Patents

Literature

64results about How to "Reduce refining process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultrasonic-assisted tea oil extraction method using subcritical CO2

ActiveCN102041164AHigh nutritional valueImprove qualityFatty-oils/fats productionUltrasonic assistedWorking pressure

The invention discloses an ultrasonic-assisted tea oil extraction method using subcritical CO2, comprising the steps as follows: (1) taking dry tea seed, hulling, crushing, and placing in an extraction kettle; (2) injecting the subcritical CO2 into the extraction kettle to mix with the tea seed; (3) extracting the raw material for 0.5-5 hours; (4) decompressing and evaporating so as to completelygasify the subcritical CO2 liquid, wherein the temperature in evaporation process is controlled at 30-70 DEG C, and finally discharging the extracted tea oil from the bottom of a separation kettle. The method has the advantages that (1), the advantages of the subcritical CO2 extraction technology and the ultrasonic extraction technology are sufficiently utilized to shorten the extraction time andimprove the extraction yield; (2), the work pressure is low, and the natural activity of heat-sensitive material cannot be influenced since the extraction temperature is less than 30 DEG C, and the nutritional value and quality of the tea oil are improved; (3), the device cost is low, the refining process is less, the tea oil loss is less and the product oil yield is high; (4) a natural green food is obtained since the CO2 solve is residue-free.

Owner:NANCHANG TONGXIN ZICHAO BIOENG +1

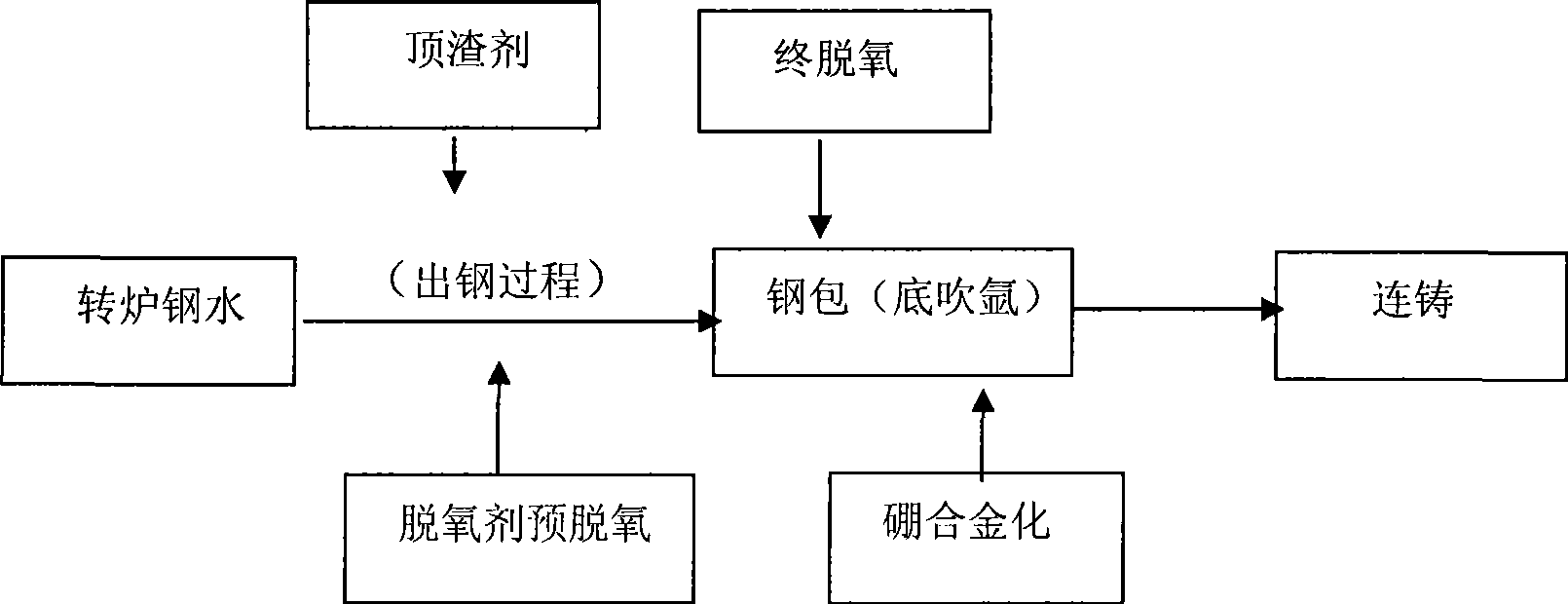

Method for producing boron steel by converter

InactiveCN101503746AAvoid stickinessAvoid water-prone mouthsManufacturing convertersAlloyMolten steel

The invention provides a method for producing boron steel in a converter, which is characterized in that argon subaeration is performed on a ladle in the whole process; a deoxidizer and alloys required by steel grades are begun to be added into the ladle for preliminary deoxidation and alloying under the condition of 1 / 4 tapping, and simultaneously a desulfurizer is added for desulfurization treatment; aluminum is added into the ladle in an argon blowing station for final deoxidation, and ferroboron is added into the ladle when the [O] is controlled to be between 0.0020 and 0.0040 percent; and the ferroboron is coated by an aluminum sheet and added into molten steel. The method has the advantages that: firstly, the method saves the refining procedure of an LF furnace and a vacuum furnace and has low production cost, short production procedure and high production efficiency; secondly, the pourability of the molten steel is good; thirdly, no requirement is put forward as for acid-soluble aluminum in the steel, so that the method solves the problems of pastiness of the molten steel, easy bonding of water gaps, reduction of the steel quality and the like caused by the increase of Al2O3 inclusion due to high acid-soluble aluminum; and fourthly, the recovery rate of boron can reach 60 to 75 percent and the wave range of the yield is small. Moreover, the method has good application prospect.

Owner:新余钢铁股份有限公司

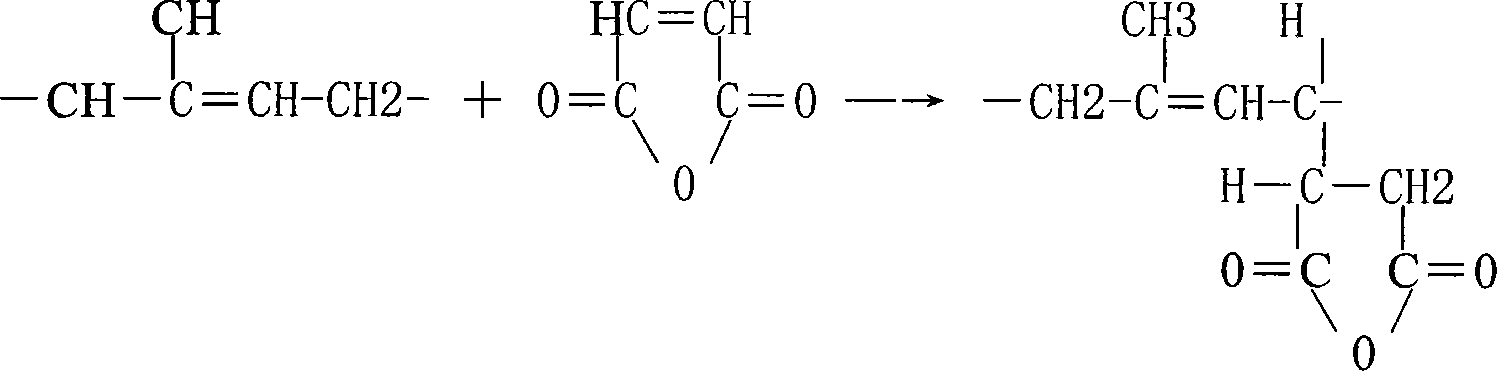

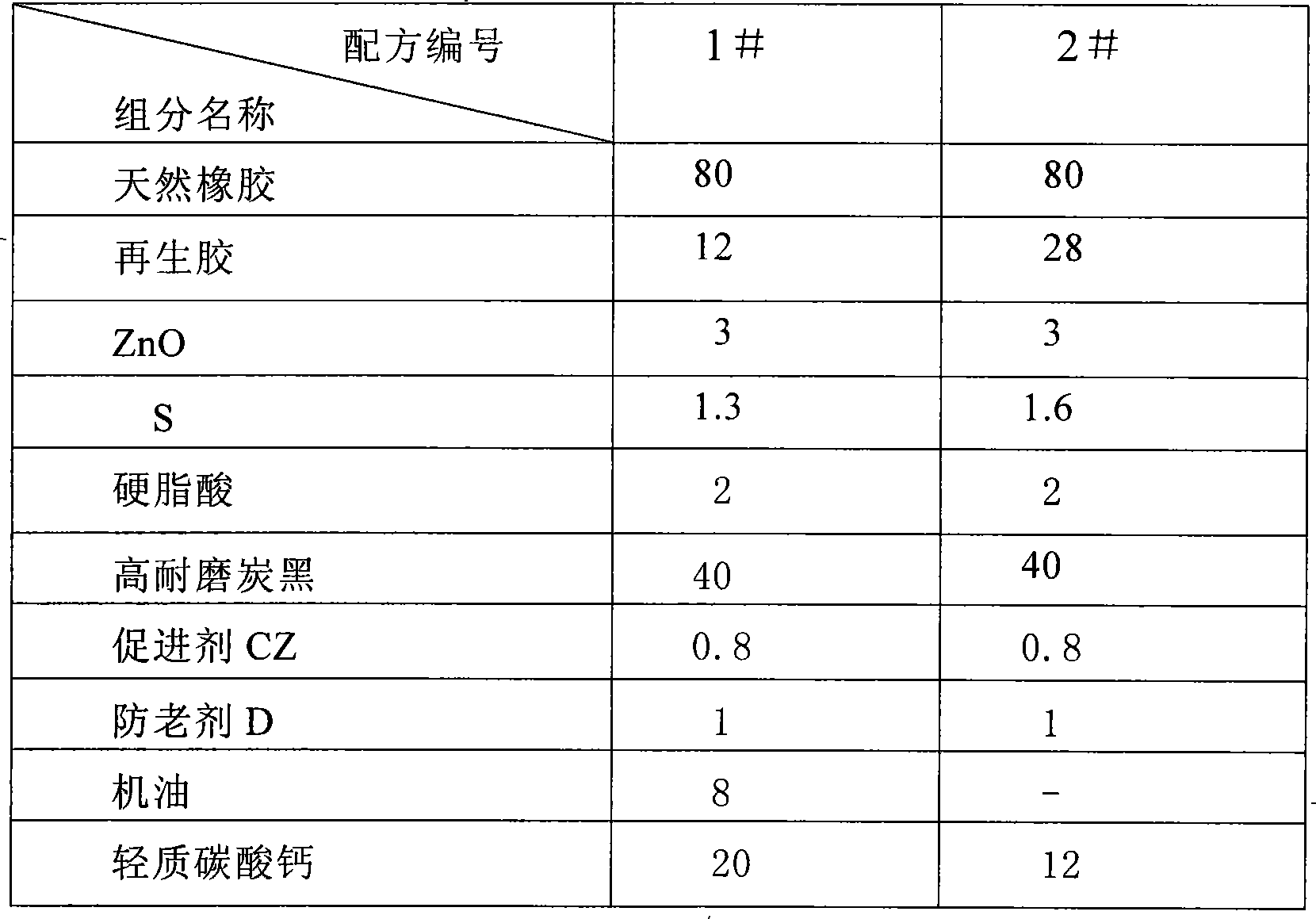

Plaster-shape regenerated rubber and preparation method thereof

InactiveCN101100534ASimple processNo need to consume electricityPlastic recyclingFiberPolymer science

A creamed reclaimed rubber and its production are disclosed. It consists of 20-50 mesh vulcanized rubber powder 100 proportion, paraffin oil as solvent 70-90 proportion, solid coumarone 10-30 proportion as solvent, catalyst and catalyst accessory phthalic acid anhydride 2-5 proportion, methyl aldehyde aqueous solution 4-6 proportion, 1,3-benzenediol 0.2-0.5 proportion. The process is carried out by adding vulcanized rubber powder into vertical de-polymerizer, adding into solvent, catalyst and catalyst accessory successively, closing feeding open, agitating, raising temperature to 160-180 deg. C, controlling pressure to 0.5-0.7 MPa, reacting for 2-2.5 hrs, lowering temperature, releasing gas, discharging and filtering to obtain final product. It's simple, has stable quality, waterproof and antiseptic performances and no environmental pollution. It can be used to synthesize rubber with petrochemical asphalt and to paving road.

