Vehicle cleaning shed with automatic vehicle cleaning function

An automatic car washing and functional technology, applied in the field of car wash sheds, can solve the problems of insufficient cleaning and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

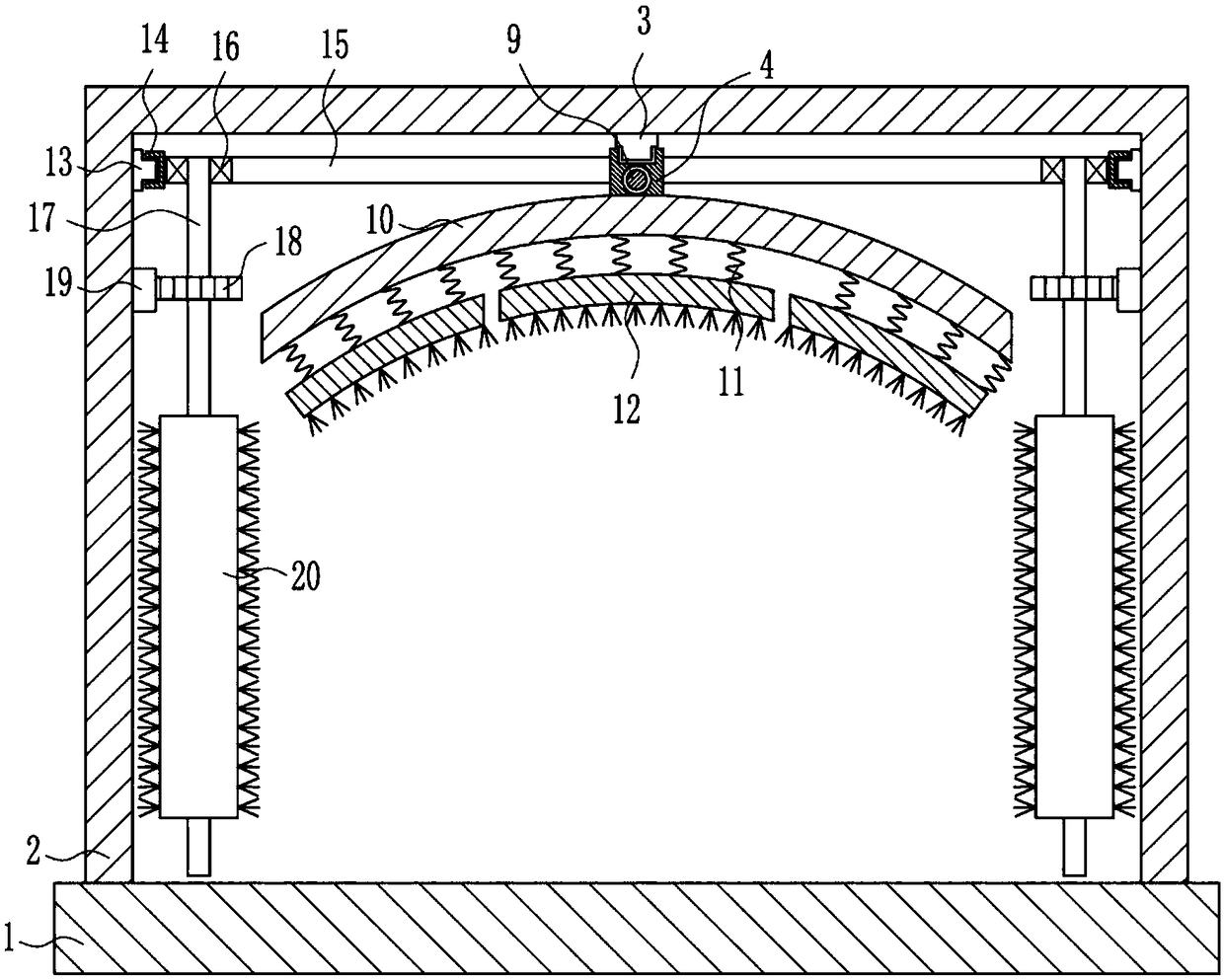

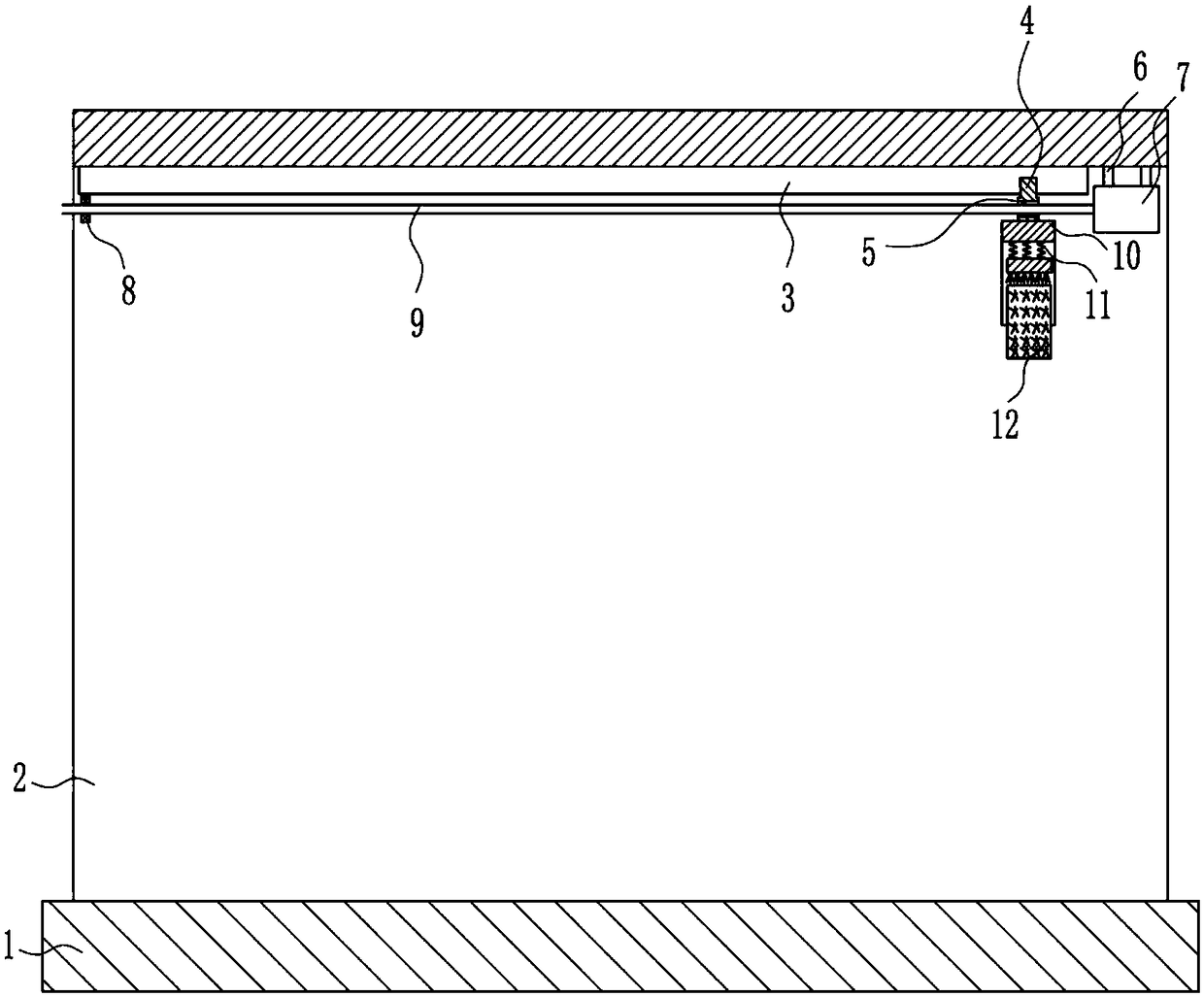

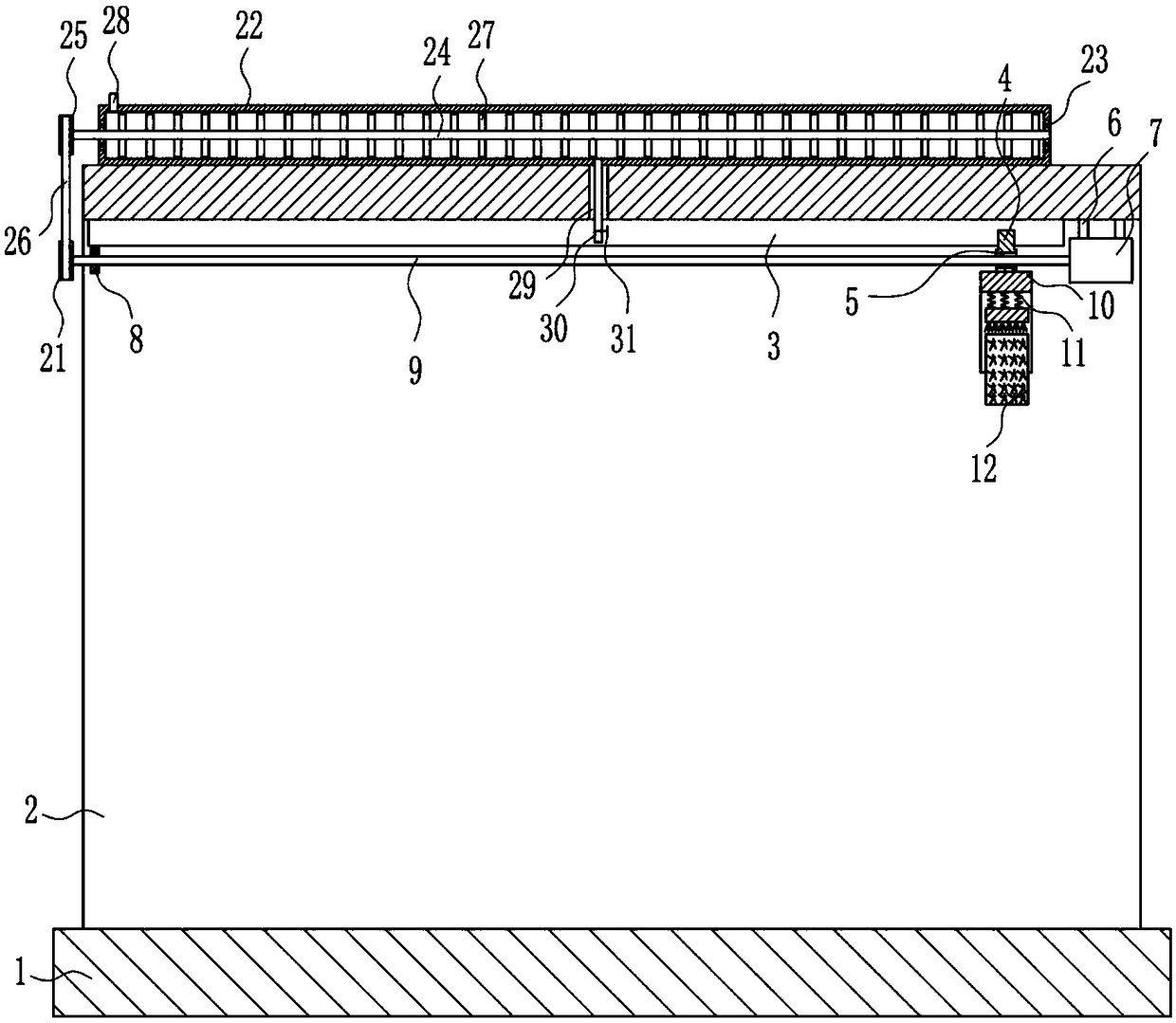

[0022] A car wash shed with automatic car wash function, such as Figure 1-5 As shown, it includes an n-shaped frame 2, a first slide rail 3, a first slider 4, a vertical rod 6, a first motor 7, a first bearing seat 8, a screw rod 9, an arc plate 10, and a first spring 11 , arc-shaped brush 12, second slide rail 13, second slide block 14, cross bar 15, second bearing seat 16, second rotating shaft 17, gear 18, rack 19 and brush roller 20, installed on the ground 1 There is an n-shaped frame 2, a first slide rail 3 is installed in the middle of the inner top of the n-shaped frame 2, and the first slide rail 3 is slidably provided with a first slide block 4, and the first slide block 4 is provided with a threaded hole 5, n A vertical bar 6 is installed