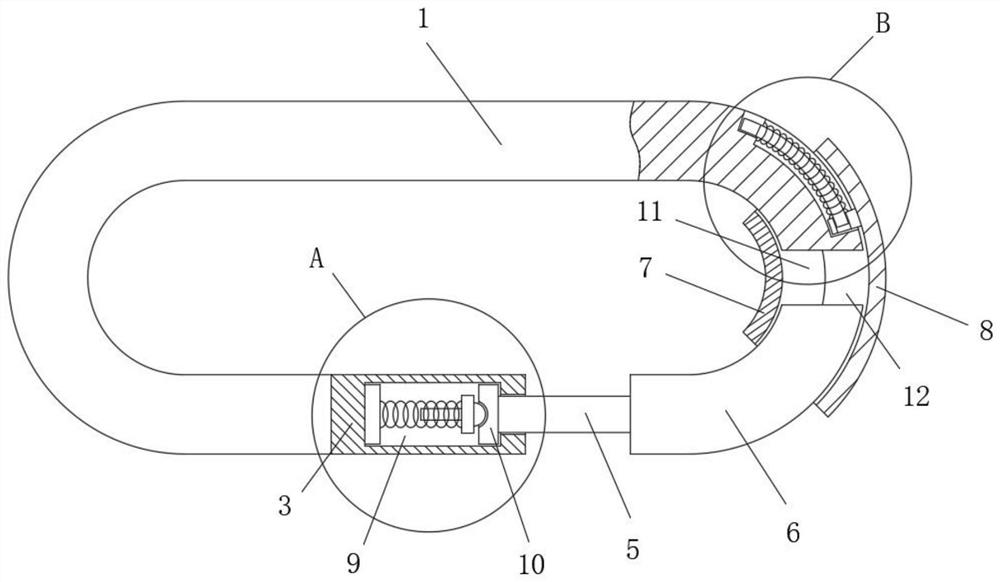

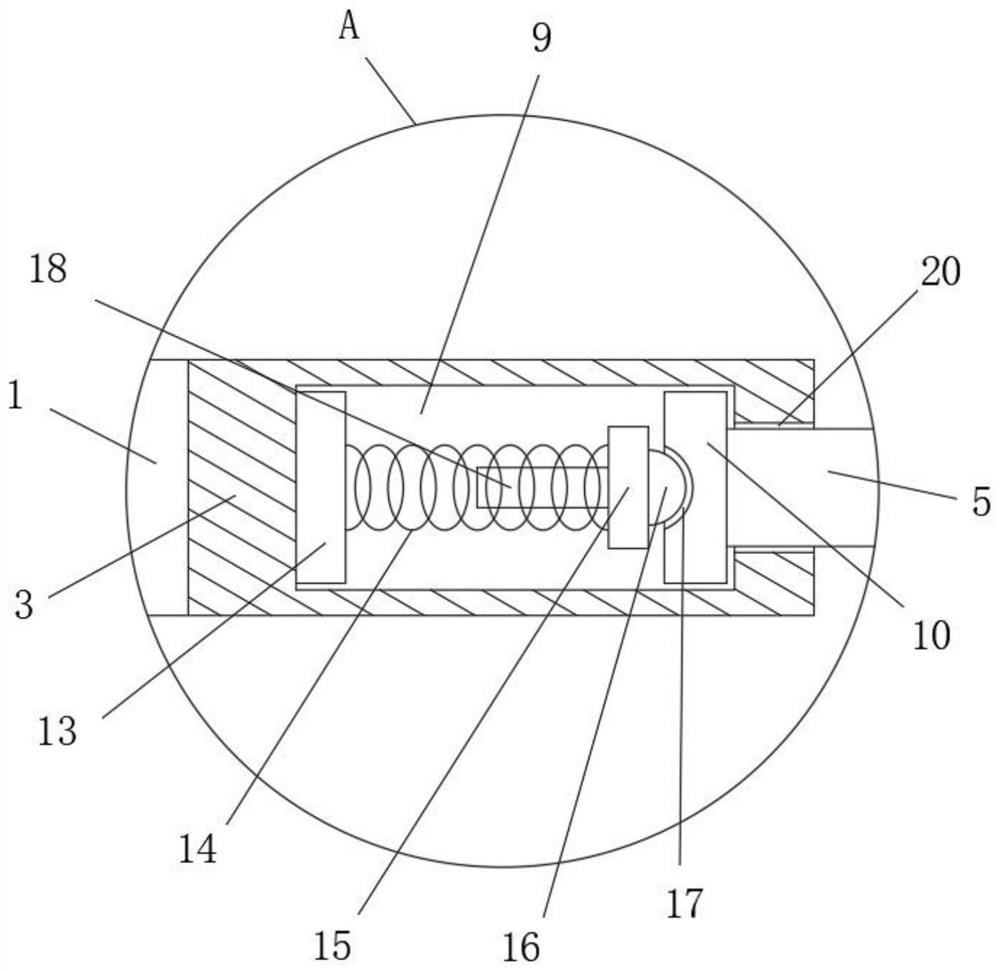

Chain linking unit and linking structure

Owner:浙江帝枫机械科技有限公司

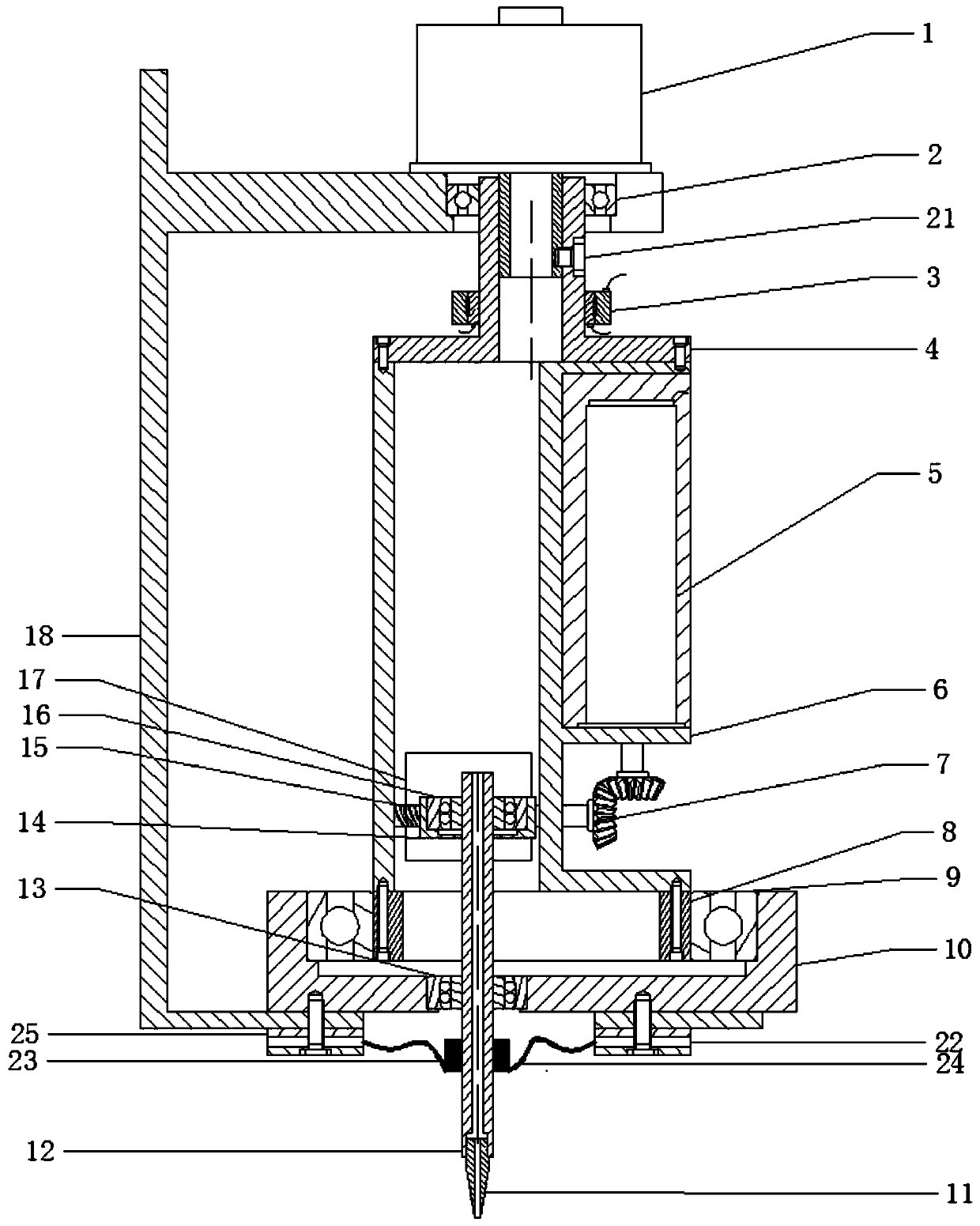

