Patents

Literature

93results about How to "High oil extraction rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for processing edible camellia oil

ActiveCN101194713ALow extraction temperatureHigh oil extraction rateEdible oils/fatsFood preparationBiologically active substancesChemistry

The invention discloses a process for preparing edible camellia oil, which comprises the steps of removing hulls of camellia oleosa seeds, drying, disintegrating, cooking camellia oleosa seed, and extracting and refining camellia oil. The invention adopts advanced hypercritical CO 2 extraction technology, changes traditional camellia process technology, increases the quality of oil, reduces refining procedures, decreases refining loss of oil, increases oil yield rate, and reduces the losses of biologically active substance and nutrition components in the process of refining, increases the contents of active substances such as VE in the camellia oil, squalene and the like, and increases the quality and the health function of the finished product of camellia oil.

Owner:SOUTH CHINA AGRI UNIV

Method for extracting schizochytrium aggregatum oil

InactiveCN102199485ASimple processOperational securityFatty-oils/fats productionOil and greaseAlkaline protease

The invention discloses a method for extracting schizochytrium aggregatum oil. The method comprises the following steps of: taking schizochytrium aggregatum mud as a raw material, homogenizing, carrying out alkali extraction, centrifuging and extracting with an organic solvent to obtain the schizochytrium aggregatum oil. The method specifically comprises the steps of: diluting the raw material byutilizing a sodium citrate buffering solution, homogenizing and then carrying out high-temperature treatment, then carrying out alkali extraction, carrying out enzymolysis on the raw material subjected to alkali extraction by adopting neutral protease and alkali protease in sequence, centrifuging and then separating clear oil, and extracting missible oil by adopting the organic solvent, and therefore the oil extraction rate is greatly improved and reaches up to more than 90 percent. The method disclosed by the invention has the advantages of simple process, safety in operation and less pollutions and is suitable for large-scale production; cells can be completely crushed by utilizing the homogenizing treatment; various enzymes in the cells can be prevented from degrading oil by adopting the high-temperature treatment; and the treatment on the missible oil is added, and the oil extraction rate is increased by extraction with the organic solvent, standing delamination and other manners.

Owner:THIRD INST OF OCEANOGRAPHY STATE OCEANIC ADMINISTATION

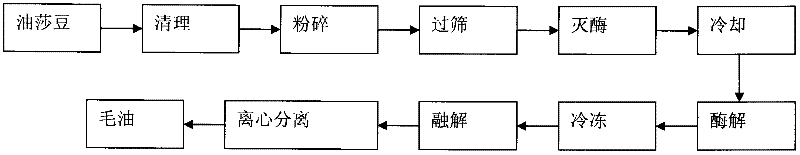

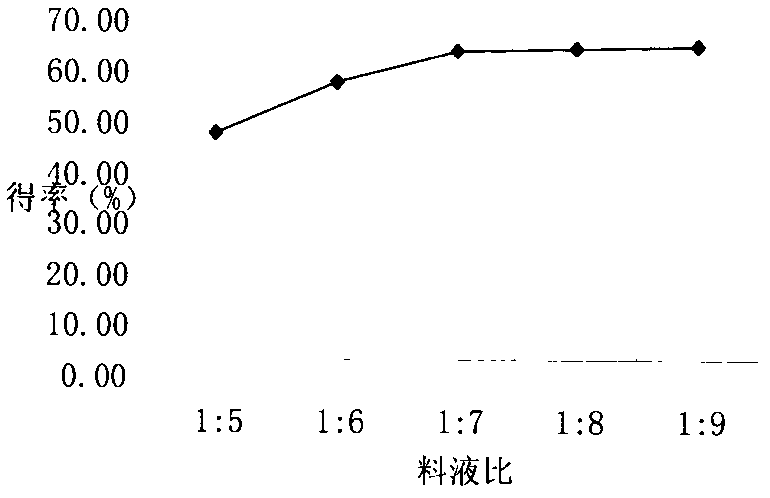

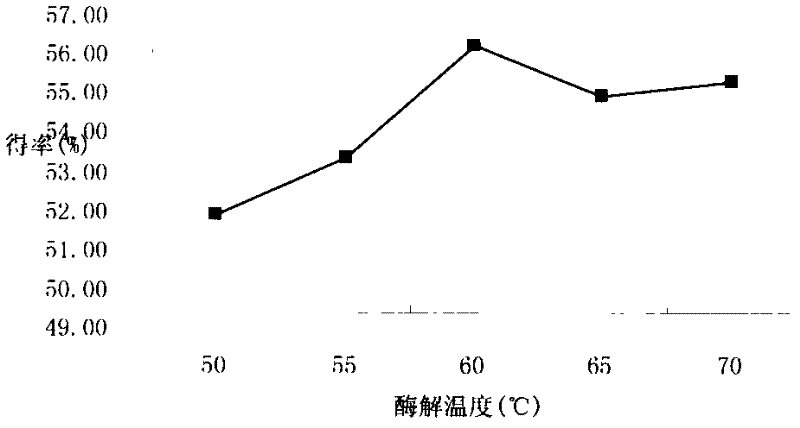

Method for extracting Cyperus esculentus oil by aqueous enzymatic extraction-freeze-thaw coupling technology

InactiveCN102311867AEasy to operateOperational securityFatty-oils/fats productionSodium bicarbonateUltra Low Temperature Freezer

The invention discloses a method for extracting Cyperus esculentus oil by the combination of aqueous enzymatic extraction and freeze-thaw, selecting plump Cyperus esculentus without insect diseases, removing impurities on the surface by washing with the use of water, and drying water on the surface; crushing, weighing 500kg of a Cyperus esculentus powder, adding a mixed buffer solution of sodium carbonate and sodium bicarbonate at the solid-liquid ratio of 1:7 (m / v), adjusting pH value to 7, immersing for 1 hour at the temperature of 50 DEG C, killing enzyme for 10 min at the temperature of 90 DEG C; adopting a compound enzyme of alkali protease and cellulase mixed at the mass ratio of 2:1 (m / m) while the solid-liquid ratio is 1:6, the enzymatic hydrolysis time is 6 hours, the enzyme addition is 2.5% and the enzymatic hydrolysis temperature is 70 DEG C; placing the enzymatic hydrolysis solution into an ultralow temperature refrigerator at the temperature of minus 30 DEG C for 30 min after enzymatic hydrolysis, followed by thawing at room temperature; centrifuging for 20 min at the rotating speed of 4000r / min, carrying out secondary centrifugation, and separating crude oil to obtain the product. According to the invention, the oil extraction rate is raised, and good grease quality is also maintained.

Owner:XINJIANG UNIVERSITY +1

Extraction method of peanut germ oil

InactiveCN103451004ACompletely degradedHigh oil extraction rateFatty-oils/fats productionEdible oils/fatsAmylaseCellulase

The invention relates to the technical field of agricultural product processing, and particularly relates to an extraction method of peanut germ oil. The extraction method comprises the following steps: crushing peanut germs; firstly, carrying out enzymolysis by cellulase and amylase under a condition that pH is 4-6, wherein the vitality ratio of cellulase toand amylase is 5:3; then, adding acid proteinase for enzymolysis of the peanut germs and deactivating the enzymes to obtain peanut germ hydrolyzing slurry; separating the oil phase to obtain the peanut germ oil; superfine grinding the peanut germs to 300-400 meshes; processing the peanut germs crushed by steam for 18-20 minutes. By adopting compound enzymes, cell walls and intracellular network structures are degraded more thoroughly, so that the oil extraction rate is improved. By adopting superfine grinding treatment, the granularity of the germs is reduced, the surface area of the germs is increased, and the effect of the enzyme is improved. Meanwhile, the germs are effectively prevented from being emulsified. By adopting steam treatment, lipase in the germs is deactivated, and meanwhile, the cell walls are loosened to increase the permeability and facilitate effect of the enzyme, so that oil is more easily released.