on the middle rear side of the inner top of the frame 2, a first motor 7 is installed on the bottom end of the vertical bar 6, a first bearing seat 8 is installed on the front side of the bottom of the first slide rail 3, and the ...

Embodiment 2

[0024] A car wash shed with automatic car wash function, such as Figure 1-5As shown, it includes an n-shaped frame 2, a first slide rail 3, a first slider 4, a vertical rod 6, a first motor 7, a first bearing seat 8, a screw rod 9, an arc plate 10, and a first spring 11 , arc-shaped brush 12, second slide rail 13, second slide block 14, cross bar 15, second bearing seat 16, second rotating shaft 17, gear 18, rack 19 and brush roller 20, installed on the ground 1 There is an n-shaped frame 2, a first slide rail 3 is installed in the middle of the inner top of the n-shaped frame 2, and the first slide rail 3 is slidably provided with a first slide block 4, and the first slide block 4 is provided with a threaded hole 5, n A vertical bar 6 is installed on the middle rear side of the inner top of the frame 2, a first motor 7 is installed on the bottom end of the vertical bar 6, a first bearing seat 8 is installed on the front side of the bottom of the first slide rail 3, and the b...

Embodiment 3

[0027] A car wash shed with automatic car wash function, such as Figure 1-5 As shown, it includes an n-shaped frame 2, a first slide rail 3, a first slider 4, a vertical rod 6, a first motor 7, a first bearing seat 8, a screw rod 9, an arc plate 10, and a first spring 11 , arc-shaped brush 12, second slide rail 13, second slide block 14, cross bar 15, second bearing seat 16, second rotating shaft 17, gear 18, rack 19 and brush roller 20, installed on the ground 1 There is an n-shaped frame 2, a first slide rail 3 is installed in the middle of the inner top of the n-shaped frame 2, and the first slide rail 3 is slidably provided with a first slide block 4, and the first slide block 4 is provided with a threaded hole 5, n A vertical bar 6 is installed on the middle rear side of the inner top of the frame 2, a first motor 7 is installed on the bottom end of the vertical bar 6, a first bearing seat 8 is installed on the front side of the bottom of the first slide rail 3, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com