Method for extracting Cyperus esculentus oil by aqueous enzymatic extraction-freeze-thaw coupling technology

A technology for extracting oil and water enzymatic method, which is applied in the directions of fat oil/fat production, fat generation, etc., can solve the problems such as no relevant reports on the extraction of sesame oil, low oil extraction rate and low oil extraction rate by water enzymatic method, To achieve good oil quality, no solvent pollution, and improve the effect of oil extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment one: the method for extracting Yousha bean oil

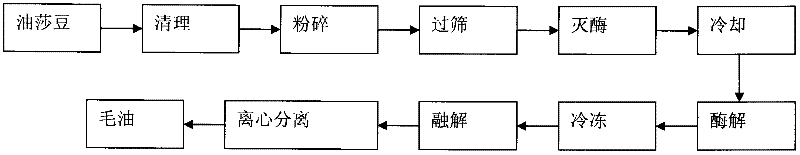

[0046] See attached figure 1 , using the hydroenzyme method-freezing-thawing coupling technology to extract the method of Yousha soybean oil, the specific extraction steps are as follows:

[0047] (1) Cleaning: Select plump, pest-free oily beans and wash with water to remove surface impurities and dry the surface moisture.

[0048] (2) Pulverization: pulverize evenly with a miniature universal pulverizer.

[0049] (3) Enzyme elimination: take by weighing 500kg oily bean powder, sodium carbonate and sodium bicarbonate by the mixed solution buffer solution (mol / L) of 1: 7 (m / v) solid-liquid ratio, adjust pH value to be 7,50 Soak for 1 hour at ℃, inactivate enzyme at 90℃ for 10 minutes;

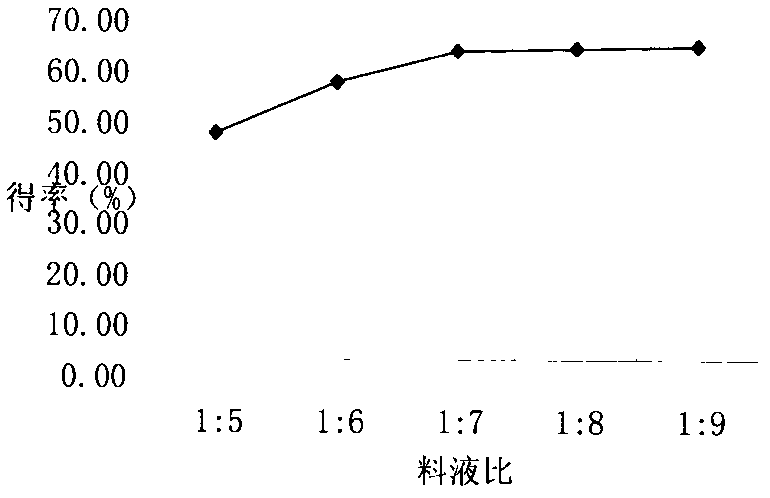

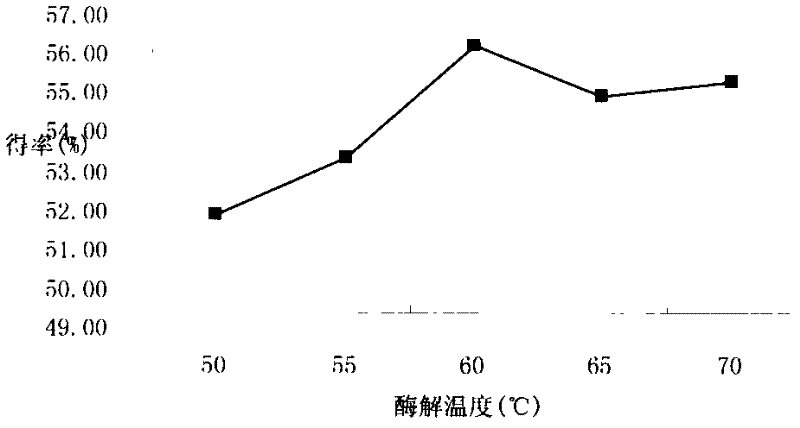

[0050] (4) Enzymolysis: Alkaline protease and cellulase composite enzymes are used, and the ratio of protease and cellulase is 2:1 (m / m). The ratio of solid to liquid is 1:6 (m / v), the enzymolysis time is 6 hours, the amount ...

Embodiment 2

[0053] Embodiment two: the mensuration of average oil content

[0054] Put about 3g of finely ground sample into the weighed filter paper bag, seal the mouth of the bag, put it in an oven at 105±2°C to dry for 3 hours, move it to a desiccator to cool to room temperature, and use long tweezers to extract Inject anhydrous diethyl ether 1.67 times the amount of a siphon into the cylinder, so that the sample package is completely submerged in diethyl ether. Connect all parts of the extractor, connect the flow of condensed water, and carry out extraction in a constant temperature water bath. Adjust the water temperature between 70 and 80°C, so that the condensed and dripping ether becomes beads (refluxing more than 7 times / h), Extract until the ether in the extraction cylinder is drip-checked with filter paper until there is no oil stain (about 6 to 12 hours). After the extraction is completed, take out the filter paper bag with long tweezers, and volatilize the ether in a ventila...

Embodiment 3

[0060] Embodiment three: the selection of enzyme kind and the mensuration of enzyme activity

[0061] 1. Determination of Enzyme Activity

[0062] (1) Determination of protease activity

[0063] ① Reagent

[0064] 0.1mol / L sodium carbonate - sodium bicarbonate buffer (pH10);

[0065] 5% trichloroacetic acid;

[0066] 1% casein solution:

[0067] Weigh 5 grams of casein and place it in 500 ml of 0.1 mol / L sodium carbonate-sodium bicarbonate buffer solution (pH10), and heat to dissolve it.

[0068] 0.4mol / L sodium carbonate solution;

[0069] 100μg / ml tyrosine solution;

[0070] Folin reagent:

[0071] Add 100 grams of sodium tungstate (Na2WO4.2H20) and 25 grams of sodium molybdate (Na2MO2.2H20) into a 2000 ml grinding mouth reflux device, add 700 ml of water, 50 ml of 85% phosphoric acid, and 100 ml of concentrated hydrochloric acid, and reflux for 10 hours. Take off the reflux condenser, add 50 grams of lithium sulfate, 50 milliliters of water and a few drops of concen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com