Owner:张瑜

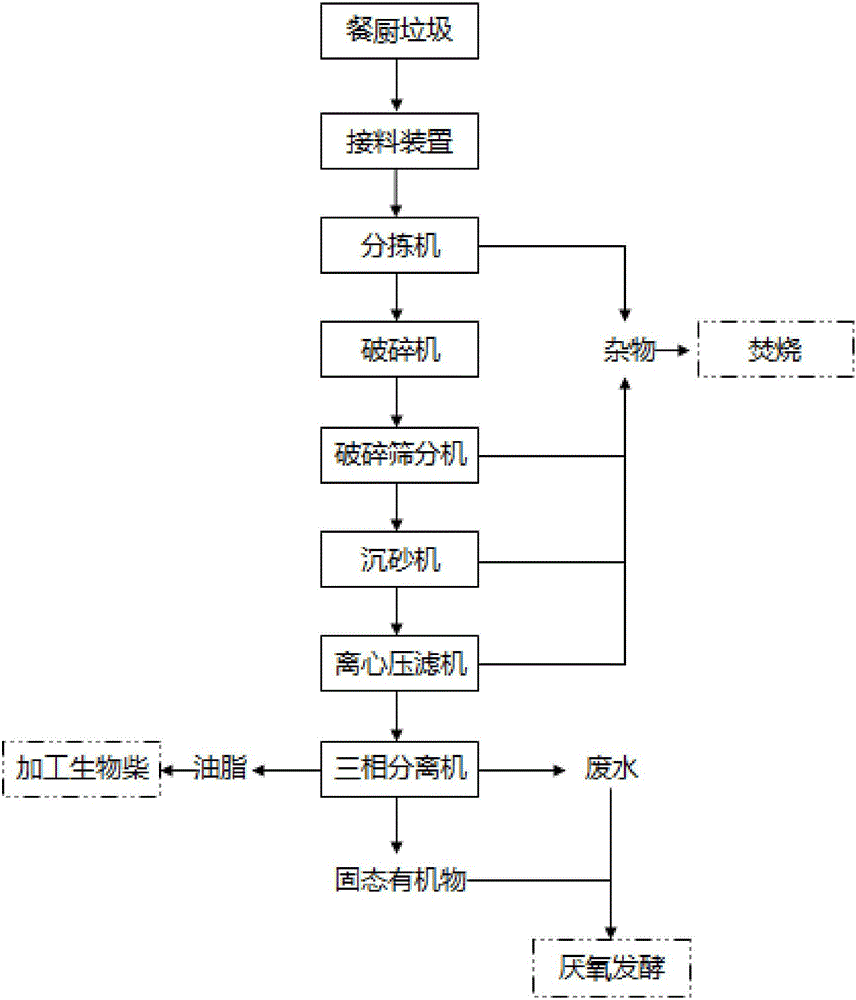

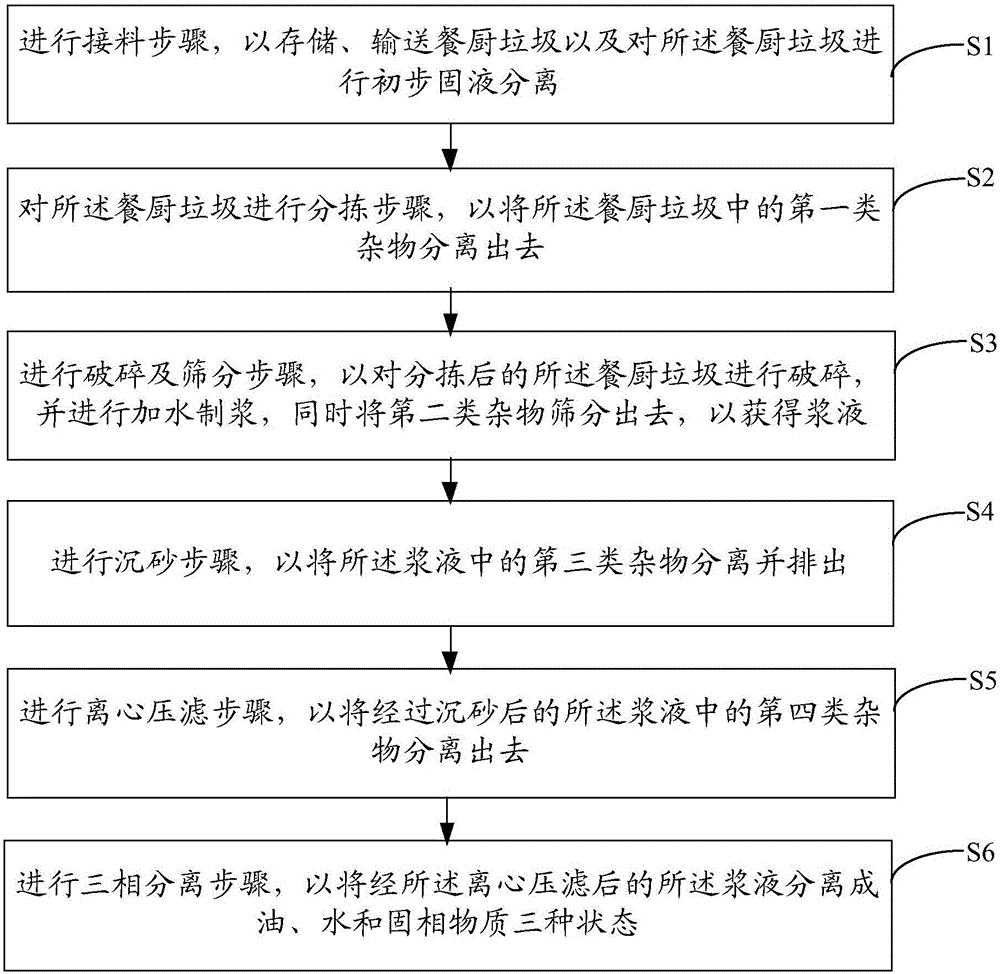

Kitchen waste pretreatment system and method

InactiveCN106552817ACompact structureEasy to follow upSolid waste disposalTransportation and packagingSlurryThree-phase

The invention relates to a kitchen waste pretreatment system and method. The system comprises a receiving device, a sorting device, a crushing and sieving device, a sand setting device, a centrifugal filter-pressing device and a three-phase separating device, wherein the receiving device is used for storing and conveying kitchen wastes and carrying out preliminary solid-liquid separation on the kitchen wastes; the sorting device receives the kitchen wastes from the receiving device and sorts the kitchen wastes to separate a first kind of sundries from the kitchen wastes; the crushing and sieving device is used for crushing the sorted kitchen wastes, adding water in the kitchen wastes and pulping, and meanwhile sieving a second kind of sundries from the kitchen wastes to obtain liquid; the sand setting device is used for separating and discharging a third kind of sundries from the liquid; the centrifugal filter-pressing device receives the liquid after the liquid is subjected to sand setting and separates a fourth kind of sundries from the liquid; and the three-phase separating device receives the liquid after the liquid is filter-pressed centrifugally, and separates the liquid into oil, water and solid-phase substances.

Owner:EVERBRIGHT ENVIRONMENTAL PROTECTION TECH RES INST SHENZHEN CO LTD +1

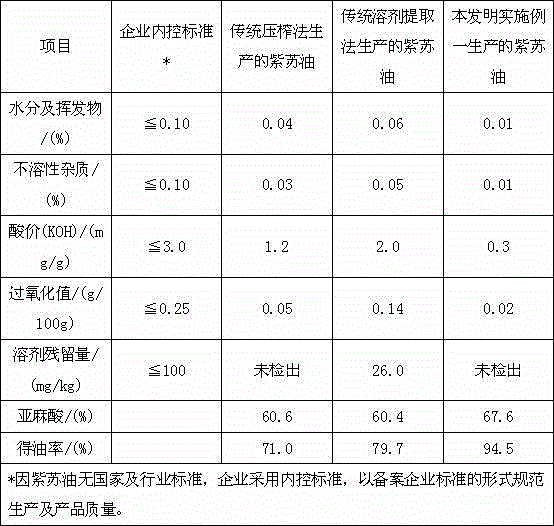

Method for comprehensively extracting and refining perilla oil

InactiveCN104531338AEasy squeezeSolve serious protein denaturationFatty-oils/fats refiningFatty-oils/fats productionAdditive ingredientPerilla oil

The invention discloses a method for comprehensively extracting and refining perilla oil. The method includes the following steps of smashing of perilla seeds, double-screw extruding-expansion, smashing, enzyme supplementation hydrolysis, centrifugal separation, low-temperature pressing and oil refining. By the adoption of the double-screw extruding-expansion procedure, the factors affecting oil quality such as nutrition ingredient loss caused by uneven preprocessing and high temperature generated by traditional unpeeling and frying procedures can be avoided; by the adoption of an aqueous enzymatic method, the expanded materials are processed for follow-up pressing, and the oil quality can be greatly improved. The aqueous enzymatic method and a pressing method are combined, chemical solvent residues brought by traditional refinement are avoided, and the method has the advantages that environment friendliness and safety are achieved, and damage to effective ingredients is low.

Owner:HUNAN ZISU SCI RES

Method for extracting rapeseed oil and passivated myrosinase from rapeseeds

ActiveCN105670769ALoose structurePromote dissolutionFatty-oils/fats refiningFatty-oils/fats productionOil and greaseRapeseed

The invention discloses a method for extracting rapeseed oil and passivated myrosinase from rapeseeds and belongs to the technical field of agricultural resources.The method has the advantages that raw materials are soaked by deionized water, moisture in cells is turned into steam during steam explosion or pressurization heat-moisture treatment, and cell walls are broken to allow the cell structure to be loose and promote the dissolution of grease in the cells; an ethanol solution is used as the oil extraction medium, glucosinolates and most degradation products are allowed to enter a water phase, the glucosinolate and glucosinolate degradation product contents in cake are lowered, and the detoxification procedure of rapeseed cake is reduced; enzyme use is avoided, oil production cycle is shortened, production cost is reduced, oil product quality is optimized, and the problems that the glucosinolate and glucosinolate degradation product contents of the cake obtained by a traditional rapeseed process are high, high-quality protein resources are wasted, a large amount of enzyme needs to be used, cost is high or environment pollution is severe, and the like are solved.

