Pushing structure based on computer vision grading equipment

A computer vision and equipment technology, applied in sorting and other directions, can solve the problems of large force on the target object, affecting product quality, single structure and function of pushing material, etc., to achieve the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

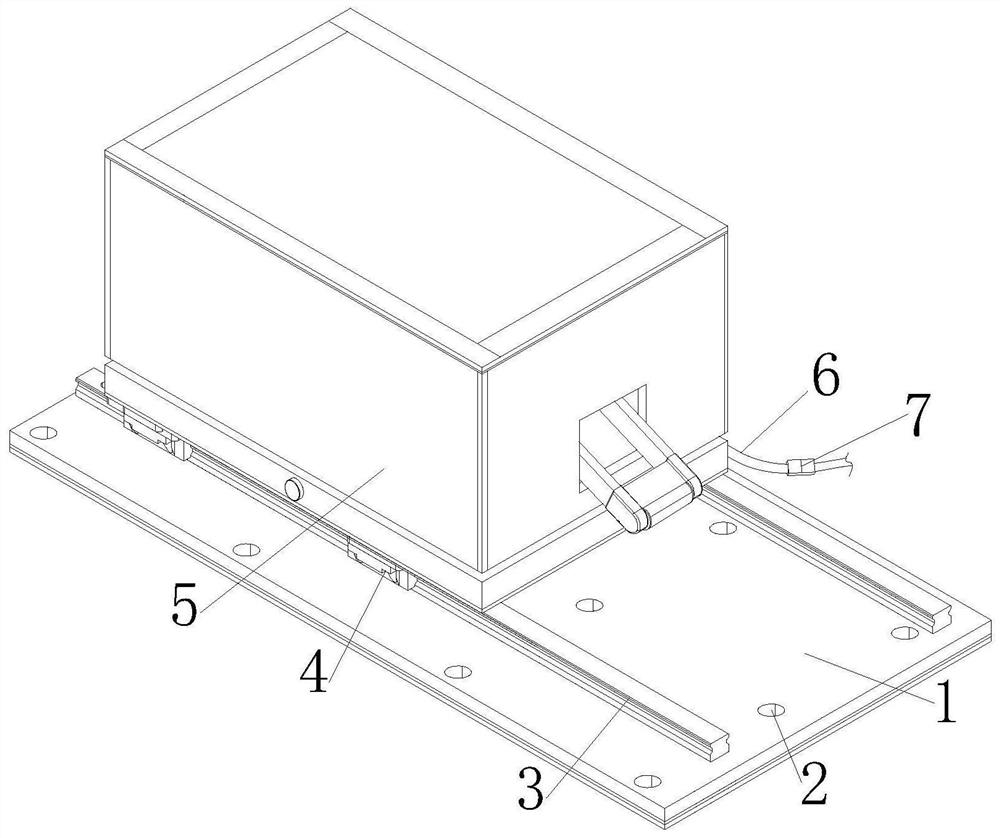

[0034] see figure 1 , a pusher structure based on computer vision grading equipment of the present invention includes a bottom plate 1, a fixing hole 2, a slide bar 3, a slider 4, a top material structure 5, a power cord 6 and a control switch 7, and the surface of the bottom plate 1 is provided with Fixing holes 2, two sliders 3 are fixed on the top of the bottom plate 1, and the top side of the sliders 3 is connected with the slider 4, a power line 6 is arranged on the rear side of the bottom plate 1, and a control switch 7 is installed on the inner side of the power line 6, and the top material The bottom side of the structure 5 is connected with the bottom plate 1, which is convenient for pushing the article and avoids a large thrust on the surface of the article.

