Production method of 2-hydroxy-4-methoxy benzophenone

A technology of methoxybenzophenone and hydroxyl, which is applied in the production field of benzophenone ultraviolet absorber 2-hydroxy-4-methoxybenzophenone, can solve the problem of excessive toluene solvent residue and production cost High-level problems, to achieve process optimization, production cost reduction, and the effect of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

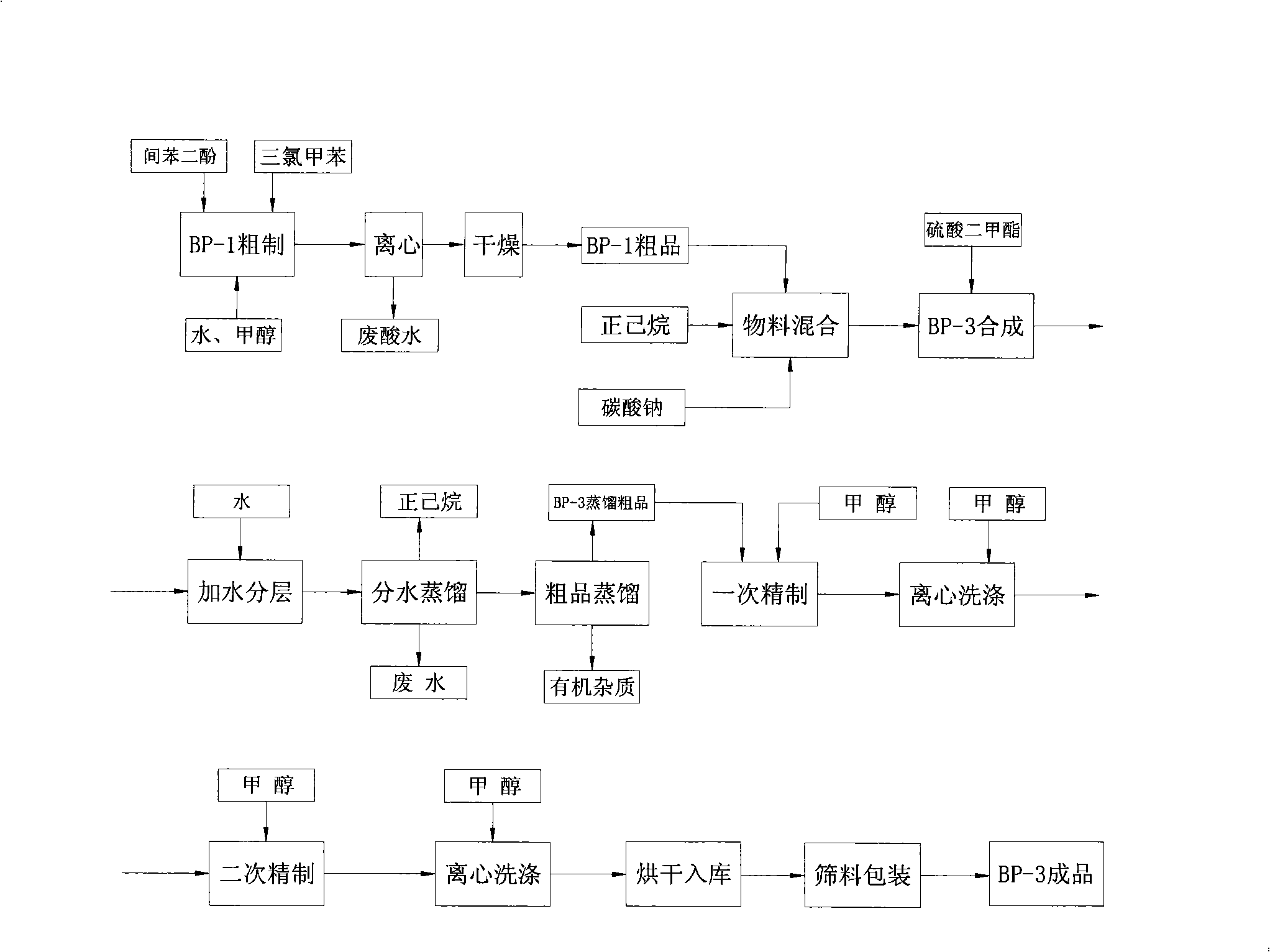

Image

Examples

Embodiment 1

[0041] 1. BP-3 crude:

[0042] a. Raw material ratio:

[0043] BP-1 crude product 100Kg

[0044] n-Hexane 120Kg

[0046] Dimethyl sulfate 20Kg

[0047] Water 200Kg

[0048] b. Mix the crude product of BP-1, n-hexane, and sodium carbonate in the reaction kettle in proportion, then add dimethyl sulfate and heat to generate 2-hydroxy-4-methoxybenzophenone. The reaction temperature is 60 -68°C, the reaction time is 4 hours.

[0049] c. Add water to the reaction kettle to separate the liquid layers, heat to 68-70°C, distill and separate n-hexane, and discharge waste water; continue to heat at 110-120°C to generate BP-3 distilled crude product, lower it to normal temperature, and obtain BP- 3 Crude product, product content 95%, light red.

[0050] 2. BP-3 refining:

[0051] a. Once refined. Add crude BP-3 to methanol solution, heat at 55-60°C until the crude BP-3 is fully dissolved, remove impurities by centrifugation, cool to 0-5°C to crystal...

Embodiment 2

[0054] 1. BP-3 crude:

[0055] a. Raw material ratio:

[0056] BP-1 crude product 100Kg

[0057] n-Hexane 90Kg

[0058] Sodium carbonate 30Kg

[0059] Dimethyl sulfate 15Kg

[0060] Water 150Kg

[0061]b. Mix the crude product of BP-1, n-hexane, and sodium carbonate in the reaction kettle in proportion, then add dimethyl sulfate and heat to generate 2-hydroxy-4-methoxybenzophenone. The reaction temperature is 45 -46°C, the reaction time is 6 hours.

[0062] c. Add water to the reaction kettle to separate the liquid layers, heat to 100-110°C, distill and separate n-hexane, and discharge waste water; continue to heat at 180-210°C to generate BP-3 distillation crude product, lower it to normal temperature, and obtain BP- 3 Crude product, product content 95%, light red.

[0063] 2. BP-3 refining:

[0064] a. Once refined. Add crude BP-3 to methanol solution, heat at 58-68°C until the crude BP-3 is fully dissolved, remove impurities by centrifugation, cool to 5-10°C for cr...

Embodiment 3

[0067] 1. BP-3 crude:

[0068] a. Raw material ratio:

[0069] BP-1 crude product 100Kg

[0070] n-Hexane 110Kg

[0071] Sodium carbonate 35Kg

[0072] Dimethyl sulfate 18Kg

[0073] Water 180Kg

[0074] b. Mix the crude product of BP-1, n-hexane, and sodium carbonate in the reaction kettle in proportion, then add dimethyl sulfate and heat to generate 2-hydroxy-4-methoxybenzophenone. The reaction temperature is 60 -68°C, the reaction time is 5 hours.

[0075] c. Add water to the reaction kettle to separate the liquid layers, heat to 68-70°C, distill and separate n-hexane, and discharge waste water; continue to heat at 110-120°C to generate BP-3 distilled crude product, lower it to normal temperature, and obtain BP- 3 Crude product, product content 95%, light red.

[0076] 2. BP-3 refining:

[0077] a. Once refined. Add crude BP-3 to methanol solution, heat at 55-60°C until the crude BP-3 is fully dissolved, remove impurities by centrifugation, cool to 4-8°C for crysta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com