Heat preservation device used for firing of earthenware and use method of heat preservation device

A technology for thermal insulation device and sand cargo, applied in the field of thermal insulation device for sand cargo firing, can solve the problems of low production efficiency, easy cracking of thermal insulation equipment, high labor intensity, etc. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

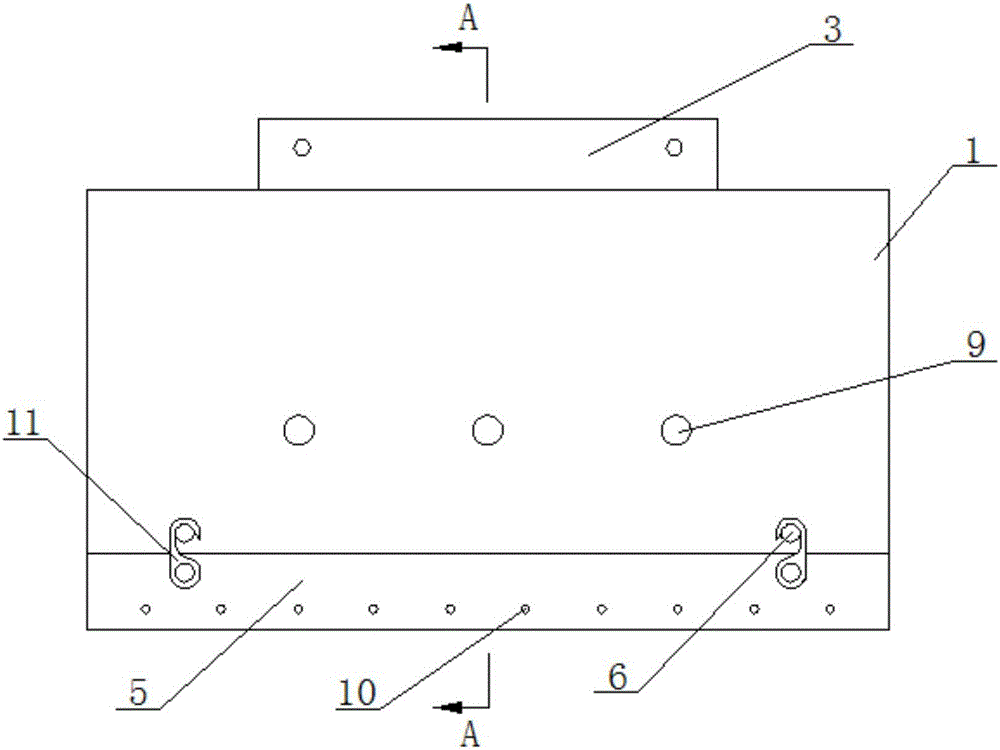

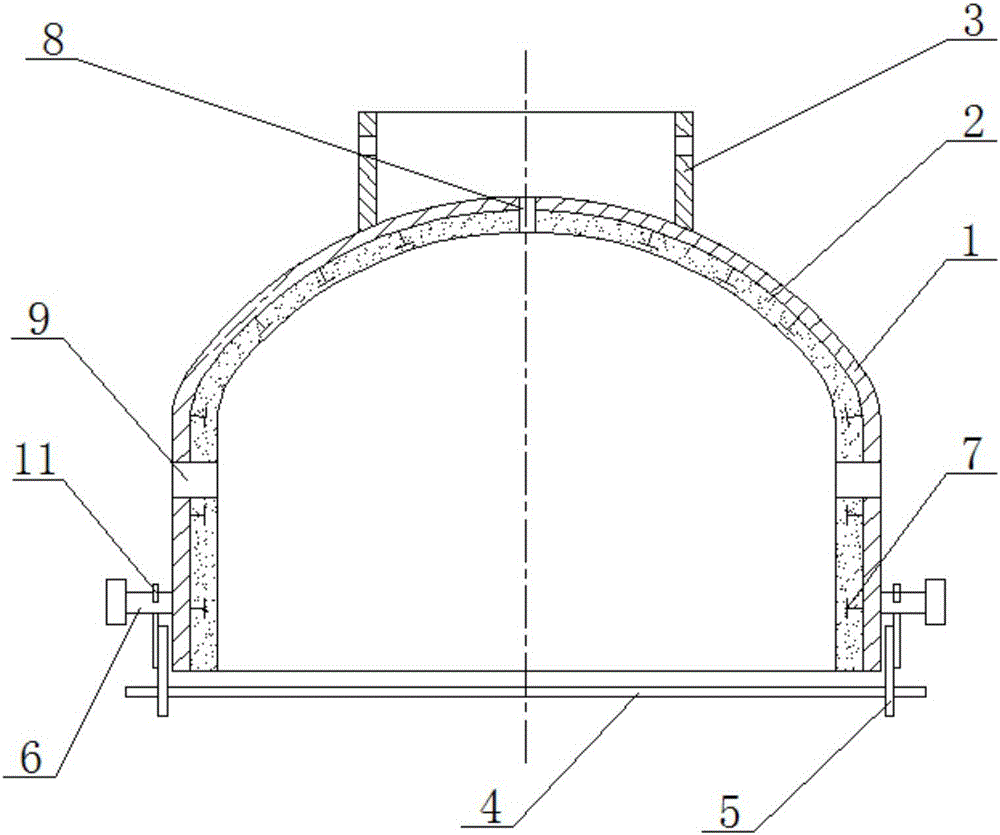

[0017] Such as Figure 1 to Figure 2 As shown, a thermal insulation device for firing sand cargo in this embodiment includes a thermal insulation cover composed of a housing 1, a thermal insulation layer 2 and a lifting member 3, wherein it also includes a number of forks 4 and a fork connecting plate 5 , a hook 11 and lifting lugs 6; the inner wall of the housing 1 is evenly provided with a number of solid claws 7, the insulation layer 2 is arranged on the inner wall of the housing 1 and fixed by the solid claws 7, and the lifting lugs 6 are symmetrically arranged on the The lower part of the outer wall on both sides of the housing 1, the lifting member 3 is arranged on the top of the housing 1, the fork 4 is arranged under the heat preservation cover, and the connecting plate 5 of the fork is provided with a plurality of through holes 10, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com