Near-remote distance comprehensive transfer placing system for building

A long-distance, building technology, applied in building construction, construction, building maintenance, etc., can solve problems such as the inability to guarantee the stability of the building and the unpredictable internal stress of the building, so as to enhance the jacking effect and reduce the Wear and improve the effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

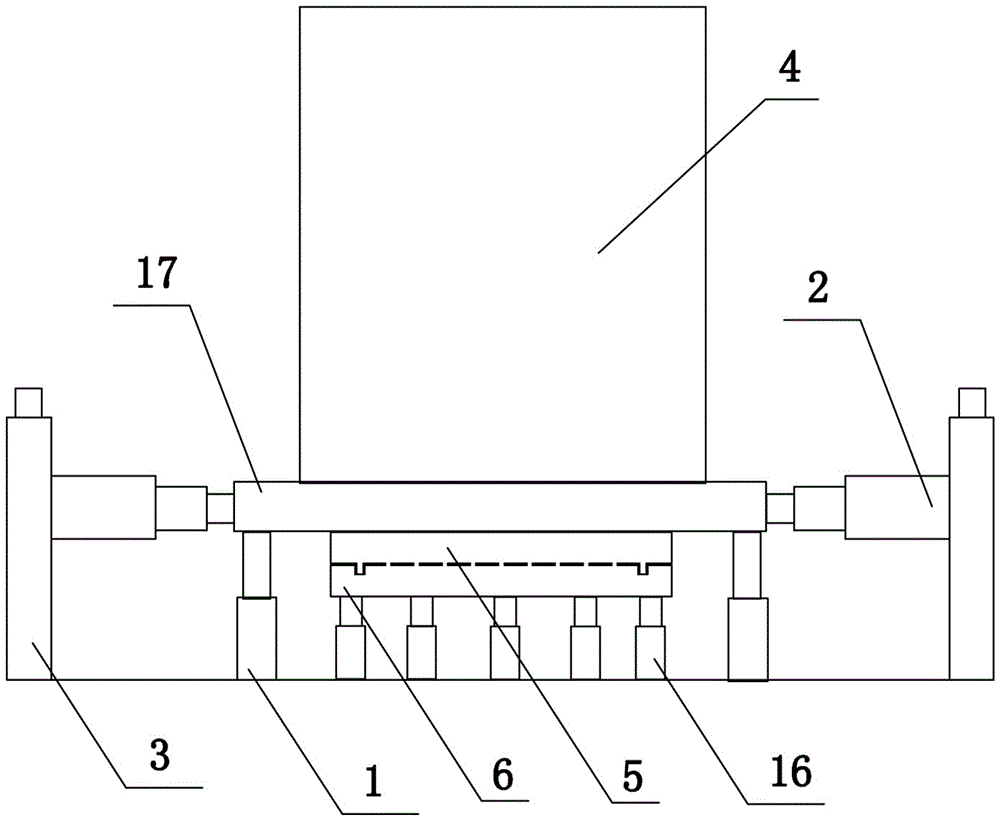

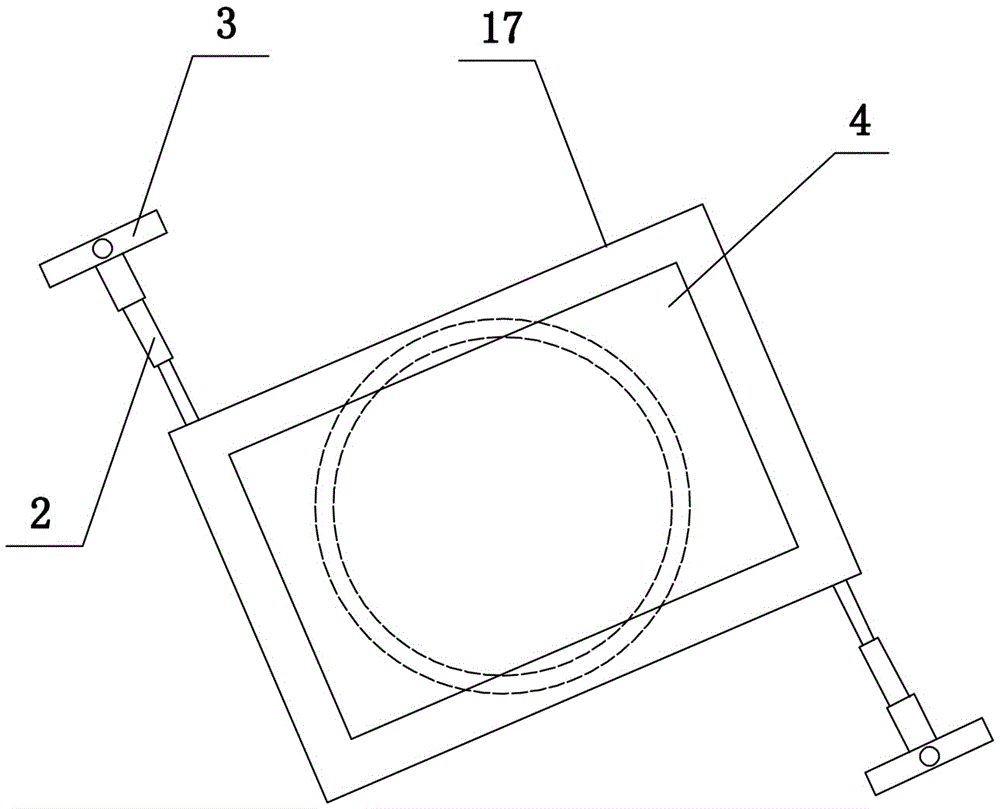

[0032] Such as Figure 1 to Figure 3 As shown, the present invention includes a translation track mechanism, a positioning mechanism, a jacking mechanism, an underpinning beam, a monitoring mechanism and a rotating mechanism. Multiple position sensors and pressure sensors on the extension mechanism, the monitoring mechanism is electrically connected with the positioning mechanism and the jacking mechanism respectively, the monitoring mechanism uses an automatic control system, the automatic control system receives the signals of the position sensor and the pressure sensor, and controls the jacking mechanism. pushing parameters, such as figure 1 As shown, the jacking mechanism includes the first jack group 1 and the third jack group 16 arranged vertically, the second jack group 2 and the reaction column 3 arranged horizontally, and the rotating mechanism is arranged on the underpinning beam The lower end surface, the rotating mechanism includes the upper rotating foundation 5 ...

Embodiment 2