Owner:JIANGNAN UNIV

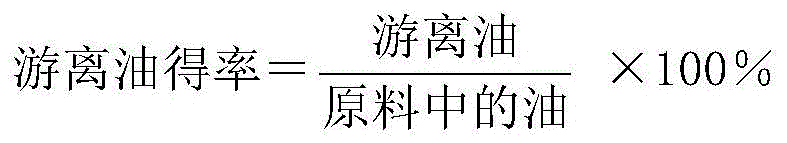

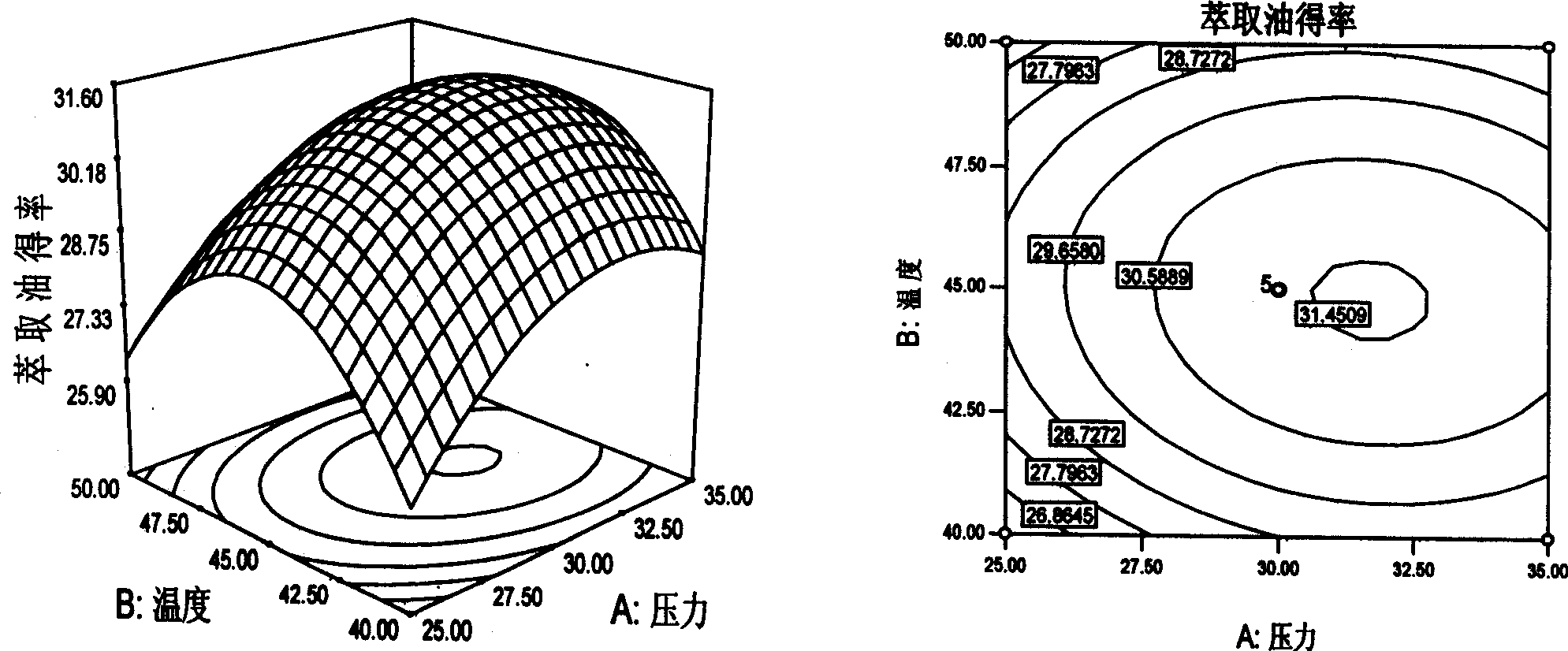

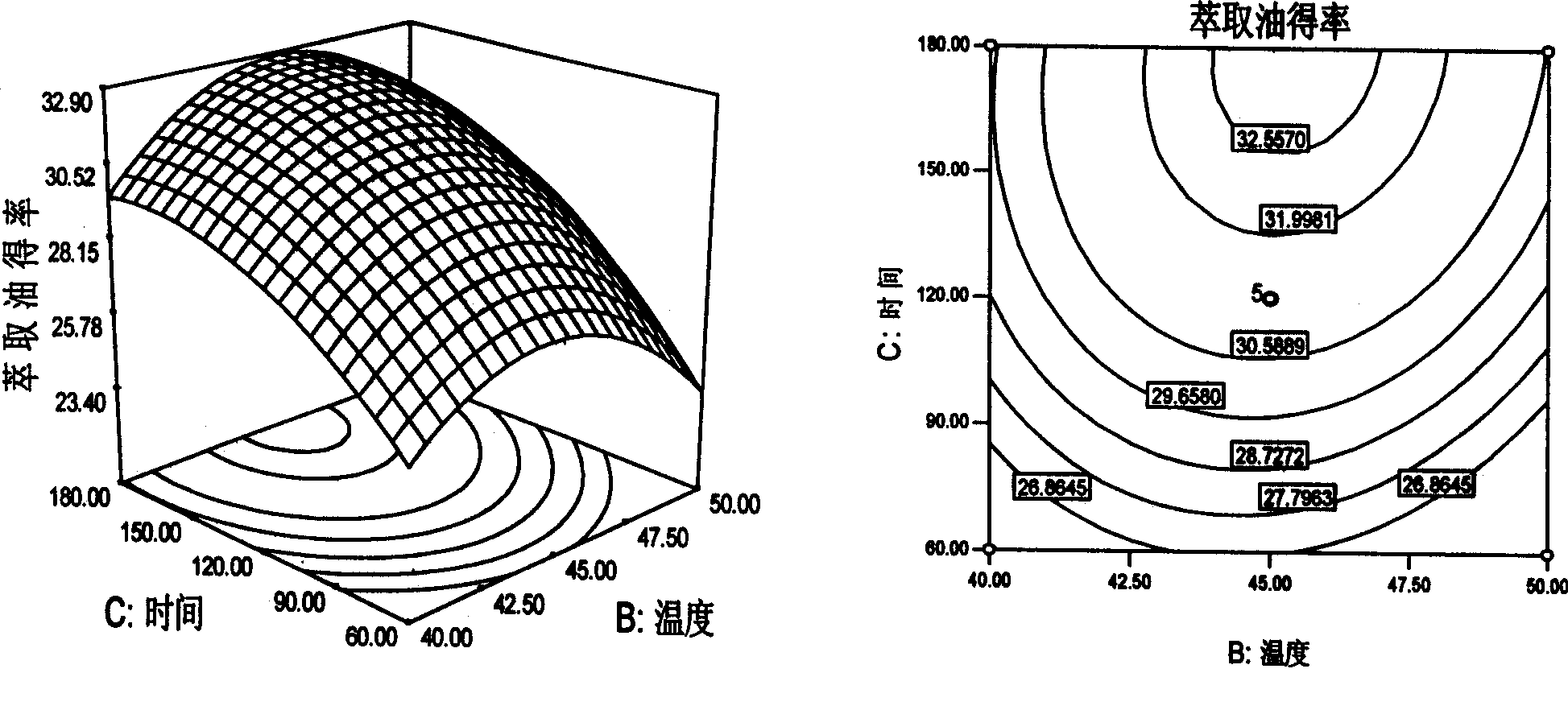

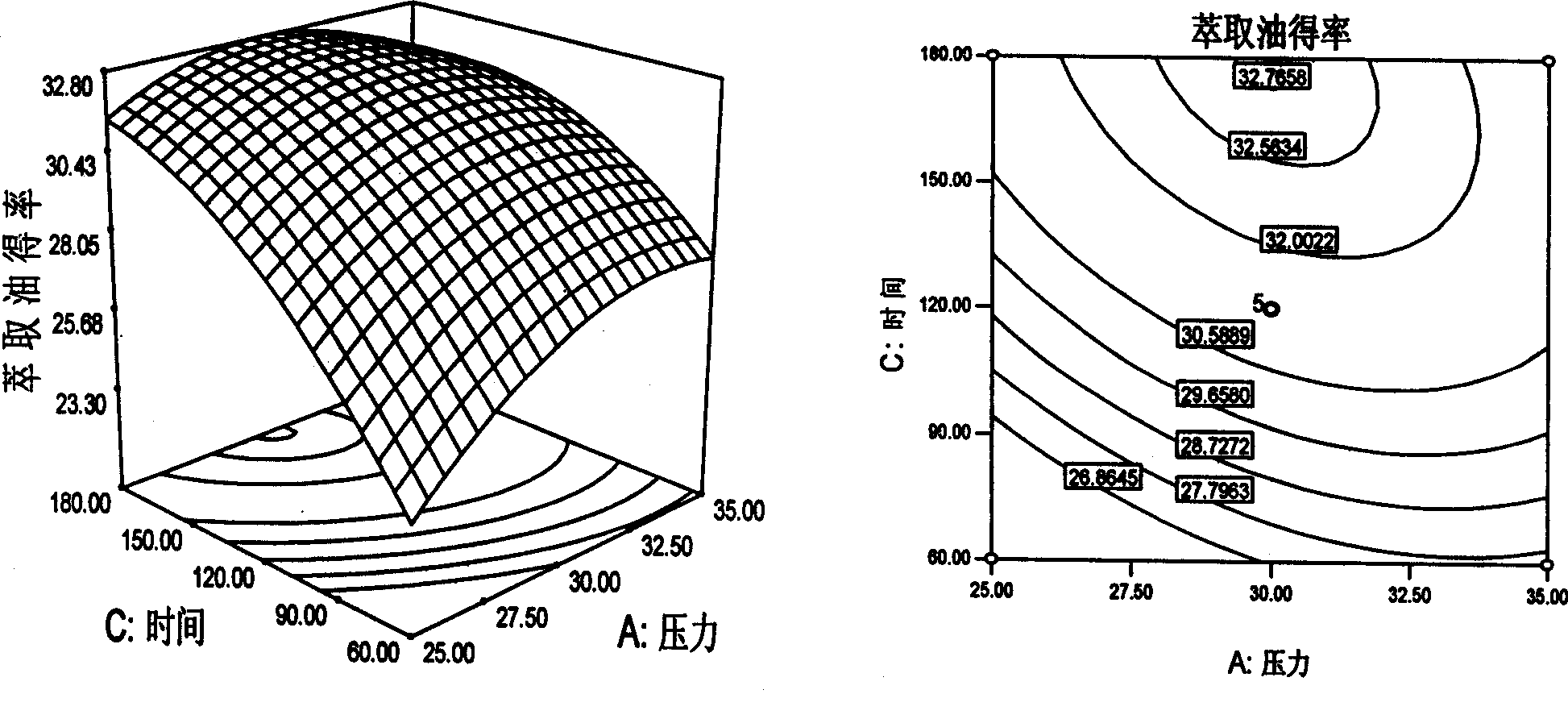

Method for extracting trichosanthis seed oil by supercritical CO2

ActiveCN101457175ASimple extraction methodHigh oil extraction rateFatty-oils/fats productionOil productionChemistry

The invention relates to a method for extracting Tricosanthes kirilowii Maxim oil by supercritical CO2 belonging to the food processing field. The material and process comprises the following steps: drying, crushing, sieving the Tricosanthes kirilowii Maxim, and extracting the Tricosanthes kirilowii Maxim by supercritical CO2 at extraction temperature 45. 5 DEG C and a pressure of 30. 15MPa for 179. 4min. The extraction rate of the Tricosanthes kirilowii Maxim oil is 32. 70-32. 80and the purity is higher than 99 The Tricosanthes kirilowii Maxim extraction process by supercritical CO2 provides a novel method for deep treatment of the Tricosanthes kirilowii Maxim and is useful for the research of Tricosanthes kirilowii Maxim extraction by supercritical CO2. The extraction method of the invention has advantages of strong operability, good security, high repeatability, simple process, high product purity and non-pollution, and can be used in Tricosanthes kirilowii Maxim oil production.

