Double oil tanks and integrated double oil tank and urea tank assembly

A technology of dual fuel tanks and urea tanks, applied in the field of auto parts, can solve the problems of damaging engine heat dissipation, limited battery power, and high energy consumption, and achieve the effects of reducing logistics and transportation costs, saving fuel costs, and stimulating activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

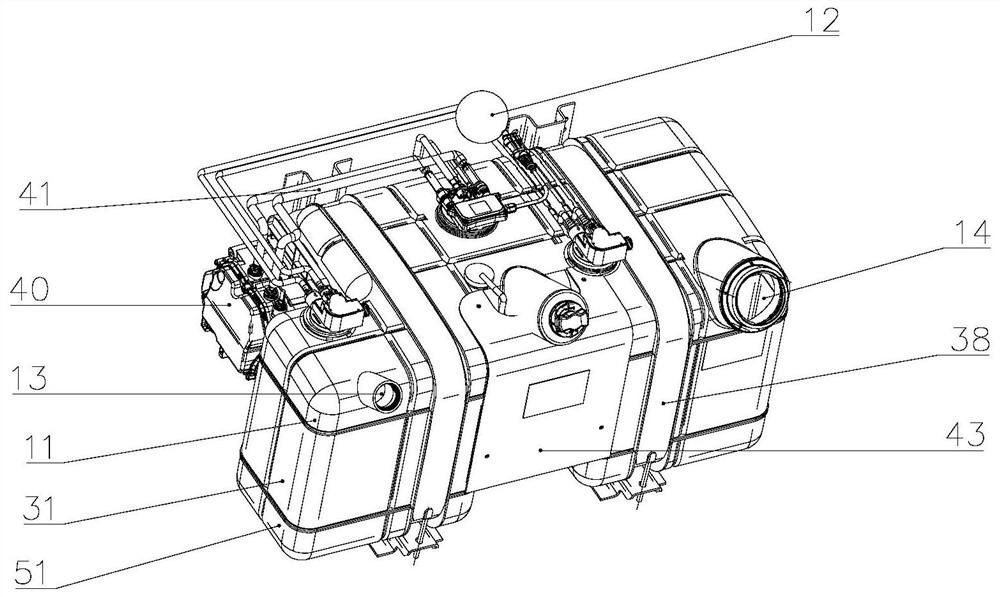

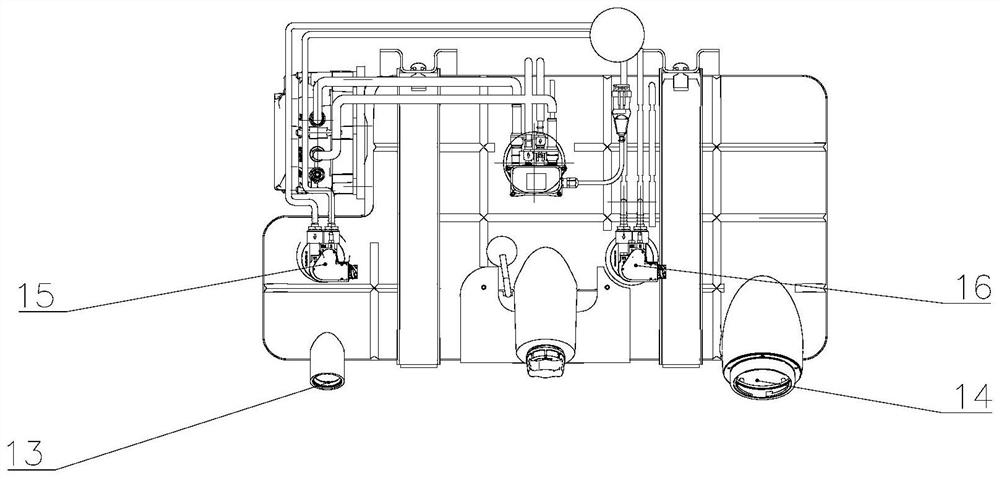

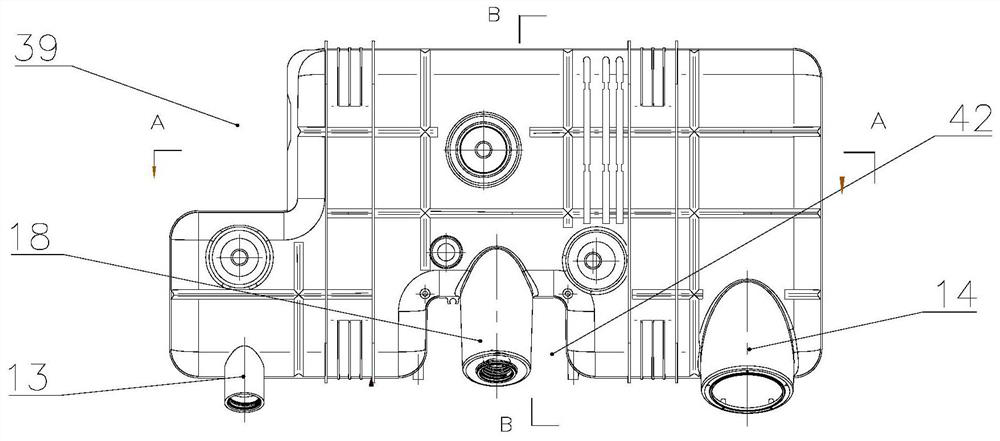

[0055] Such as Figure 1-10 As shown, Embodiment 1 of the present application discloses a double fuel tank assembly, which includes: a fuel tank housing, the fuel tank housing encloses a cavity, and the fuel tank housing includes the upper upper housing 11 area, the middle middle housing 31 area and the lower shell 51 area of the lower part; the middle grid rib structure is set in the cavity corresponding to the height area of the middle shell 31, and the middle grid rib structure divides the middle part of the cavity into several middle grid cavities, and the middle grid cavity There is no connection between them in the radial direction, and the middle grid rib structure includes the first middle grid cavity group 33 and the second middle grid cavity group 34 which are not connected to each other, and the bottom end of the first middle grid cavity group 33 is provided with a first The oil ports communicate with each other to form the first fuel chamber, and the bottom end...

Embodiment 2

[0087] Such as Figure 1-10 As shown, Embodiment 2 of the present application provides an integrated double fuel tank and urea tank assembly, which includes the double fuel tank assembly and urea chamber in Embodiment 1; the urea chamber is located in the cavity surrounded by the fuel tank shell. By setting the urea chamber in the cavity surrounded by the fuel tank shell, the integrated arrangement of the fuel chamber and the urea chamber is realized, which reduces the volume of the integrated fuel tank, reduces the combined weight of the two, and makes the vehicle lighter; in addition, By integrating the fuel oil chamber and the urea chamber, the urea liquid in the urea chamber is heated by the oil return temperature of the first fuel oil chamber and / or the second fuel chamber to prevent the crystallization of the urea liquid in a low-temperature environment and realize the reuse of heat. Simplify your vehicle's thermal management system.

[0088] As an embodiment, at least ...

Embodiment 3

[0107] The integrated double fuel tank and urea tank assembly 1# and 2# are respectively processed by injection molding and rotomolding, the urea chamber volume, the first fuel chamber volume, and the second fuel oil chamber volume of the assembly 1# and 2# The cavity volume, volume and weight of the double fuel tank assembly are shown in Table 1:

[0108] Table 1

[0109]

[0110] It can be seen from Table 1 that the total volume of each cavity of the integrated double fuel tank and urea tank assembly processed by injection molding method is larger, which can increase the storage volume of fuel and urea solution, and is lighter in weight, which is beneficial to Lightweight vehicles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com