Low-temperature slurry reactor Fischer-Tropsch synthesis system and separation technology thereof

A Fischer-Tropsch synthesis, slurry bed technology, which is applied in the preparation of liquid hydrocarbon mixtures, petroleum industry, chemical instruments and methods, etc., can solve the problems that do not involve the effective separation of catalyst fine particles and/or dust, and are not specified.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

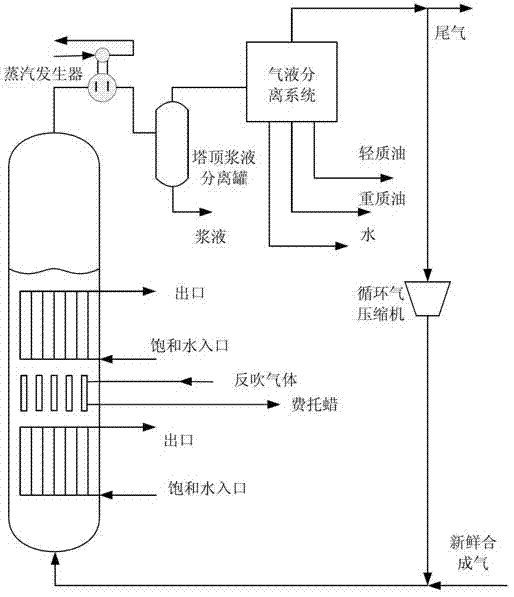

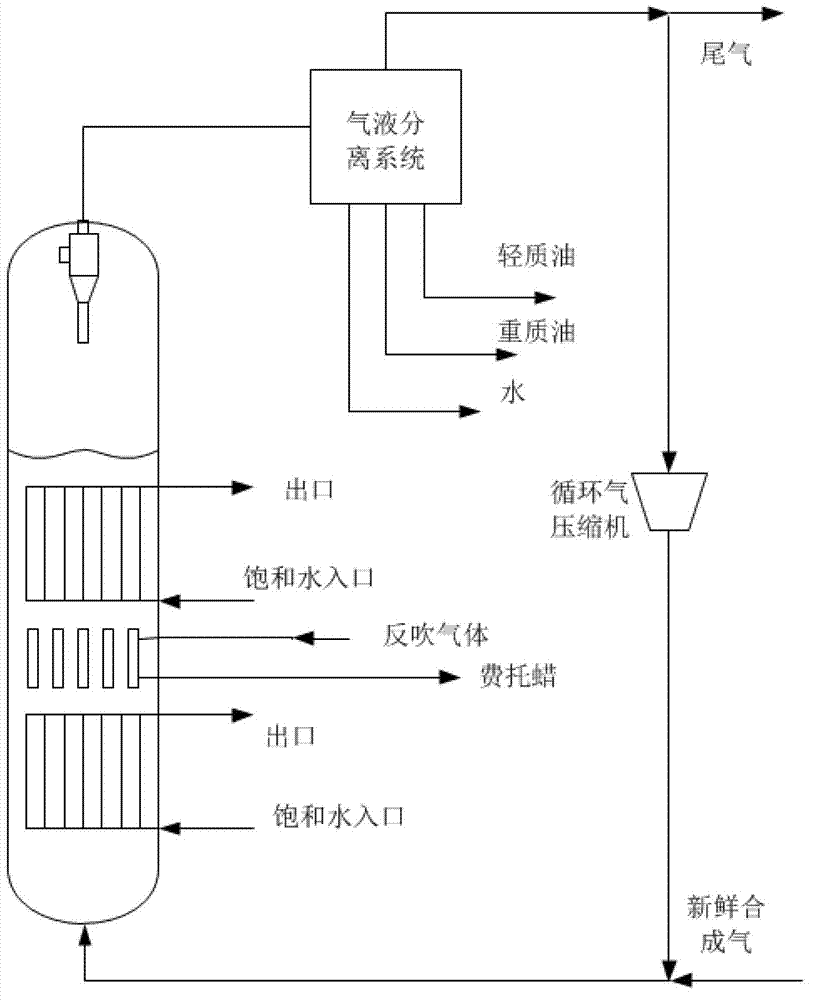

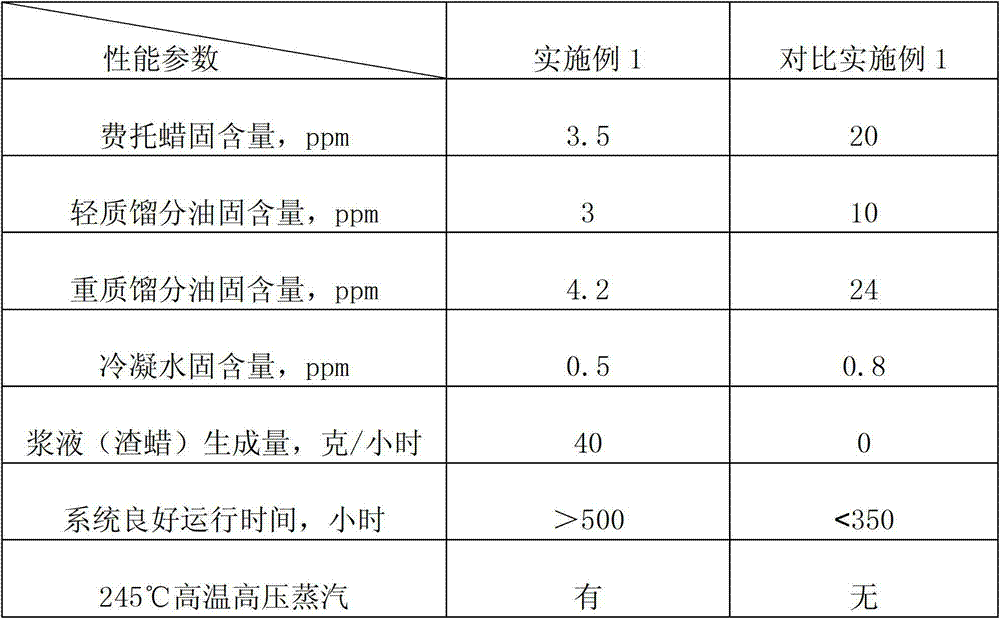

[0051] use figure 2 The shown system of the present invention carries out the Fischer-Tropsch synthesis process, and the reactor is a low-temperature slurry bubble-bed Fischer-Tropsch synthesis reactor with an internal diameter of 150 millimeters and a height of 22 meters. The Fischer-Tropsch synthesis reaction is carried out in a reactor, wherein the operating conditions and operating parameters of the reactor are as follows: operating temperature: 255°C; operating pressure: 2.9MPa; H 2 / CO feed volume ratio: 1.5; space velocity: 2500 Nm3 / ton catalyst / hour, superficial gas velocity at reactor inlet: 0.25m / s.

[0052] The selected catalyst is: Precipitated 100Fe-3Cu-4K-12SiO prepared by spray drying method 2 (Mass ratio) Microspherical iron-based Fischer-Tropsch synthesis reaction catalyst, the particle size is between 30 and 100 microns, the average particle size is about 75 microns, and the density is about 0.75g / cm 3 .

[0053] When the reactor starts running, H 2 and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com