Owner:NANJING AGRICULTURAL UNIVERSITY

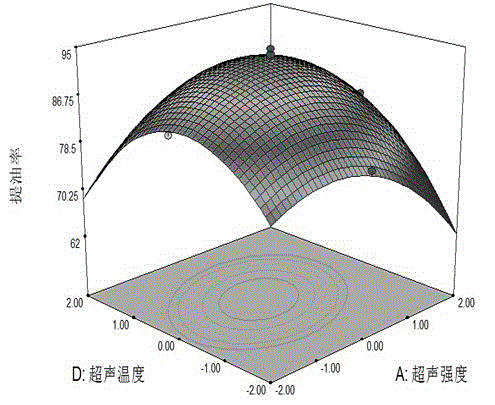

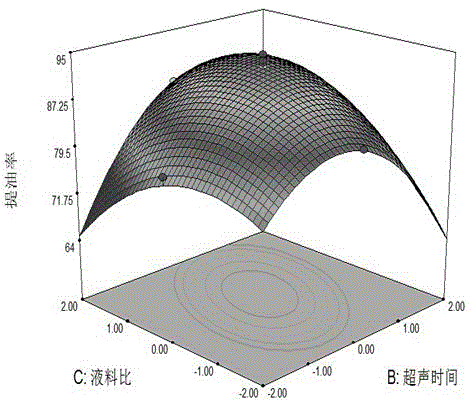

Method for extracting maize germ oil by adopting ultrasonic-assisted aqueous enzymatic method

InactiveCN104745286ANo residueReduce usageFatty-oils/fats refiningFatty-oils/fats productionWater bathsCellulose

The invention relates to a method for extracting maize germ oil by adopting an ultrasonic-assisted aqueous enzymatic method. The method for extracting the maize germ oil by adopting the ultrasonic-assisted aqueous enzymatic method is characterized by comprising the following steps: smashing maize germs taken as a raw material, sieving, then adding citric acid-sodium citrate buffer solution, and carrying out ultrasonic pretreatment; cooling, regulating pH value, then adding cellulose and alpha-amylase, stirring in constant-temperature water bath, and carrying out enzymatic hydrolysis; after the enzymatic hydrolysis is finished, deactivating enzymes, cooling to room temperature, centrifuging a sample, collecting supernate, demulsifying emulsion, centrifuging secondarily, then separating supernate, and mixing the supernates, so that the maize germ oil is obtained. The method for extracting the maize germ oil by adopting the ultrasonic-assisted aqueous enzymatic method has the advantages of mild conditions, high oil yield, no pollution, easy operation, safety, rapidness and applicability of large-scale production.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

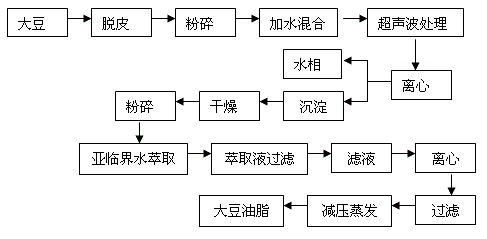

Method for assisting in subcritical extraction of soybean oil by using ultrasonic waves

InactiveCN102911787AFacilitated releaseEasy extractionFatty-oils/fats productionOil and greaseFiltration

The invention relates to a method for assisting in subcritical extraction of soybean oil by using ultrasonic waves, belonging to a plant oil extraction technology. The method comprises the following steps of: (1) peeling and crushing soybeans, mixing with water to obtain a mixed solution, performing ultrasonic treatment on the mixed solution, and performing centrifugal separation after ultrasonic treatment to obtain a water phase and precipitates; and (2) drying and crushing the precipitates obtained in the step (1), putting into a subcritical extraction kettle, performing subcritical fluid extraction to obtain extraction liquid, taking water as an extraction solvent, performing extraction, then filtering the extraction liquid to obtain filtrate, performing centrifugation and filtration on the filtrate, and then performing reduction vaporization to remove ethanol so as to obtain the soybean oil. The method has the advantages of relatively low equipment requirements, simple process, short extraction time, low energy consumption, low production cost, greenness and environmental friendliness, and is favorable for realizing industrial production; and furthermore, the obtained soybean oil has no residual solvent, the extraction rate is high, and the quality is good.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

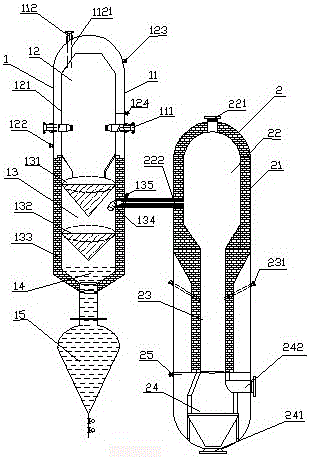

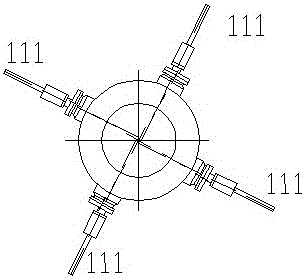

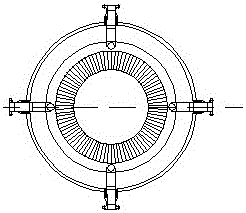

Coupled coal powder gasification pyrolysis reactor and process

ActiveCN105861065AHigh oil extraction rateImprove recycling ratesGasifier feeding meansChemical industrySlagProcess engineering

The invention provides a coupled coal powder gasification pyrolysis reactor and process, and relates to the coal gasification and pyrolysis technology. The technical problems of low oil extraction rate, high equipment manufacturing cost, serious heat energy waste and difficult process conversion are solved. The coupled coal powder gasification pyrolysis reactor consists of a gasification furnace and a pyrolysis furnace, wherein the gasification furnace comprises a gasification furnace body, a gasification reaction chamber, a gasification shock chamber, a slag pool and a lag collector; the pyrolysis furnace comprises a pyrolysis furnace body, a pyrolysis reaction chamber, a pyrolysis shock chamber and a separation chamber. The coupled coal powder gasification pyrolysis reactor and the process are used in the technical field of oil preparation from coal and gas preparation through coal, and have the advantages that the equipment structure is simple; the process is advanced; the energy is saved; the environment is protected; the energy consumption is low; the heat energy recovery and utilization rate is high; the oil extraction rate by the coil is high; the technical route can be determined according to the market practical conditions.

Owner:中美新能源技术研发(山西)有限公司

Sea-buckthorn seed-grape seed composite vegetable bended oil and preparation method thereof

InactiveCN102422902AEasy to operateOperational securityEdible oils/fatsSodium bicarbonateHydrolysate

The invention discloses sea-buckthorn seed-grape seed composite vegetable bended oil and a preparation method thereof. According to a weight ratio, grape seed oil is 20 to 40 percent, safflower seed oil is 10 to 50 percent, sea-buckthorn seed oil is 1 to 20 percent, sophora alopecuroide oil is 1 to 5 percent, and the balance is Sinkiang wild rapeseed oil; materials are respectively chosen, washed by water and ground; the materials are soaked in the mixed buffer solution of sodium carbonate and sodium bicarbonate to inactivate enzyme, 1.5 percent of complex enzyme which is the mixture of alkali protease and cellulose according to 4:3 is adopted according to the material-to-solution ratio of 1:4 to carry out enzymolysis for 5 hours, enzymatic hydrolysate is kept still under 20 DEG C below the zero for 30 minutes after enzymolysis under 70 DEG C, and after the enzymatic hydrolysate is melted under the room temperature, centrifugated for two times, crude oil is separated; and the crude oil is added into a blending tank, kept at 45 DEG C, added with 0.01 to 0.02 percent of tea polyphenol, stirred at constant speed for 15 minutes, filtered and filled, and thereby the finished vegetable bended oil product is obtained. The composite vegetable bended oil prepared by the invention has a broad application value.

Owner:周天

Extracting method of camellia oleosa seed oil

The invention provides an extracting method of camellia oleosa seed oil. The extracting method comprises the following steps: (1) steam explosion; (2) regulation of pH value; (3) extracting with an aqueous extraction process; (4) emulsion breaking. The method provided by the invention solves the problems of difficult grinding and low oil extraction rate in traditional aqueous extraction process; through the steam explosion, the cellulose and hemicellulose in the cell walls of camellia oleosa seeds are degraded, the cell walls are effectively damaged, and oil is separated from a lipid complex,thus the oil in the cells is quickly released, and the oil extraction rate is effectively increased. The emulsion breaking is performed in an alkaline condition, and the glycosidic bond of tea saponinis hydrolyzed so as to lose the surface activity and increase the clear oil yield.

Owner:HAIKOU EXPERIMENTAL STATION CHINESE ACAD OF TROPICAL AGRI SCI

Sesame oil capable of protecting blood vessels and activating appetite

InactiveCN103621686AHigh oil extraction rateDoes not destroy bioactive ingredientsEdible oils/fatsSesamumTribulus terrestris

The invention relates to the technical field of health foods, particularly to sesame oil capable of protecting blood vessels and activating appetite. The sesame oil is prepared by the following raw materials in weight parts: 1400 to 1500 parts of black sesame, 40 to 45 parts of perila seeds, 20 to 30 parts of almond, 25 to 30 parts of black fungus, 15 to 20 parts of garlic, 12 to 15 parts of cashew nut, 10 to 12 parts of tribulus terrestris, 15 to 20 parts of malt and 12 to 15 parts of chrysanthemum; in the sesame oil provided by the invention, various oil plants and Chinese herbal medicine components are contained, so that the health caring effect of the traditional sesame oil provided by the invention can be effectively promoted, and the obtained sesame oil is mellow in aromas, has transparent red and yellow color, and has health caring effects such as softening vessels, reducing blood fat, activating blood and reducing noise, appetizing and tonifying spleen, a relatively simple carbon dioxide subcritical extraction technology is adopted, the production process is environmentally friendly and efficient, and promotion and application values are achieved.