Owner:TIANJIN YATENGDA RUBBER & PLASTIC PRODS DEV

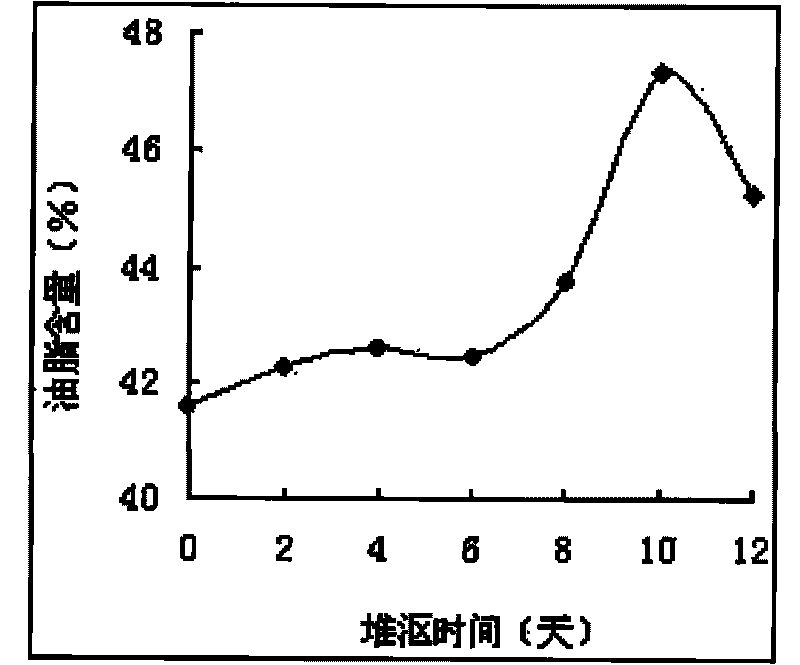

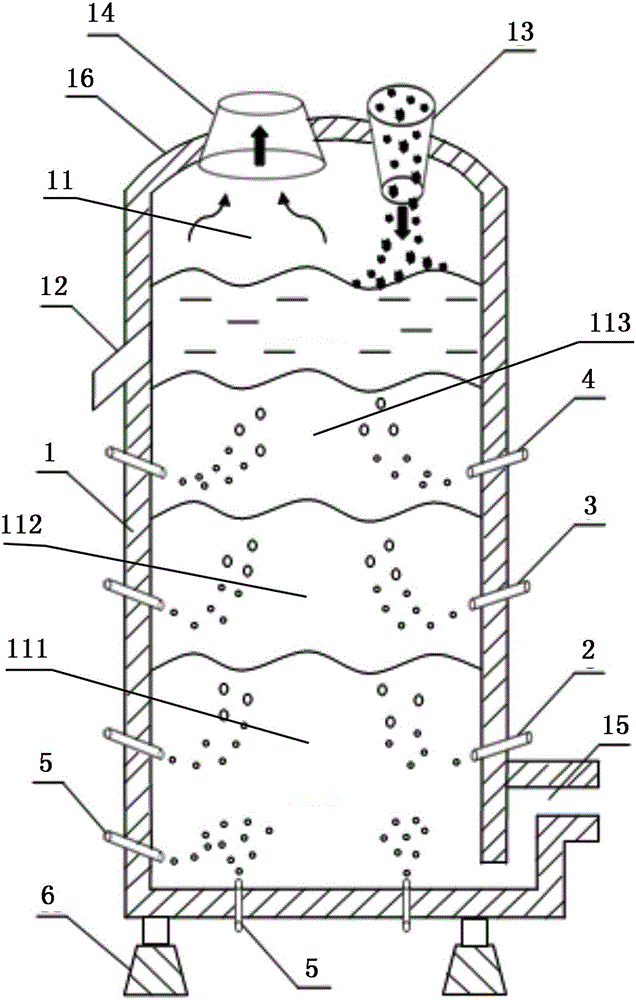

Method for preparing edible safflower tea oil

InactiveCN101692854AHigh oil contentQuality improvementEdible oils/fats production/working-upFlavorLoss rate

The invention discloses a method for preparing edible safflower tea oil, comprising the following steps: taking safflower tea seeds as raw materials; conducting stackretting, removal of the oil tea fruit shells, and taking-off of the tea seeds for low-temperature drying below safe moisture content on the harvested mature safflower oil tea fruits, and then cleaning stone, removing shells, separating kernels and shells, and crushing till the particle size is 20 to 60 meshes and adding water for tempering; adopting a cold pressing method for extracting the tea oil; and finally conducting simple refining processes such as filtration, wintering and the like so that the quality index can achieve national first-class edible tea oil standards. The method for preparing edible safflower tea oil hassimple and feasible process, easily-controlled production conditions, less refining processes, low refining loss rate, can keep various nutritional components in the safflower tea seeds from being destroyed, leads the finished tea oil to have light, clear and transparent color, aromatic natural flavor of the tea seeds, and is a nutritional and healthy tea oil.

Owner:SOUTH CHINA AGRI UNIV

High nitrogen raw material hydrocracking method

ActiveCN103102966AEffectively play an active roleReduce hydrogen sulfideTreatment with hydrotreatment processesGas phaseFractionation

The present invention relates to a high nitrogen raw material hydrocracking method, which is characterized in that a high nitrogen heavy distillate oil is adopted as a raw material; a two stage process is adopted; under a hydrorefining condition, a heavy distillate oil raw material and hydrogen are mixed and enter a first stage reaction zone, wherein the first stage reaction zone adopts a hydrorefining catalyst, and a nitrogen removing rate is controlled to 60-95%; the effluent of the first stage reaction zone is subjected to gas-liquid separation, the separated gas phase is subjected to impurity removing so as to be recycled, and the liquid phase is subjected to fractionation to obtain a light oil product and tail oil; the tail oil and hydrogen are mixed and enter a second stage reaction zone, wherein the second stage reaction zone adopts a hydrorefining catalyst and a hydrocracking catalyst; and the reaction effluent of the second stage reaction zone enters a separation system. Compared to the existing two stage hydrocracking technology, the high nitrogen raw material hydrocracking method of the present invention has the following advantages that: the process is flexible, and poor quality raw materials can be processed. Compared to the existing one stage series connection hydrocracking technology, the high nitrogen raw material hydrocracking method of the present invention has the following advantages that: processing capacity of the device can be substantially improved. In addition, the method can be operated under relatively mild conditions so as to easily improve an operation period of the hydrogenation device.

Owner:CHINA PETROLEUM & CHEM CORP +1

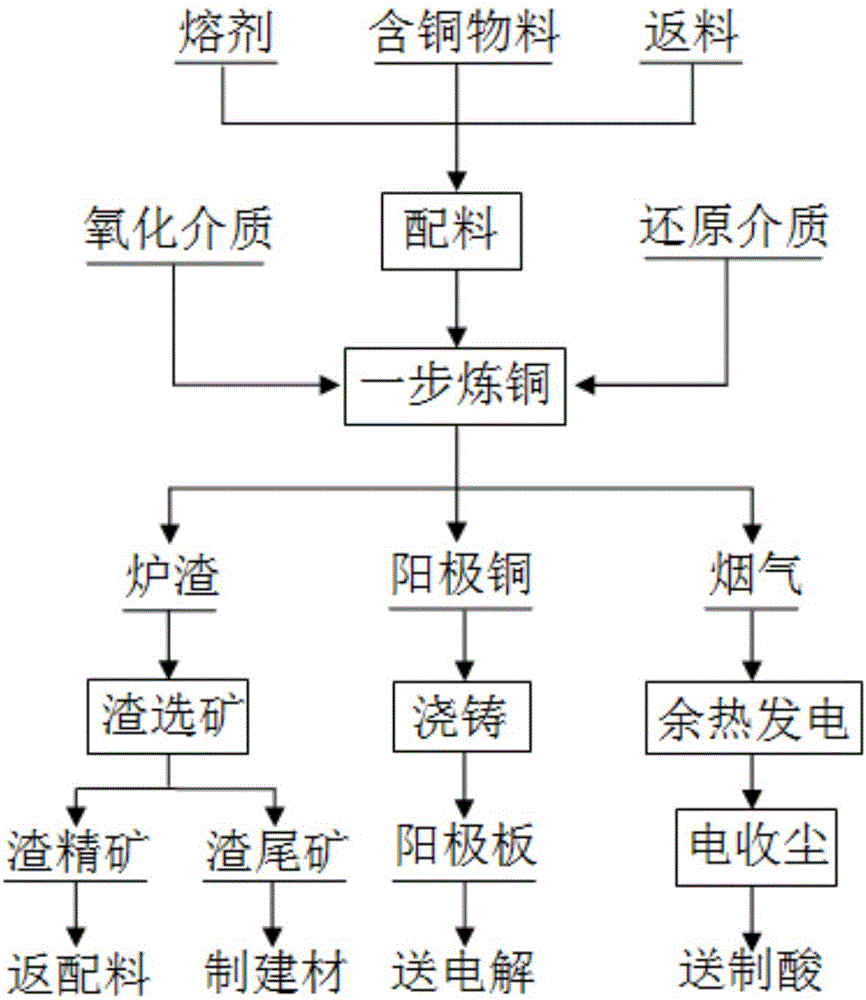

One-step copper smelting process and device

ActiveCN104988332ALow granularityLower requirementRotary drum furnacesCrucible furnacesElectrolysisSmelting process

The invention discloses a one-step copper smelting process and device. The device comprises a furnace body provided with a closed furnace chamber. From the bottom, the closed furnace chamber is sequentially provided with a refining area, a converting area and a smelting area from bottom to top. A plurality of first spray guns are arranged on the portions, around the refining area, of the furnace wall. A plurality of second spray guns are arranged on the portions, around the converting area, of the furnace wall. A plurality of third spray guns are arranged on the portions, around the smelting area, of the furnace wall. A plurality of fourth spray guns located below the first spray guns are arranged on the portions, around the refining area, of the furnace wall and / or the bottom. A slag discharging opening is formed in the portion, above the smelting area, of the furnace wall. A feeding port and a flue outlet are formed in the top of the closed furnace chamber. A copper discharging opening is formed in the bottom of the closed furnace chamber. The device has the advantages of being simpler in structure, durable, high in efficiency, less in investment, low in operation cost and the like; the process comprises the steps of distributing and discharging materials, carrying out smelting, converting and refining respectively, carrying out anode copper electrolysis, and treating slag and smelter off-gas, and has the advantages of being short in flow, high in adaptability, low in energy consumption, environmentally friendly and the like.

Owner:CENT SOUTH UNIV

Method for preparing activated rubber crumb by catalysis and activation reaction

InactiveCN101381476AImprove dynamic performanceEasy to usePlastic recyclingPolymer sciencePlasticizer

The invention provides a method for preparing activated rubber powder by catalytic reaction and activating reaction, and relates to a method for comprehensive utilization of waste and scrap rubber. Compared with the production of regenerated rubber, the method reduces processes of desulfurizing, kneading and refining, thereby avoiding secondary pollution to the environment. The prepared activated rubber powder has excellent compatibility with matrix rubber, and improves the physical and mechanical properties of the product. The formulation comprises the following compositions in weight portion: 100 portions of 30 to 40 meshes of waste rubber powder, 8 to 17 portions of plasticizer-dipentene, 5 to 8 portions of dusting agent-pottery clay, 0.2 to 0.5 portion of catalyst-cuprous chloride, 7 to 1.0 portion of promoting agent-polyalkylphenol disulfide, and 1 to 2.5 portions of dispersing agent-ethanol. The method comprises the following steps: placing the 30 to 40 meshes of waste rubber powder into a high-speed stirring reactor, and heating the waste rubber powder to the temperature of between 80 and 100 DEG C; adding the plasticizer, the dusting agent, the catalyst, the promoting agent and the dispersing agent into the reactor sequentially for reacting for 10 to 20 minutes at a temperature of between 80 and 120 DEG C, and cooling and discharging to produce the activated rubber powder. The prepared activated rubber powder can be used in rubber industry and building industry.

Owner:TIANJIN RUBBER IND RES INST

Low-temperature refining method of tea seed oil

InactiveCN101914413AAchieve the purpose of refiningHigh yieldFatty-oils/fats refiningFatty acidImpurity

The invention discloses a low-temperature refining method of tea seed oil, comprising an absorbing and refining step and a filtering step. The invention adopts the core technology of utilizing a mixed absorption agent to absorb and filter impurities in crude oil, such as free fatty acid, various pigments, phospholipid, and the like to achieve the aim of refining the tea seed oil so as to substitute traditional procedures, such as degumming, deacidifying, bleaching, deodorizing, and the like. The invention adopting a low-temperature physical absorption technology only needs an absorbing and refining pot and filtering equipment, reduces the traditional refining procedures, shortens the production period, lessens the refining loss of the tea seed oil, avoids the execution of the high-temperature process of the traditional refining process, reserves biological active substances and nutrient contents in the tea seed oil, such as vitamins, squalene, and the like and improves the product quality and the health function. The tea seed oil obtained through refining is colorless and transparent and has high yield, equipment investment is small, and the method is simple and suitable for industrial production, keeps the pure natural characteristics of the tea seed oil and greatly improves the added values of the tea seed oil.

Owner:FUJIAN NORMAL UNIV

Anchor rod steel for coal mines and production method thereof

The invention provides anchor rod steel for coal mines. The anchor rod steel is composed of the following elements according to mass percent: 0.20-0.25% of C, 0.85-1.55% of Mn, 0.40-0.70% of Si, 0.025-0.095% of V, not larger than 0.040% of P, not larger than 0.040% of S, not larger than 0.10% of Cr, not larger than 0.10% of Ni, not larger than 0.15% of Cu and the balance of Fe and impurity elements. The invention further provides a production method of the anchor rod steel for coal mines. The production method adopts a technological process of converter refining, vanadium in steel micro-alloying, full protection casting, billet checking, heating in a heating furnace, continuous rolling and rapid cooling after rolling, a refining procedure is omitted, thereby not only simplifying the procedures, but also saving the energy resources, and the anchor rod steel produced by the method provided by the invention is characterized in that the yield strength is not smaller than 400 MPa, the tensile strength is smaller than 585 MPa and the stretch rate is not smaller than 18%.

