Motor with thrust bearing

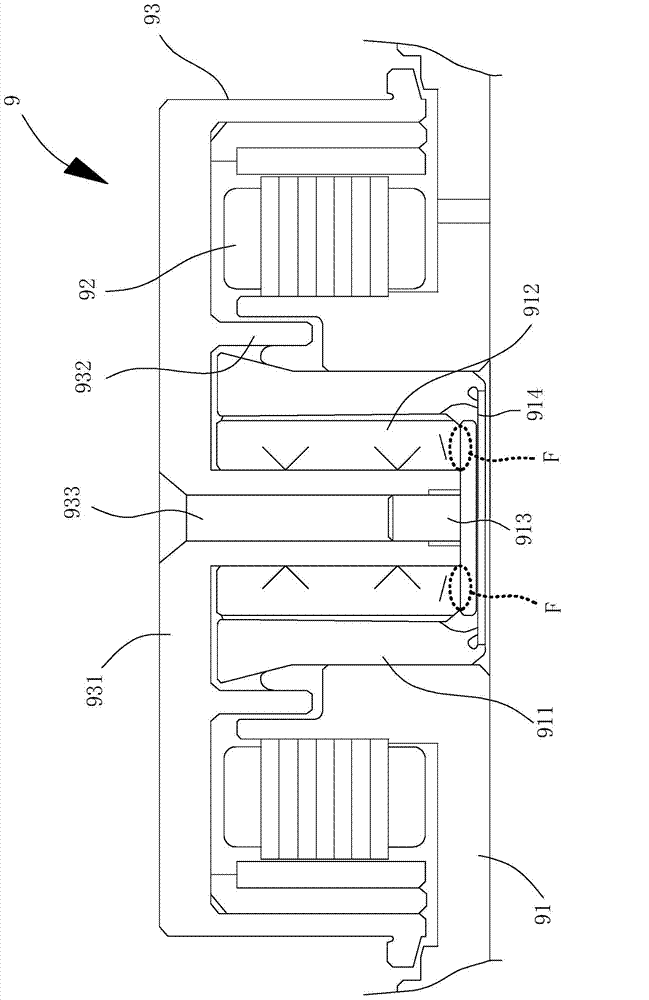

A technology of thrust bearings and motors, applied in the field of motors, can solve the problems affecting the smooth rotation of the rotor 93 and the increase of frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

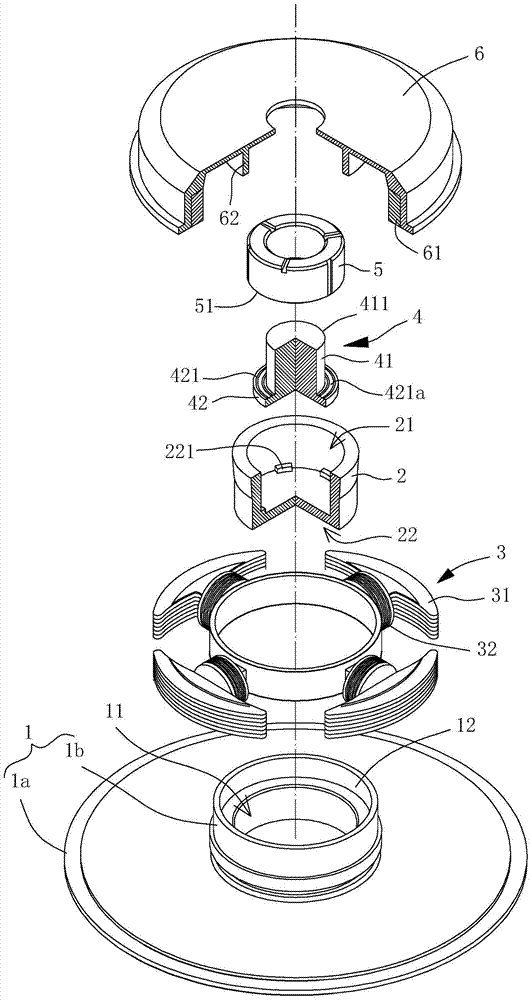

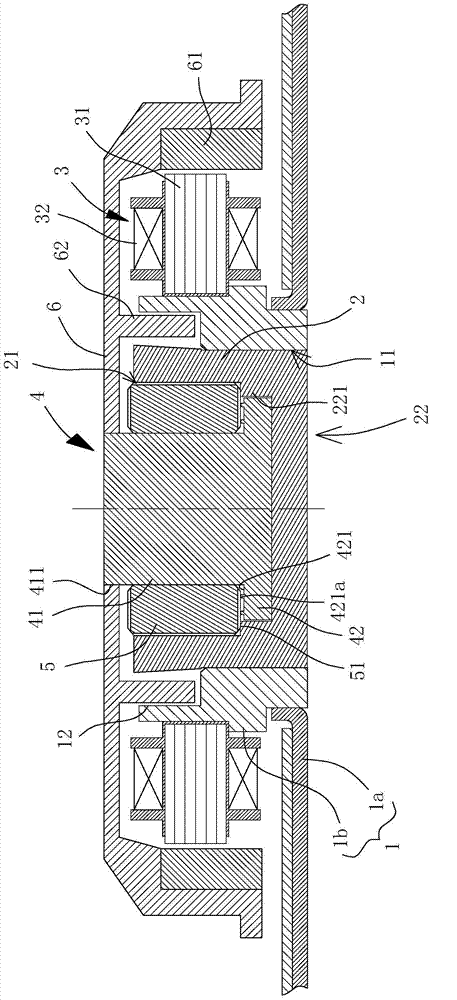

[0054] In order to make the above-mentioned and other objects, features and advantages of the present invention more comprehensible, the preferred embodiments of the present invention are specifically cited below, together with the accompanying drawings, as follows:

[0055] Please refer to figure 2 and 3 As shown, the motor with thrust bearing of the present invention at least includes a base 1 , a bearing sleeve 2 , a stator 3 , a rotating member 4 , a thrust bearing 5 and a hub 6 . The bearing sleeve 2 and the stator 3 are combined with the base 1 , the rotating member 4 and the thrust bearing 5 are combined inside the bearing sleeve 2 , and the hub 6 is combined with the rotating member 4 .

[0056] Above-mentioned base 1 is provided with a joint portion 11, and this joint portion 11 can be various structural designs that can be combined with above-mentioned bearing sleeve 2; figure 2 In the illustrated embodiment, the base 1 may include a base plate 1a and a sleeve 1b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com