Owner:太和县庄老汉杂粮有限公司

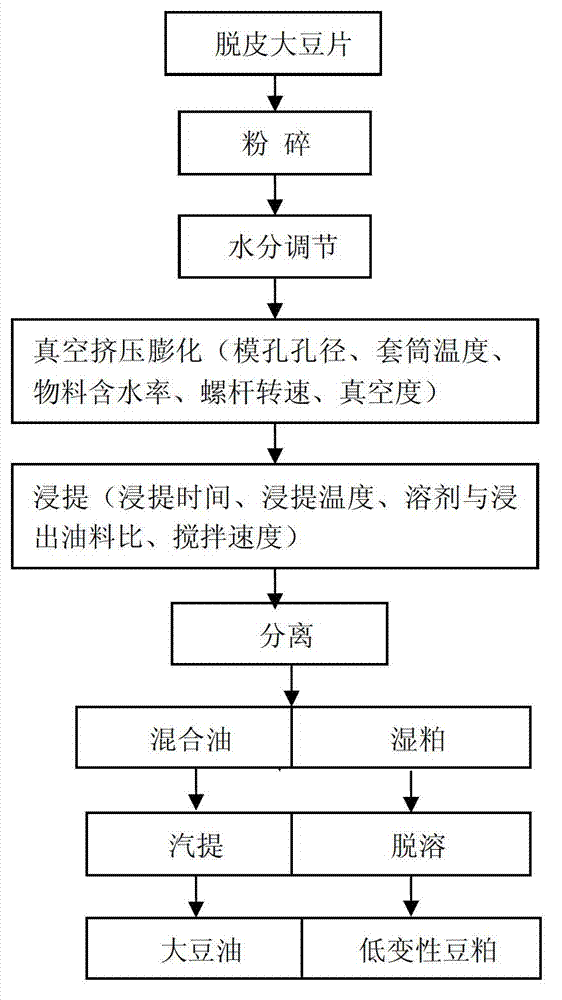

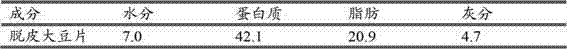

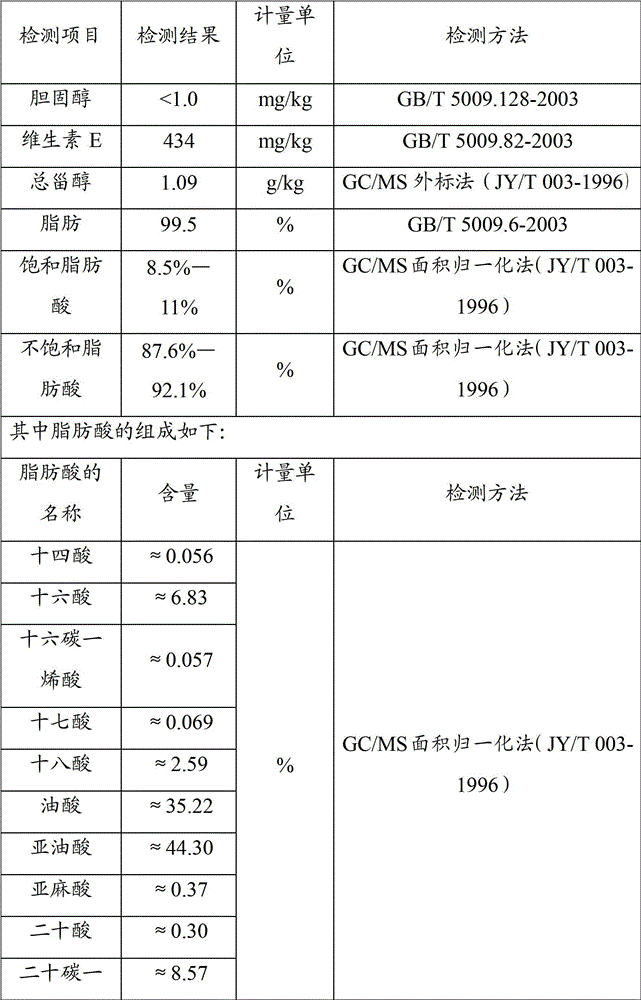

Method for extracting soybean oil and soybean meal by using vacuum extrusion puffing pretreatment solvent method

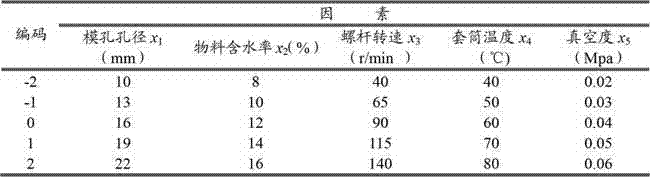

The present invention relates to a method for extracting soybean oil and low degeneration soybean meal by using a vacuum extrusion puffing pretreatment solvent method. The method comprises the following steps: crushing peeled soybean flakes, carrying out vacuum extrusion puffing by using a vacuum extrusion puffing machine, carrying out leaching on the obtained soybean product by using a solvent n-hexane, then carrying out separation to obtain mixing oil and wet meal, carrying out steam stripping on the mixing oil through a vacuum rotation evaporator to obtain the soybean oil, and carrying out flash evaporation precipitation on the wet meal to obtain the soybean meal, wherein a mold pore size of the vacuum extrusion puffing machine is 10-22 mm, a screw rotation speed is 40-140 r / min, a bush temperature is 40-80 DEG C, a vacuum degree is 0.02-0.06 MPa, a water content of the crushed soybean material is 8-16%, a leaching time is 40-100 min, a leaching temperature is 60-92 DEG C, a ratio of the solvent n-hexane volume to the weight of the soybean product after vacuum extrusion puffing is 0.6:1-2.2:1 ml / g, a stirring speed is 60-120 r / min, and the number of leaching is 1-5. With the present invention, purposes of soybean oil yield improvement, soybean meal degeneration degree reduction, and leaching time shortening are achieved.

Owner:KEDONG YUWANG SOY PROTEIN FOOD CO LTD

Method for extracting maize germ oil assisted by ethyl alcohol and steam explosion

ActiveCN104629902APromote dissolutionHigh oil extraction rateFatty-oils/fats productionEdible oils/fatsEnzymeChemistry

The invention discloses a method for extracting maize germ oil assisted by ethyl alcohol and steam explosion and belongs to the technical field of elaborate processing of the agricultural and sideline products. The method comprises the steps of after using low-concentration citric acid solution to immerse the maize, adopting the steam explosion method to greatly shorten the thermal processing time; adopting ethyl alcohol solution as oil extracting medium and adopting a demulsifier to substitute plenty of enzymes used in the traditional aqueous enzymatic method so as to save the production cost and modify the quality of the product. The method used in the invention has the advantages of high oil extracting efficiency, low cost and high quality, and solves the problems of low oil extracting efficiency, high cost and long period of maize germ oil extracting process in the traditional aqueous enzymatic method.

Owner:JIANGNAN UNIV

Method for extracting volatile oil and polyphenol from tsaoko fruit

InactiveCN104971513AIncrease the added valueEasy to produceOrganic chemistryEssential-oils/perfumesSupercritical fluid extractionAqueous ethanol

The invention discloses a method for extracting volatile oil and polyphenol from a tsaoko fruit. The method utilizes a supercritical CO2 fluid extraction technology. The method comprises extracting volatile oil from fresh tsaoko fruit powder as a raw material by weak polar alcohol and alkane solvents as entrainers, and extracting polyphenol from the tsaoko fruit powder subjected to supercritical CO2 fluid extraction of volatile oil by a strong-polarity ethanol aqueous solution as an entrainer. Through control and adjustment of an extraction temperature, extraction pressure, CO2 flow, extraction time and entrainer flow, high-quality tsaoko fruit volatile oil and polyphenol extract are obtained. The method has a volatile oil extraction ratio of 6%. The extract has polyphenol content of 10.25%. The method solves the problem that other methods damage volatile oil quality and have low raw material utilization rates, improves a tsaoko fruit added economic value, has simple processes and is convenient for implementation.

Owner:KUNMING UNIV OF SCI & TECH

Method for extracting shinyleaf yellowhorn seed kernel oil with supercritical or subcritical fluid

InactiveCN102977995AImprove extraction efficiencyImprove oil yieldFatty-oils/fats productionFood preparationAfter treatmentSolvent

The invention discloses a method for extracting shinyleaf yellowhorn seed kernel oil with a supercritical or subcritical fluid, which comprises the following steps: (1) selecting shinyleaf yellowhorn seed kernel, and pulverizing to 10-120 meshes; and (2) extracting the pulverized shinyleaf yellowhorn seed kernel in the step (1) with a supercutical fluid or subcritical fluid to obtain the shinyleaf yellowhorn seed kernel oil, wherein the residual material is shinyleaf yellowhorn dregs. Compared with the traditional pressing method, the method disclosed by the invention obviously enhances the oil extraction rate, and avoids the problems of severe damage of unsaturated fatty acids and other components in oil, and protein denaturation at high temperature in the pressing method. Compared with the leaching method, the method disclosed by the invention solves the problems of solvent residues, complex after-treatment process and high tendency of environmental pollution. According to the method disclosed by the invention, the oil extraction rate is not lower than 50%, the protein content in the shinyleaf yellowhorn dregs is not lower than 55g / 100g, and the obtained oil product has high quality.