Owner:WUHU XINXING DUCTILE IRON PIPES

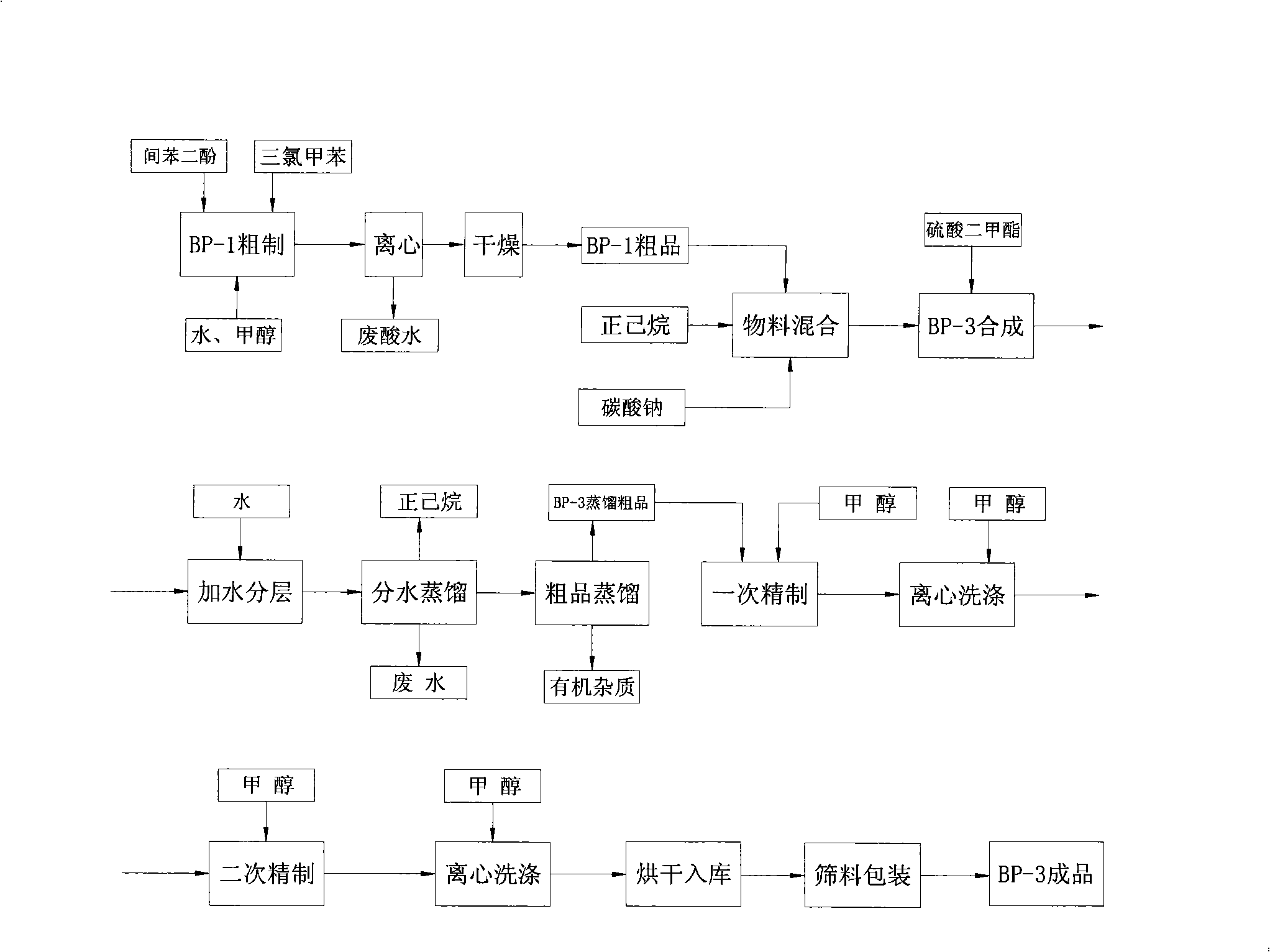

Production method of 2-hydroxy-4-methoxy benzophenone

ActiveCN101323564AReduce refining processOrganic compound preparationCarbonyl compound preparationFiltrationDistillation

The invention relates to a production method of 2-hydroxy-4-methoxyl benzophenone (BP-3) which is an ultraviolet ray absorbent. The production process mainly comprises rough preparation of BP-3: BP-1 crude product is reacted with dimethyl sulfate in a normal hexane solution with sodium carbonate as a neutralizing agent to produce the BP-3; preparation of BP-3 crude product by heating distillation; refinement of the BP-3: the BP-3 crude product can be prepared into BP-3 fine product in a methanol solution through heating, crystallization by cooling and filtration and finished product can be gained through drying with product content of not less than 99.9 percent. The production method of the 2-hydroxy-4-methoxyl benzophenone (the BP-3) provided by the invention reduces residue of solvent, with no residue of toluol existing in the products, thus improving the safety of the products. In addition, production procedures are reduced so as to reduce production cost.

Owner:宜都市华阳化工有限责任公司

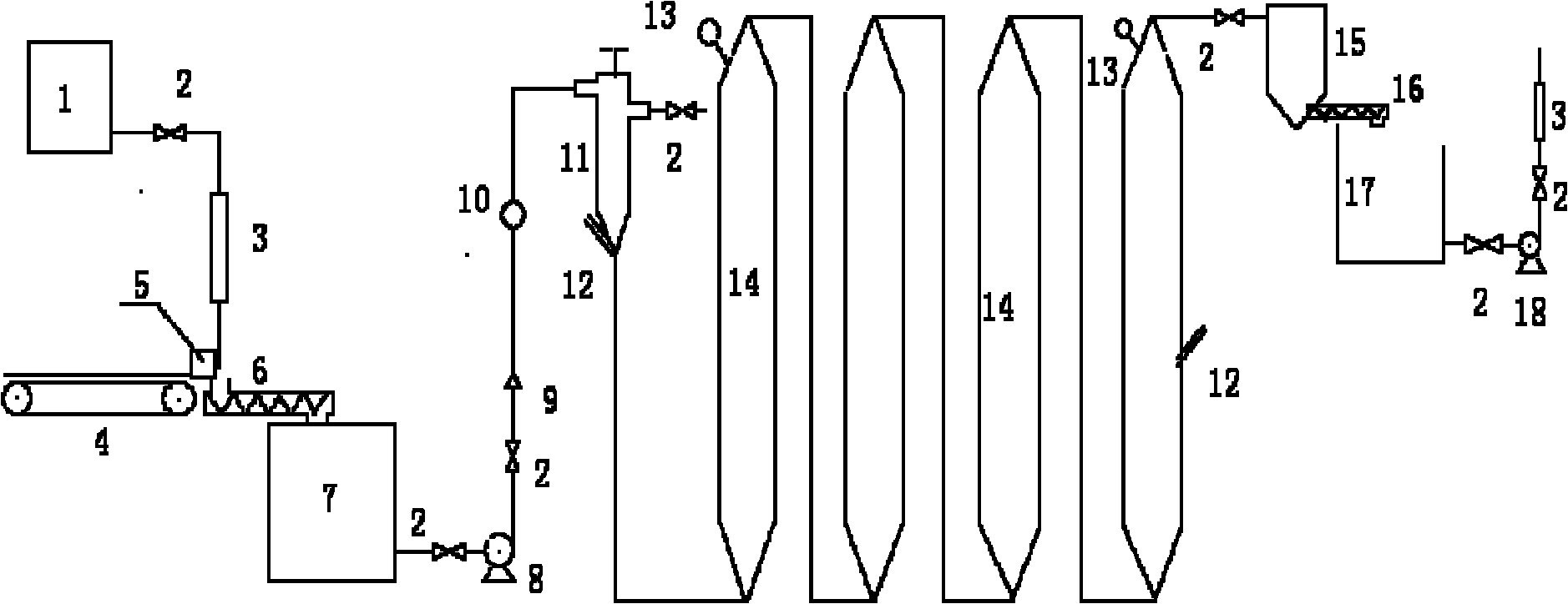

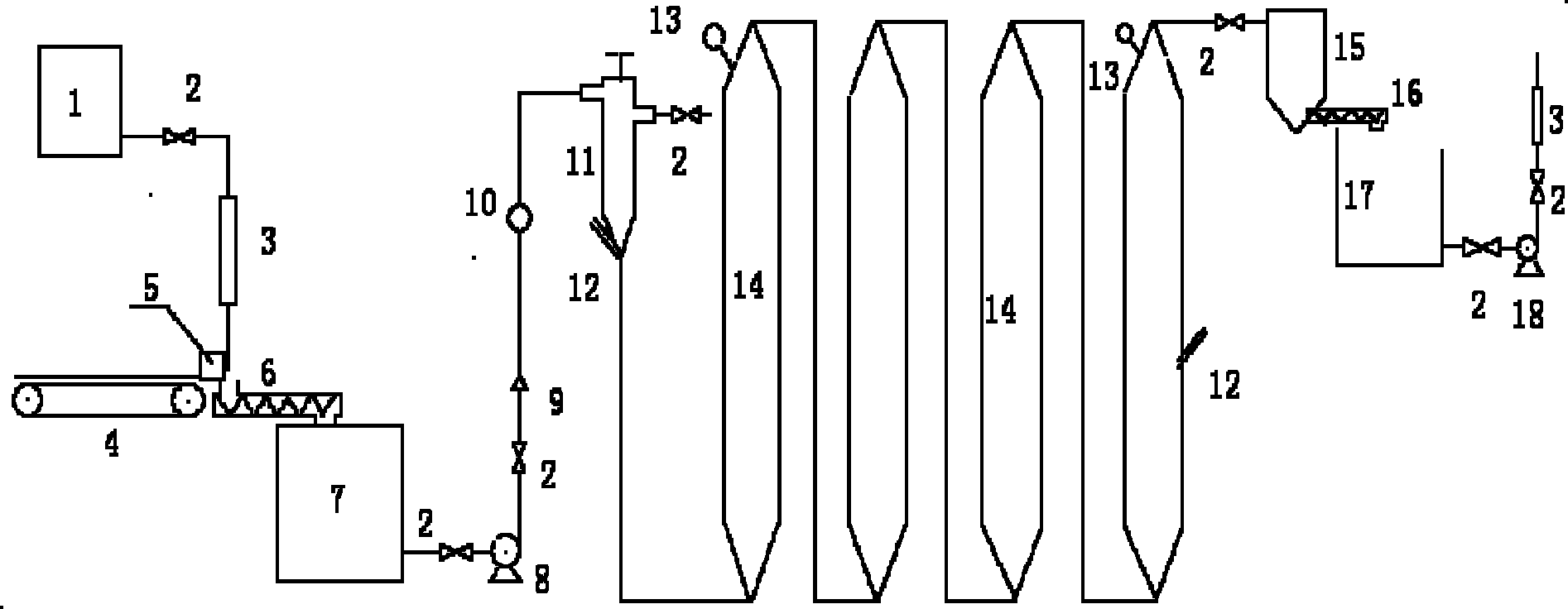

Method and device for continuously hydrolyzing corn bran

The invention relates to a method and device for continuously hydrolyzing corn brans, belonging to the technical field of corn deep processing. The method comprises the following steps: (1) mixing the corn brans with hydrolytic acid, and pre-leaching for 5-10 minutes; (2) heating the material mixed and pre-leached in the step (1) to 115-125 DEG C, and hydrolyzing for 2.5-3.5 hours to obtain hydrolyzate; (3) cooling the hydrolyzate prepared in the step (2), and then separating the hydrolyzate from residues; and (4) when the component content in the hydrolyzate separated in the step (3) meets the requirement, exporting the hydrolyzate separated in the step (3), and carrying out sugar separation; when the component content in the hydrolyzate separated in the step (3) is lower than the required content, leading the hydrolyzate to enter the step (1) to mix with the corn brans, pre-leaching for 5-10 minutes, and recycling. By the method and equipment in the invention, the continuous hydrolysis of the corn brans is achieved, the yield equipment with the same scale has the advantages of low investment, high production efficiency and low energy consumption and is convenient for automatic operation, and the quality of the hydrolyzate is stable.

