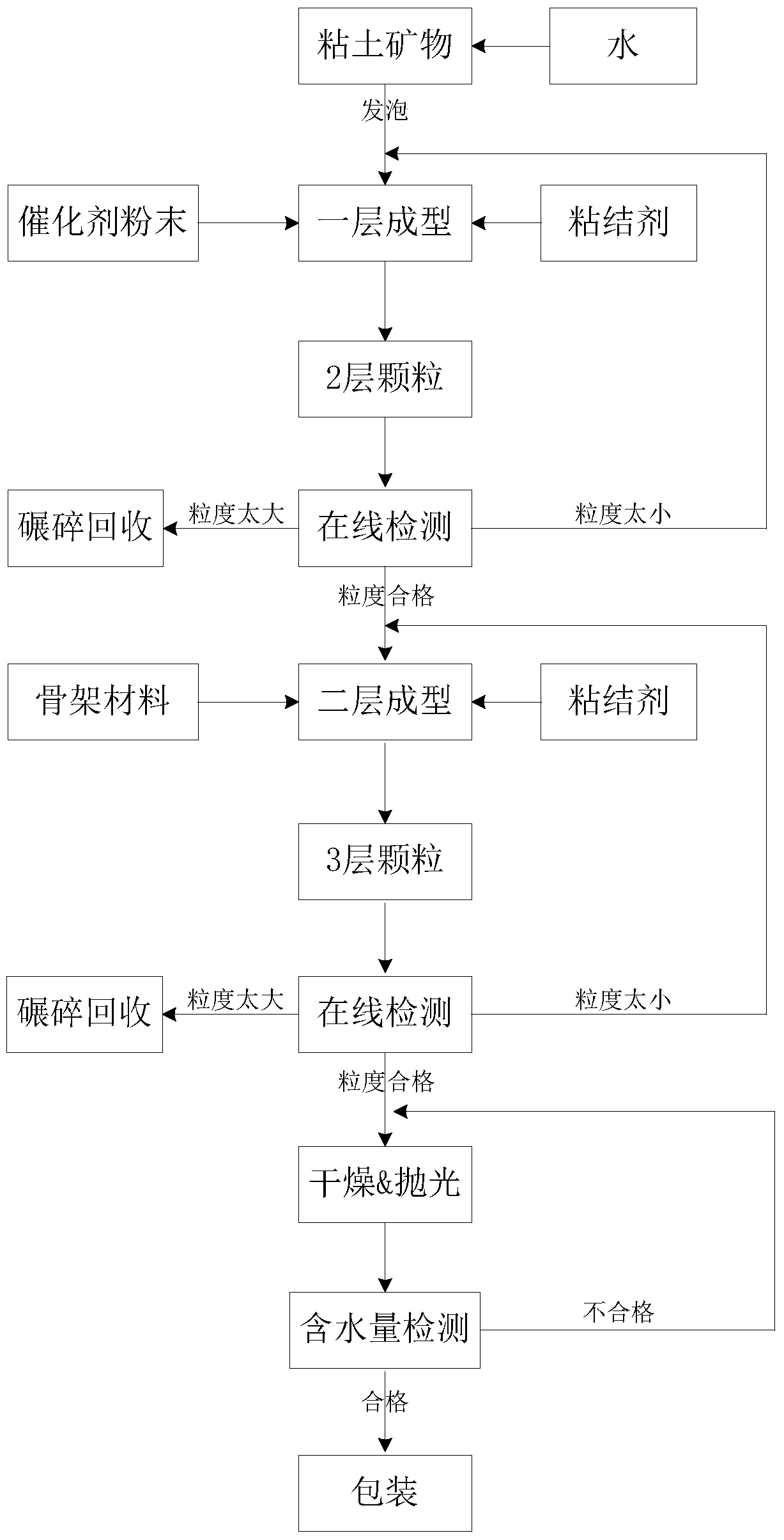

A kind of catalyst particle for air purifier and its layer-by-layer overmolding method

A catalyst particle and catalyst layer technology, which is applied in chemical instruments and methods, physical/chemical process catalysts, catalyst protection, etc., can solve problems such as difficult automatic control, and achieve improved purification efficiency, high catalytic efficiency, and increased contact area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