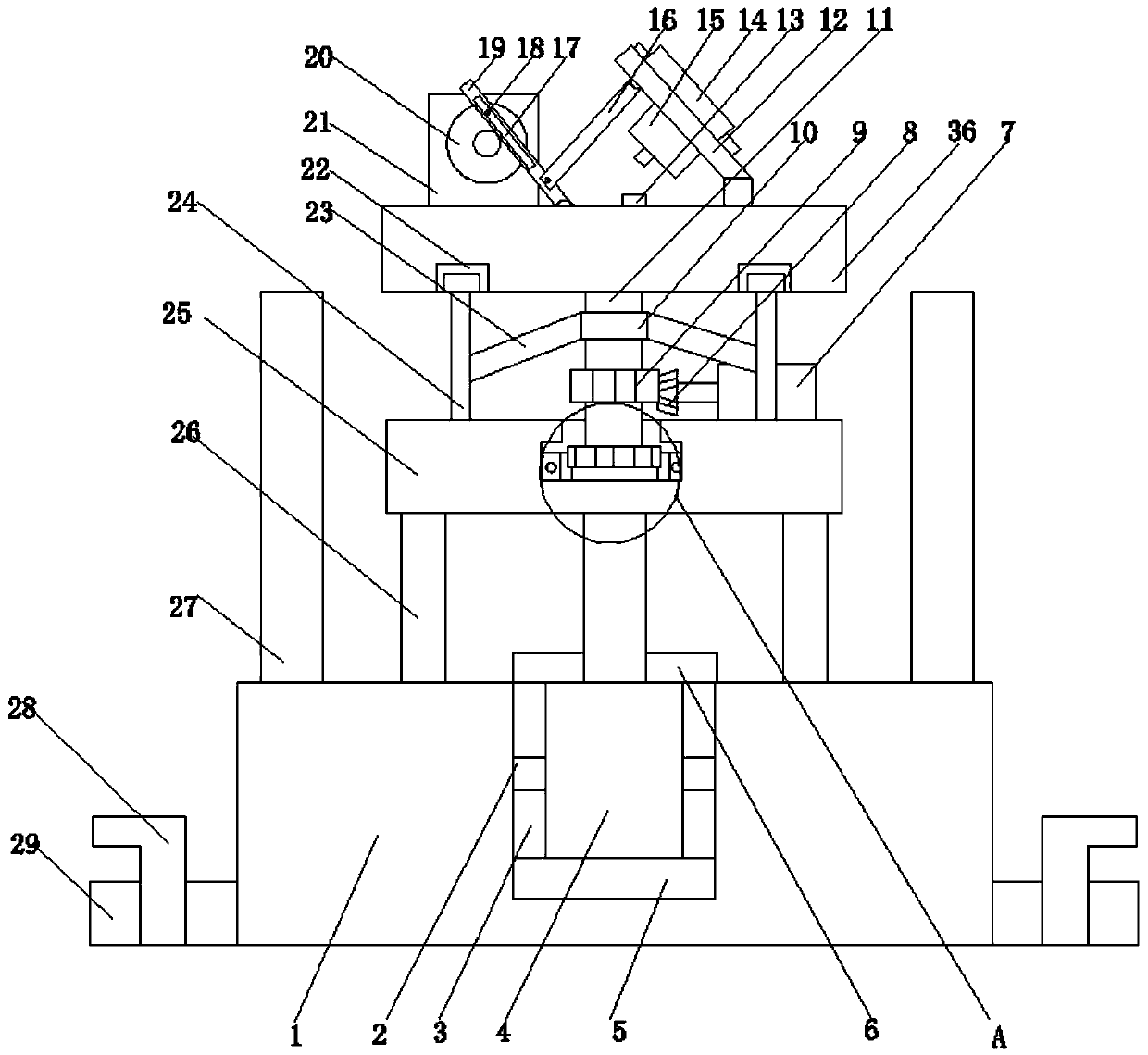

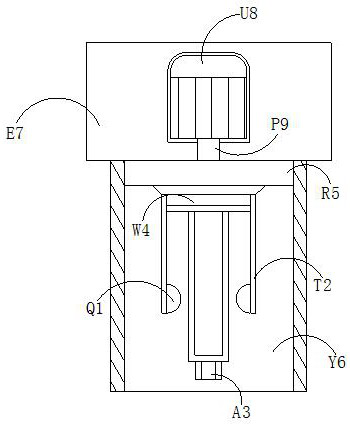

Rotating electric arc welding torch with stepless eccentricity adjusting function and adjusting method thereof

