Axle-free load type gear-free traction machine

A gear traction machine and shaftless technology, which is applied in the field of elevators, can solve the problems of decreased running quality of the traction machine, reduced service life of the traction machine, and vibration of the elevator running, and achieves increased power factor, easy manufacturing, and high power factor Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

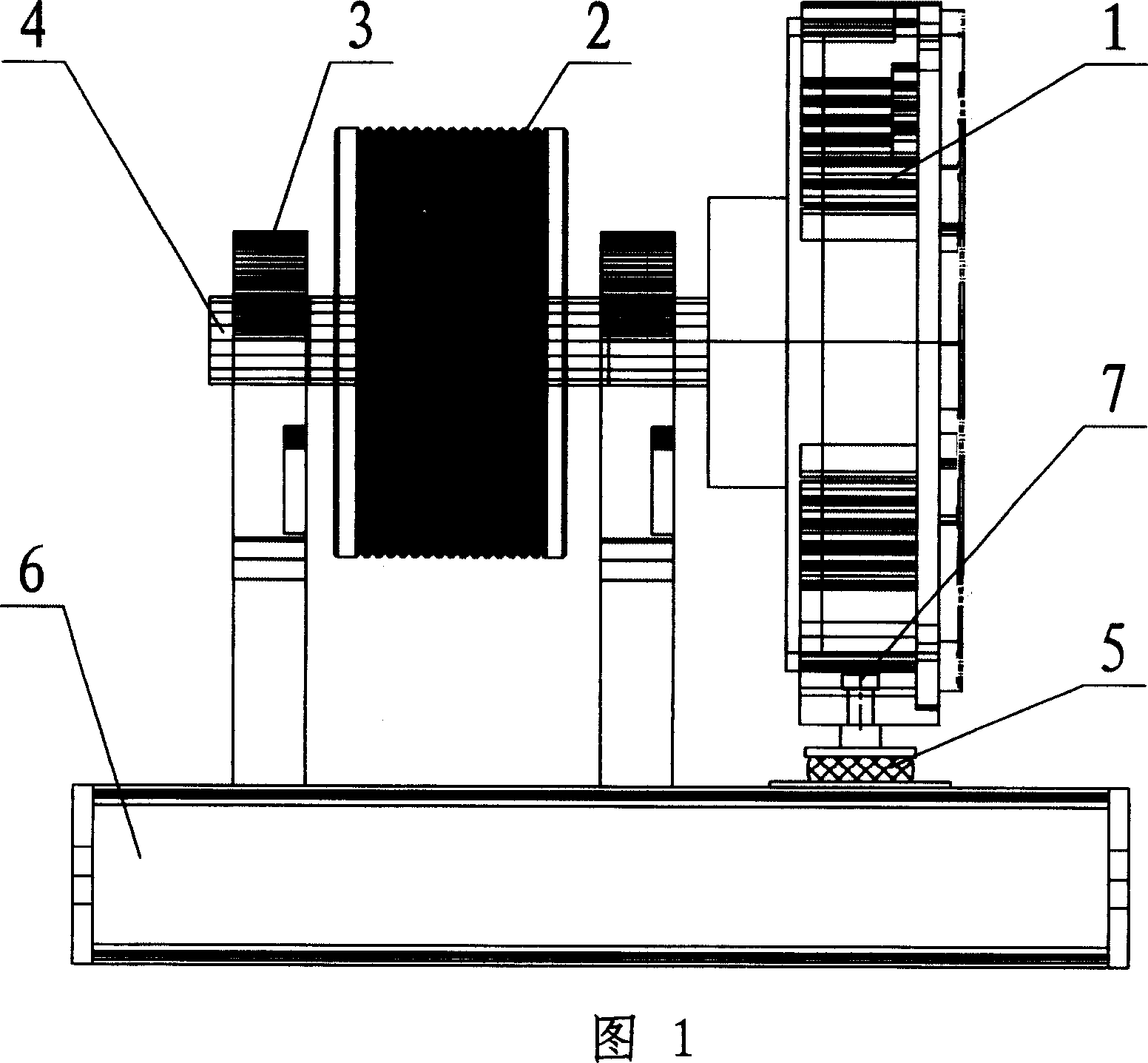

[0010] Two bearing frames 3 with bearings are installed on the base 6, the traction sheave 2 is first installed on the load-bearing main shaft 4, and then the load-bearing main shaft 4 and the traction sheave 2 are erected on the two bearing frames 3 through bearing installation. The traction motor 1 is installed on the shaft head of the load-bearing main shaft 4 protruding from the outer side of the bearing frame 3 . A flexible connection is used between the bottom of both sides of the traction motor 1 and the base 6. Firstly, a connecting seat is set on the base, and a rubber pad 5 is set in the cavity of the connecting seat. The installation hole of the motor is sleeved on the pressure adjustment screw, and the traction motor 1 is suspended on the soft connection seat formed by the rubber pad and the pressure adjustment screw. A traction motor 1 can be installed on the axle head at the outer end of the load-bearing main shaft 4 that stretches out from the bearing frame 3 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com