Owner:玉荣

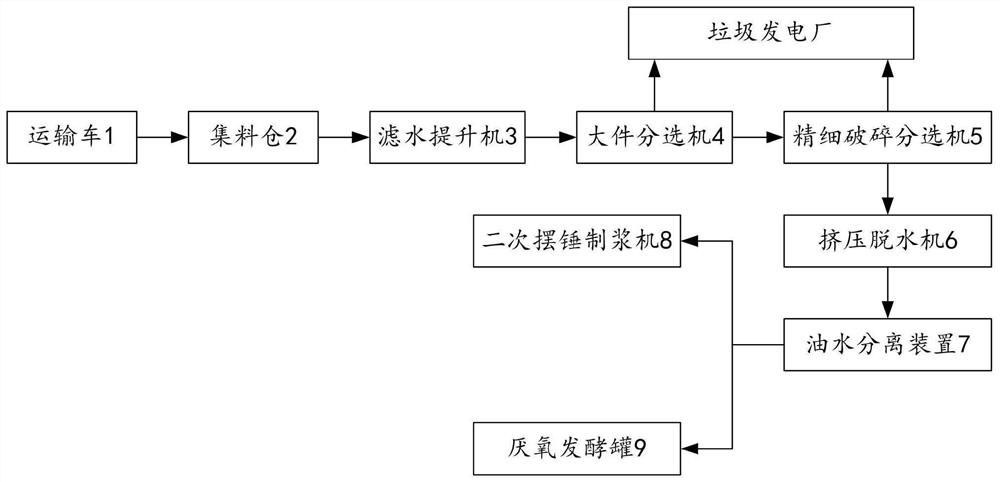

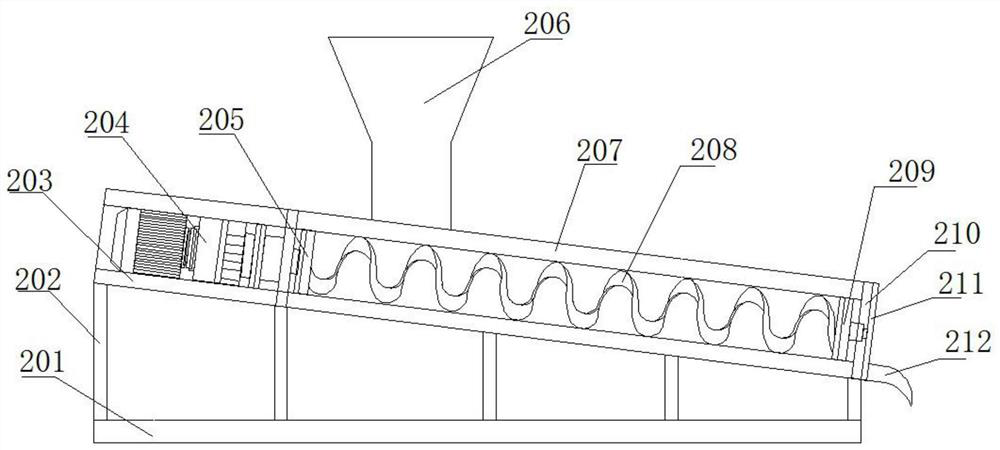

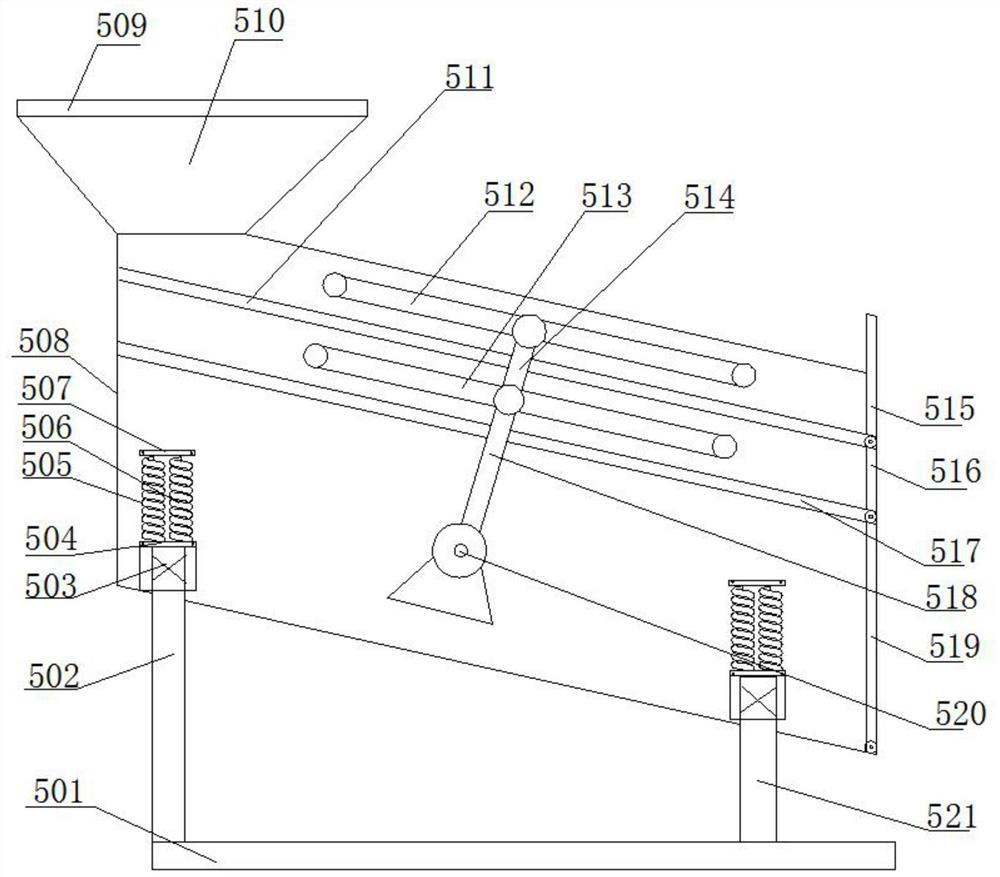

Automatic sorting treatment system for kitchen waste and treatment process

ActiveCN112139222ASolve the problem of uneven deliveryStirring effect is evenSolid waste disposalTransportation and packagingForeign matterWater filter

The invention discloses an automatic sorting treatment system for kitchen waste and a treatment process, relates to the field of domestic waste treatment, and solves the problems that existing kitchenwaste is large in reserve and threatens human health. The automatic sorting treatment system comprises a transport vehicle, a material collecting bin, a water filtering elevator, a large-foreign matter sorting machine, a fine crushing and sorting machine, an extrusion dehydrator, an oil-water separation device, a secondary pendulum bob pulping machine and an anaerobic fermentation tank, wherein the water filtering elevator is used for receiving the kitchen waste uniformly conveyed by the material collecting bin and carrying out water filtering treatment; the large-foreign matter sorting machine is used for sorting large foreign matters in the kitchen waste residues; the fine crushing and sorting machine is used for carrying out fine crushing on the large sorted kitchen waste residues andsorting out inorganic impurities; the extrusion dehydrator is used for carrying out extrusion dehydration treatment on the finely sorted kitchen waste residues; the oil-water separation device is usedfor mixing kitchen waste swill obtained after water filtration and kitchen waste slurry obtained after extrusion dehydration and then carrying out oil extraction and dehydration treatment; the secondary pendulum bob pulping machine is used for finely pulping the kitchen waste residues subjected to oil extraction and dehydration; and the anaerobic fermentation tank is used for carrying out anaerobic fermentation on kitchen waste liquid subjected to oil extraction and dehydration. The automatic sorting treatment system is high in treatment efficiency, good in treatment effect, energy-saving andenvironmentally-friendly.

Owner:吉林省佳园再生科技有限公司

Microwave-assisted green solvent wet-process oil extraction method for microalgae

ActiveCN102994220AQuick extractionSimple processFatty-oils/fats productionVegetable oilOrganic solvent

The invention discloses a wet-process oil extraction method for microalgae, comprising the steps of adding a medium-polarity solvent in microalgae mud, and performing microwave heating extraction. Wall breakage and oil extraction for microalgae are performed simultaneously in the method, the process is simple and easy to operate, and the oil of wet microalgae can be rapidly extracted in one step, thus facilitating realizing industrialization; the method is suitable for oil extraction for the algae produced by autotrophic cultivation and heterotrophic cultivation, capable of achieving a high oil extraction rate, and free from the limits of cultivation methods; the obtained oil is good in quality and beneficial to maintaining the high-added-value active ingredients of microalgae; and a slightly-toxic or lowly-toxic organic solvent with an oil-dissolving capacity is used for extraction and harmless to environment, wherein in particular, isopropanol is an extraction solvent for vegetable oil which is recommended by FDA (Food and Drug Administration), and capable of being used for extracting and processing the high-nutrition oil of microalgae.

Owner:ENN SCI & TECH DEV

Health protection tea-seed oil and manufacturing technology thereof

ActiveCN103275804AAdd flavorImprove nutritional compositionFatty-oils/fats refiningFatty-oils/fats productionVegetable oilManufacturing technology

The invention discloses health protection tea-seed oil and a manufacturing technology of the health protection tea-seed oil. The health protection tea-seed oil consists of the following raw materials in percentage by weight: 50-70 percent of tea-seed oil, 9-15 percent of sesame oil, 6-10 percent of walnut oil, 12-20 percent of peanut oil and 2-5 percent of pumpkin seed oil. The tea-seed oil is obtained by an aqueous enzymatic method; other types of plant oil are added, so that the flavor of the tea-seed oil can be well improved; furthermore, the nutritious substance compositions of the tea-seed oil are optimized, so that the nutrition of the tea-seed oil is better enriched; the tea-seed oil is obtained by the aqueous enzymatic method, so that the oil extraction rate and the purity of the tea-seed oil are improved; and the taste of the tea-seed oil is guaranteed.

Owner:周萍

Health-care oil capable of lowering blood pressure and containing rauvolfia verticillate

InactiveCN103651975AImprove food valueSimple processFatty-oils/fats refiningFatty-oils/fats productionBULK ACTIVE INGREDIENTBiology

The invention relates to the field of health-care food, in particular to health-care oil capable of lowering blood pressure and containing rauvolfia verticillate. The health-care oil comprises the following raw materials in parts by weight: 1400-1550 parts of soybean, 45-50 parts of olive, 35-40 parts of sesame, 20-25 parts of rauvolfia verticillate, 18-20 parts of eucommia ulmoides, 15-18 parts of panax notoginseng, 12-15 parts of cacumen biotae, and 15-18 parts of folium artemisiae argyi. The manufacturing process of the health-care oil adopts a carbon dioxide subcritical extraction technology, is simple and easy to implement, the extraction temperature is low, active ingredients in the raw materials cannot be broken; the health-care oil integrates the heath care effects of the raw materials such as soybean oil, olive oil, sesame oil, the rauvolfia verticillate and the eucommia ulmoides, is particularly suitable for the daily health care of patients suffering from hypertension, and has wide market prospect.

