Preparation method of Cazro3 type shell for precision casting of titanium and titanium alloy

A precision casting and titanium alloy technology, applied in the direction of casting molding equipment, molds, mold components, etc., can solve the problems of easy gelling, pH value change sensitivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

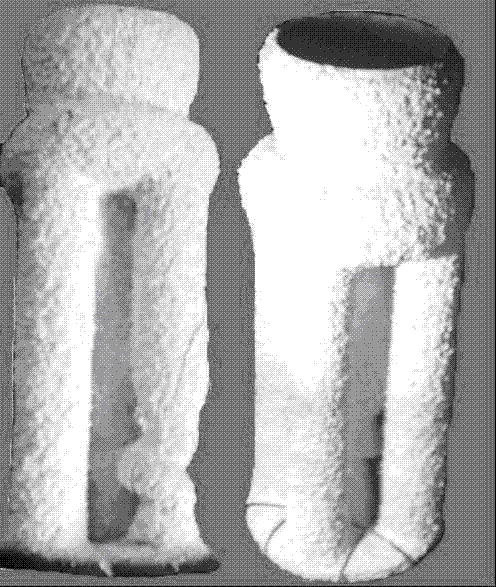

[0027] This embodiment is the preparation process and steps of preparing TiAl alloy castings with calcium zirconate shells:

[0028] (1) Preparation of paint: add binder zirconium diacetate to the calcium zirconate powder that has been ground and passed through a 200-mesh sieve, and stir continuously with a stirrer to control the viscosity of the paint slurry at about 30s. Calcium zirconate powder The weight ratio of material to binder is 4.5:1;

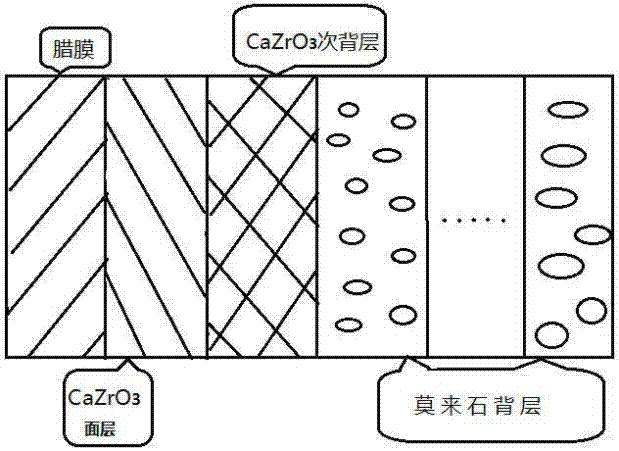

[0029] (2) Preparation of the mold shell: Dip the wax mold into the above-mentioned coating, wait for a while, let the coating evenly hang on the wax mold, sprinkle sand, and evenly scatter the dry powder of calcium zirconate on the coating. On the coating wax model, the sanding process is repeated once; then the back coating is carried out; the binder used in the back coating is ethyl silicate or silica sol, and the filler used is mullite powder, and the weight ratio of the two is 1:4; apply the back coating slurry to the outer lay...

Embodiment 2

[0035] This embodiment is the preparation process and steps of preparing TiNi alloy castings with calcium zirconate shells

[0036] (1) Preparation of paint: add binder zirconium diacetate to the calcium zirconate powder that has been ground and passed through a 200-mesh sieve, and stir continuously with a stirrer to control the viscosity of the paint slurry at about 30s. Calcium zirconate powder The weight ratio of material to binder is 3.5:1;

[0037] (2) Preparation of the mold shell: Dip the wax mold into the above-mentioned coating, wait for a while, let the coating evenly hang on the wax mold, sprinkle sand, and evenly scatter the dry powder of calcium zirconate on the coating. On the coating wax model, the sanding process is repeated once; then the back coating is carried out; the binder used in the back coating is ethyl silicate or silica sol, and the filler used is mullite powder, and the weight ratio of the two is 1:4; apply the back coating slurry to the outer laye...

Embodiment 3

[0043] This embodiment is the preparation process and steps of preparing Ti-6Al-4V alloy castings with calcium zirconate shells

[0044](1) Preparation of paint: add binder zirconium diacetate to the calcium zirconate powder that has been ground and passed through a 200 mesh sieve, and stir continuously with a stirrer to control the viscosity of the paint slurry at about 30s. Calcium zirconate powder The weight ratio of material to binder is 4:1;

[0045] (2) Preparation of the mold shell: Dip the wax mold into the above-mentioned coating, wait for a while, let the coating evenly hang on the wax mold, sprinkle sand, and evenly scatter the dry powder of calcium zirconate on the coating. On the coating wax model, the sanding process is repeated once; then the back coating is carried out; the binder used in the back coating is ethyl silicate or silica sol, and the filler used is mullite powder, and the weight ratio of the two is 1:4; apply the back coating slurry to the outer la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com