Clinker production line for novel dry process cement kiln and denitration process method for clinker production line

A dry-process cement and production line technology, applied in clinker production, cement production, etc., can solve the problems of inapplicability, affecting the stable operation of the system, large coal feeding power, etc., and achieve the suppression of fuel-type NOx generation, operation quality and stability Performance improvement and reduction of NOx production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] The specific implementation of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings, so as to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concepts and technical solutions of the present invention.

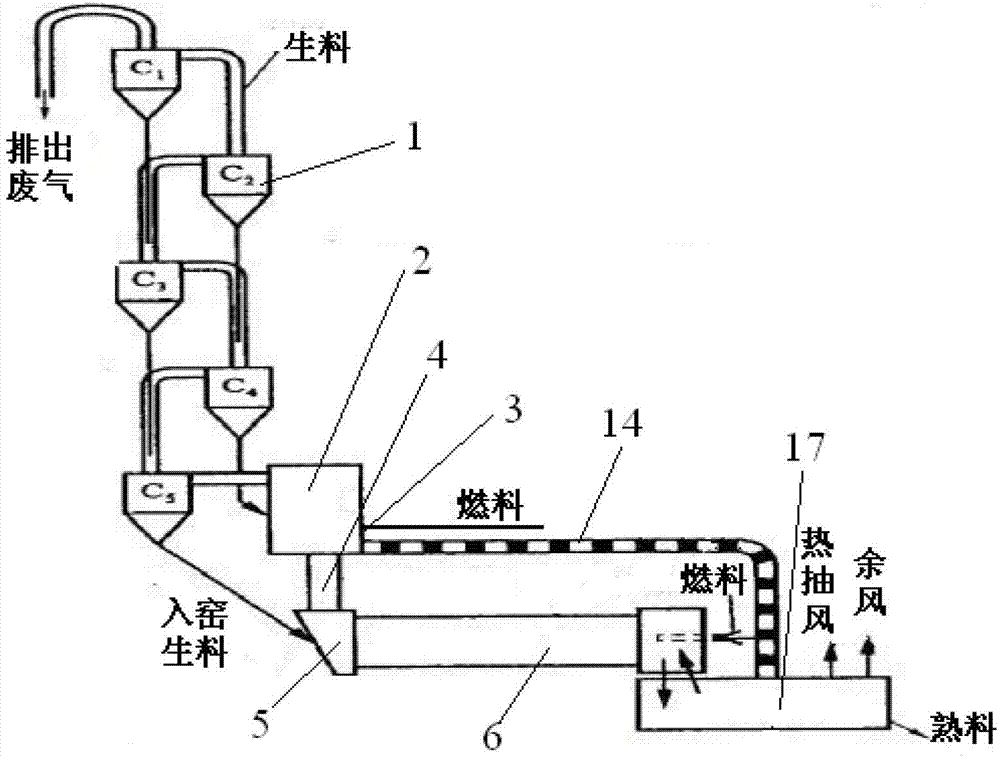

