Rotating electric arc welding torch with stepless eccentricity adjusting function and adjusting method thereof

A rotary arc welding, stepless adjustment technology, applied in the characteristics of electrodes, welding accessories, electrode support devices, etc., can solve the problems of severe vibration, complex assembly, inconvenient adjustment of eccentric radius, etc., to ensure stability and ensure rotation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The structure and working principle of a non-polar eccentric rotating arc welding torch suitable for welding will be further described in detail below.

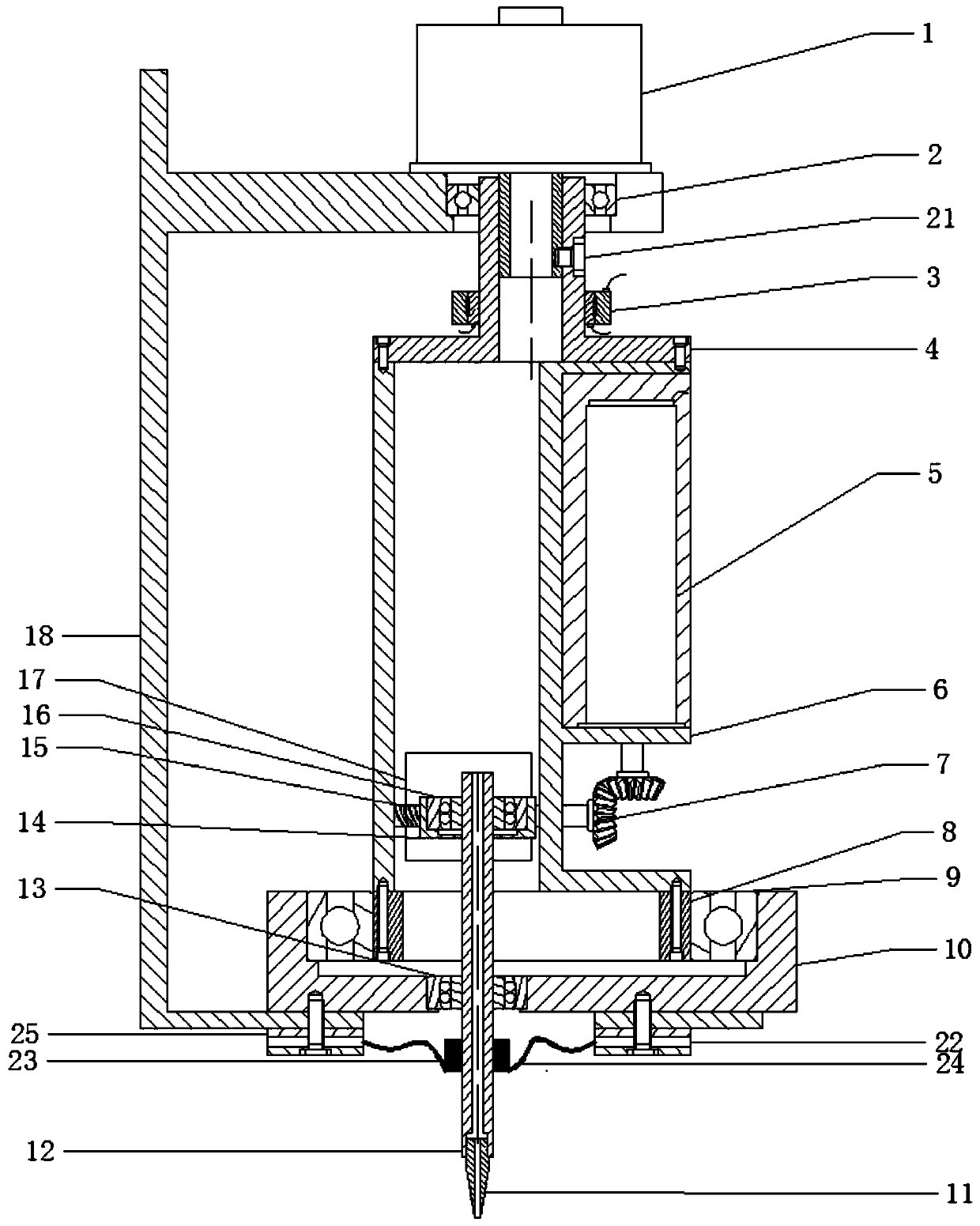

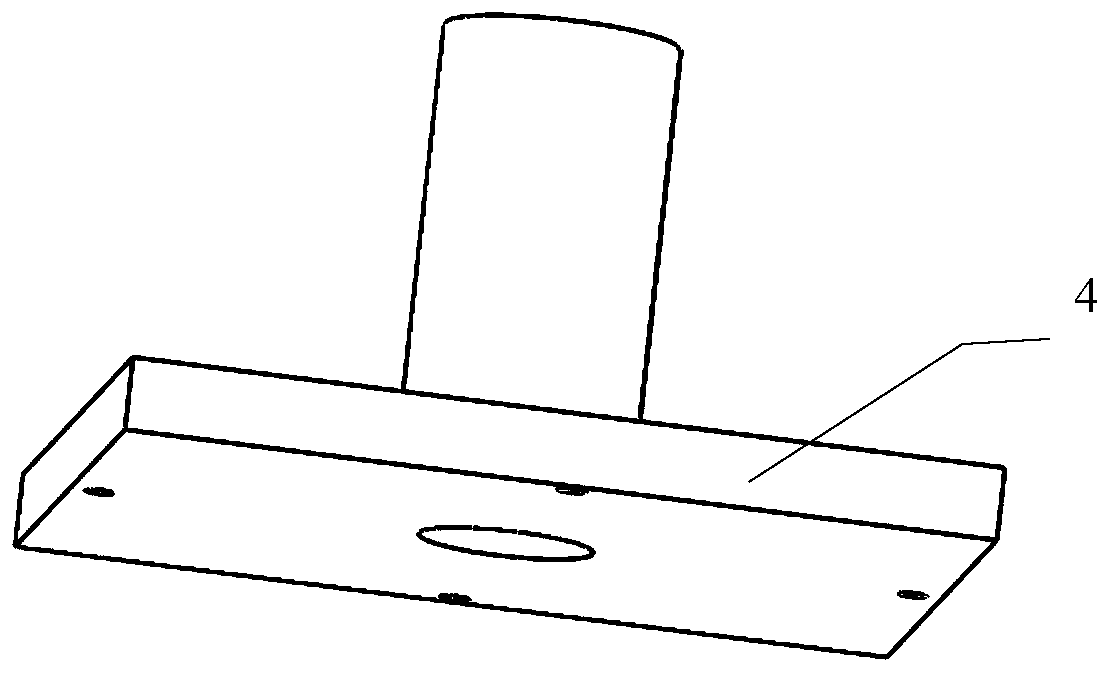

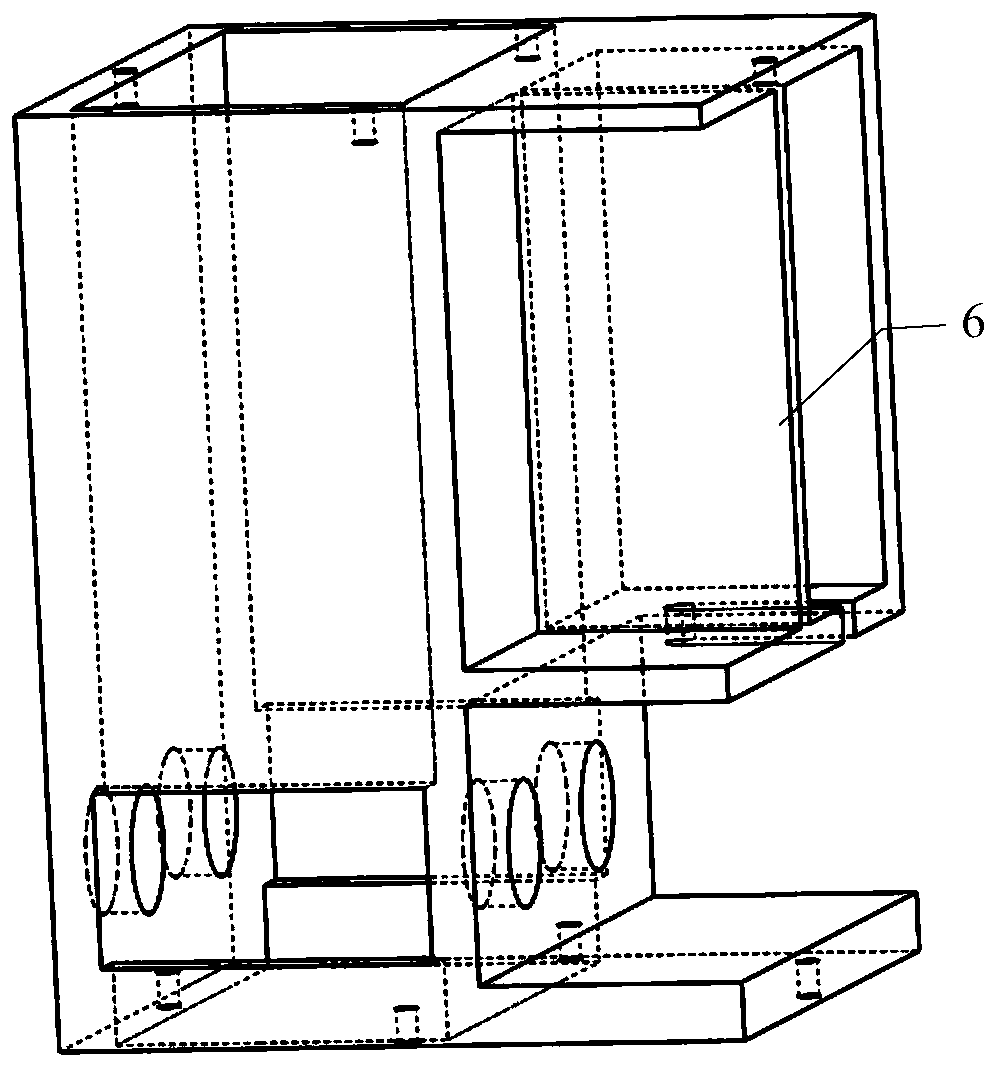

[0031] Such as figure 1 As shown, the steplessly adjustable eccentric rotating arc welding torch is composed of a frame 18, a hollow shaft motor 1, a rotating sleeve, a fixed bearing sleeve 10, and a feed system. Wherein the rotating sleeve is composed of three parts, namely an upper sleeve 4 , a middle sleeve 6 and a lower sleeve 8 . Wherein the eccentric platform is made up of the center ball bearing 16, the center ball bearing sleeve 14, the eccentric adjustment motor 5, the ball bearing 20, the bevel gear 7, the polished rod 19 and the screw mandrel 15, and the center bearing 13 is formed. The feed system includes a conductive plate 22 , a spring carbon brush 23 , a flexible cable 24 , an insulating washer 25 , a conductive rod 12 , and a conductive tip 11 .

[0032] Such as figure 1 As shown, the side of the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com