A low energy consumption insulator box and electric tar capture device

An insulator, low energy consumption technology, applied in the field of low energy consumption and long life electric capture equipment, can solve the problems of high energy consumption, corona wire breakage and other problems, to eliminate stress and fragile, ensure long life, and reduce use costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

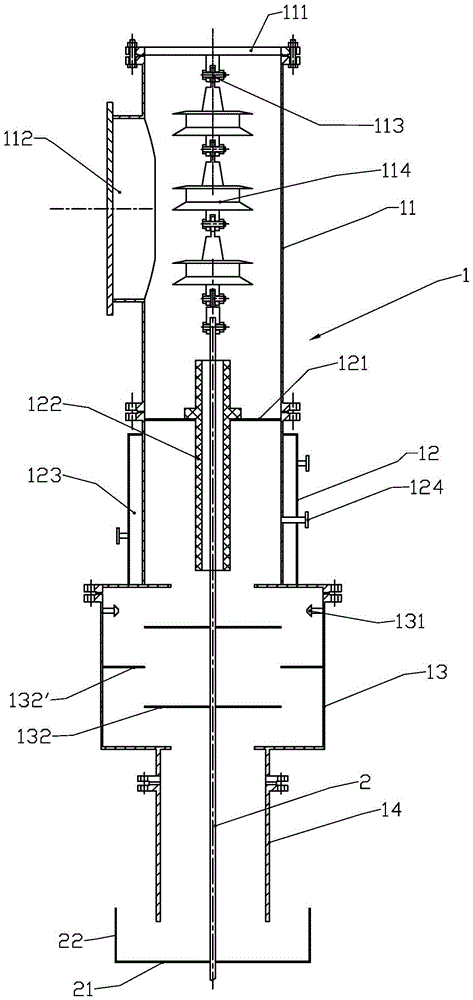

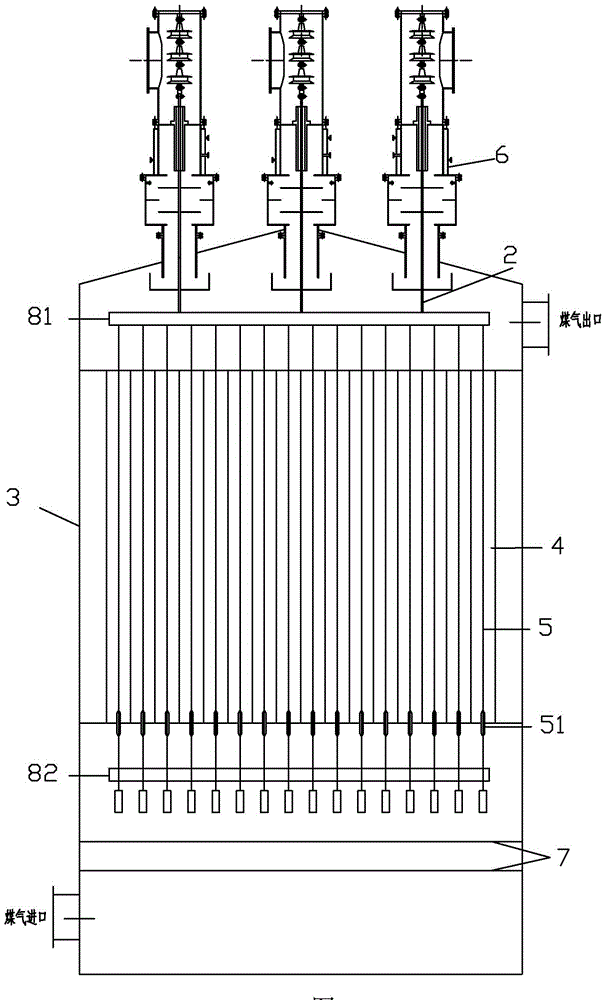

[0032] Such as figure 1 As shown, a low-energy insulator box includes a vertically arranged cylinder 1 connected to the ground, and the cylinder is sequentially composed of a silica gel insulator section 11, a vertical ceramic insulator section 12, and a labyrinth ionization section from top to bottom. 13 and cover type barrier ionization section 14. The structure and description are described below.

[0033] The silicone insulator section 11 is a cylindrical shell made of steel plate, the top is an air outlet 111, and the side is provided with a maintenance manhole 112. The top of the inner cavity of the rubber insulator section is provided with a suspension point 113, and there are three series connected in series suspended at the suspension point. A silicone insulator 114 is used for power feeding.

[0034] The lower end of the silicone insulator is connected with a pull rod 2 extending downwards and passing through the inner cavity of the vertical ceramic insulator secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com