Folding mechanism and treadmill using same as column folding mechanism

A technology of a folding mechanism and a column is applied in the field of treadmills, which can solve the problems of high cost, inability to fold and store, and occupy a large space, and achieve the effects of fast operation, low noise and wide application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

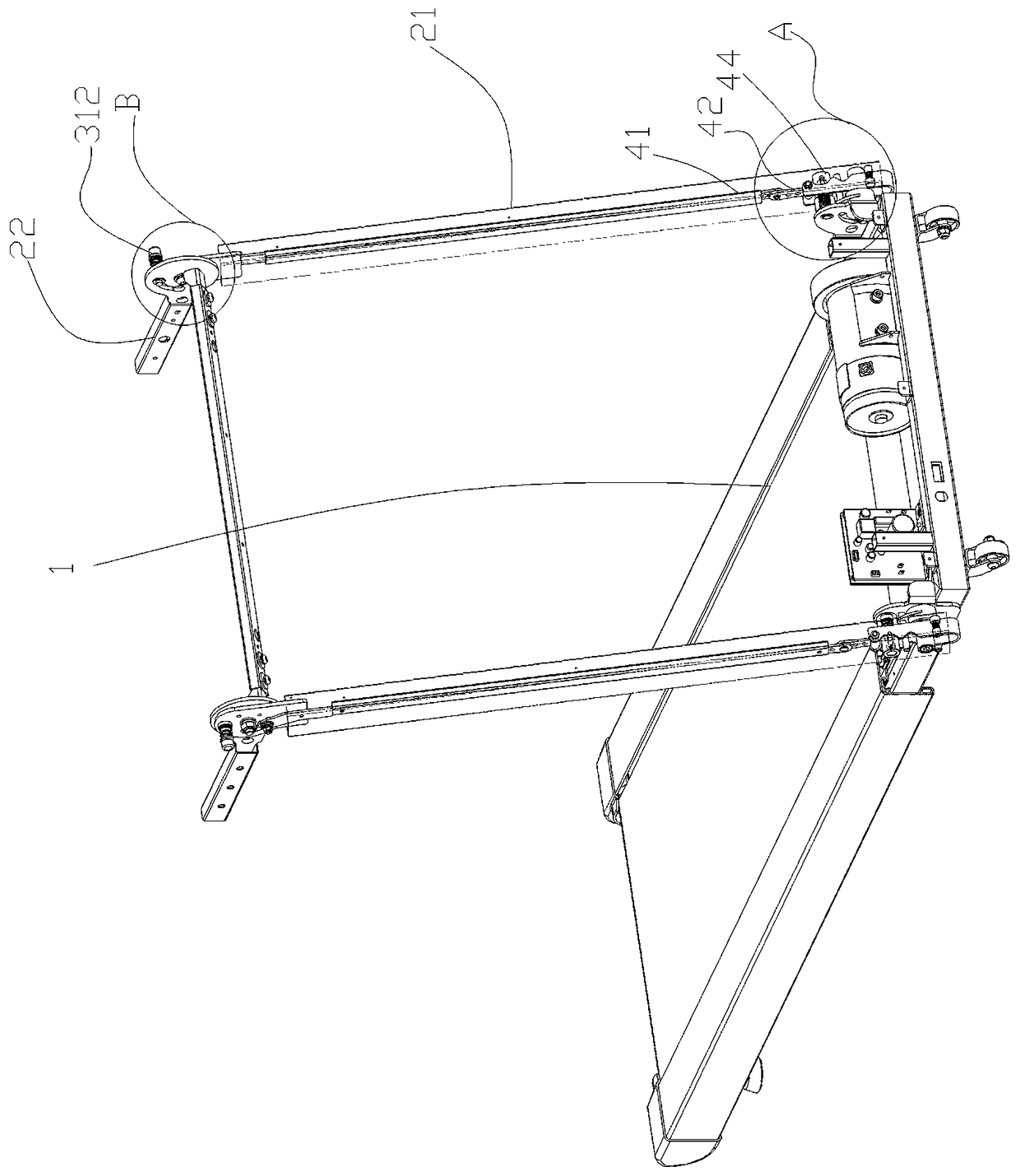

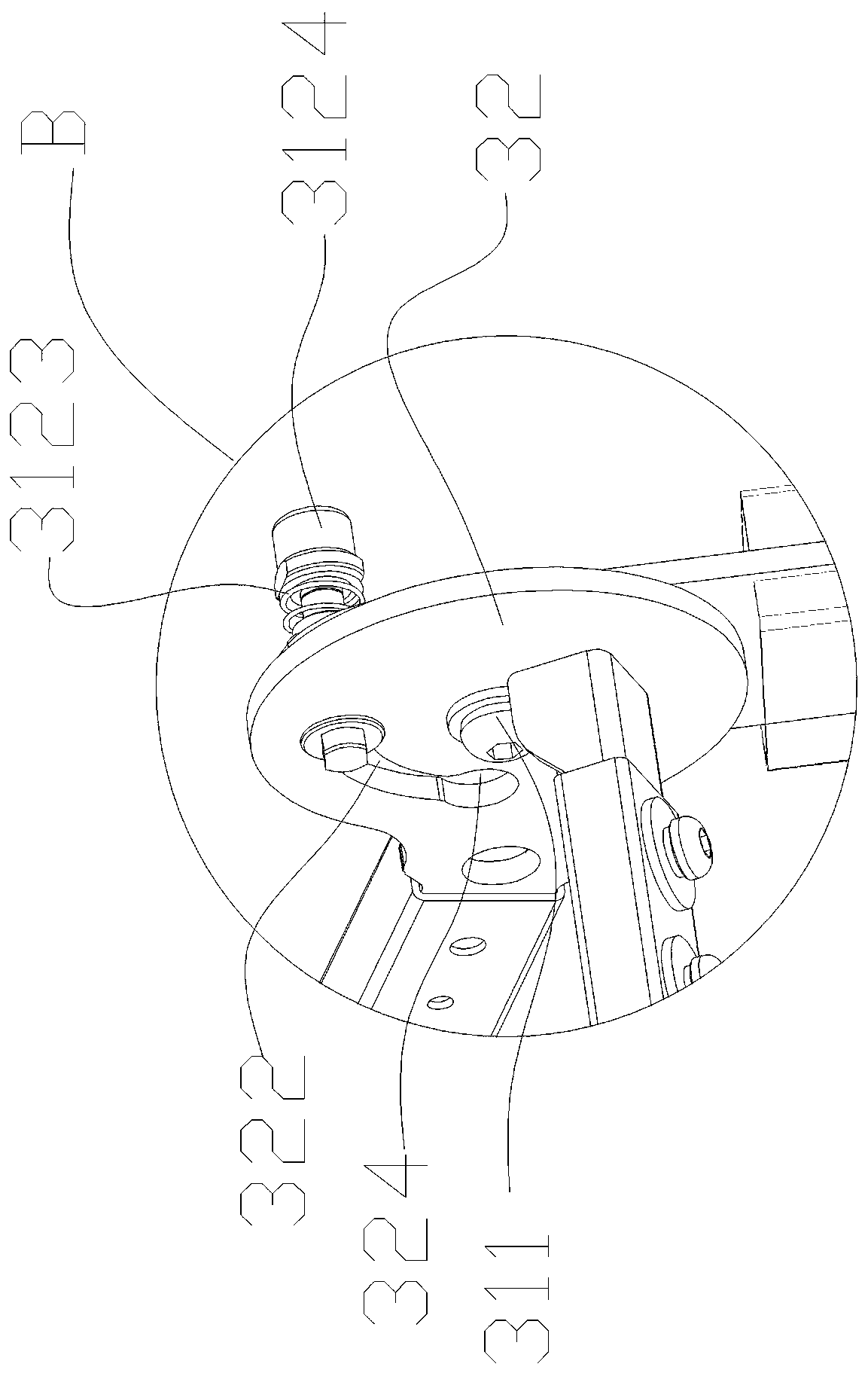

[0057] Such as Figure 1-Figure 13 As shown, a folding mechanism of the present invention includes a bracket body 1 and a folder 2 connected to the bracket body 1 at an angle, and also includes a folding control component 3 and a linkage locking component to operate the folder 2 It is folded and installed on the bracket body 1, the folding control component 3 is installed on the upper end of the folder 2, and the interlocking locking component 4 is co-located on the folder 2 and the bracket body 1;