Owner:SHANDONG LUZHOU FOOD GROUP

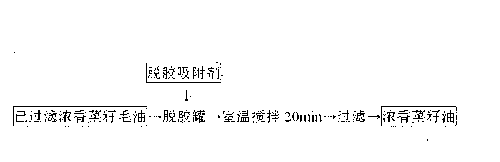

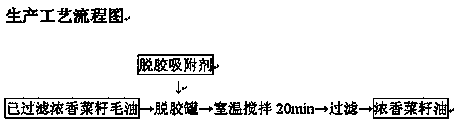

Simple degumming method of concentrated-fragrance colza oil

ActiveCN103215123AThe supporting facilities are simpleShort degumming timeOther chemical processesFatty-oils/fats refiningSlagPhospholipid

The invention relates to a simple degumming method of concentrated-fragrance colza oil. The degumming method comprises the following steps of: (1) pumping squeezed concentrated-fragrance colza crude oil with slag removed into a degumming tank, wherein the concentrated-fragrance colza crude oil does not need to be heated or cooled and just is operated at normal temperature; (2) adding a degumming absorption agent into the degumming tank; (3) stirring for 15-20min at room temperature; and (4) filtering and separating the absorption agent by using a plate frame filtering machine of which the filtering aperture is 5mu m, so as to obtain the refined concentrated-fragrance colza oil. The degumming absorption agent is prepared from montmorillonoid, silicate, modified bentonite and filter aids with different apertures which are mixed and stirred. According to the simple degumming method, the gum impurities such as phospholipids and protein in the concentrated-fragrance colza oil are absorbed by using the degumming absorption agent and then filtered and separated, thus degumming the concentrated-fragrance colza oil; and the conventional process that the concentrated-fragrance colza oil stands for a long time or is subjected to hydration degumming firstly and then dried and dehydrated is replaced, both the gum impurities can be simply and rapidly eliminated, and the concentrated fragrance of the oil is not lost, so that colza oil which is fragrant, pure in quality, nutritive and sanitary is obtained.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

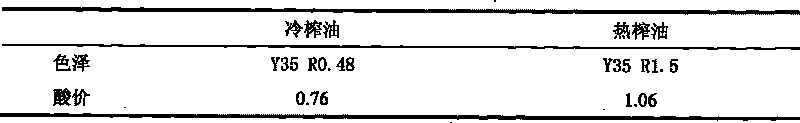

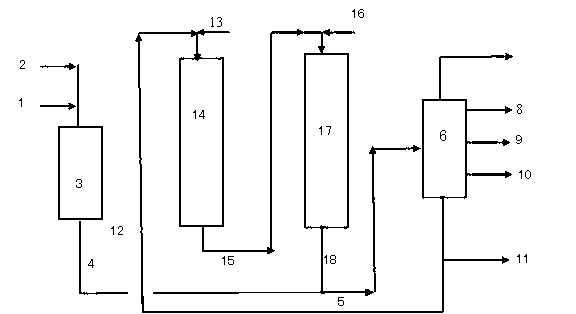

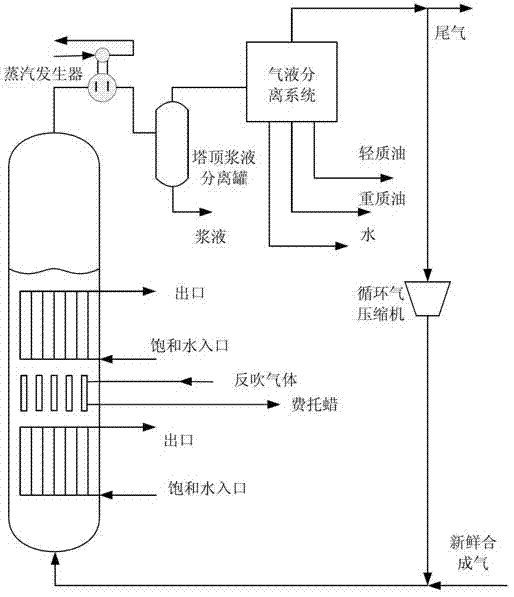

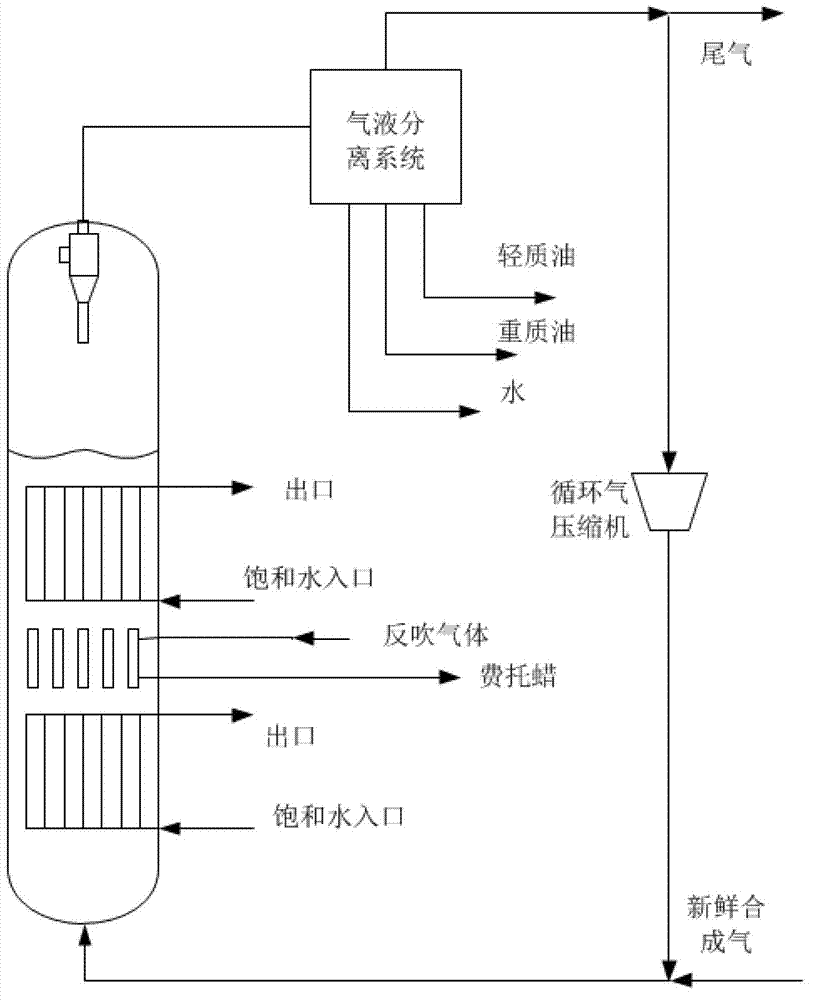

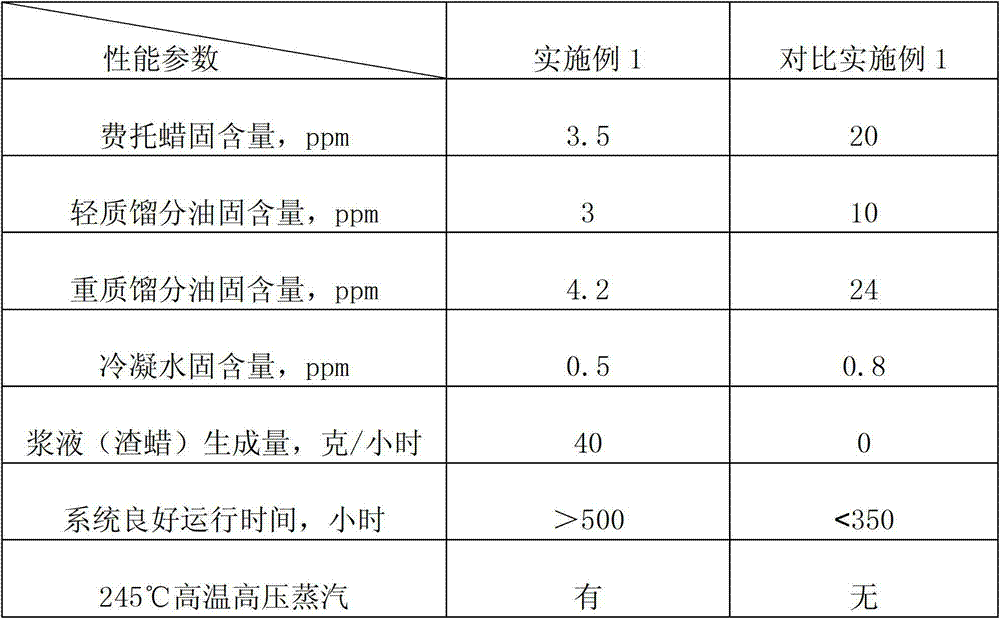

Low-temperature slurry reactor Fischer-Tropsch synthesis system and separation technology thereof

InactiveCN103111241AGuaranteed uptimeQuality improvementLiquid hydrocarbon mixture productionChemical/physical processesWaxLiquid product

The invention discloses a low-temperature slurry reactor Fischer-Tropsch synthesis system and a separation technology thereof. The system comprises at least one low-temperature slurry reactor Fischer-Tropsch synthesis reactor, at least one heat exchanger, at least one gas-slurry separator and at least one gas-liquid separation system, wherein the heat exchanger is used for partially cooling a gaseous product from the reactor and condensing partial gaseous product; the gas-slurry separator is used for separating the condensation product from other gaseous products and / or steam; the gas-liquid separation system is used for separating the other gaseous products and / or steam into a condensable liquid product and a non-condensable gaseous product; the heat exchanger and the gas-liquid separator are located outside the reactor; and the catalyst fine particles and / or dust carried by the gaseous product and / or steam is separated from other gaseous products and / or steam along with the condensation product of the heat exchanger so that the catalyst fine particles and / or dust does not exist in the Fischer-Tropsch wax product and in the condensable liquid product.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

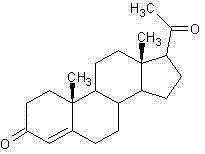

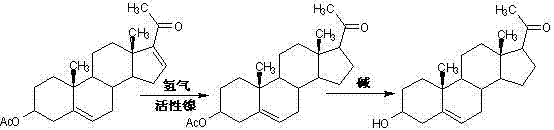

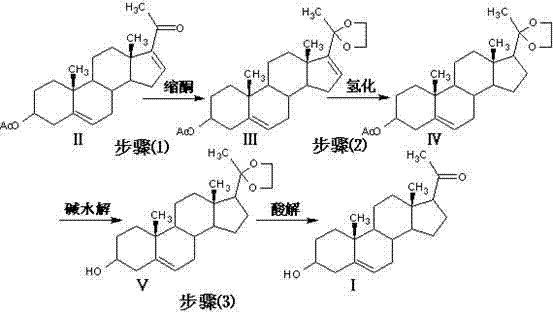

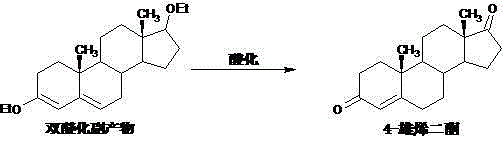

Method for synthesizing progesterone midbody 3beta-hydroxy-5-pregnene-20-ketone

ActiveCN102964415AAvoid it happening againReduce oxidation recovery processSteroidsPregneneProgesterones

The invention relates to a method for synthesizing progesterone midbody 3beta-hydroxy-5-pregnene-20-ketone. By the method, a refining procedure and a by-product oxidation recovery processing procedure of a traditional synthesizing process are saved. The obtained midbody does not need to be refined, the once quality yield is more than 86%, and the product purity is more than 99.0%.

Owner:HUAZHONG PHARMA

Preparation process for sodium 1-amino-4-bromoanthraquinone-2-sulfonate

ActiveCN106083660AReduce consumptionIncrease profitSulfonic acids salts preparationSulfonic acid preparationChlorosulfuric acidSulfite salt

The invention discloses a preparation process for sodium 1-amino-4-bromoanthraquinone-2-sulfonate. The preparation process comprises the following steps: (1) sulfonation: with 1-aminoanthraquinone as a raw material, copper sulfate as a catalyst and dichloroethane as a solvent, carrying out dehydration, then adding chlorosulfonic acid drop by drop for a sulfonation reaction, adding 98% concentrated sulfuric acid after completion of the reaction, extracting 1-aminoanthraquinone-2-sulfonic acid out, allowing 1-aminoanthraquinone-2-sulfonic acid to enter the concentrated sulfuric acid, separating out an acid phase at a lower layer and subjecting the acid phase to a subsequent reaction; (2) bromination: adding bromine into the concentrated sulfuric acid solution of 1-aminoanthraquinone-2-sulfonic acid drop by drop for a reaction so as to obtain the concentrated sulfuric acid solution of bromoamine acid; (3) dilution: adding water into the concentrated sulfuric acid solution of bromoamine acid for dilution and successively carrying out cooling, crystallization and filtering so as to obtain bromoamine acid; and (4) salt formation: adding water to dissolve bromoamine acid and adding sodium sulfite to obtain bromoamine acid sodium salt. The preparation process provided by the invention can reduce energy consumption during solvent recovery; the utilization rate of bromine in bromination is high; sodium sulfite is used for salt formation, so the amount of impurities is reduced; and product quality is high.

