Method for extracting rapeseed oil and passivated myrosinase from rapeseeds

A technology of rapeseed oil and rapeseed, which is applied in the field of extracting rapeseed oil and inactivating glucosidase, can solve the problems of high content of glucosinolate and its degradation products in cake, waste of high-quality protein resources, and low extraction rate of free oil. , to achieve the effect of shortening the oil production cycle, eliminating the use of enzymes, and reducing the detoxification process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Dried rapeseeds are not pretreated, only crushed, pre-crushed by a traditional Chinese medicine grinder, and then crushed by a three-roller grinder to a volume average particle size of about 45 μm to obtain oil extraction raw materials.

[0039] The oil extraction raw material is carried out at 50°C, according to the material-water ratio of 1:6 (w / v), and the pH of the system is adjusted to 5.0, and 3% pectinase, cellulase, and xylanase are added, and the enzymatic hydrolysis time is 3 hours. After the enzymatic hydrolysis, adjust the pH to 9.0 with 2N sodium hydroxide, raise the temperature to 60°C, and carry out alkaline extraction for 1.5 h. After the alkaline extraction, add 3% alkaline protease and continue enzymatic hydrolysis for 1 hour. Centrifuge at 6000rpm for 10min after the reaction to obtain incompatible four phases—free oil, emulsion, water phase and slag phase, obtain free rapeseed oil with a scoop, and weigh it.

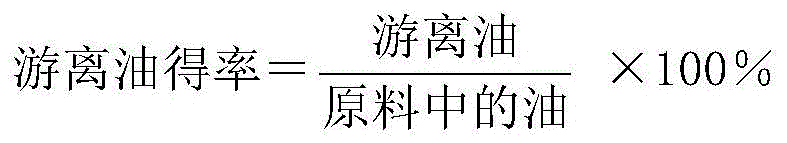

[0040] The extraction rate of free oil ...

Embodiment 2

[0042] Dried rapeseeds are directly subjected to pressurized heat treatment, put the soaked rapeseed 2 into an autoclave for pressurized heat treatment, the pressure is 0.50Mpa, the temperature is 110°C, the time is set to 20min, and the processed rapeseeds are collected 3.

[0043] The steam-exploded rapeseed was dried in a blast drying oven at 50°C; it was pre-crushed by a traditional Chinese medicine grinder, and then crushed by a three-roller grinder until the volume average particle size was about 28 μm to obtain the raw material for oil extraction.

[0044] The oil extraction raw material is carried out at 50°C, according to the material-water ratio of 1:6 (w / v), and the pH of the system is adjusted to 5.0, and 3% pectinase, cellulase, and xylanase are added, and the enzymatic hydrolysis time is 3 hours. After the enzymatic hydrolysis, adjust the pH to 9.5 with 2N sodium hydroxide, raise the temperature to 60°C, and carry out alkaline extraction for 1.5 h. After the alk...

Embodiment 3

[0048] Dried rapeseed 1 was soaked in deionized water for 5 hours according to the material-to-water ratio of 1:2 (w / v), drained and the filtrate was discarded, and soaked rapeseed 2 was collected.

[0049] The soaked rapeseed 2 is subjected to steam explosion treatment, the steam explosion pressure is set at 1.5MPa±0.1MPa, and the pressure holding time is 180s. After the blasting is over, open the steam blaster collection bin to collect the steam-exploded rapeseed 3 .

[0050] The steam-exploded rapeseed 3 was dried in a blast drying oven at 50°C; pre-crushed by a traditional Chinese medicine grinder, and then crushed by a three-roller grinder to a volume average particle size of about 21 μm to obtain oil extraction raw material I.

[0051] The raw material I obtained is at 70°C, according to the ratio of material to liquid 1:6 (w / v), the concentration of ethanol aqueous solution is 50% (v / v), and the pH of the system is adjusted to 9.0 with 2N sodium hydroxide solution to ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com