ActiveCN110722257AOvercome the shortcomings of adjusting the rotation radius in real timeGuaranteed stabilityElectrode supporting devicesWelding accessoriesFixed bearingSet screw

The invention relates to a rotating electric arc welding torch with a stepless eccentricity adjusting function and an adjusting method of the rotating electric arc welding torch. The welding torch comprises a frame. The frame is provided with a bottom plate and a top plate. The bottom plate and the top plate of the frame are respectively provided with a through hole, wherein the center lines of the through holes deviate from each other. The upper plane of the top plate is provided with a hollow shaft motor through one through hole. A fixed bearing sleeve coaxial with the hollow shaft motor isfixedly mounted on the upper plane of the bottom plate. The longitudinal section of the fixed bearing sleeve is U-shaped. A mounting hole deviating from an axial line is formed in the bottom. A lowerdeep groove ball bearing and a rotating sleeve are sequentially embedded in the fixed bearing sleeve from outside to inside. The upper end of the rotating sleeve is connected with an output shaft of the hollow shaft motor through a set screw. The middle of the rotating sleeve is provided with an eccentricity adjusting device for clamping one end of a conductive rod. The other end of the conductiverod penetrates through the mounting hole of the fixed bearing sleeve and the through hole of the bottom plate. A spring carbon brush sleeves the outer circle of the end portion. A tip is connected with a conductive nozzle. By means of the rotating electric arc welding torch with the stepless eccentricity adjusting function and the adjusting method of the rotating electric arc welding torch, stepless adjusting of the rotating radius is realized, and related noise in the operation process of the welding torch is reduced. The structure is simple, and the performance is stable.

Owner:JIANGSU UNIV OF SCI & TECH

A kind of photovoltaic bracket with rotating function

ActiveCN107634711BReduce vibrationIncrease profitPhotovoltaic supportsSolar heating energyHydraulic cylinderRotation function

The present invention discloses a photovoltaic support with a rotating function. The photovoltaic support comprises a pedestal, an installing groove is arranged at the top of the pedestal, and a buffer cushion is fixedly connected at the internal bottom of the installing groove. A hydraulic cylinder is fixedly installed at the top of the buffer cushion, a fixing rod is fixedly connected between the hydraulic cylinder and the inner wall of the installing groove, and a water stop ring sleeves the outer side of the hydraulic cylinder. According to the present invention, by arranging a first motor, a bevel gear, a connecting shaft and a transfer wheel, the first motor drives the bevel gear to rotate, and the transfer wheel drives the connecting shaft and a workbench to rotate, so that the position of a solar panel can be adjusted timely according to the illumination intensity and direction, and the utilization rate of the solar energy is improved. By arranging a fastening groove, a gear disc, a turntable and a rotating gear, the fastening groove is in snap joint with the rotating gear, thereby preventing the connecting shaft from breaking away from a supporting plate. By utilizing therelative rotation of the gear disc and the rotating gear and the adjustment of the balls, the rotation process of the connecting shaft is smoother.