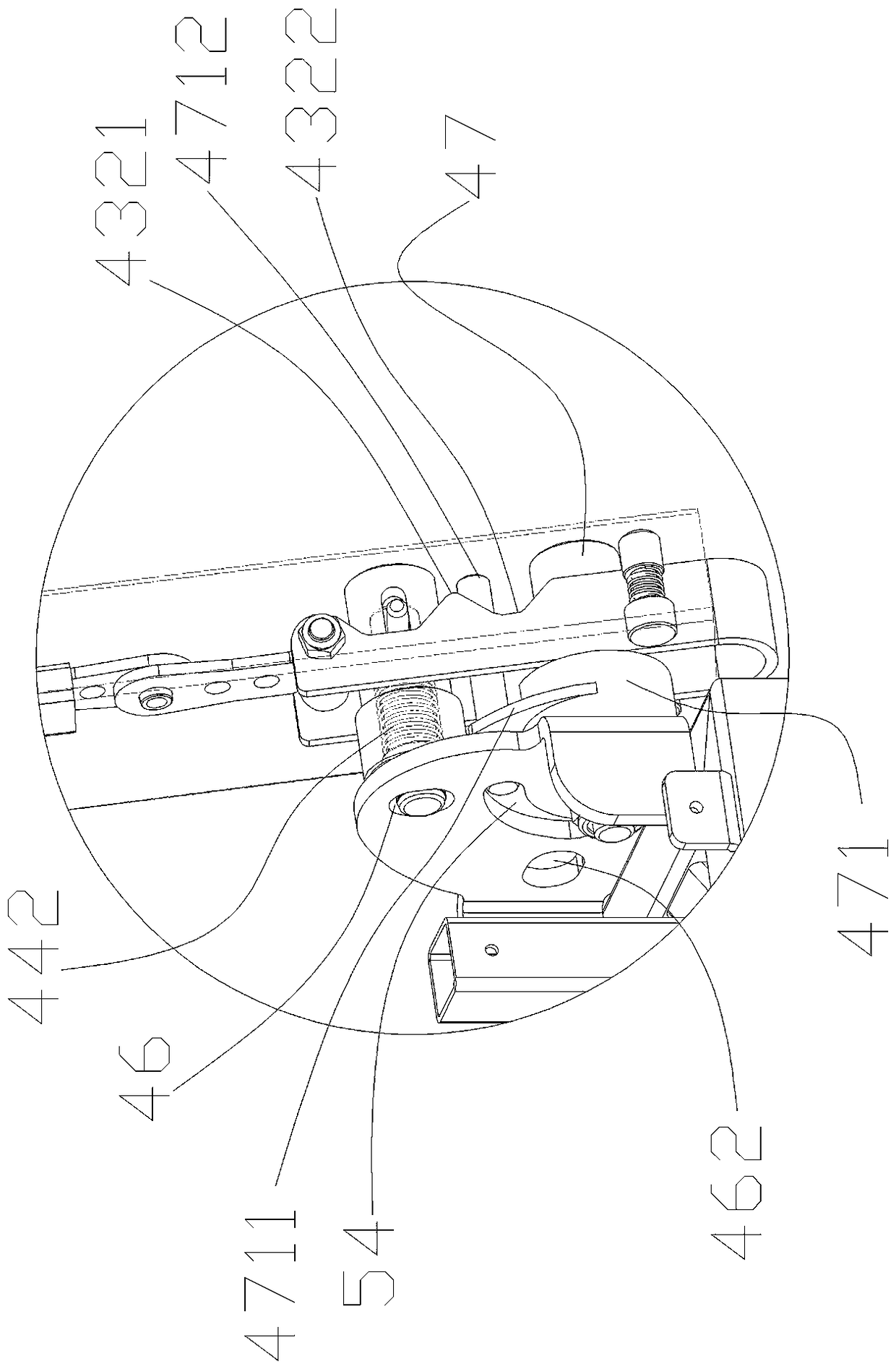

[0058] The linkage locking assembly includes a linkage assembly and a locking assembly, one end of the linkage assembly is connected to the operating member 31 by transmission, and the other end is transmission connected to the locking assembly; the locking assembly includes a push body 43 and a lock A tongue 44, and a slot 46 that is inserted into the locking tongue 44 to fix the locking assembly on the bracket body 1;

[0059] The push body 43 is provided with a push-pull slide...

Embodiment 2

[0135] Such as Figure 1-Figure 14 As shown, the treadmill using the folding mechanism in the above-mentioned embodiment 1 as the column folding mechanism includes a treadmill and a column 20, and the treadmill includes a main body steel frame 11, a running belt 12 arranged on the main body steel frame, and a drive The driving device 13 for the movement of the running belt 12, the column 20 is folded and connected to the main steel frame 11, the main steel frame 11 is the bracket body, and the folding control assembly 3 is pivotally connected to the column of the column 20 At the upper end, the interlocking locking assembly 4 is cooperatingly arranged on the column and the steel frame of the main body.

[0136] The uprights 20 are tubular, arranged symmetrically, and cover the folding control assembly 3 and the interlocking locking assembly 4 arranged symmetrically on both sides;

[0137] The operating section 3124 is a button, or the button is provided with anti-skid grooves...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com