Simple degumming method of concentrated-fragrance colza oil

A degumming method, rapeseed oil technology, applied in chemical instruments and methods, edible oil/fat, fat oil/fat refining, etc., can solve the problems of long dephosphorization time, large flavor loss, high hydration temperature, etc., and achieve supporting facilities Simplicity, lower production cost, less effect of refining process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

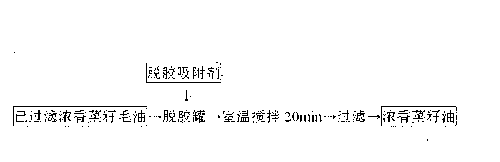

Image

Examples

Embodiment 1

[0021] Pump 100kg of hot-pressed crude rapeseed oil into a 200L degumming tank, add an adsorbent accounting for 1% of the crude oil weight, start the agitator at a speed of 60 rpm, and react at room temperature for 20 minutes. The plate and frame filter is used for filtration and separation to obtain clear and transparent fragrant rapeseed oil that meets the fourth-grade standard of GB 1536. There is no precipitate in the 280°C heating test, and the dephosphorization effect is 94.2%.

Embodiment 2

[0023] Pump 100kg of hot-pressed crude rapeseed oil into a 200L degumming tank, add an adsorbent accounting for 1.5% of the crude oil weight, start the agitator at a speed of 60 rpm, and react at room temperature for 20 minutes. The plate and frame filter is used for filtration and separation to obtain clear and transparent aromatic rapeseed oil that meets the fourth-grade standard of GB 1536. There is no precipitate in the 280°C heating test, and the dephosphorization effect is 98.2%.

Embodiment 3

[0025] Pump 100kg of hot-pressed crude rapeseed oil into a 200L degumming tank, add an adsorbent accounting for 2% of the crude oil weight, start the agitator at a speed of 60 rpm, and react at room temperature for 15 minutes. The plate and frame filter is used for filtration and separation to obtain clear and transparent fragrant rapeseed oil that meets the fourth-grade standard of GB 1536. There is no precipitate in the 280°C heating test, and the dephosphorization effect is 99.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com