Owner:JIANGSU SHILIN ELECTRIC EQUIP

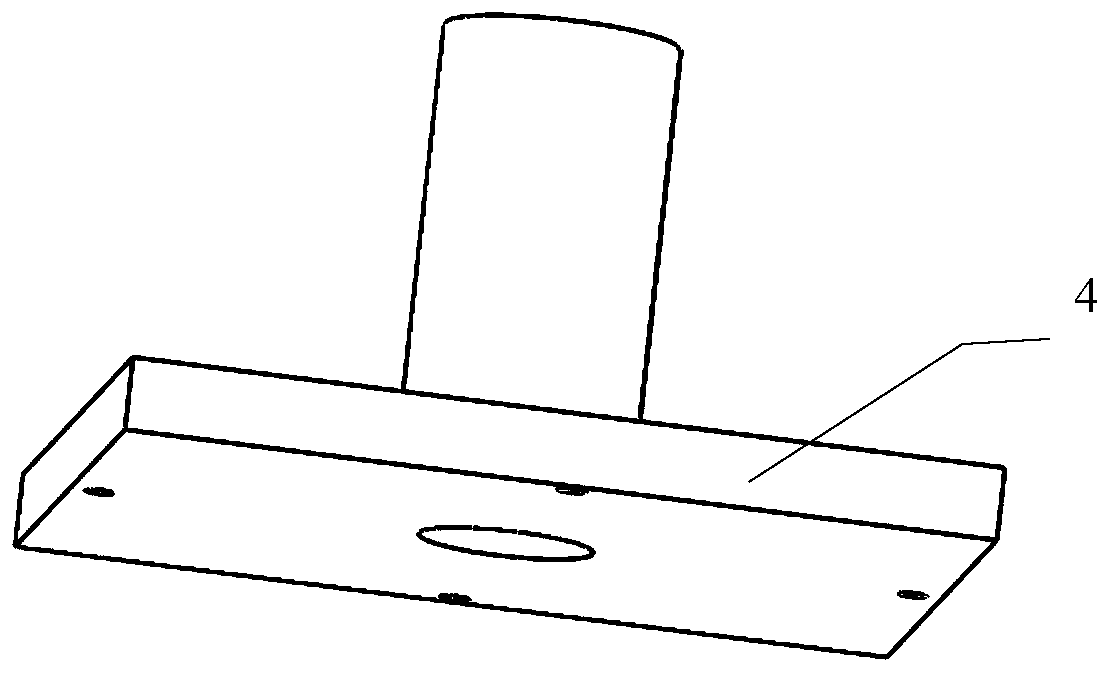

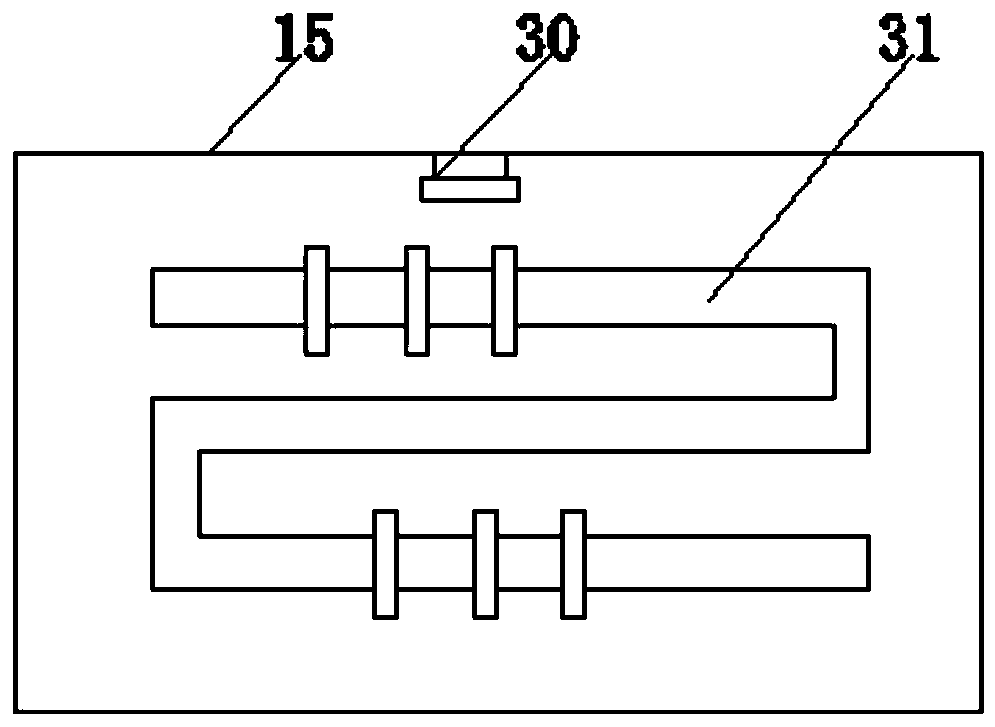

Pushing structure based on computer vision grading equipment

The invention discloses a pushing structure based on computer vision grading equipment. The pushing structure comprises a bottom plate, a fixing hole, a sliding strip, a sliding block, a material ejecting structure, a power line and a control switch, and the fixing hole is formed in the surface of the bottom plate. According to the pushing structure, the material ejecting structure is optimally arranged, a small motor is used as a power source, a rectangular seat moves in the horizontal direction through cooperation of a gear and a rack, a worm and a worm gear are installed in the rectangular seat, then a roller can be driven to adjust the position and change the orientation angle in the horizontal direction, meanwhile, a driving motor serves as a power source, one end of the roller is lifted upwards through rotation cooperation of a connecting rod piece and a rod piece, and the roller can slightly move under the action of springs, so that the situation that objects are directly pushed to cause overlarge stress on the objects is avoided, and the quality of the objects during grading is guaranteed to a certain extent.

