Speed sensor assembly of high-speed vehicle motor and manufacturing method thereof

A speed sensor, high-speed car technology, applied in the direction of linear/angular speed measurement, speed/acceleration/shock measurement, speed/acceleration/electric shock meter detailed information, etc., can solve problems such as pad damage, motor failure, loose hidden dangers, etc. Achieve the effects of improving the overall strength and watertightness, facilitating production management and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the embodiments of the accompanying drawings.

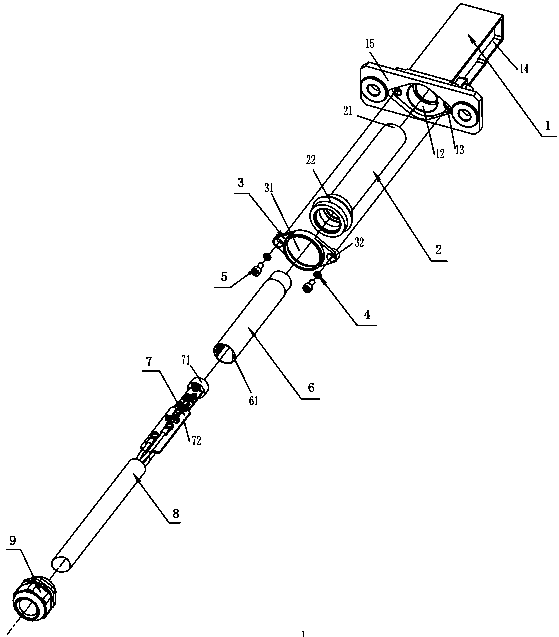

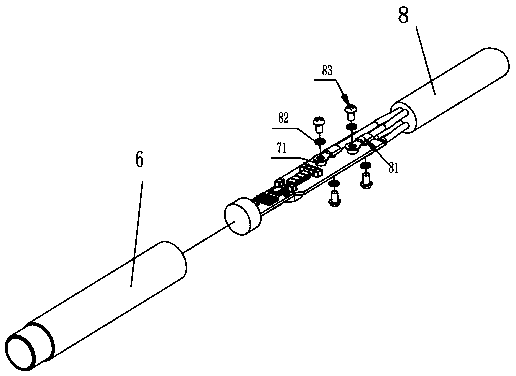

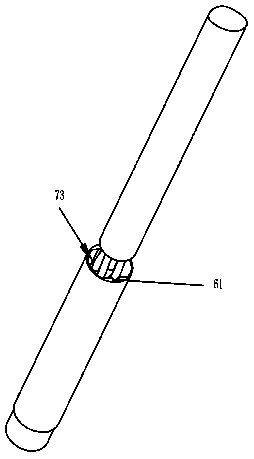

[0034] Such as Figure 1-7 As shown, the speed sensor assembly of a high-speed vehicle motor includes an outer shell 1, an inner shell 2, a gland 3, a printed board casing 6, a printed board assembly 7, a cable 8, and a waterproof pipe joint 9.

[0035] The head of the outer shell 1 is provided with the mounting hole 11 of the head 2 of the inner shell, and the tail of the outer shell 1 is a mounting part 15, and a gland hole 12 and an mounting hole 13 of the inner shell are respectively arranged on the mounting parts.

[0036] Hollows 11 are also provided on both sides of the housing 1, which can reduce the weight of the product without affecting the structural strength.

[0037] The above-mentioned inner shell 2 is an inner hollow cavity, the cavity head 21 is closed, the cavity head 21 extends out of the shell installation hole 11 and is limited ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com