[0036] Such as Figure 4 to Figure 8 As shown, the structure of this embodiment is basically the same as that of Embodiment 1, the difference is: the center of the lower rotating base 6 is provided with a rotating shaft 9, the upper rotating base 5 is provided with a rotating hole matched with the rotating shaft 9, and the reaction column 3 includes The load-bearing beam 10 and the fixed base 11, the fixed base 11 is fixedly connected with the positioning shaft 12, the fixed base 11 is provided with a scale line 13, the load-bearing beam 10 is provided with a positioning hole that cooperates with the positioning shaft 12, and the positioning hole and the positioning shaft 12 A damping mechanism 14 is arranged between them, and the load-bearing beam 10 is provided with an accommodating chamber 15, the diameter of which is slightly larger than the diameter of the bottom of the jack in the second jack group 2.

[0037] In this embodiment, by adding a rotating hole and a rotating ...

Embodiment 3

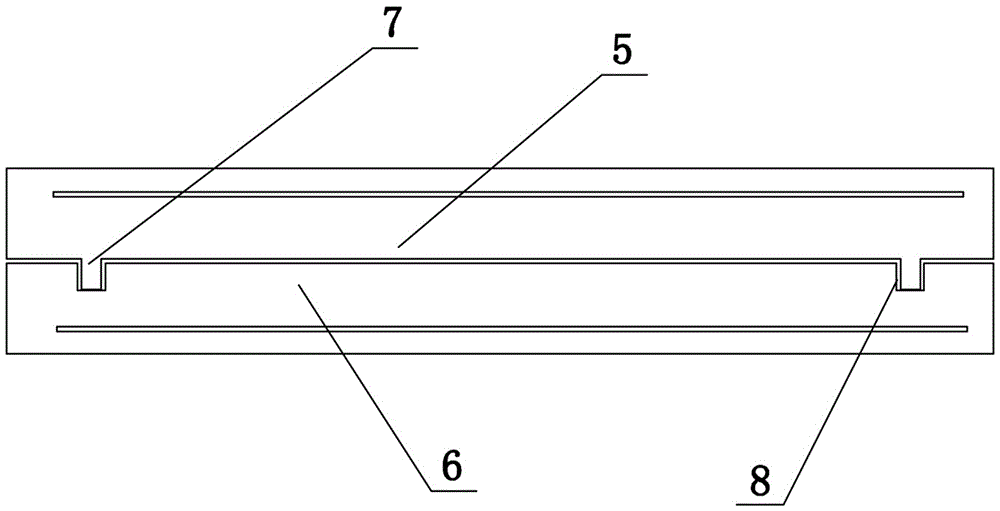

[0039] The structure of this embodiment is basically the same as that of the implementation two, the difference is: as Figure 7 As shown, the upper rotating base 5 is provided with a plurality of annular protrusions 7, the lower rotating base 6 is provided with a plurality of annular grooves 8, and the upper rotating base 5 and the lower rotating base 6 pass through a plurality of annular protrusions 7 and a plurality of annular grooves. 8 slide and cooperate with each other to realize the rotational connection between the two, the multiple annular protrusions 7 and the multiple annular grooves 8 are conducive to increasing the contact area between the upper rotating base 5 and the lower rotating base 6, and improving the structural stability of the rotating mechanism sex.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com