Owner:泉州市晟禄产品设计有限公司

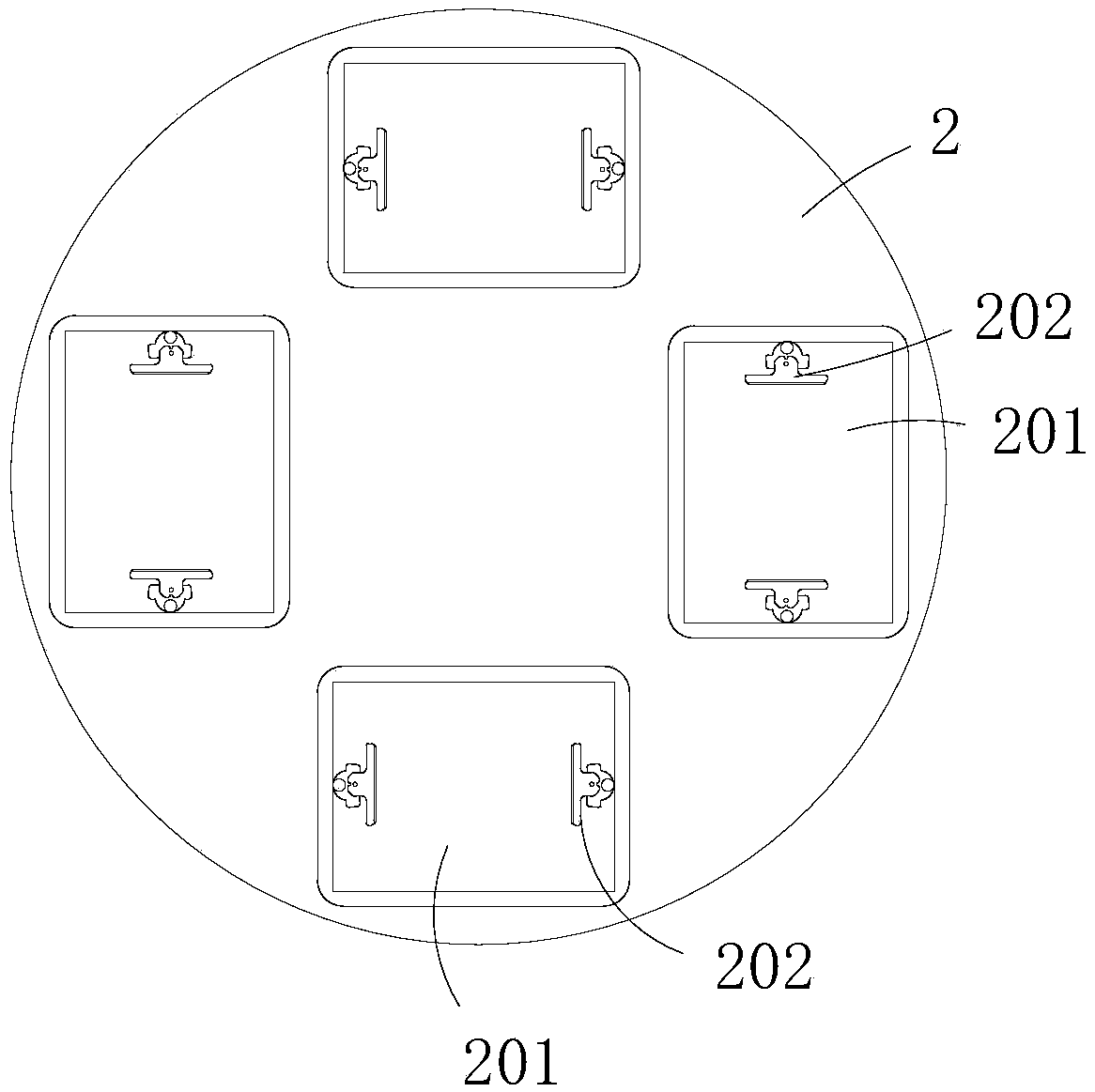

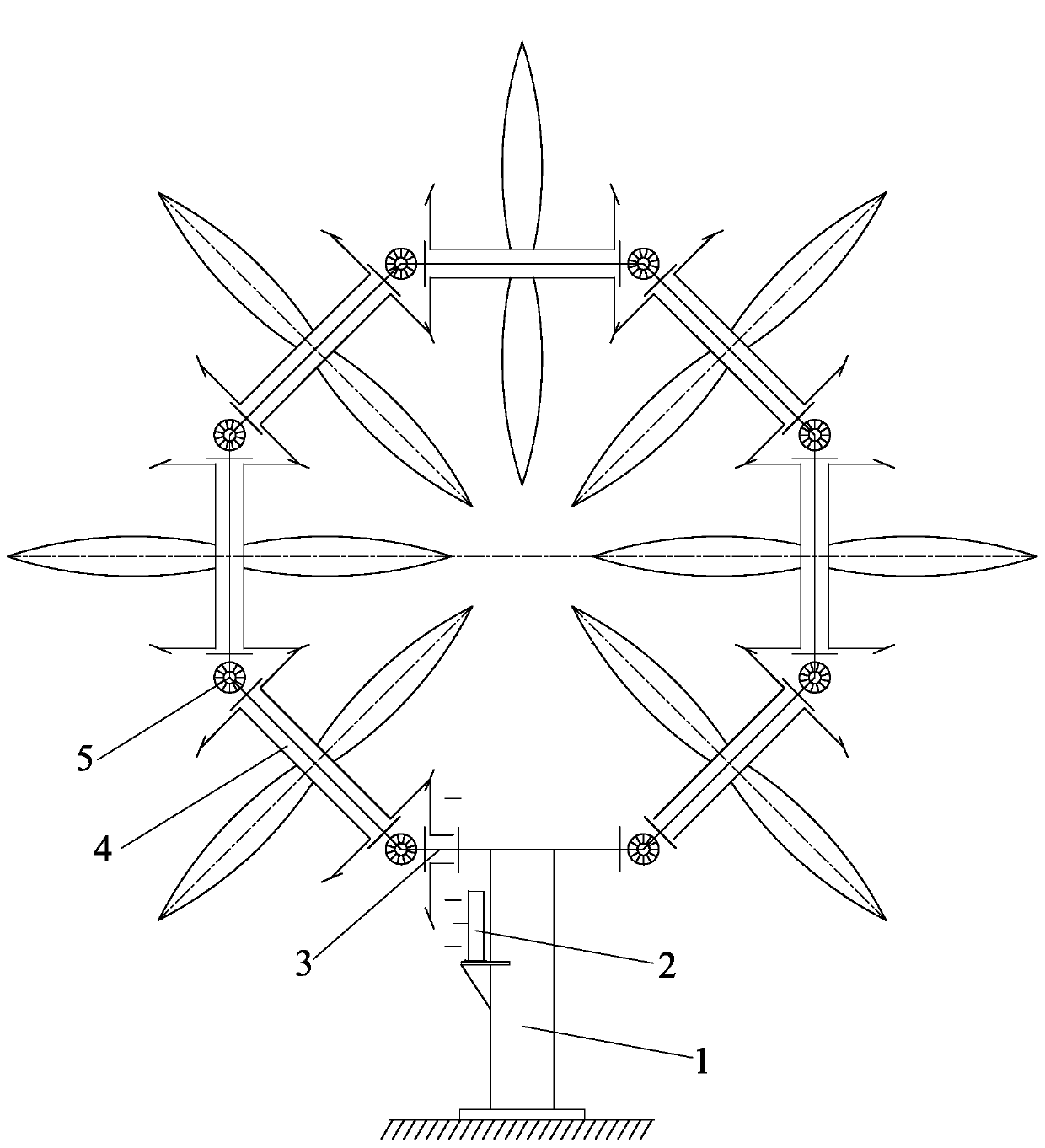

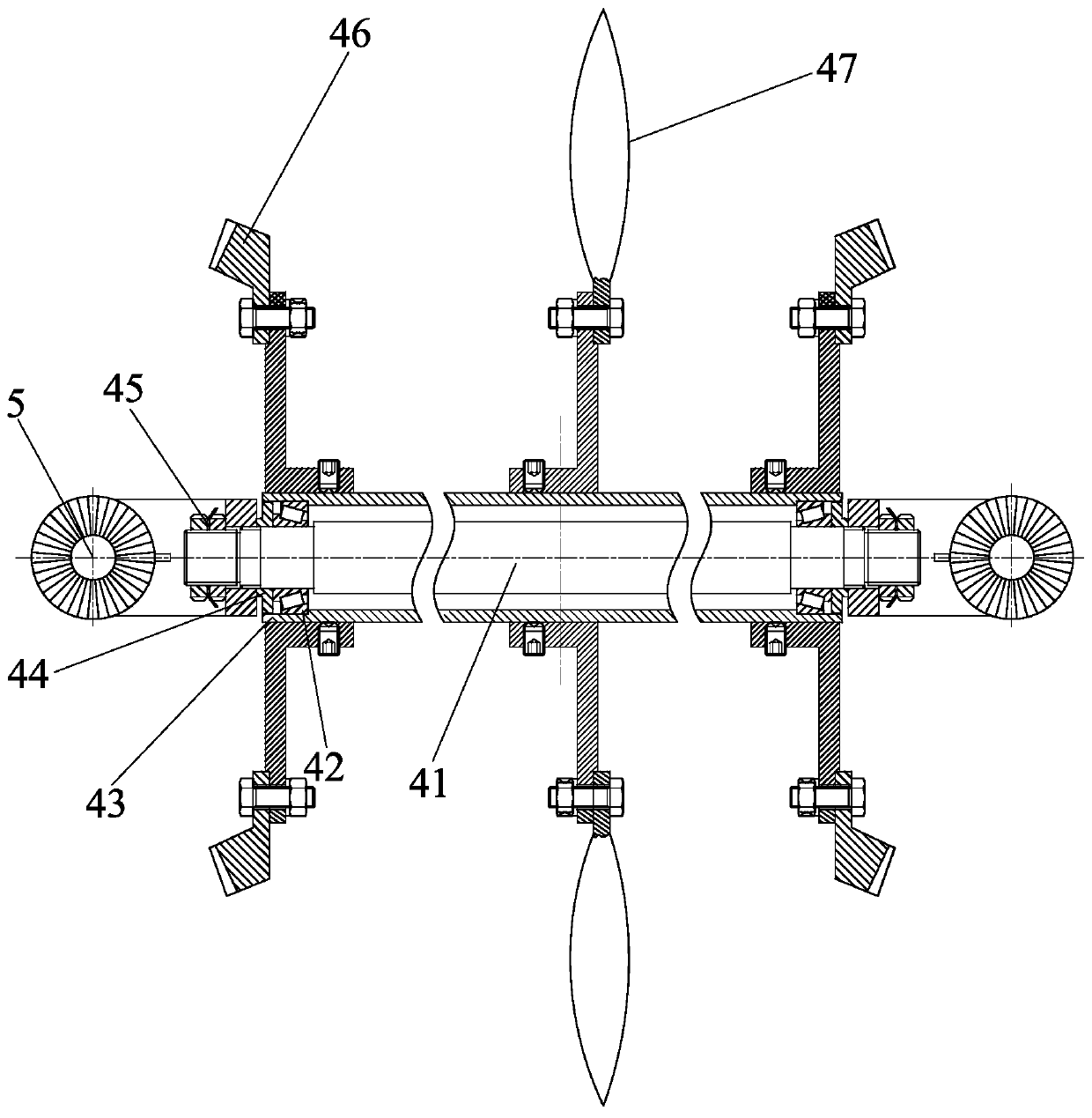

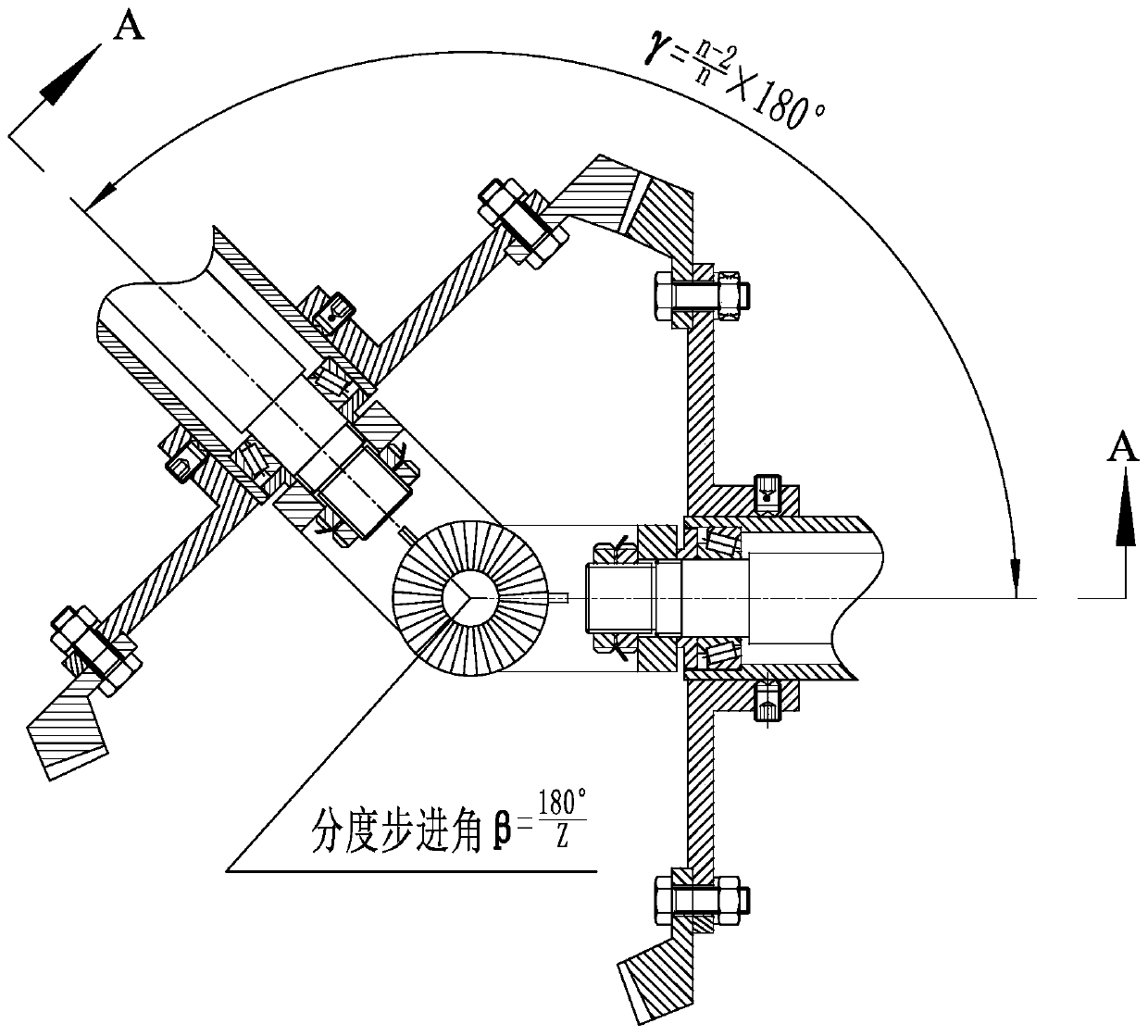

Adjustable positioning and clamping device for regular polygonal dynamic sculpture and adjustable positioning method thereof

ActiveCN109703262ASmooth and stable rotationReduce typesOrnamental structuresPivotal connectionsComputer moduleHigh intensity

Owner:JIMEI UNIV

A kind of plastic pipe surface processing technology

ActiveCN112337670BGuaranteed spraying effectUniform thicknessLiquid surface applicatorsLiquid spraying apparatusSpray coatingSlide plate

Owner:YANCHENG JIACHENG PLASTIC

An intelligent follow-up universal wheel

ActiveCN105966174BReduce vibration and shakingSmooth and stable rotationCastorsMechanical engineeringEngineering

