Feeding machine capable of throwing bait for 360 degrees

A technology of a feeder and a bait box, which is applied to the field of 360-degree bait-casting feeders, can solve the problems of complex structure, limited bait-casting area, and large destructiveness of the discharging mechanism, and achieve the effect of large feeding area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The 360-degree bait throwing feeder of the present invention will be further described in detail below in conjunction with the accompanying drawings.

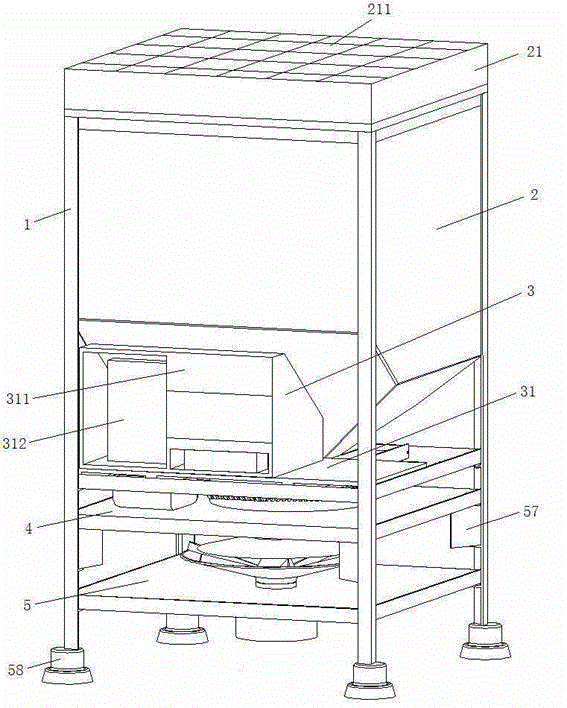

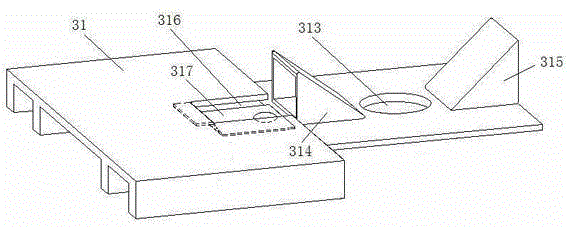

[0028] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 and Figure 10 , the 360-degree bait-throwing feeder of the invention includes a frame 1, the frame 1 is a vertical cuboid frame formed by a vertical angle iron and a horizontal angle iron, and the described frame is formed by a vertical angle iron A foot suction cup 58 is respectively provided at the lower ends of the vertical angle irons of the vertical cuboid frame formed by the horizontal angle irons.

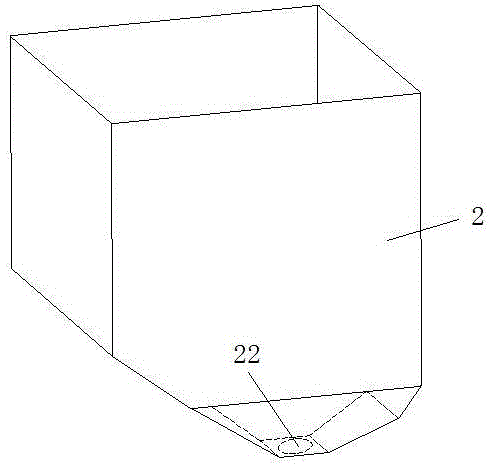

[0029] A bait box 2, a control box 3, a feed box 4 and a bait throwing layer 5 are successively established in the frame 1 from top to bottom.

[0030] One side of the upper port of the bait box 2 is spliced to connect an upper cover 21 with a solar panel 211 on the upper end surface, the lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com