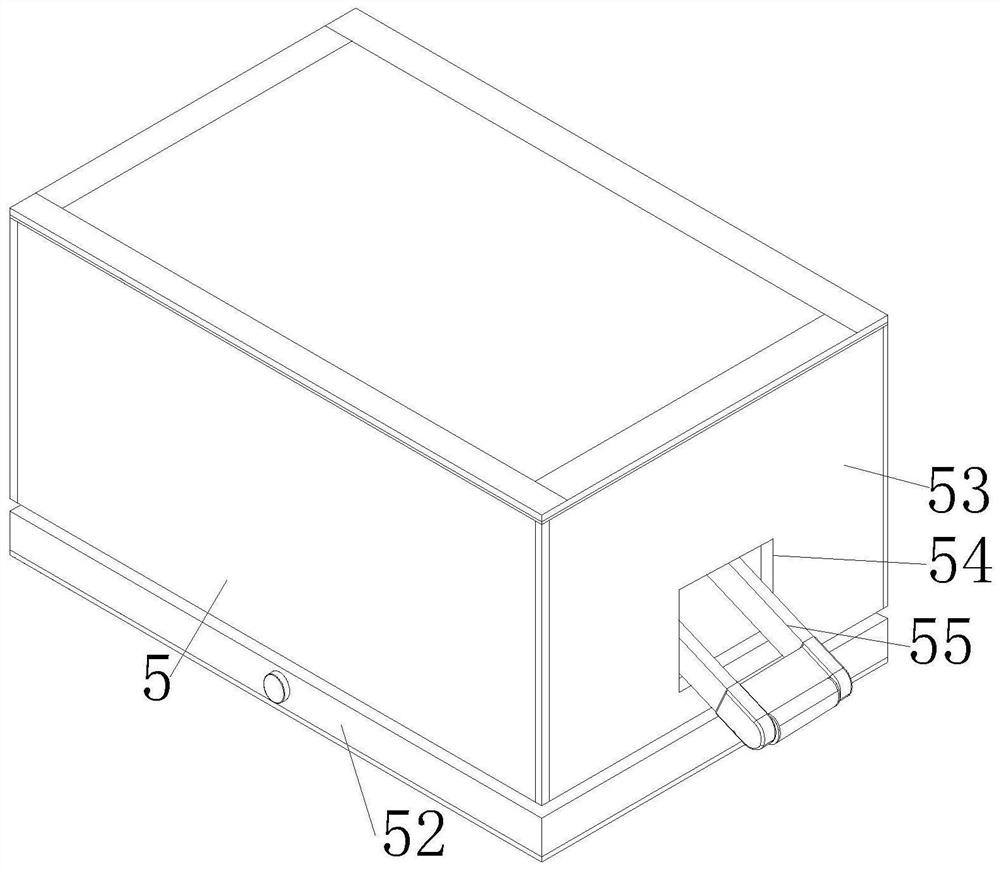

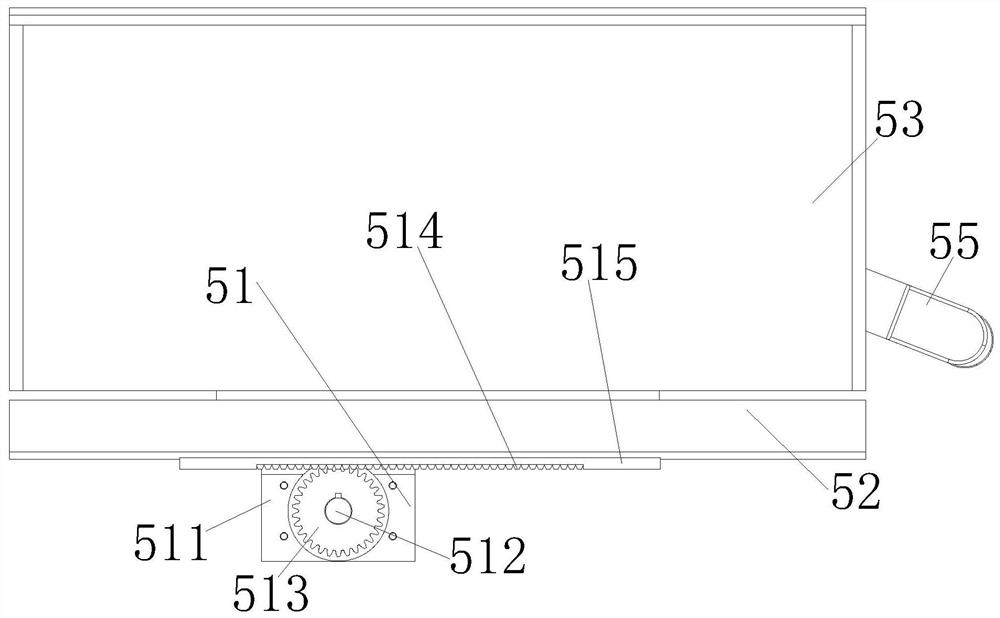

[0035] see figure 2 and image 3, a pusher structure based on computer vision grading equipment of the present invention, the ejector structure 5 includes a displacement assembly 51, a steering assembly 52, ...

Embodiment 2

[0039] In the pusher structure based on computer vision grading equipment of the present invention, the shifting assembly 51 is arranged at the middle side of the bottom of the steering assembly 52, and the front and rear sides of the bottom of the steering assembly 52 are fixed with the slider 4, which is beneficial to the steering assembly. 52 is shifted and supported to ensure stability. The middle side of the top of the rectangular seat 521 is provided with a circular opening, and a bearing ring is embedded inside the circular opening. The inner surface of the bearing ring is in contact with the pole 526 to ensure the rotation of the pole 526. The middle side of the link piece 555 is provided with a bar-shaped groove 5551, and the middle part of the boss 554 runs through the inner side of the bar-shaped groove 5551 to slide and connect with it, and the movement of the boss 554 in the bar-shaped groove 5551 drives the link piece 555 Rotate to ensure the stability of the tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com