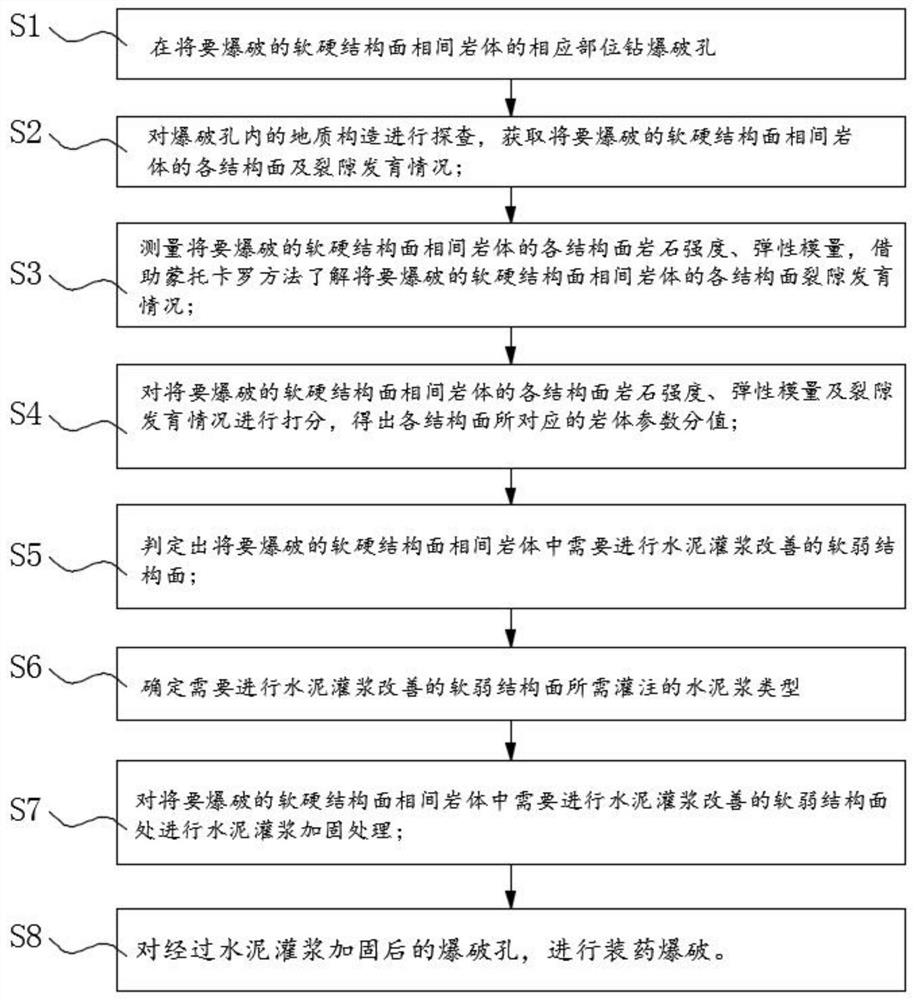

A Blasting Method Applicable to Alternate Rock Mass with Soft and Hard Structural Surfaces

A technology for weak structural surfaces and structural surfaces, which can be used in blasting, earthwork drilling, wellbore/well components, etc., and can solve problems such as energy leakage and uneven damage in weak structural layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