Owner:南通市埃唯卡新材料有限公司

Production process of biological diesel

ActiveCN1861749AAvoid pollutionGood miscibilityBiofuelsLiquid hydrocarbon mixture productionBiodieselTriglyceride

This invention relates to the preparation of the biological diesel fuel from the fat acid triglyceride, and special from the animal, vegetable tallow and oil. This invention takes the solid alkali as the catalyst, and the addition of the amine is as the third component. It can gain the high ratio of conversion and the lifetime of the catalyst is long. Comparing to the existing technology, the process of this invention is simple, the condition is moderate, the conversion is high, the by-product is less, and the lifetime of the catalyst is long. The diesel fuel can be produce from the animal and vegetable tallow and oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Composite boiling-dyeing one-bath enzyme and dyeing method

ActiveCN103669011ADeep stainingStaining smallBiochemical fibre treatmentDyeing processFiberPectinase

The invention relates to the field of dyeing, in particular to a composite boiling-dyeing one-bath enzyme and a dyeing method. The enzyme comprises the following components by mass percentage: 5-30 percent of acidic cellulase, 2-30 percent of alkaline pectinase, 0.1-20 percent of alkaline xylanase, 0.1-10 percent of mannose and balance of water. The method for formula treatment is a boiling-dyeing one-bath short-flow process, a refining process is omitted, and pretreatment and one-bath dying are enabled to be synchronously performed. The boiling-dyeing one-bath enzyme is sued for boiling-dyeing one-bath short-flow treatment, treated fabrics are dyed more deeply, the chromatic aberration of dyed cotton fiber and modal fabrics is small, horizontal marks which occur on the surfaces of the fabrics are remarkably reduced and the grade of chromatic aberration reaches grade 5 through national standard grey card chromatic aberration rating.

Owner:WUHAN SUNHY BIOLOGICAL

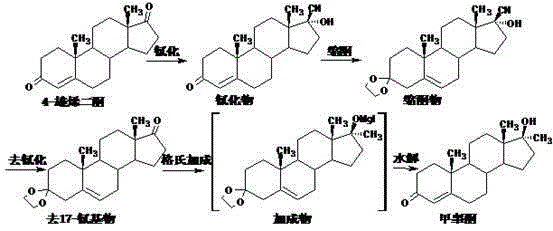

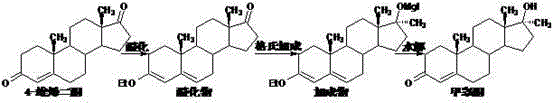

Preparation method for methyltestosterone

The invention provides a preparation method for methyltestosterone. According to the preparation method, methyltestosterone is prepared by taking androstenedione as a raw material and successively performing position-3 keto protection reaction, grignard addition reaction, position-3 keto deprotection and position-17 hydrolysis reaction. The technology possesses the characteristics of being high in reaction selectivity, high in operation safety, simple and easily-realizable for industrialization, low in production cost, high in yield, applicability to industrial large-scale production.

Owner:HUAZHONG PHARMA

Novel powder cationic polymer for preventing clay from hydration swelling

InactiveCN104650287ALow effective concentrationReduce recyclingDrilling compositionPolymer scienceCationic polymerization

The invention relates to a novel powder cationic polymer for preventing clay from hydration swelling, and belongs to the technical field of clay hydration swelling prevention in oil-gas field development. The novel powder cationic polymer is prepared from acrylamide, dimethyl diallyl ammonium chloride and methyl acrylyl ethyl trimethyl ammonium chloride as raw materials, and an ammonium persulfate and sodium hydrogen sulfite redox initiation system is adopted to prepare a novel powder cationic polymer solution for preventing clay from hydration swelling through polymerization of solution free radicals, and the cationic polymer solution is further transferred into micro drying equipment to be dried, and is successively further prepared into crude powder and fine powder, thereby obtaining the powder cationic polymer. By adopting the novel powder cationic polymer, a great amount of expensive, combustible or even toxic solvents are not used, separation equipment is not needed, and the problems that to maintain the flowability of a polymer solution, a conventional solution cationic polymer is relatively low in effective concentration, the package and transportation cost can be increased, a raw material holding space is large and the cationic polymer is inadaptive to the space of an ocean marine petroleum exploitation working platform can be solved.

Owner:JINGZHOU TIANHE SCI TECH CHEM IND

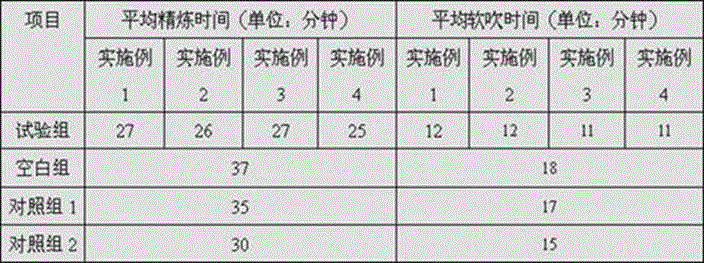

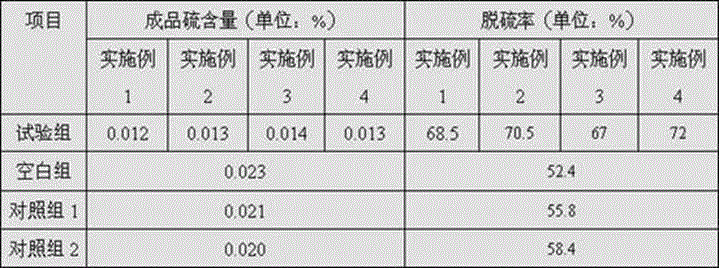

Compound slag cleaning agent for electric furnaces and converters and preparation method thereof

ActiveCN105132630AReduce smelting costReduce refining timeProcess efficiency improvementElectric arc furnaceSlag

The invention provides a compound slag cleaning agent for electric furnaces and converters and a preparation method thereof, and belongs to the technical field of metallurgical auxiliary materials. The compound slag cleaning agent comprises the following components in percentage by weight: calcium oxide 30-50%, alumina oxide 20-40%, barium oxide 5-20%, magnesium oxide 3-15%, and a reducing agent 5-15%. The comprehensive performance of the slag cleaning agent is outstanding the deoxidization, desulphurization and dephosphorization effect of the existing slag cleaning agent is improved and increased, the LF refining time is obviously shortened, the impurity absorption capacity is good, impurities are not introduced during smelting of molten steel; moreover, the kinds and proportion of the raw materials are reasonable, so that compared with the existing dephosphorization slag cleaning agent, the cost of the compound slag cleaning agent is obviously reduced, and the compound slag cleaning agent has obvious market advantage.

Owner:HENAN TONGYU METALLURGY MATERIALS GRP

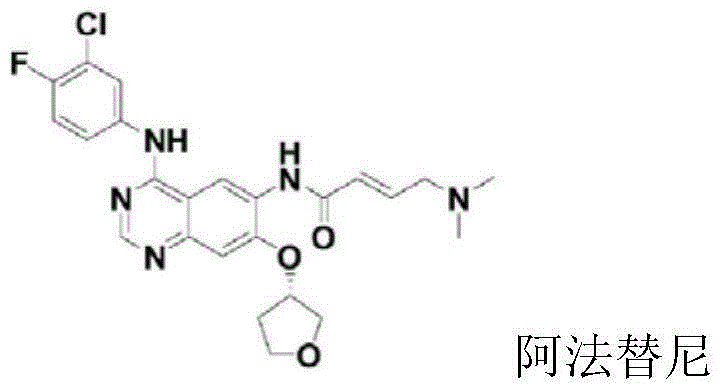

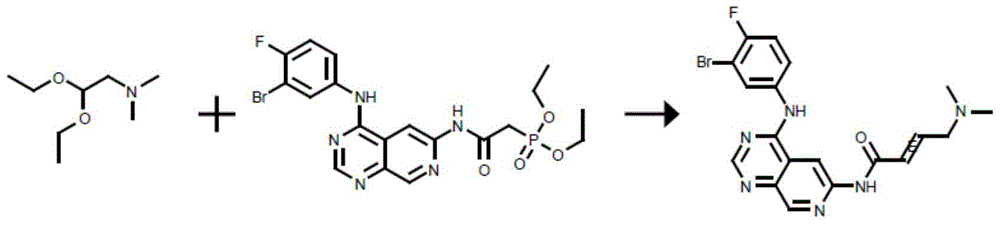

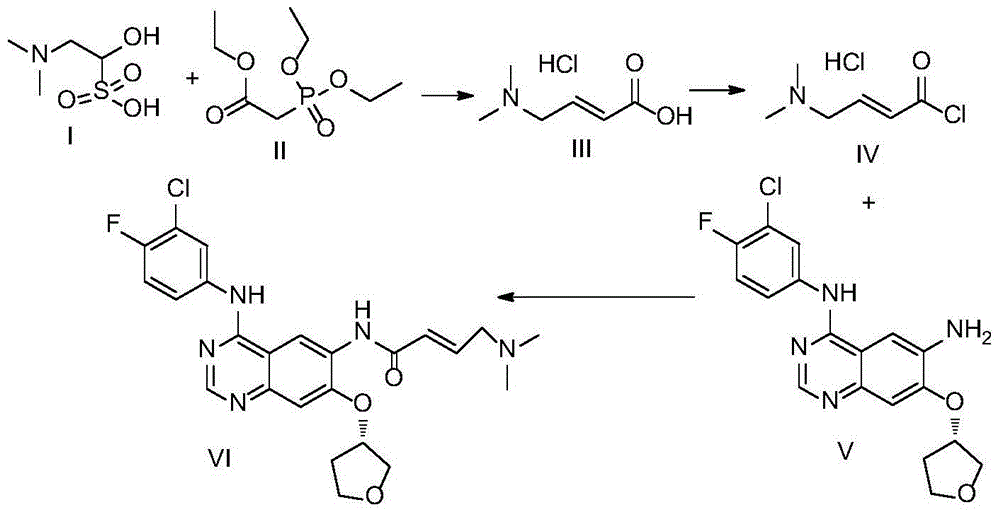

Preparation method for afatinib

ActiveCN105330652AHigh purityHigh yieldOrganic compound preparationAmino-carboxyl compound preparationChlorideCombinatorial chemistry

The invention provides a preparation method for afatinib. The preparation method comprises the following steps: subjecting trans-4-dimethylaminocrotonic acid hydrochloride (III) to chlorination so as to obtain trans-4-dimethylaminocrotonyl chloride hydrochloride (IV); and reacting the compound (IV) with N4-(3-chloro-4-fluoro-phenyl)-7-((S)-tetrahydrofuran-3-yl-oxy)quinazoline-4,6-diamine (V) so as to prepare afatinib (VI). Reaction equations are described in the specification.