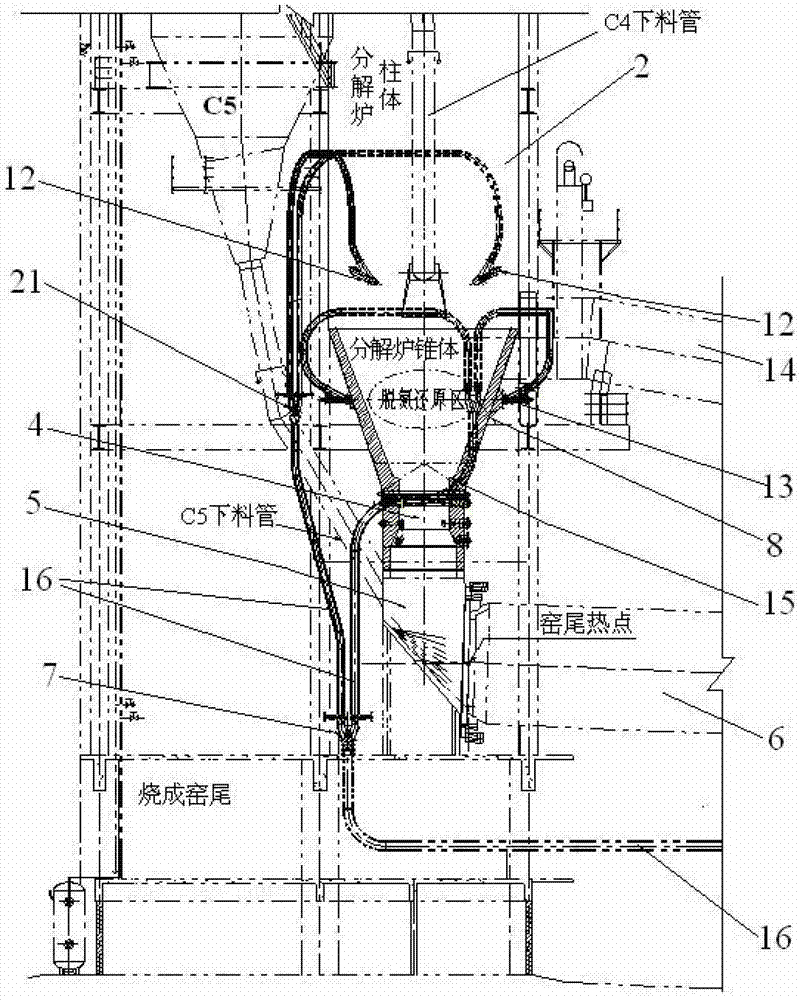

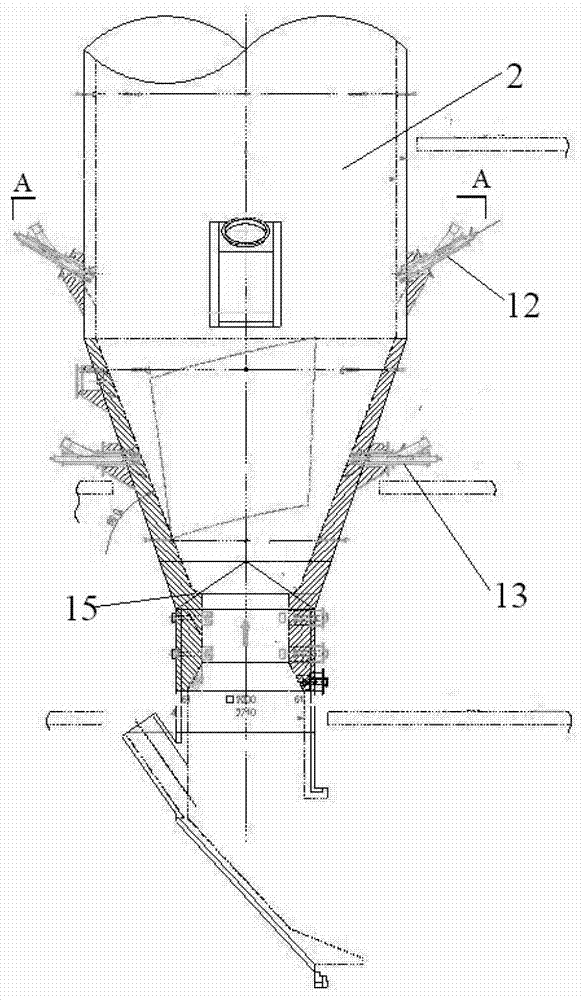

[0076] Such as figure 1 The structure of the present invention expressed is a new dry-process cement kiln clinker production line and its denitrification process, including a cyclone 1, a calciner 2, a burner 3, a tertiary air duct 14, a kiln tail ascending flue 4, and a kiln tail Smoke chamber 5 and rotary kiln 6. The present invention is a NOx emission reduction technology completely different from the staged combustion of the prior art.

[0077] Such as Figure 6 As shown, the air duct 1 includes two columns from top to bottom: C1A, C2A, C3A, C4A, C5A; C1B, C2B, C3B, C4B, C5B.

[0078] Figure 6 It also stated that the new d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com