Owner:严格科创产业发展集团有限公司

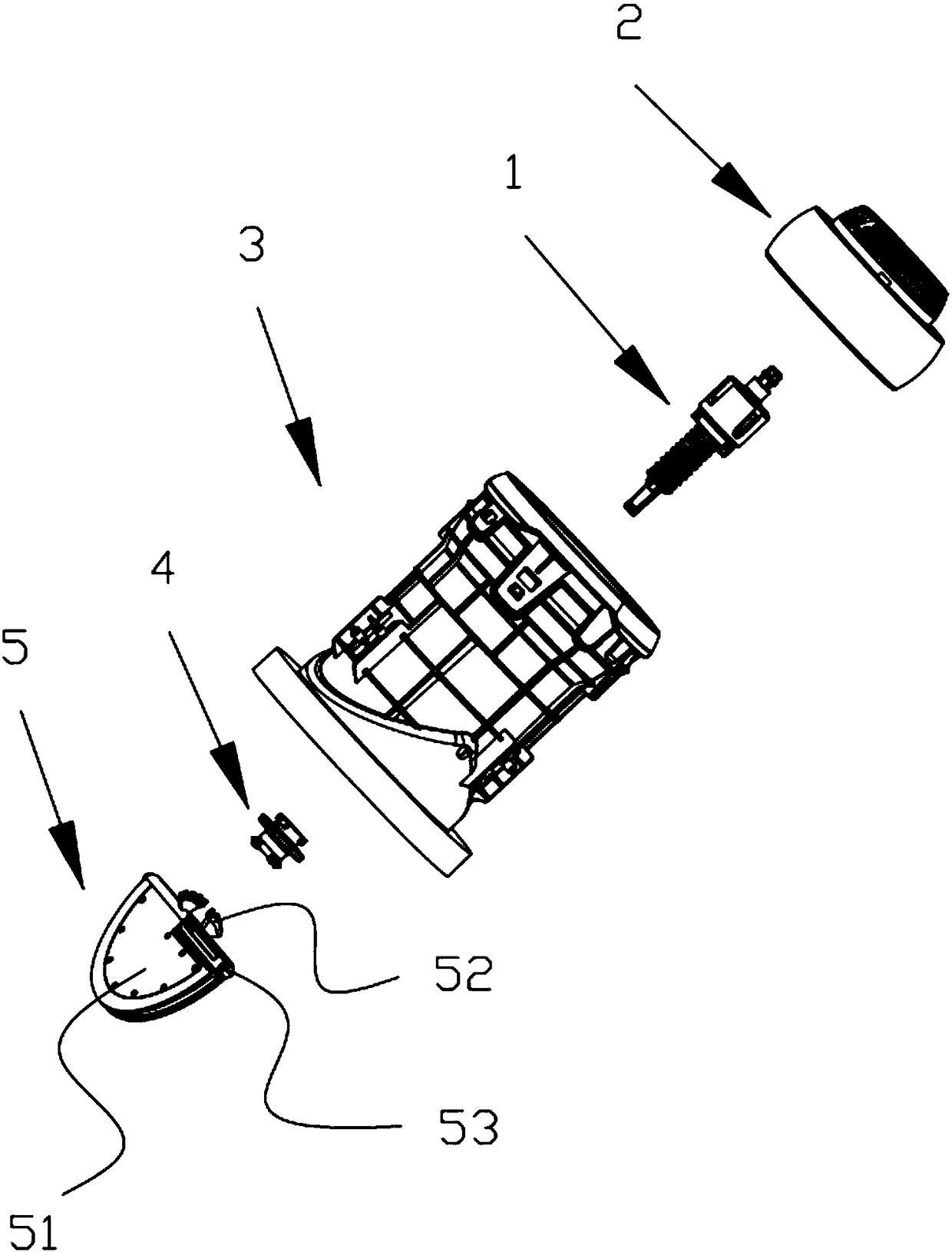

Microbial sensor for detecting cadmium ions

InactiveCN114778788APlay a closed rolePrevent spilloverPreparing sample for investigationTesting waterMicroorganismWastewater

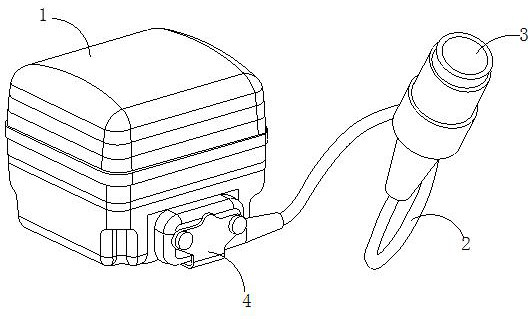

The invention discloses a microbial sensor for detecting cadmium ions, which structurally comprises a machine body, a detection device, a transmission line and a collection module, when the microbial sensor is used, a sampled test tube vertically extends between two clamping pieces, the lower end parts of the clamping pieces are connected with resisting blocks, and the resisting blocks can be pressed at the two ends of the outer side of the test tube, so that the test tube is effectively limited; a test tube is translated upwards and extends into a sealing connecting piece, the sealing connecting piece has a sealing effect on the test tube, the phenomenon that waste water in the test tube overflows during shaking is prevented, a shaft rod drives a mounting ring to move under the action of a motor, and the sealing connecting piece drives the test tube to stably rotate under the action of the mounting ring; substances in the wastewater are effectively and uniformly mixed.

Owner:重庆市忠县人民医院

An armrest level limiting device, a seat and an automobile

ActiveCN113352972BImplement the rotation functionRealize the locking functionArm restsRatchetClassical mechanics

The invention relates to an armrest level limiting device, a seat and a car, the limiting device includes a gravity component and a ratchet component, the gravity component is used to control the unlocking and locking of the ratchet component, and the ratchet component includes a ratchet Lock plate, ratchet swing teeth, ratchet swing teeth unlock the rotating shaft and the main shaft, the ratchet swing teeth are engaged with the ratchet lock plate, the ratchet lock plate is used to control the rotation of the armrest, and the ratchet swing teeth are rotatably connected to the main shaft , the gravity assembly includes a gravity lock and a gravity lock plate, the gravity lock is fixedly mounted on the ratchet lock plate, the gravity lock is engaged with the gravity lock plate when it is in the first position, the gravity lock plate and The main shaft is fixedly connected, and the ratchet swing teeth are rotatably connected around the unlocking shaft of the ratchet swing teeth. Through the cooperation of the gravity component and the ratchet component, the one-way locking function of the armrest is realized; the problem in the prior art that the armrest cannot be kept horizontal after the seat back is rotated and affects the comfort of passengers is solved.