Owner:TIANJIN PHARMACN MEDICAL TECH

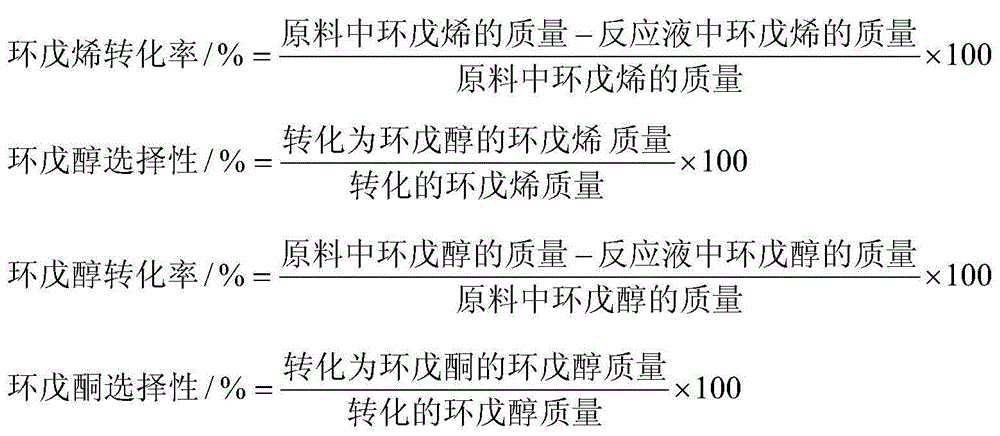

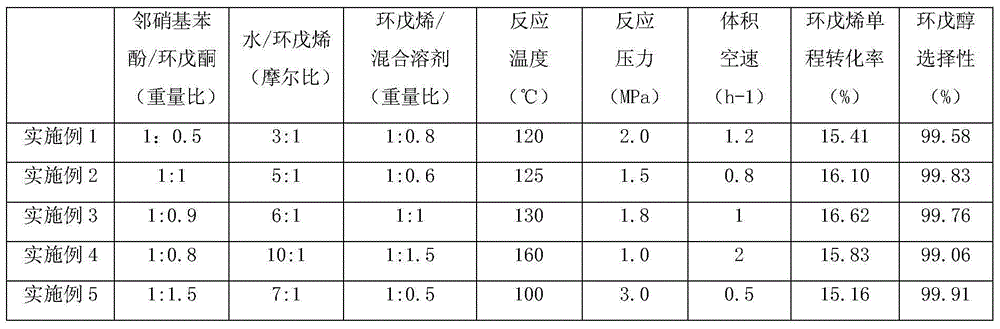

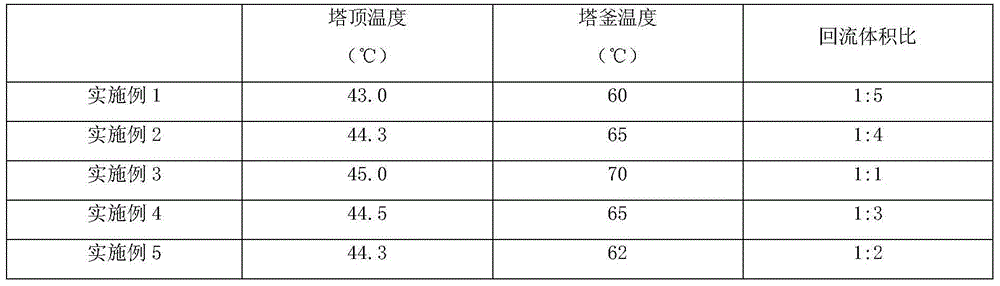

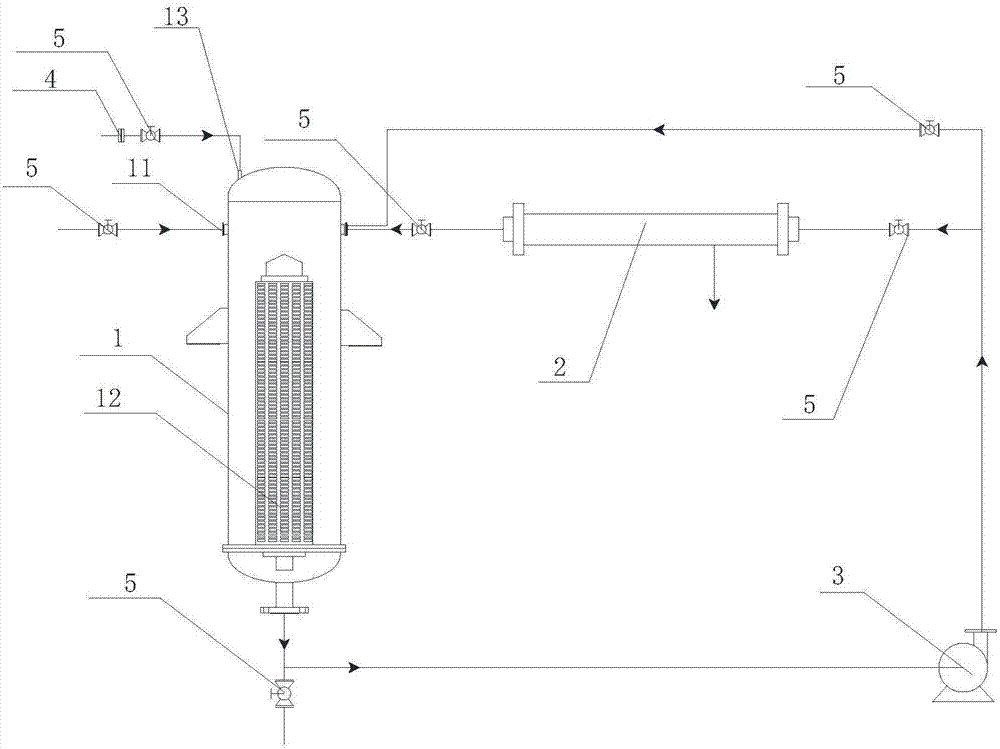

Method for preparing cyclopentanone by using cyclopentene as raw material

ActiveCN105585468AReduce recyclingReduce refining processCarbonyl compound preparation by oxidationCarbonyl compound separation/purificationCyclopenteneHydration reaction

The invention belongs to the technical field of organic chemical industry and specifically relates to a method for preparing cyclopentanone by using cyclopentene as a raw material. According to the method, materials composed of cyclopentene, water and a mixed solvent continuously pass through a fixed bed loaded with a catalyst to undergo a hydration reaction, and then the hydration reaction product undergoes catalytic dehydrogenation so as to prepare cyclopentanone. The mixed solvent is composed of o-nitrophenol and cyclopentanone at the mass ratio of 1: (0.5-1.5). Conversion rate of cyclopentene is high, and cyclopentene and the solvent are hardly subjected to side reaction. By the method, separation technology is simplified, and energy consumption is lowered.

Owner:CHINA PETROLEUM & CHEM CORP +1

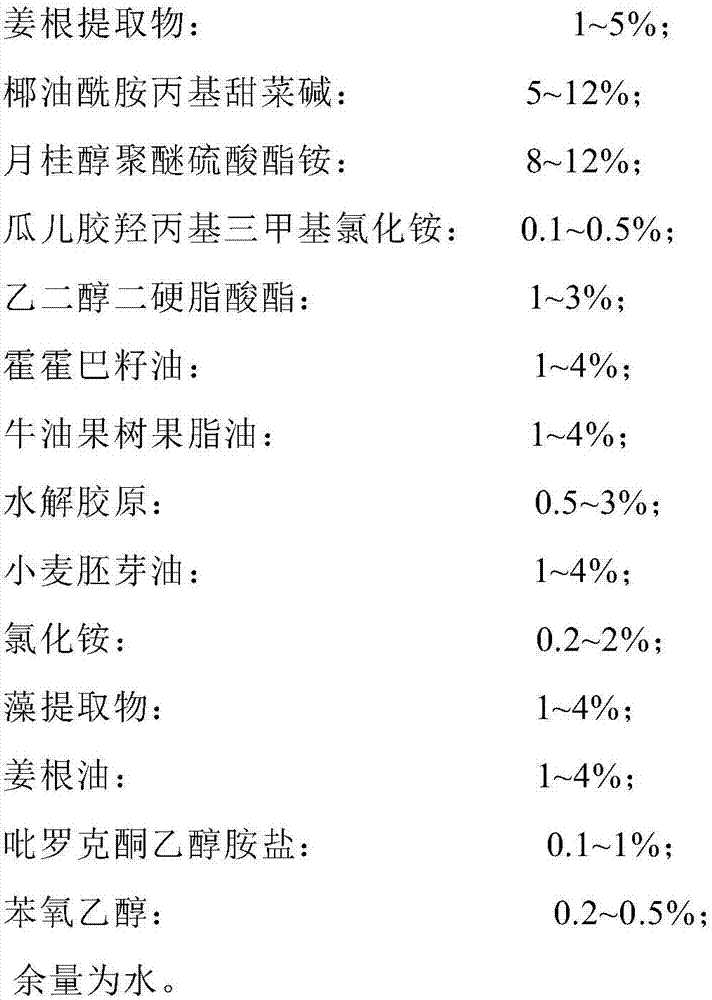

Preparation method and device for ginger root extract and hair-loss-preventing shampoo composition

PendingCN107028847AKeep active ingredientsImprove the effect of impurity removalCosmetic preparationsHair cosmeticsBiotechnologyBotany

The invention provides a preparation method of ginger root extract. The preparation method comprises the following steps: juicing fresh ginger, and separating the ginger juice from ginger dregs; carrying out normal temperature extraction on the ginger dregs, thus obtaining the extracted liquid; and mixing the ginger juice and the extracted liquid, carrying out centrifugalizing, carrying out refining, and carrying out concentrating by adopting a nanofiltration membrane, thus obtaining the ginger juice extract. Compared with the prior art, the preparation method has the beneficial effects that 1, through the combined extraction, the active ingredients in the fresh ginger are extracted to the maximum; 2, through the full-course low-temperature operation process, the active ingredients in the fresh ginger are protected from being decomposed and destroyed to the maximum; 3, through the special refined integrated device, the impurity removal effect is enhanced, the refining process is shortened, and the efficiency is improved.

Owner:SHANGHAI JIAYU BIOLOGICAL TECH CO LTD

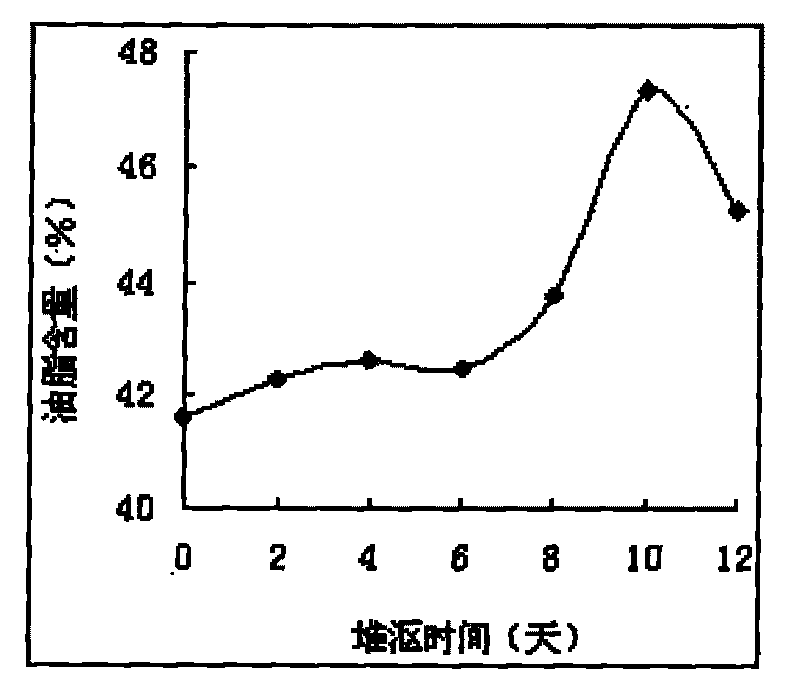

Walnut brain nourishing tea oil subcritical extraction technology

InactiveCN106147989ASo as not to damageImprove qualityFatty-oils/fats refiningFatty-oils/fats productionAdditive ingredientFiltration

The invention discloses walnut brain nourishing tea oil and a subcritical extraction technology thereof. The technology specifically comprises the following steps: selecting camellia seed, walnut, black sesame, sunflower seed, pumpkin, corn germ, peanut and millet; grinding, sieving and mixing for later use; with subcritical fluid as an extraction solvent, repeatedly extracting walnut brain nourishing tea powder by using a subcritical fluid extraction device; after the extraction, separating the extraction solvent from target product in a way of compressor desolvation and vacuum pump-compressor linked desolvation to obtain crude oil; and performing refined filtration on the crude oil to obtain high-quality walnut brain nourishing tea oil. The method has the characteristics of easiness in operation, low energy consumption, little pollution, short extraction time and high oil extraction rate and facilitates industrial production. The subcritical fluid extraction technology is finished in a low-temperature condition, and the physicochemical properties and nutritional ingredients of the target product can be protected from damage; and moreover, the refining processes are reduced, the industrial cost is lowered, and the technology is of great significance to the industrial production of new-resource functional grease.

Owner:YUEXI GUANGSHENG TEA OIL CO LTD

Method for processing edible camellia oil

ActiveCN101194713BLow extraction temperatureHigh oil extraction rateEdible oils/fatsFood preparationCamellia oleiferaAdditive ingredient

The invention discloses a process for preparing edible camellia oil, which comprises the steps of removing hulls of camellia oleosa seeds, drying, disintegrating, cooking camellia oleosa seed, and extracting and refining camellia oil. The invention adopts advanced hypercritical CO2 extraction technology, changes traditional camellia process technology, increases the quality of oil, reduces refining procedures, decreases refining loss of oil, increases oil yield rate, and reduces the losses of biologically active substance and nutrition components in the process of refining, increases the contents of active substances such as VE in the camellia oil, squalene and the like, and increases the quality and the health function of the finished product of camellia oil.