Owner:安徽大平油脂有限公司

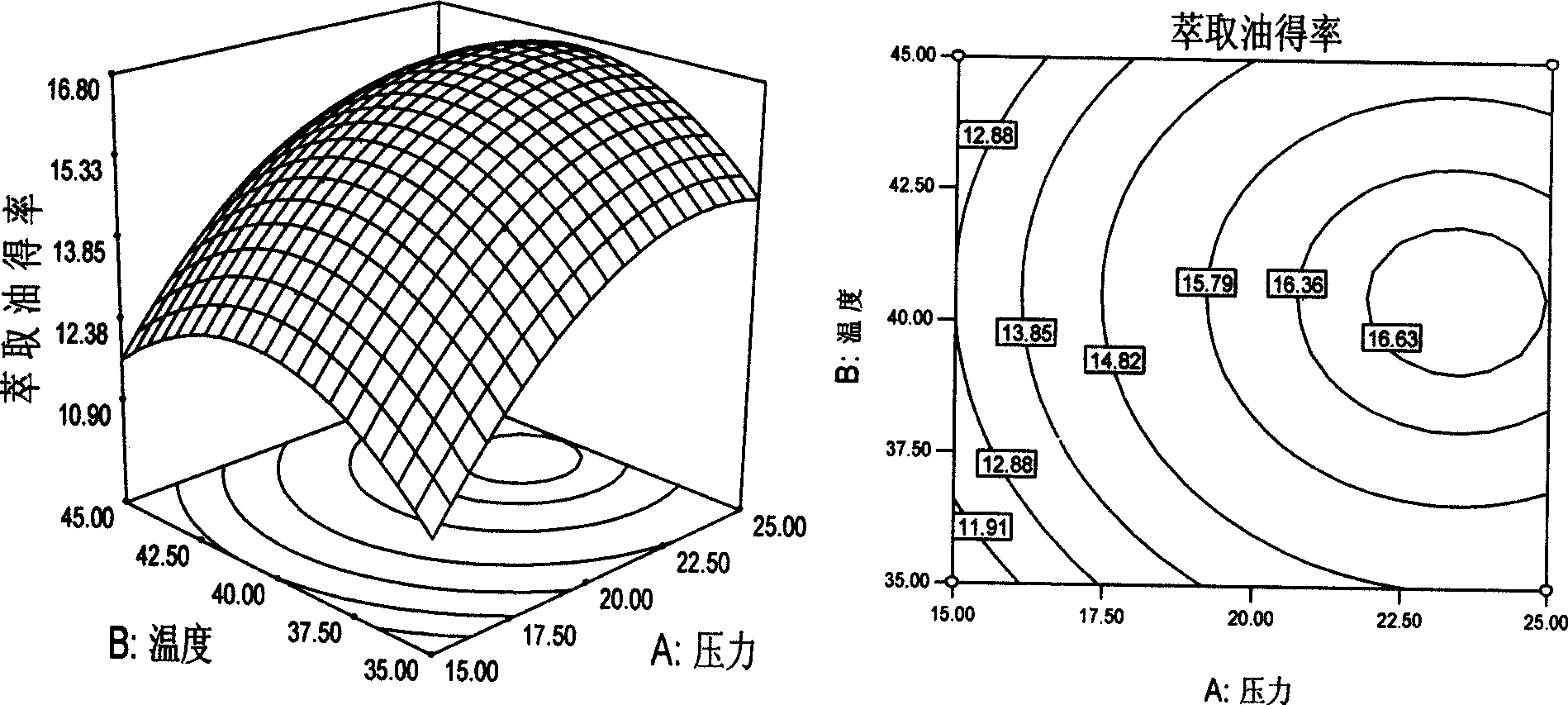

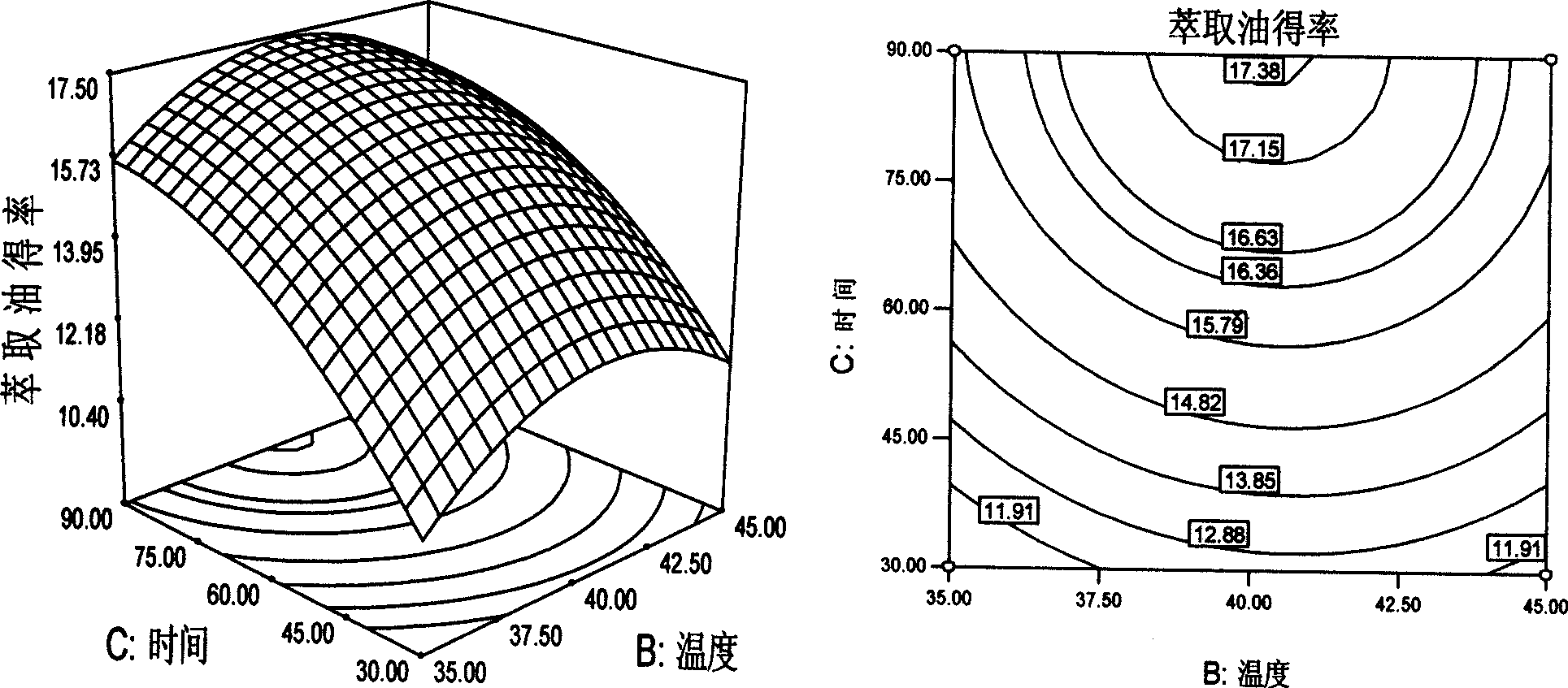

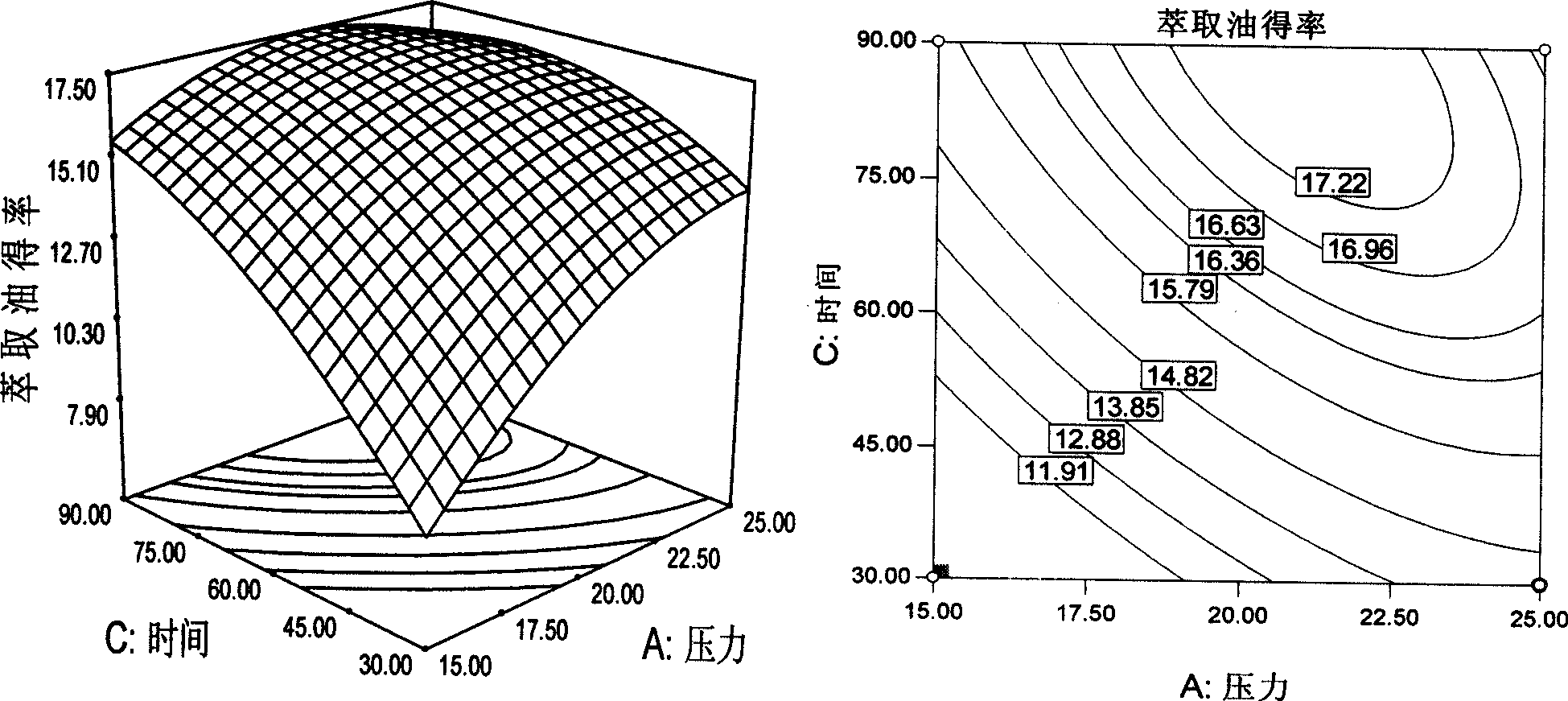

Method for extracting Chinese chive seed oil by supercritical carbon dioxide

InactiveCN101451089AHigh oil extraction rateImprove extraction efficiencyFatty-oils/fats productionChinese ChiveRapeseed

The invention relates to a method for extracting leek rapeseed oil through supercritical carbon dioxide, which belongs to the field of food processing and is specially used for deep processing of leek rapeseeds. The raw materials and the technology comprise the following: the leek rapeseeds are dried and crushed and subjected to supercritical CO2 extraction; the extraction temperature is 40.40 DEG C, the extraction time is 86.70 minutes, and the extraction pressure is 22.25 MPa; the leek rapeseed oil is extracted; and the purity of the leek rapeseed oil is more than 99 percent, and the yield of the leek rapeseed oil is between 17.23 and 17.52 percent. The invention provides a novel method for deeply processing the leek rapeseeds. The method has the advantages of strong maneuverability, good safety, higher yield and good repeatability.

Owner:NANJING AGRICULTURAL UNIVERSITY

Demulsification treatment method for aqueous enzymatic method extracted tea seed oil

The invention discloses a demulsification treatment method for aqueous enzymatic method extracted tea seed oil. According to the demulsification treatment method, emulsion generated when tea seed oil is extracted by using an aqueous enzymatic method is collected in a centrifugal mode, and alkaline protease is adopted to break stability of the emulsion, so that clear oil can be extracted. The oil extraction rate of tea seed oil can be increased, and the economic benefits can be increased. By the adoption of the demulsification treatment method disclosed by the invention and under appropriate reaction conditions, the demulsification rate can be up to 92.1%, and the technical difficulty of demulsification can be solved before industrialized application of tea seeds.

