Swing arm of thin seam mining machine

A technology of swing arm and coal shearer, which is applied in the direction of slitting machinery, cutting machinery, earth drilling and mining, etc. It can solve the problems of large impact of force on the whole machine, small mining height and heavy weight of the rear drum, and achieve shortening of left and right The effect of shortening the length, shortening the front and rear length, and improving the transmission accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

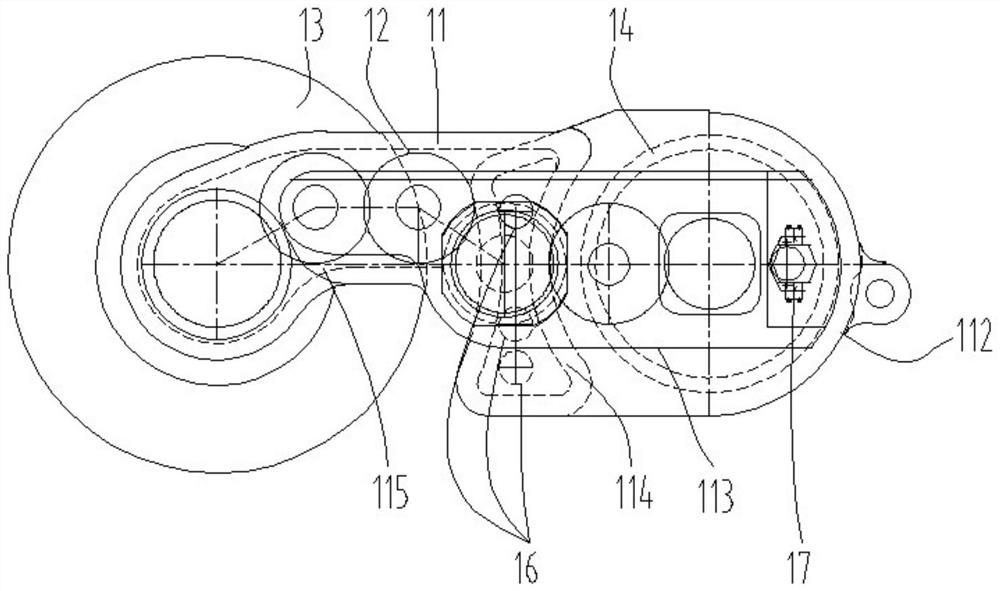

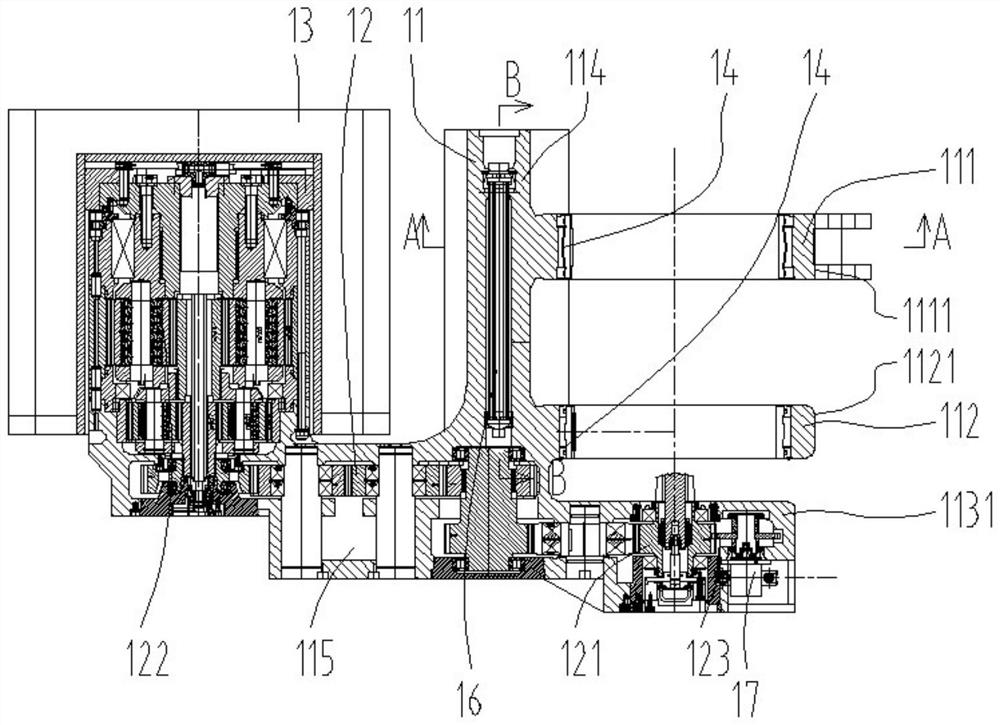

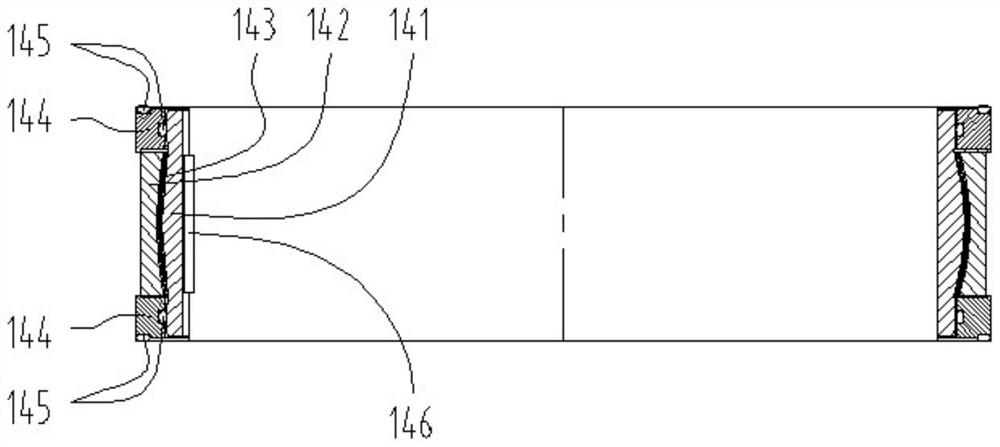

[0035] The present invention discloses a thin coal seam shearer swing arm (may be referred to as a swing arm), such as Figure 1-7 Shown, comprising a swing arm housing 11, the main body of the swing arm housing is a left and right extension of the arm frame 113, the arm frame is installed with a cutting transmission mechanism 12. The cutting transmission mechanism adopts a fixed shaft gear transmission mechanism. In order to facilitate the distinction between the two ends of the boom, the input end gear 121 (also a high-speed end gear) and the output end gear (also a low-speed end gear) of the interception transmission mechanism are respectively used as the high-speed end and low-speed end of the boom, respectively, the middle of the arm frame is provided with a connecting arm 114 that is overhanged forward by the self-arm, and the connecting arm is provided with a self-connecting arm that can be extended to the left or right, and the forearm, the rear arm and the high-speed end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com