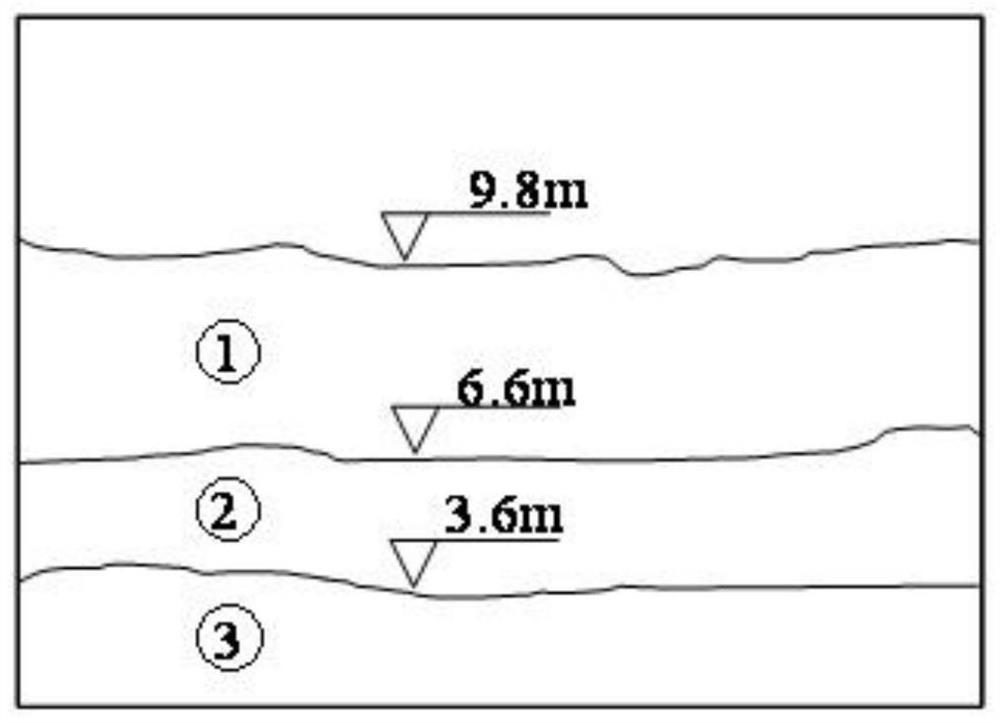

[0154] Embodiment 1: see figure 2 As shown, it is a schematic diagram of the geological situation of an embodiment of a rock mass with soft and hard structural surfaces to be blasted that is detected by the blasting method of the present invention. figure 2 Among them, the first and third layers are granite, and the strength of granite is 127MPa, and the elastic modulus is 32GPa; the second layer is slate, and the strength of slate is 45MPa, and the elastic modulus is 21GPa; In addition, in There is an east-west micro-crack inside the granite of the first layer; there is no crack inside the granite of the third layer; there are two main cracks inside the slate of the second layer.

[0155] According to the scoring method in the above rock mass parameter scoring table 1, it can be obtained:

[0156] The rock mass parameter score corresponding to the first layer of granite is F1=1 (that is, the score corresponding to the strength)+1 (that is, the score corresponding to the el...

Embodiment 2

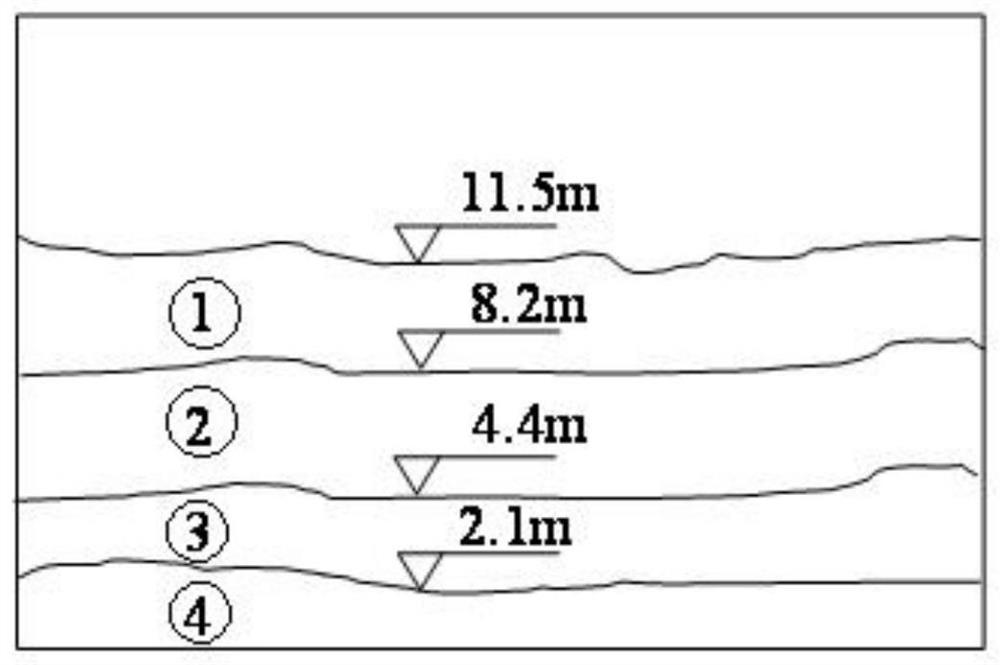

[0164] Embodiment 2: see image 3 As shown, it is a schematic diagram of the geological situation of another rock mass embodiment with soft and hard structural surfaces to be blasted by the blasting method of the present invention. image 3 Among them, the first layer and the third layer are both sandstone, and the strength of sandstone is 67MPa, and the elastic modulus is 27GPa; the second layer is mudstone, and the strength of mudstone is 23MPa, and the elastic modulus is 12GPa; the fourth layer is mudstone The strength of argillaceous sandstone is 31MPa, and the elastic modulus is 17MPa; in addition, there is a micro-crack in the first layer of sandstone; there is a main crack in the second layer of mudstone; in the third layer of sandstone No cracks exist; there is 1 micro-crack inside the fourth layer of argillaceous sandstone.

[0165] According to the scoring method in the above rock mass parameter scoring table 1, it can be obtained:

[0166] The rock mass parameter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com