Device and method for treating solid waste of iron and steel plant

A solid waste and treatment device technology, applied in crucible furnaces, fluidized bed furnaces, electric furnaces, etc., can solve problems such as high equipment investment, difficulty in handling solid waste, gas pipeline blockage, etc., and achieve high heat transfer density and energy utilization efficiency The effect of high and low furnace equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

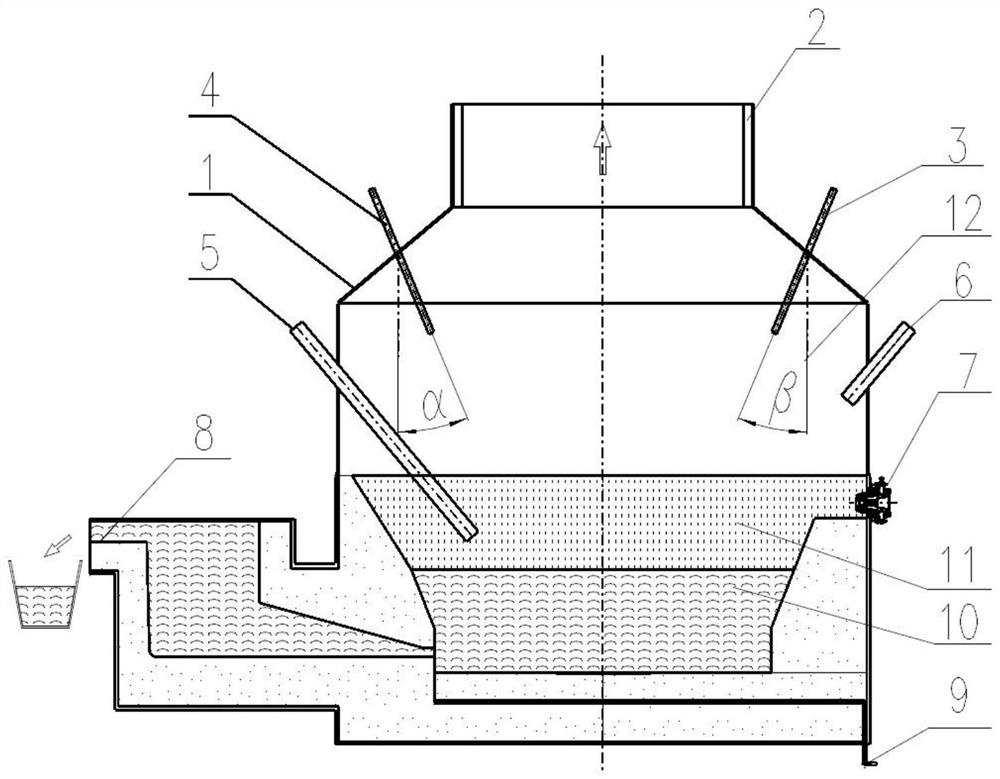

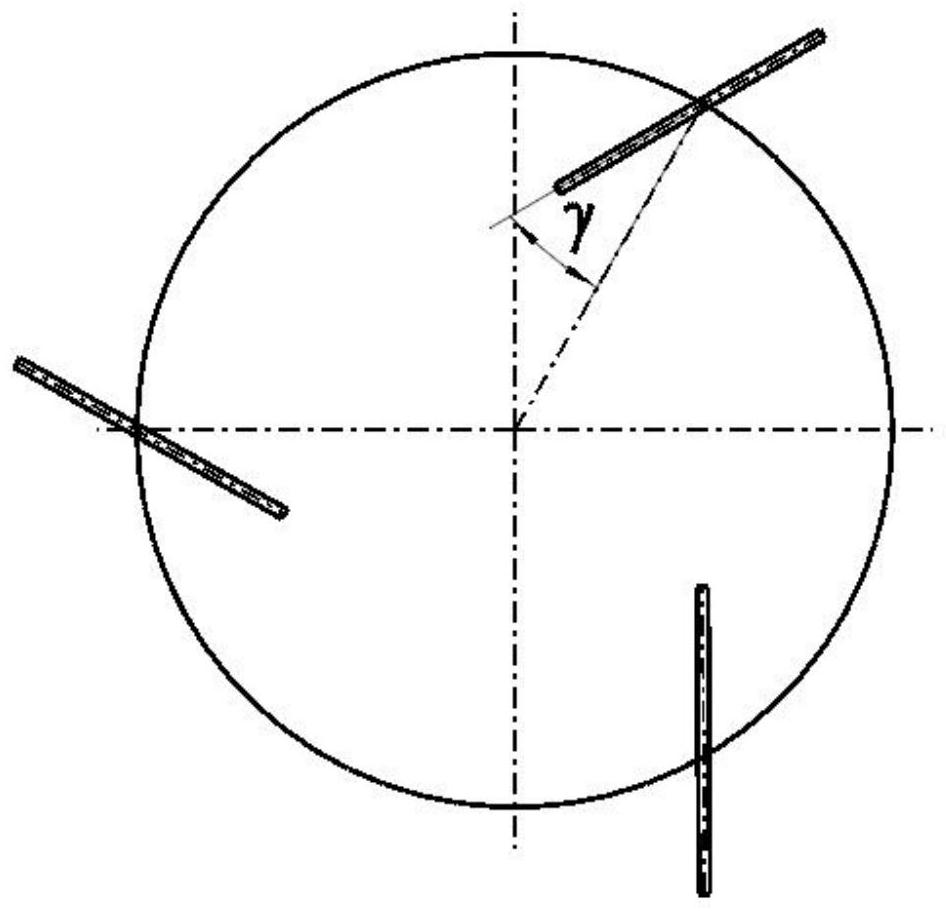

[0047] After drying, the solid waste of iron and steel plant has a moisture content of less than 2%, and then undergoes screening treatment. After screening, the material below 6 mm is mixed with coal powder and flux, and then sprayed into the furnace through the solid waste powder spray gun 5, with a thickness of 15-20 mm. The solid waste bulk materials are sent into the solid waste treatment furnace through the bucket elevator and belt conveyor equipment through the solid waste bulk material feeding port 6; the oxygen-rich gas sprayed into the furnace through the oxygen-rich gas spray gun 3 O 2 % content is controlled at 60-75%; oxygen-enriched gas spray guns 3 are arranged on the cone section of the furnace shell, the number is 2, the vertical arrangement angle β on the furnace shell is 25°, and it is a rotary angle in the circumferential direction of the furnace shell distribution, the rotation angle γ is 30°. The substances injected into the furnace through the fuel lanc...

Embodiment example 2

[0049] After the solid waste of the iron and steel plant is preheated and pre-reduced in a high-temperature four-stage fluidized bed, the temperature of the raw material entering the furnace reaches 800 °C, and the pre-reduction degree of the raw iron element is 75%. After the flux is mixed, the solid waste powder material spray gun 5 is sprayed into the furnace through the high-temperature airtight nitrogen conveying pipe; the oxygen-rich gas injected into the furnace through the oxygen-rich gas spray gun 3 2 % content is controlled at 60-75%; oxygen-enriched gas spray guns 3 are arranged on the cone section of the furnace shell, the number is 2, the vertical arrangement angle β on the furnace shell is 30°, and it is a rotary angle in the circumferential direction of the furnace shell distribution, the rotation angle γ is 30°. The substances injected into the furnace through the fuel lance 4 can be fuels such as high calorific value gas, natural gas, biomass gas, oil, etc. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com