Molten iron desilication method for stainless steel smelting

A stainless steel and desiliconization technology, applied in the manufacture of converters, etc., can solve the problems of high tapping temperature, limited desiliconization capacity, and large temperature drop of molten iron in blast furnaces, so as to prevent splashing, improve labor productivity, and reduce investment costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

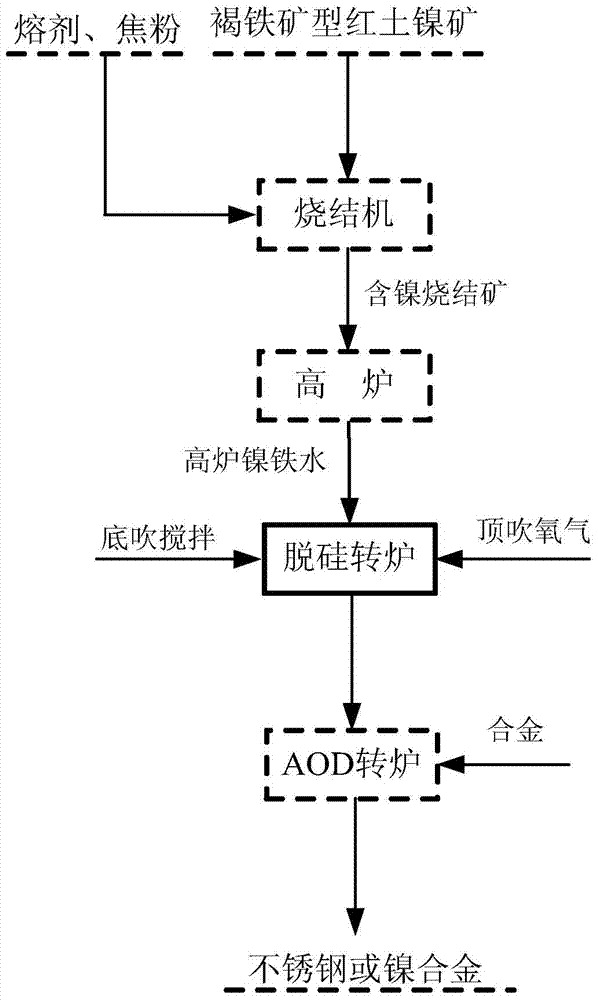

[0028] In order to better understand the object of the present invention, the method for desiliconization of molten iron for stainless steel smelting according to the present invention will be described in detail below in combination with the background of the present invention, flow chart and actual working conditions.

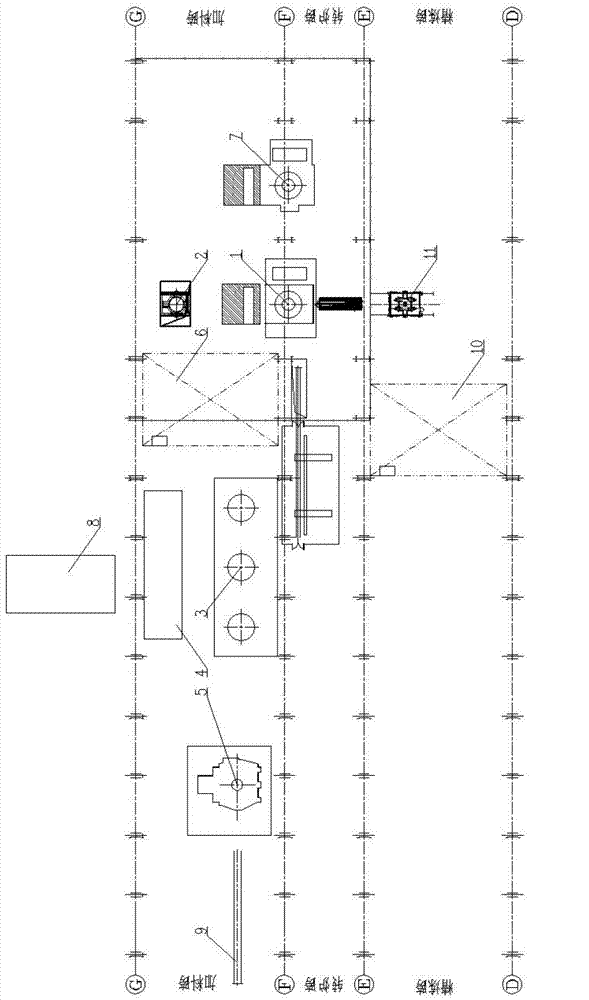

[0029] 1. Introduce the main equipment used in the molten iron desiliconization process for stainless steel smelting:

[0030] Two 318m 3 Ironmaking blast furnace: used to melt the nickel-containing sinter formed by laterite nickel ore, flux, and coke powder into nickel-containing high-silicon molten iron;

[0031] Two 40t intermediate frequency furnaces: used to melt scrap steel and alloys;

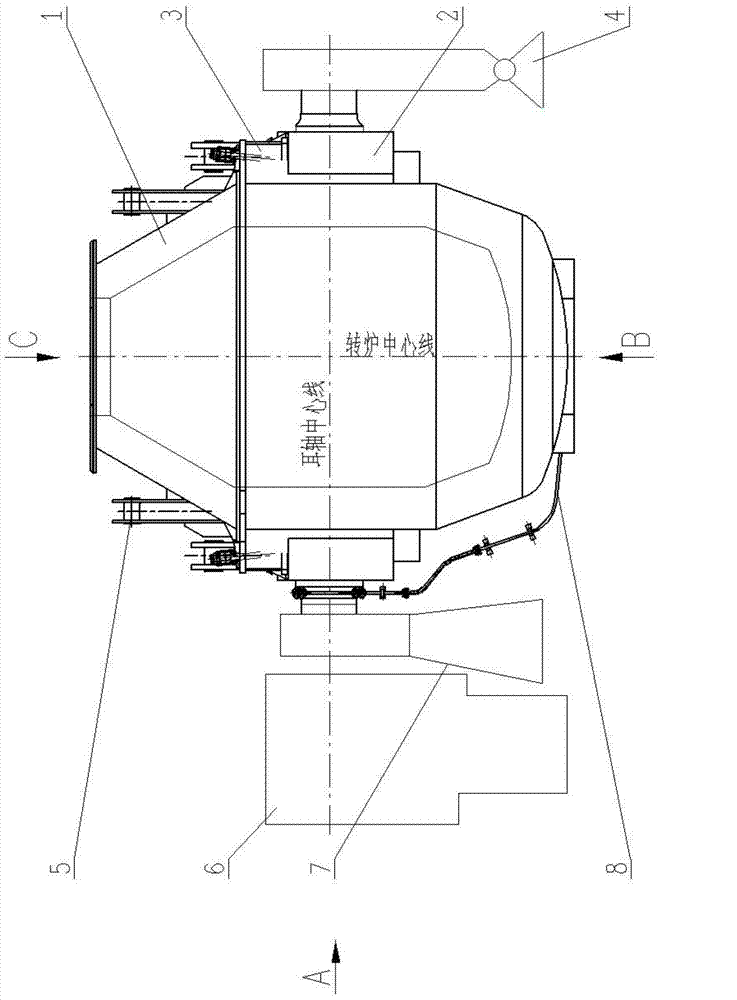

[0032] A 110t desiliconization converter 1: used for desiliconization, decarburization, dephosphorization and desulfurization to obtain stainless steel

[0033] semi-steel;

[0034] A 120tAOD converter 7: The final smelting of stainless steel.

[0035] 2. The specif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com