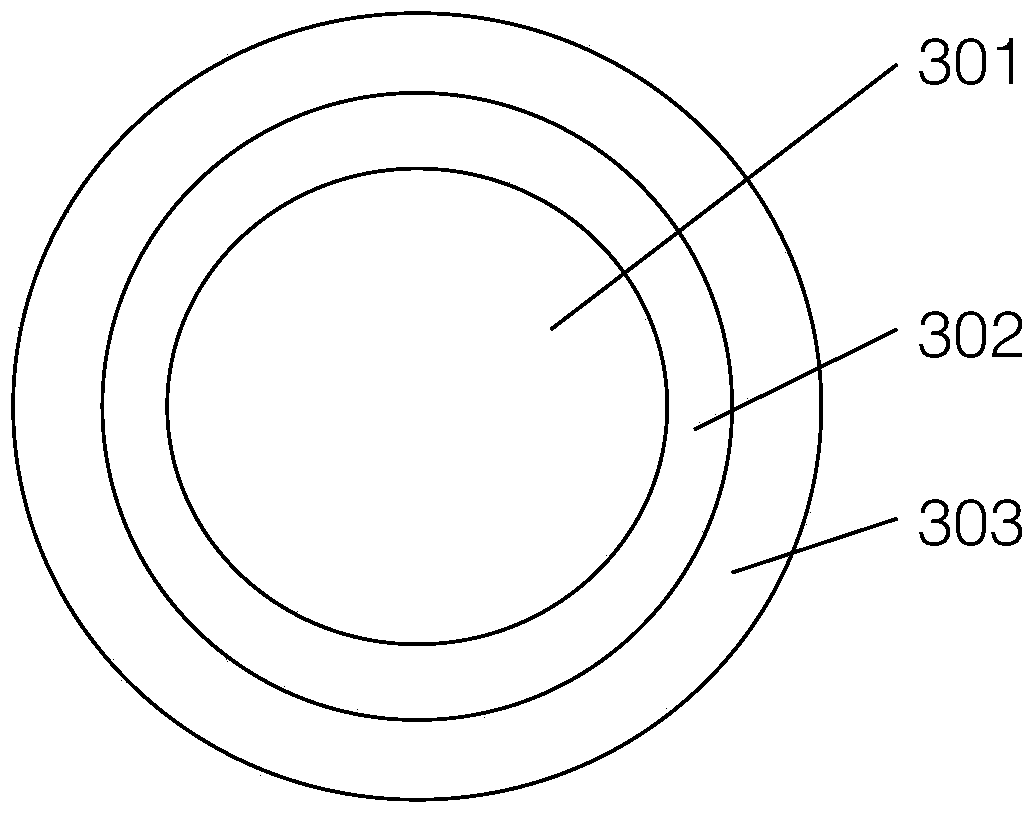

Embodiment 1

[0059] Add 2g of water to 2g of diatomaceous earth, sieve the obtained core after the mixing is completed, take 0.4-0.6mm particles and add them to the sugar coating machine, and the rotation speed is 30 rpm. Add silica sol with a mass solubility of 20% at a rate of 2mL / min, and at the same time add catalyst powder at a rate of 5g / min, and collect 1.5-1.8mm particles through online detection to enter the next coating process. Add the above granules to another sugar-coating machine operating at the same speed, add silica sol with a mass solubility of 20% at a rate of 2mL / min, and simultaneously add activated carbon powder at a rate of 20g / min, and collect 2 -3mm particles. Add the above-mentioned collected granules to a drum dryer at 90°C and a rotating speed of 5r / min for drying and polishing, and take out the dried granules after 30 hours to be the final product.

[0060] Through BET test (see table 1), show that prepared catalyst particle specific surface area is at 550-700...

Embodiment 2

[0063] Add 1.5g of water to 1.5g of sepiolite, sieve the obtained core after the mixing is completed, take 0.4-0.6mm particles and add them to the sugar coating machine, and the rotation speed is 35 rpm. The CMC aqueous solution with a mass solubility of 20% was added at a rate of 5mL / min, and the catalyst powder was added at a rate of 5g / min at the same time, and particles of 1.5-1.8mm were collected by online detection to enter the next coating process. Add the above granules to another sugar coating machine running at the same speed, add a CMC aqueous solution with a mass solubility of 20% at a rate of 5mL / min, and simultaneously add silicon micropowder at a rate of 18g / min, and collect 2 -3mm particles. Put the above-mentioned collected granular products into a drum dryer with a temperature of 120°C and a rotational speed of 4 r / min for drying and polishing, and take out the dried particles after 20 hours to be the final product.

[0064] The performance test of the parti...

Embodiment 3

[0066]Add 1g of water to 1g of diatomaceous earth, sieve the obtained core after the mixing is completed, take 0.4-0.6mm particles and add them to the sugar coating machine, and the rotation speed is 20 rpm. Alumina sol with a mass solubility of 20% was added at a rate of 1 mL / min, and catalyst powder was added at a rate of 5 g / min, and particles of 1.5-1.8 mm were collected by online detection to enter the next coating process. Add the above granules to another sugar-coating machine operating at the same speed, add alumina sol with a mass solubility of 20% at a rate of 1mL / min, and add diatom mud at a rate of 15g / min at the same time, and pass the online detection Collect particles of 2-3 mm. Add the above-mentioned collected granules to a drum dryer with a temperature of 100°C and a rotational speed of 3r / min for drying and polishing, and take out the dried granules after 28 hours to be the final product.

[0067] The particle performance test is the same as in Example 1. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com