Owner:SOUTH CHINA AGRI UNIV

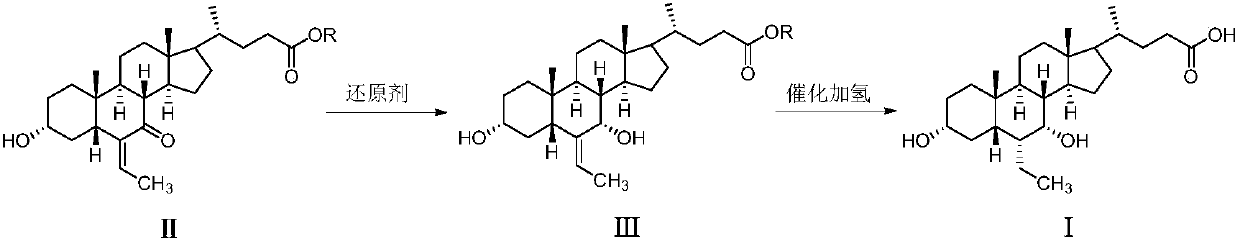

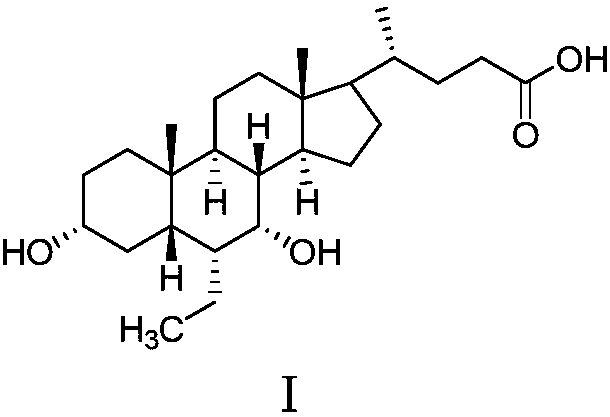

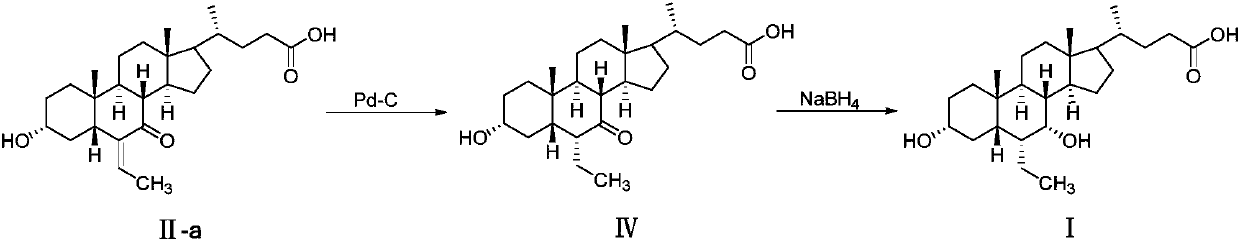

Preparation method of OCA (obeticholic acid)

The invention discloses a preparation method of OCA (obeticholic acid). (E)-3 alpha-hydroxy-6-ethylidene-7-one-5 beta-cholane-24-acid or (E)-3 alpha-hydroxy-6-ethylidene-7-one-5 beta-cholane-24-acid ester, a solvent and a reducing agent are placed in a reactor to react to produce (E)-3 alpha, 7 alpha-dihydroxy-6-ethylidene-5 beta-cholane-24-acid or (E)-3 alpha, 7 alpha-dihydroxy-6-ethylidene-5 beta-cholane-24-acid ester. (E)-3 alpha, 7 alpha-dihydroxy-6-ethylidene-5 beta-cholane-24-acid or (E)-3 alpha, 7 alpha-dihydroxy-6-ethylidene-5 beta-cholane-24-acid ester, alkali, a solvent and a catalyst are placed in the reactor for hydrogenation to produce OCA. OCA with the purity of 99.5% or above can be obtained with the preparation method, the process is simple and good in reproducibility, thesolvent is safe, non-toxic, conventional and easy to obtain, post-treatment is simple, and the production cycle is short.

Owner:NANJING CHANGAO PHARMA SCI & TECH CO LTD

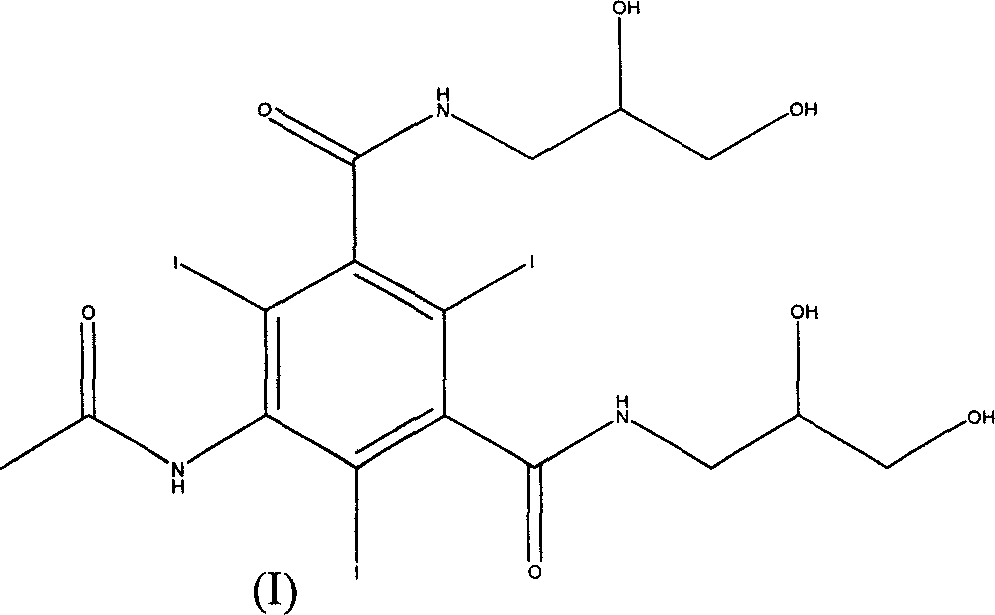

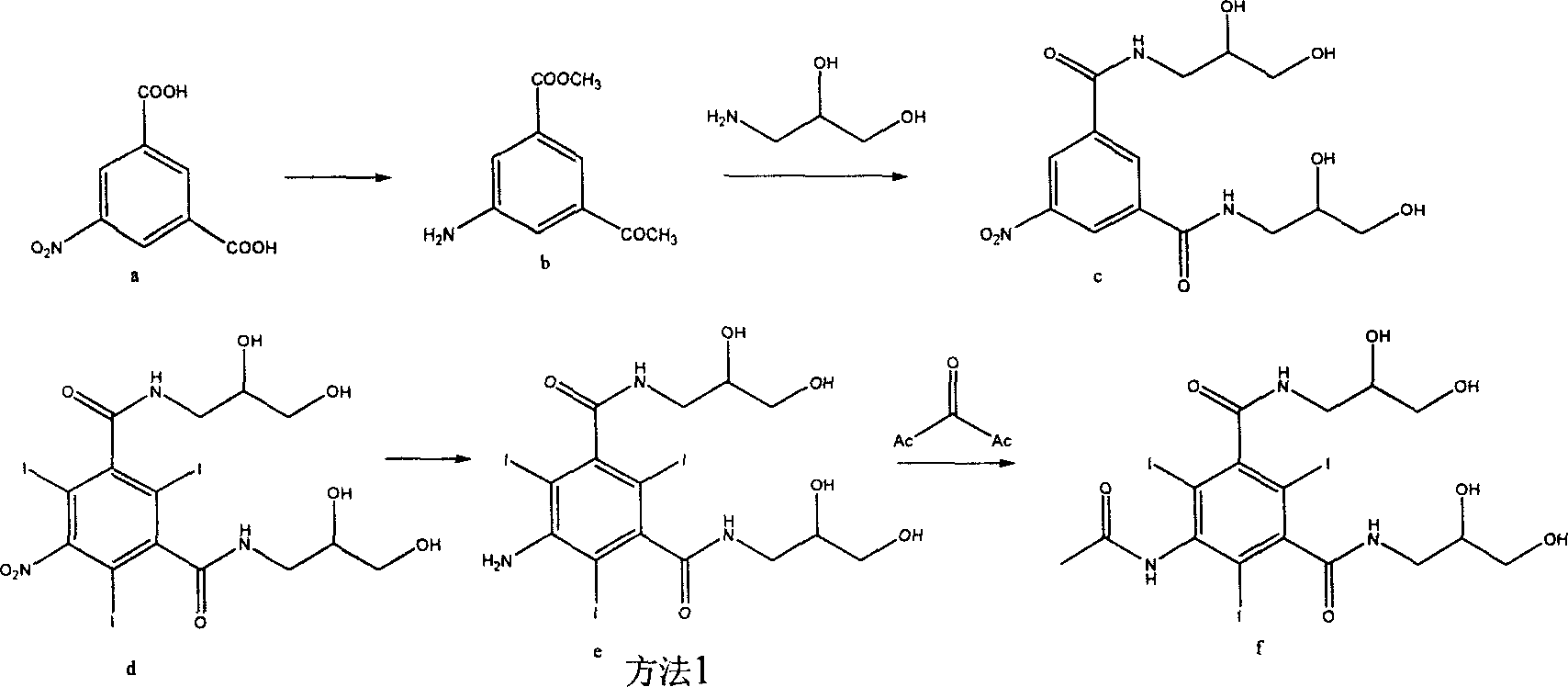

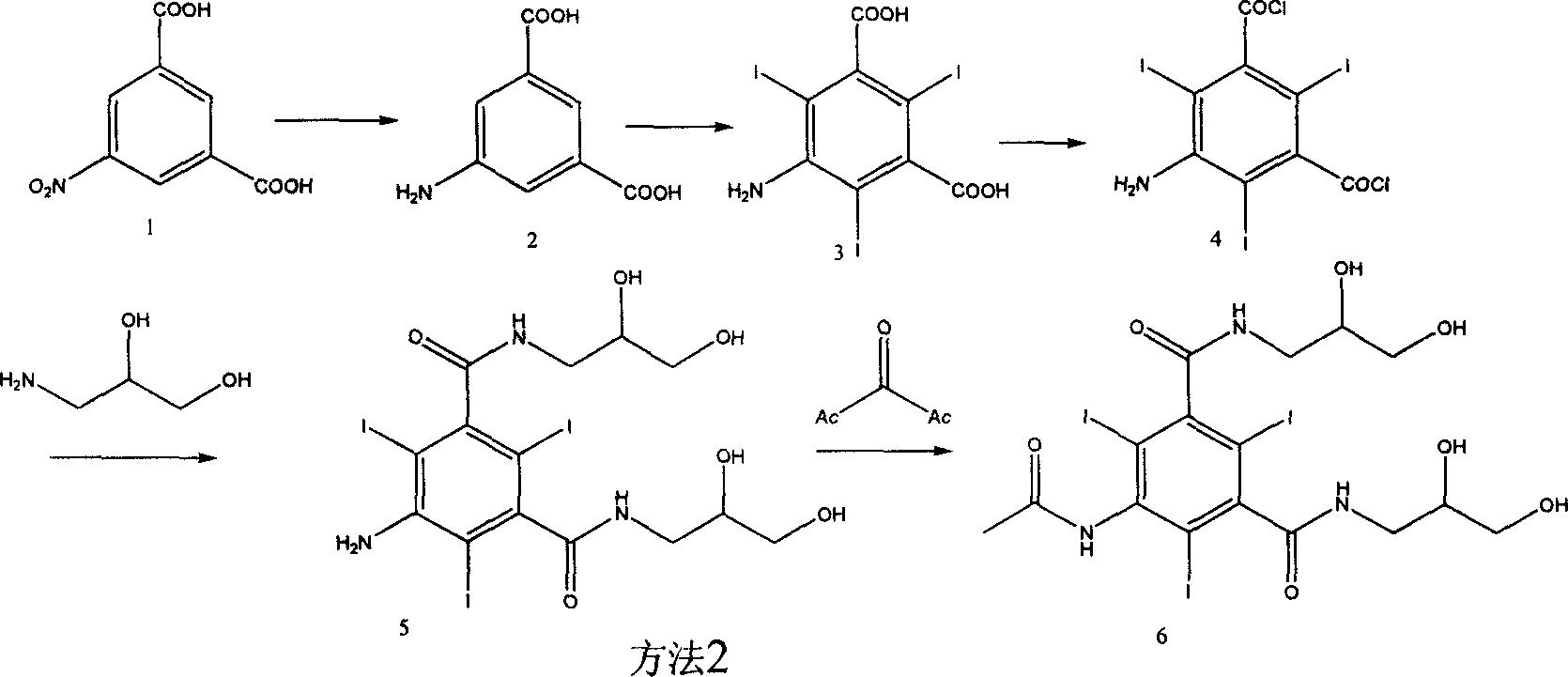

Process for preparing 5-acetamino-N,N'-bis (2,3-dihydroxypropyl)-2,4,6-tri-iodo isophthalamide

InactiveCN1721393ASimplify production stepsShorten the production cycleOrganic compound preparationCarboxylic acid amides preparationAcetic acidOrganic layer

The preparation process of 5-acetylamino-N, N'-bis(2, 3-dihydroxypropyl)-2, 4, 6-triiodo isophthalamide with 5-nitro metaphthalic acid as initial material includes the following steps: the first reduction and iodation; dissolving 5-amino-2, 4, 6-triiodo isophthalic acid generated in the iodation step in solvent and adding thionyl chloride for reflux reaction of 1-18 hr; adding glacial acetic acid to reaction at 5-80 deg.c and washing; adding acid-binding agent, aminoglycerin and dimethyl methanamide to the washed organic layer to react at -10 deg.c to +50 deg.c; and filteing and cleaning after reaction. The preparation process of the present invention is simple, short, convenient in operation and high in yield.