Owner:HUAQIAO UNIVERSITY

Method for detecting acid value and peroxide value through oil in low-oil food

InactiveCN105424872AHigh precisionHigh extraction rateChemical analysis using titrationMaterial analysis by observing effect on chemical indicatorOil and greaseAcid value

The invention belongs to the technical field of food, particularly relates to a method used for detecting the acid value and the peroxide value by using oil extracted from low-oil food through supercritical (CO2) extraction and discloses a method for detecting the acid value and the peroxide value through the oil in the low-oil food. The method comprises specific steps as follows: samples are pretreated, dried, crushed and put in a supercritical extraction instrument, the oil is extracted after conditions of the instrument are set, and the obtained oil is used for detecting the acid value and the peroxide value. According to the method, the extraction rate is high, the use range is wide (oil with the content being 0.1% or higher can be extracted), the extraction time is shortened, and the accuracy of a detection result is high.

Owner:PONY TESTING INT GRP SHANGHAI CO LTD

Method for synchronously extracting silybum marianum oil and hydrolyzed protein

InactiveCN109266432ARelease fullyHigh yieldProtein composition from vegetable seedsFatty-oils/fats refiningSocial benefitsSilybum Marianum Seed

The invention discloses a method for synchronously extracting silybum marianum oil and hydrolyzed protein and belongs to the technical field of biological processing. The method comprises the following steps: taking silybum marianum seeds as raw materials; carrying out crushing, enzymolysis and carrying out high-temperature enzyme killing; centrifuging and separating an oil-water mixture obtainedby the enzymolysis; then preparing the silybum marianum oil and hydrolyzed protein powder respectively. The method disclosed by the invention has the advantages of moderate processing conditions, lowextraction temperature, high oil yield and uneasiness of denaturing the protein; two high-quality products including the silybum marianum oil and the hydrolyzed protein can be synchronously obtained;the prepared hydrolyzed protein can be used as a nutrient enhancing agent or a material of a health-care food, and has remarkable economic and social benefits.

Owner:JIANGSU UNIV

Oil plant pre-treatment method applicable to aqueous phase process oil extraction

ActiveCN104087411ASolve the shortcomings of uneven pretreatment processSolve the disadvantage of unevennessFatty-oils/fats productionRough surfacePretreatment method

The invention provides an oil plant pre-treatment method applicable to aqueous phase process oil extraction. Oil plants are pretreated by adopting an improved roller type grinding technology, and the improvement ways comprise: mutually extruding the oil plants by utilizing surfaces of multiple rollers; adjusting space between rollers and number of the rollers according to granularity required by different oil plants for extruding in different degrees; adjusting radian and medium height of each roller according to hardness of different materials, bending deformation resistance of each roller, rolling pressure and feeding grain size, wherein the medium height ranges from dozens of microns to several millimeters; guaranteeing uniform grain size in axial discharging; regulating pressure between rollers to be 10-80MPa for controlling the grain size; arranging the rollers in a vertical type (triangle shape), and atomizing the surface of each roller, so that smooth surface of each roller is changed into a rough surface; and promoting feeding, and improving capacity. The oil plant pre-treatment method applicable to the aqueous phase process oil extraction has the advantages that the problems that an oil plant pre-treatment technology is difficult and oil extraction rate is limited in an aqueous phase oil extraction technology are solved, the oil extraction rate is greatly increased and the industrialization development of the oil plant pre-treatment method applicable to the aqueous phase process oil extraction is further promoted.

Owner:JIANGNAN UNIV

Production process for camellia seed oil

InactiveCN107653054ARetain nutrientsRetention of active substancesFatty-oils/fats productionEdible oils/fatsCamellia oleiferaCell separation

The invention relates to a production process for camellia seed oil. The production process comprises the following steps: 1) raw material cleaning and selecting; 2) hulling treatment; 3) seed-hull separation; 4) camellia seed baking; 5) material steaming and tempering; and 6) cooling, squeezing and oil discharging. The production process provided by the invention adopts physical squeezing, so nutritional components, active substances and camellia fragrance in oil are retained; meanwhile, specific processes like hull-seed separation, camellia seed baking and material steaming and tempering greatly improve the extraction rate of the oil compared with a conventional squeezing process; and the process provided by the invention can produce purely-natural, organic and green camellia seed edibleoil which is comparable to olive oil.

Owner:怀化盛源油脂有限公司

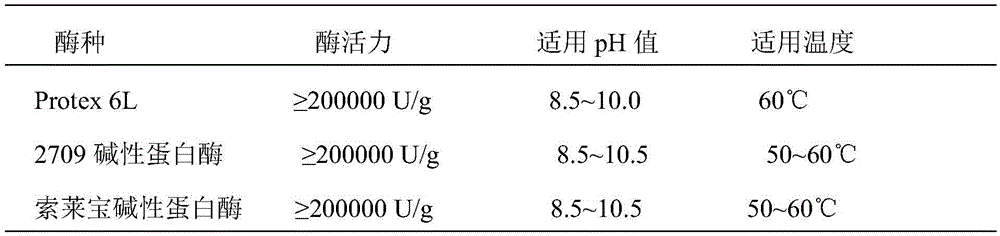

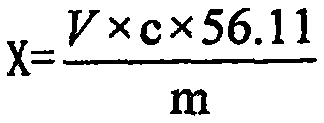

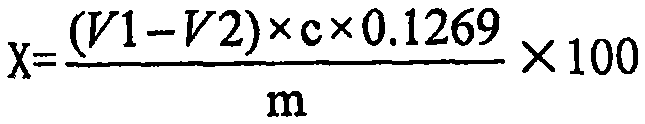

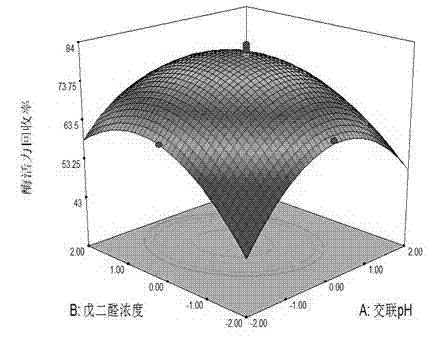

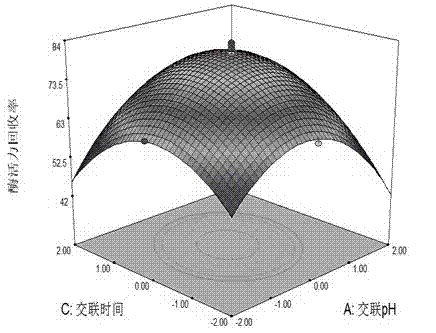

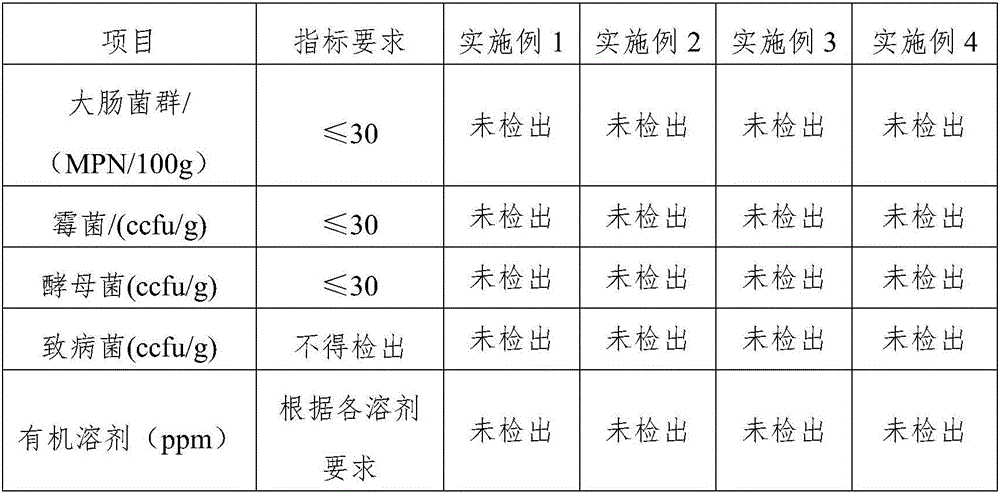

Method for preparing soybean oil through enzymatic hydrolysis of immobilized enzyme

InactiveCN103074152AReduce wasteHigh oil extraction rateFatty-oils/fats productionAlkaline proteaseEnzymatic hydrolysis

The invention discloses a method for preparing soybean oil through enzymatic hydrolysis of an immobilized enzyme, and belongs to a plant oil extracting technology. The method comprises the following steps: (1) dissolving alkaline protease into a phosphate buffer solution, adding ethanol, precipitating and aggregating, adding glutaraldehyde, and crosslinking to obtain a crosslinked enzyme aggregate, namely immobilized alkaline protease; and (2) crushing soybeans, performing extrusion preprocessing to obtain an extruded material, crushing the extruded material, mixing the extruded material with water, regulating pH and temperature, adding the immobilized enzyme obtained in the step (1) for enzymatic hydrolysis, recycling the immobilized enzyme after the enzymatic hydrolysis, and centrifuging enzymatic hydrolysate to obtain the soybean oil. Processing equipment needed in the method is simple; the prepared immobilized enzyme is high in activity; the immobilizing time is short; a high-cost carrier is not required, so that the cost is greatly reduced; when the immobilized enzyme is applied to extraction of the soybean oil through the enzymatic hydrolysis, oil extracting rate is high; the immobilized enzyme can be recycled for reuse, so that resource waste is reduced; therefore, the method has very good economic benefit and development prospect.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Production method for extracting tea oil through aqueous enzymatic method

InactiveCN106190524AQuick releaseGuaranteed qualified microbiological contentFatty-oils/fats refiningFatty-oils/fats productionAcetic acidMicroorganism

The invention discloses a production method for extracting tea oil through an aqueous enzymatic method. Under proper pH, mixed enzyme is added, vibrating extraction is conducted in a glacial acetic acid-sodium chloride solution, osmotic pressure is formed by means of enzymolysis and a sodium chloride solution so that tea oil in tea seed kernels can be quickly released, then the tea oil is sterilized and dried, and the tea oil is obtained. The tea seed oil extraction yield is high, the content of microorganisms in the tea oil reaches the standard, no organic solvent residues exist, and the method is suitable for large-scale popularization.

Owner:贵州石阡佛顶山野生油茶油业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com