Preparation method and application of titanium-modified hierarchical pore mordenite

A technology of mordenite and mordenite, which is applied in the preparation of titanium-modified multi-level porous mordenite and its application field, can solve the problems of low conversion capacity of thiophene sulfur-containing compounds and high catalyst cost, and achieve good catalytic activity, multiple Effect of reaction space and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

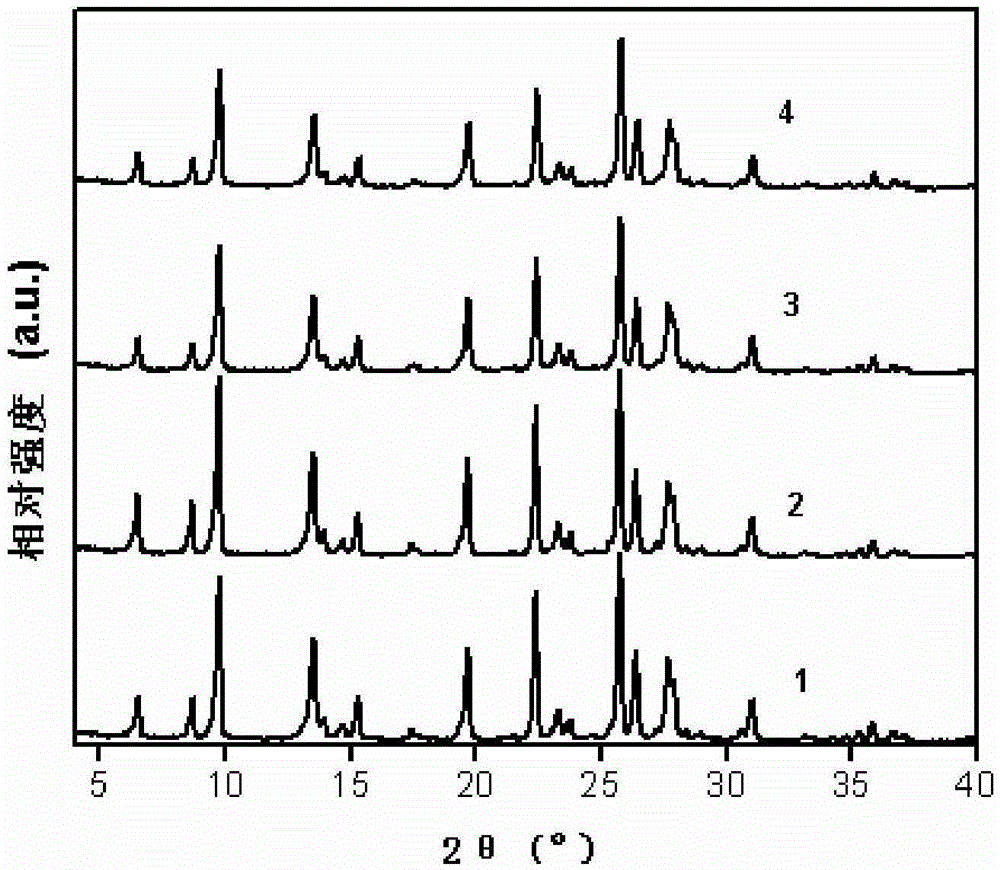

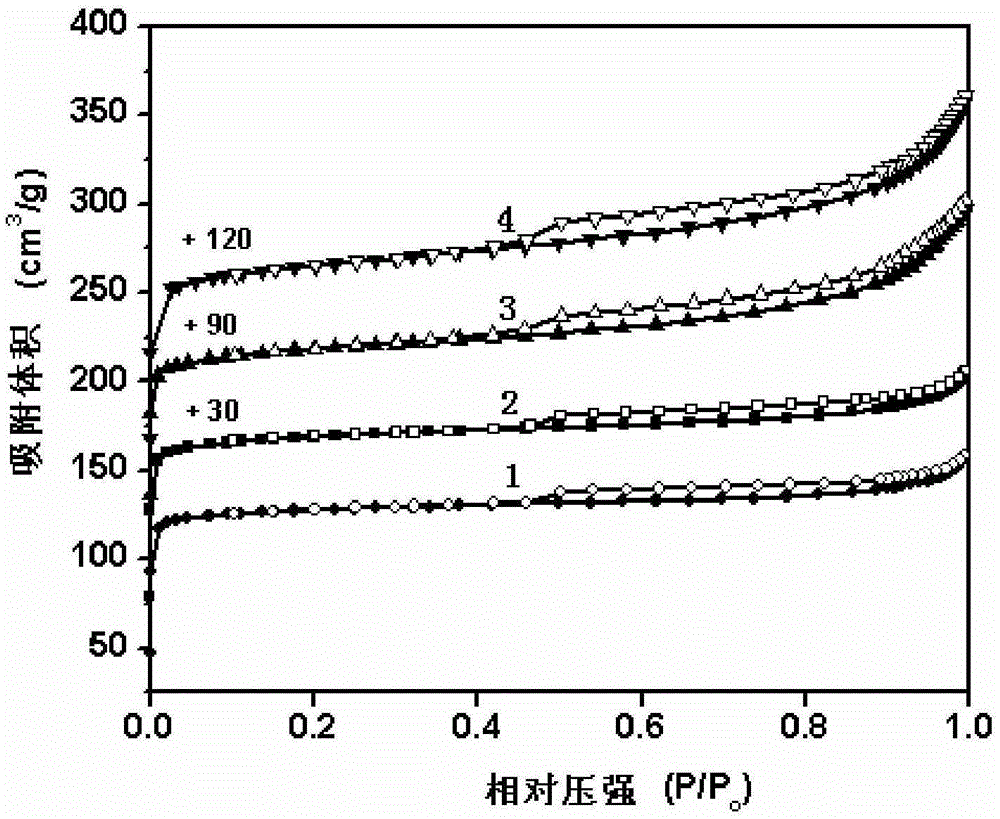

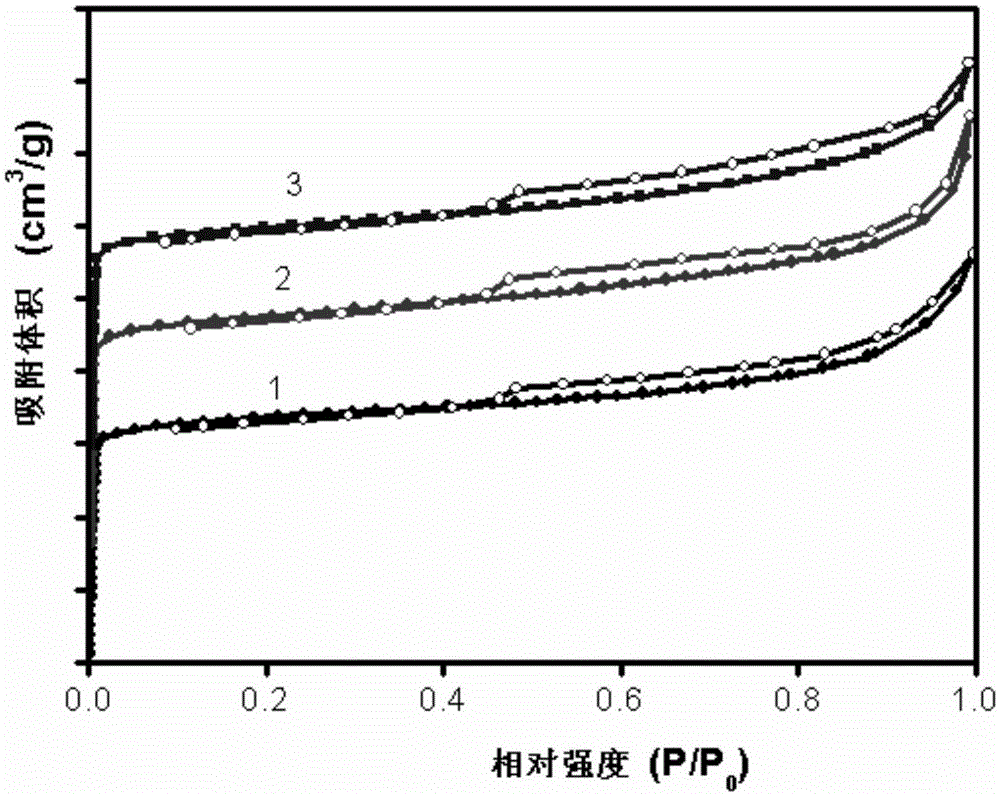

[0027] Specific embodiment one: the preparation method of the titanium-modified hierarchically porous mordenite of the present embodiment is specifically carried out according to the following steps:

[0028]1. Mix 10-25g of silicon source, 1-3g of aluminum source, 3-5g of NaOH and 30-50mL of deionized water evenly, and then crystallize at a temperature of 150-200°C for 2-7 days to obtain sodium mordenite. Add ammonium nitrate aqueous solution, exchange 2 to 4 times, and each exchange time is 1.5 to 3 hours to obtain ammonium-type mordenite, and then calcinate at a temperature of 500-550 ° C for 2-6 hours to obtain hydrogen-form mordenite; wherein, The solid-to-liquid ratio of sodium mordenite and ammonium nitrate aqueous solution in the exchange process is 1g:(15~30)mL;

[0029] 2. Add the hydrogen mordenite obtained in step 1 to HNO 3 In the aqueous solution, reflux at a temperature of 90-110°C for 1.5-4 hours, wash with deionized water until the filtrate is neutral, then d...

specific Embodiment approach 2

[0033] Embodiment 2: This embodiment differs from Embodiment 1 in that: in step 1, the silicon source is silicic acid, tetraethyl orthosilicate or organosilane, and the aluminum source is sodium metaaluminate or alumina. The other specific embodiments are the same.

specific Embodiment approach 3

[0034] Embodiment 3: This embodiment differs from Embodiment 1 in that: the concentration of the ammonium nitrate aqueous solution in step 1 is 0.5-2 mol / L. The other specific embodiments are the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com