Owner:XINCHANG GUOBANG CHEM IND

Simple degumming method of concentrated-fragrance colza oil

ActiveCN103215123BThe supporting facilities are simpleShort degumming timeOther chemical processesFatty-oils/fats refiningSlagPhospholipid

The invention relates to a simple degumming method of concentrated-fragrance colza oil. The degumming method comprises the following steps of: (1) pumping squeezed concentrated-fragrance colza crude oil with slag removed into a degumming tank, wherein the concentrated-fragrance colza crude oil does not need to be heated or cooled and just is operated at normal temperature; (2) adding a degumming absorption agent into the degumming tank; (3) stirring for 15-20min at room temperature; and (4) filtering and separating the absorption agent by using a plate frame filtering machine of which the filtering aperture is 5mu m, so as to obtain the refined concentrated-fragrance colza oil. The degumming absorption agent is prepared from montmorillonoid, silicate, modified bentonite and filter aids with different apertures which are mixed and stirred. According to the simple degumming method, the gum impurities such as phospholipids and protein in the concentrated-fragrance colza oil are absorbed by using the degumming absorption agent and then filtered and separated, thus degumming the concentrated-fragrance colza oil; and the conventional process that the concentrated-fragrance colza oil stands for a long time or is subjected to hydration degumming firstly and then dried and dehydrated is replaced, both the gum impurities can be simply and rapidly eliminated, and the concentrated fragrance of the oil is not lost, so that colza oil which is fragrant, pure in quality, nutritive and sanitary is obtained.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Preparation method of sapropterin dihydrochloride

ActiveCN109776540AAvoid refiningReduce refining processEsterified saccharide compoundsSugar derivativesAcetic acidAcetic anhydride

The invention relates to a preparation method of sapropterin dihydrochloride shown as formula (I) as shown in the specification. The preparation method comprises the steps of taking 5-deoxy arabinoseas a raw material, performing acetylation reaction in the presence of acetic anhydride to form an intermediate DL-1, allowing DL-1 to react with phenylhydrazine under the catalysis of acetic acid to form an intermediate DL-2, allowing DL-2 and pyrimidylamine sulfate to give a ring closing reaction under the catalysis of anhydrous lithium perchlorate to form an intermediate DL-3, directly oxidizingDL-3 through elemental iodine without purification to form an intermediate DL-4, hydrolyzing DL-4 through potassium hydroxide to form L-biopterin (DL-5), and reducing and salifying L-biopterin through a platinum catalyst to form sapropterin dihydrochloride. The preparation method is easy and simple to operate, high in yield, low in energy consumption and suitable for industrial production, the total yield of the preparation method is greater than 70%, and the purity of a final product reaches above 99.5%.

Owner:北京启慧生物医药有限公司 +1

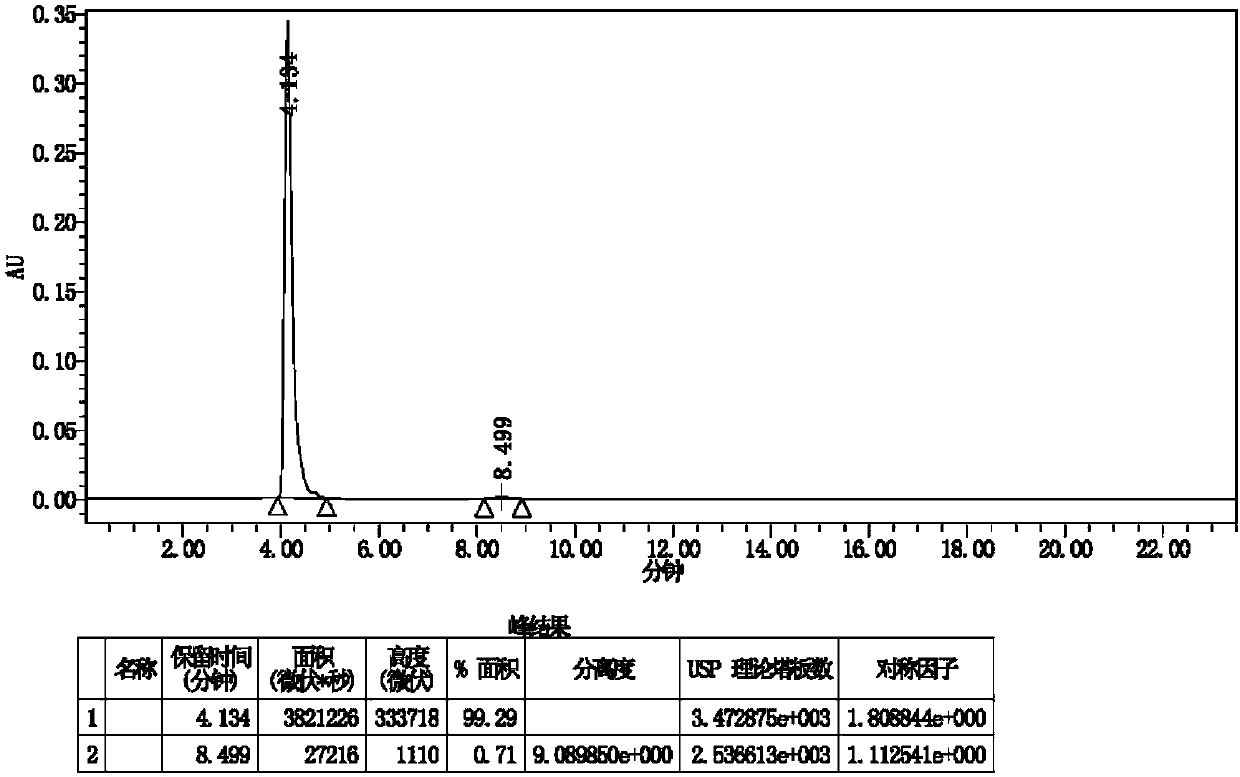

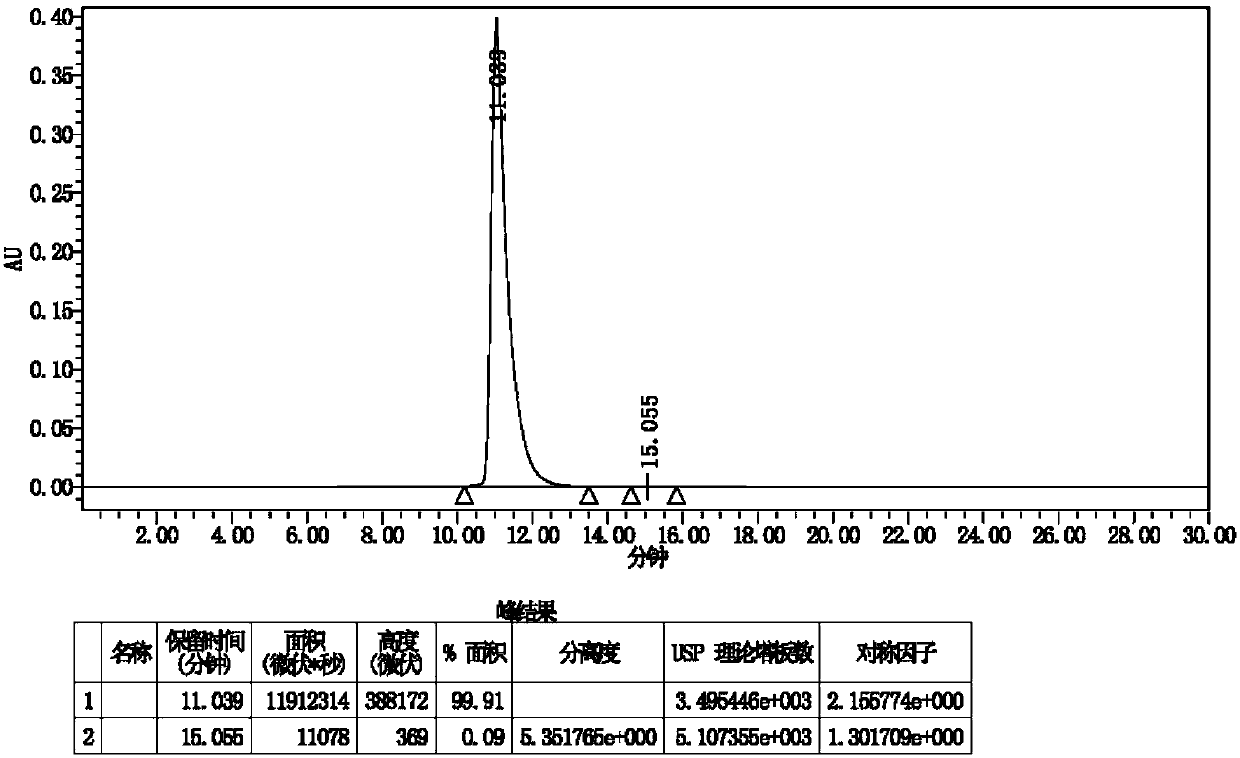

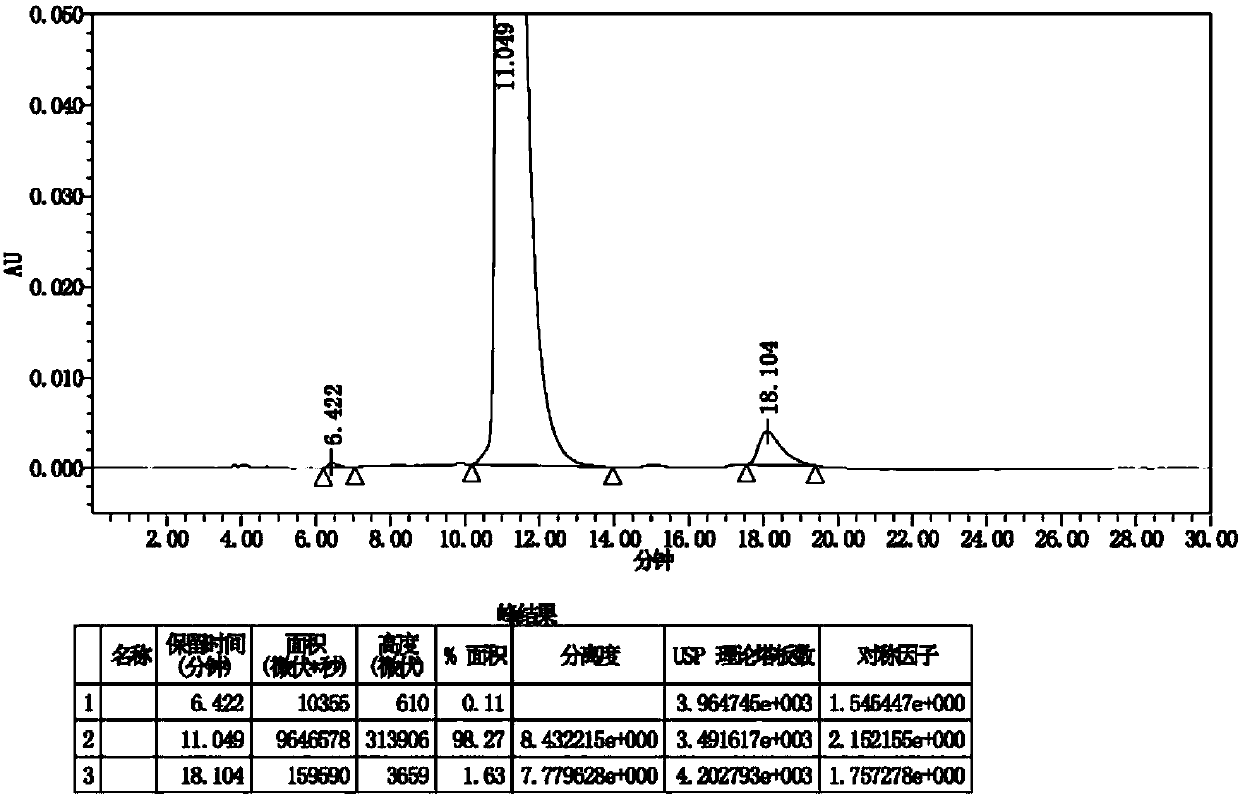

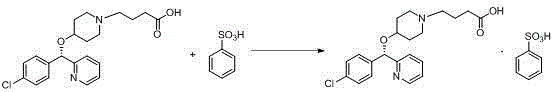

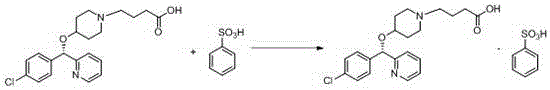

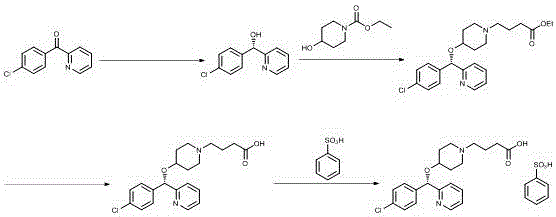

Salt-forming method of bepotastine besilate

ActiveCN106045974AIncrease productivityShort crystallization timeOrganic chemistryN-Butyric acidAlcohol

The invention discloses a salt-forming method of bepotastine besilate, wherein the method includes the steps of: 1) adding benzenesulfonic acid monohydrate to organic alcohol, stirring the solution until the benzenesulfonic acid is completely dissolved for later use; 2) dissolving (+)-(S)-4-{4-[(4-chlorophenyl)(2-pyridyl)methoxyl]piperidyl}n-butyric acid in organic alcohol, controlling the temperature at -20 - 20 DEG C and stirring speed at 50-200 rpm, adding a less amount of bepotastine besilate crystal seeds, dropwisely adding the benzenesulfonic acid organic alcohol solution, and then continuously stirring the solution with temperature maintained; and 3) performing crystallization for 1-5 h and filtering the solution, pour-washing a filter cake with the organic alcohol, and performing pressure reduced drying to obtain the bepotastine besilate. The method can form uniform granules in the product, is high in yield, has good impurity removal effect and excellent operability, is low in production cost and high in efficiency, and is suitable for industrial production.

Owner:HANGZHOU HEZE PHARMA TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com