Owner:SCI SEATING (NINGBO) CO LTD

A sling structure for lifting and turning aircraft

Owner:CHINA ACAD OF LAUNCH VEHICLE TECH

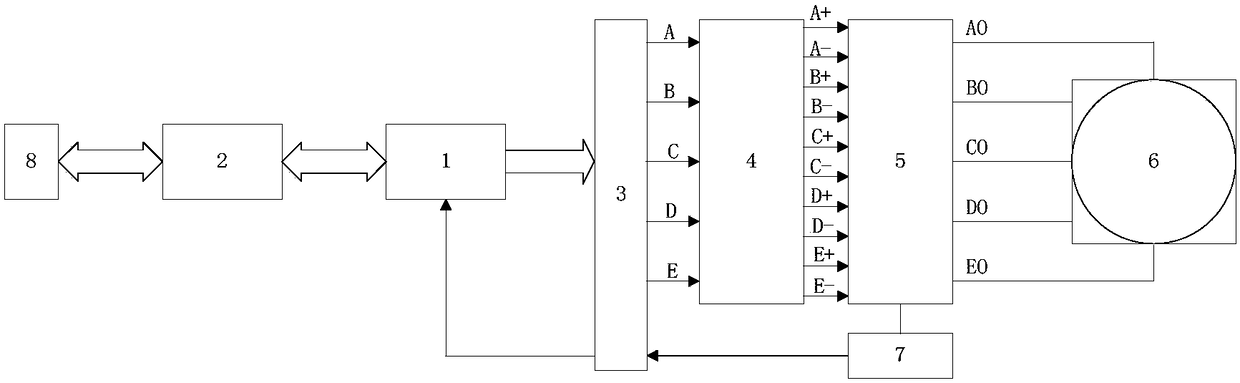

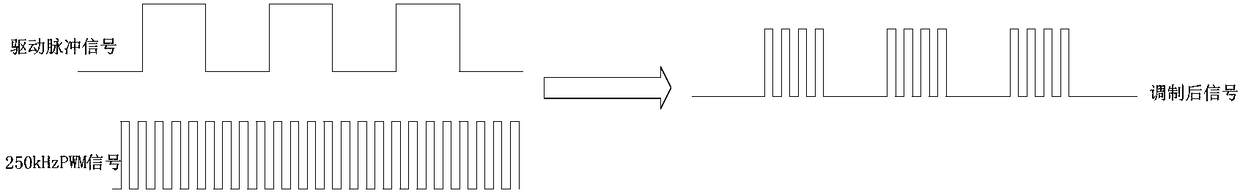

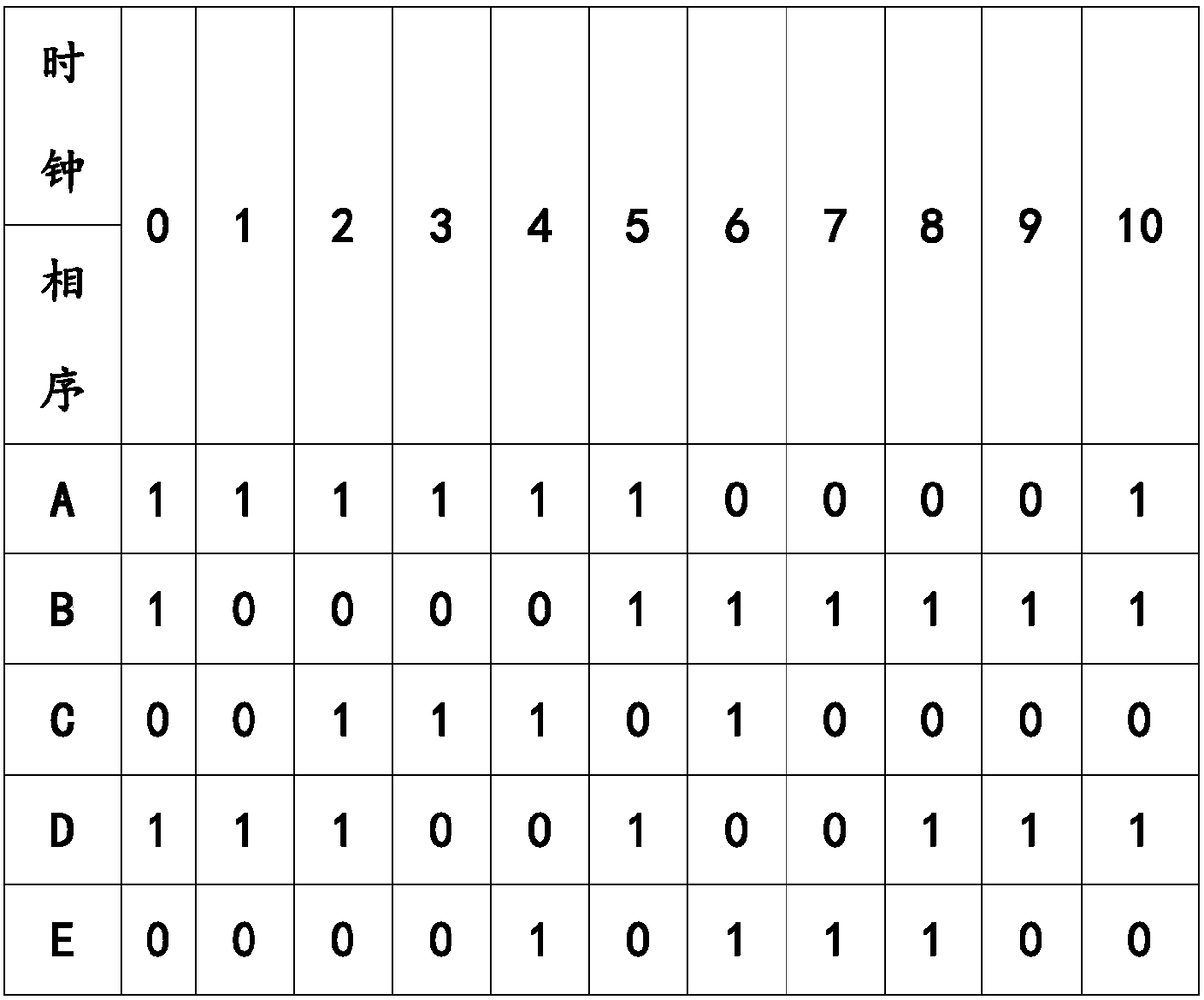

High-precision five-phase stepping motor driving and controlling device and method

InactiveCN108599642AReduce manufacturing costEasy to implementDynamo-electric converter controlSequence signalMicrocontroller

The invention relates to a high-precision five-phase stepping motor driving and controlling device and method. Through the high-precision five-phase stepping motor driving and controlling device provided by the invention, the precise driving and control of a five-phase stepping motor is completed, and a low-cost precise application scene for realizing the five-phase stepping motor can achieve highprecision and high stability requirements. The high-precision five-phase stepping motor driving and controlling device mainly comprises an upper PC, a serial port communication circuit, a single chipmicrocomputer circuit, a high-speed optical coupling isolation circuit, an MOSFET high-side / low-side driving circuit and an MOSFET circuit; the upper PC is connected with the single chip microcomputer circuit through the serial port communication circuit; the single chip microcomputer circuit sends a power-on phase sequence signal to the MOSFET high-side / low-side driving circuit after passing through the high-speed isolation circuit; the MOSFET high-side / low-side driving circuit is connected with the MOSFET circuit; and the MOSFET circuit is connected to each winding inside the five-phase stepping motor to be controlled.

Owner:西安明松电子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com